This document discusses bamboo composites and their potential uses. It begins by providing background on bamboo, noting that it is widely available globally and has traditionally been used for various purposes. Bamboo has desirable properties like being lightweight and strong, making it suitable for construction and manufacturing applications. The document then describes the anatomical structure of bamboo, including its vascular bundles and fibers. It provides definitions of composites and their key characteristics. Composites have a matrix and reinforcement to produce properties different from the individual components. The main components of a composite are discussed as the matrix, reinforcement, and interface. Finally, classifications of composites are mentioned based on the type of matrix material.

![3 | P a g e

1.1 ABOUT BAMBOO COMPOSITS

Bamboo or Bambusa in botanical has 7-10 subfamilies of genres and there are 1575 difference

species ranging from the type of wood to bamboo herb. However, each particular species of bamboo

has different properties and qualities. Bamboo is easily accessible globally, 64% of bamboo

plantation, as can be seen below, originated from Southeast Asia, 33% grown in South America,

and the rest comes from Africa and Oceania. Bamboo productions dated back to thousands of years

ago and thus they are rich with traditional elements. Bamboo naturally, suitable for varieties of uses

and benefits.

Bamboo as the great potential to be used as solid wood substitute materials, especially in the

manufacturing, design, and construction usage. Bamboo properties of being lightweight and high-

strength has attracted researchers to investigate and explore, especially in the field of bio-composite

bamboo and is acknowledged as one of the green-technology that is fully responsible for eco-

products on the environment. Agricultural biomass solid wood made from bamboo have been

identified by many researchers as the largest source of natural fibre and cellulose fibre bio

composite, which are provided at minimal cost and will bring a new evolution into production chain

and manufacturing world.

High elasticity and strength of bamboo are suitable for the construction industry, and bamboo has

proven to serve as a foundation structure. The creation of bio-composite fibre board is also used in

wall construction and are potentially to contribute of making cost effective home possible. [9] Use

of bio-composite material is seen increasingly high and the use bamboo as an alternative can be seen

in productions such as furniture, automotive and other related productions. The natural colours of

bamboo is unique compared to solid wood and other materials. In fact, the effect of the texture and

tie on the outer skin of bamboo has the exotic value and at the same time creates a unique identity

in the design, particularly furniture.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-3-320.jpg)

![5 | P a g e

1.3 DEFINATION OF COMPOSITE

The most widely used meaning is the following one, which has been stated by Jartiz [1965]

“Composites are multifunctional material systems that provide characteristics not obtainable

from any discrete material. They are cohesive structures made by physically combining two or

more compatible materials, different in composition and characteristics and sometimes in

form”. Kelly [1967] very clearly stresses that the composites should not be regarded simple as

a combination of two materials. In the broader significance; the combination has its own

distinctive properties. In terms of strength to resistance to heat or some other desirable quality,

it is better than either of the components alone or radically different from either of them.

Beghezan [1966] defines as “The composites are compound materials which differ from alloys

by the fact that the individual components retain their characteristics but are so incorporated

into the composite as to take advantage only of their attributes and not of their short comings”,

in order to obtain improved materials. [1] J.Van Suchtelen [1972] explains composite materials

as heterogeneous materials consisting of two or more solid phases, which are in intimate

contact with each other on a microscopic scale. They can be also considered as homogeneous

materials on a microscopic scale in the sense that any portion of it will have the same physical

property.

1.4 CHARACTERISTICS OF THE COMPOSITES

Composites consist of one or more discontinuous phases embedded in a continuous phase. The

discontinuous phase is usually harder and stronger than the continuous phase and is called the

‘reinforcement’ or ‘reinforcing material’, whereas the continuous phase is termed as the

‘matrix’. Properties of composites are strongly dependent on the properties of their constituent

materials, their distribution and the interaction among them. The composite properties may be

the volume fraction sum of the properties of the constituents or the constituents may interact in

a synergistic way resulting in improved or better properties. Apart from the nature of the

constituent materials, the geometry of the reinforcement (shape, size and size distribution)

influences the properties of the composite to a great extent. The concentration distribution and

orientation of the reinforcement also affect the properties. The shape of the discontinuous phase

(which may by spherical, cylindrical, or rectangular cross-sectioned prisms or platelets), the

size and size distribution (which controls the texture of the material) and [10] volume fraction](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-5-320.jpg)

![11 | P a g e

2.1 BAMBOO FIBRE REINFORCED POLYMER COMPOSITES

Natural fibre reinforced polymer composites have raised a great attention and interest among

scientists and engineers in recent years due to the consideration of developing environmental

friendly materials. They are high specific strength and modulus materials, low priced,

recyclable and are easily available. It is known that natural fibres are non-uniform with

irregular cross sections which make their structures quite unique and much different with man-

made fibres such as glass fibres, carbon fibres etc. [11] various researchers have worked on the

natural fibres containing polyolefin, and polystyrene, polyester and epoxy resins. Properties

like low cost, light-weight, high specific strength, free from health hazard are the unique selling

points of these composites. Though the presence of hydroxyl and other polar groups in the

natural fibres leads to the weak interfacial bonding between the fibres and the hydrophobic

polymers, these properties can be significantly improved by interfacial treatment. Among the

various natural fibres, bamboo fibre is a good candidate for use as natural fibres in composite

materials. Jindal [2] has observed that tensile strength of bamboo-fibre reinforced plastic

(BFRP) composite is comparatively equivalent to that of the mild steel, whereas their density

is only 12% of that of the mild steel. Hence, the BFRP composites can be extremely useful in

structural applications. Jain and Kumar [3] have investigated that a uniform strength can be

achieved in all directions of the composites by using multidirectional orientation of fibres.

Considerable interest has been generated in the manufacturing of thermoplastic composites due

to their good fracture toughness and thermal stability. Thermoplastic matrix composites

materials offer an extended solution in different applications in automotive industry,

construction, electrical appliances and home/urban furniture. Bio-degradable resins have

received a considerable attention as earth conscious materials in the present day engineering

society. They offer very little environmental load because they can be resolved in both water

and carbon dioxide after perfect biodegradation by micro-organisms. However, most of the

biodegradable resins have relatively low strength, making them a poor choice for the high

strength structural applications. Thus, a lot of research is focused to strengthen the

biodegradable resins by combining with string natural fibres like hemp, bamboo, pineapple etc.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-11-320.jpg)

![12 | P a g e

2.2 MECHANICAL PROPERTIES OF COMPOSITES

The attractive physical and mechanical properties that can be obtained with bamboo fibre

reinforced composites, such as high specific modulus, strength and thermal stability, have been

well documented in the literature. Jain et al [4] have compared the Bamboo fibre reinforced

epoxy composites (BFRP) epoxy with Bamboo fibre reinforced unsaturated polyester

composites (BFRP) USP in terms of their cost and mechanical strength. Cost of unsaturated

polyester (USP) was found to be only 20% to that of the epoxy resin, whereas the mechanical

properties of these two composite were comparable. Thus giving an edge to the USP based

composites. BFRP composites have shown more elongation and 10% high tensile strength.

These composites can be used for a variety of commercial application such as crash helmet,

low cost housing and wind mills. Kumar et al [5] have studied the effect of coating bamboo

fibres with Polyurethane (PU) and Polyurethane/Polystyrene.

Interpenetrating Network (PU/PSIPN) on tensile property of the composites. Both the untreated

/ alkali treated bamboo fibres were coated with polyethylene glycol based PU and its semi inter

penetrating network (SIPN) with PS. It was found that tensile strength of bamboo has increased

after coating with PU and PU/PS system. PU/PS coating on alkali treated bamboo fibres has

shown a rise (74%) in the tensile load at break than PU (11%) coating on alkali treated fibre.

These improvements were due to enhanced interfacial adhesion between polymer matrix and

bamboo fibre. Results of enzymatic degradation showed that biodegradability could be

adjusted by controlling degree of interfacial adhesion using LDI. They have observed that these

bio-composites are beneficial in areas where biocompatibility and environmentally responsible

design and construction are required.

Takagi et al. have studied the effect of fibre content and fibre length on mechanical properties

of bamboo fibre reinforced green composites (BFGC). Fibre length up to 15mm has given

positive effect on tensile strength and flexural strength. It was observed that tensile strength

and flexural strength increase with increase in fibre content. Mechanical properties of BFGC

were similar to those composites made from bamboo powder and biodegradable resin. These

results showed that bamboo fibre with aspect ratio of 20 acts as filler and not the reinforcement.

Tokoro et al [6] have chosen three different categories of bamboo fibre to prepare Bamboo

fibre-Polylactic acid composites and investigate the method to improve mechanical properties](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-12-320.jpg)

![13 | P a g e

of BF/PLA composites. Three types of bamboo fibres were extracted from raw bamboo by

either NaOH treatment or steam explosion. Amongst them, Highest bending strength was

obtained when steam exploded filaments were put into PLA matrix. Impact strength was

improved when medium length fibre bundles were put into PLA. Thermal properties and heat

resistance of composite were improved by annealing. Authors have studied the impact of steam

explosion technique on mechanical properties of bamboo composites. Tensile strength and

Young modulus of steam exploded BFEC increased about 15% and 30% respectively in

comparison with conventional BFEC. Thwea and Liao [12] have fabricated the bamboo

reinforced polypropylene (BFRP) and bamboo-glass reinforced Polypropylene (BGRP)

composites. They have studied the effect of fibre content, fibre length, bamboo to glass ratio,

coupling agent (Maleate polypropylene) on tensile and flexural properties of these composites.

They have also studied the sorption behaviour and retention in mechanical properties of

composite after environmental aging. It was observed that flexural strength, flexural modulus

and tensile modulus increases with increase in bamboo fibre length. They have reported that

poor adhesion between the matrix/fibre decreased tensile strength at higher bamboo fibre

content in BFRP. Fibre content increased the void formation during processing, which further

leads to micro crack information under loading, hence reducing the tensile strength.

Incorporation of glass fibre and Compatilizers has improved the tensile strength and tensile

modulus. It was reported that moisture absorption of BFRP during aging can be reduced by

replacing bamboo fibre with glass fibre and by using Compatilizers. Mechanical properties of

BFRP and BGRP have degraded after aging in water.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-13-320.jpg)

![14 | P a g e

2.3 WATER ABSORPTION

New applications and end uses of composites for decking, flooring, and outdoor facilities with

strong exposure to atmosphere or contact with aqueous media have made it necessary to

evaluate the water uptake characteristics of natural fibre composites. Because of the

hygroscopic nature of natural fibres, water uptake of composites containing these fibres as

fillers and/or reinforcement can be a limiting parameter for a number of applications of the

composites. Water absorption can adversely affect a number of mechanical properties and can

also build up the moisture content in the fibre cell wall and in the fibre–matrix inter phase

region. Moisture build up in the cell wall could result in fibre swelling and affect the

dimensional stability of the product. If necessary, the moisture absorbed in the fibre cell wall

can be reduced through the acetylation of some of the hydroxyl groups present in the fibre.

Good wetting of the fibre by the matrix and adequate fibre–matrix bonding can decrease the

rate and amount of water absorbed in the interphone region of the composite. For water

absorption test, composite samples are weighed and then weighed samples are immersed in the

distilled water at room temperature. The samples are taken out periodically and weighed

immediately after wiping out the water on the surface of the sample, using a precise four digit

balance to find out the content of water absorbed.

All the Samples are dried until constant weight with four digit balance, previous to immersing

in water. Percentage of water uptake is calculated by the following equation-

W1 = initial weight of specimen gm.

W2= specimen weight after N hours of water soaking, gm.

Water absorption behaviour of natural fibre thermoplastic composites have been studied by a

number of researchers and the effectiveness in reducing the amount and rate of water

absorption. Tajvidi et al. [7] have investigated the long-term water absorption behaviour of

various natural fibre (wood flour, kenaf fibre, rice hulls, newsprint etc.) polypropylene

WA (%) = (W2 - W1) × 100

W1](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-14-320.jpg)

![15 | P a g e

composites and have also studied the effect of natural fibre type and fibre content. Authors

have found that the Chemical composition of the natural fibres is responsible for the different

water uptake behaviour. It appears that the RH/PP has the lowest water absorption. This

behaviour can be attributed to the higher amount of extract and ash and lower amount of

cellulose and pentose in rice hulls. Suharav Panthpulakkal et al [8] studied the water absorption

of injection-moulded short hemp fibre/glass fibre reinforced poly propylene hybrid composites.

Hybridization with glass fibre enhanced the Resistance to water absorption properties of the

hemp fibre composites.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-15-320.jpg)

![21 | P a g e

2. Preparation of Matrix Composite using Bamboo Fibres and Glass Fibres

Following steps has been carried out in order to prepare it:-

The process of fibre extraction is shown below:

Preparing a Mould having a simple base and top made of plastic plate having

dimensions 220mm×200mm×20mm which was cut from plastic sheet all three sides of

sheet was surrounded by a thin strip of plastic having dimension: 2 strips of dimension

220mm×30mm×5mm and 2 strips having dimensions 140mm×30mm×5mm which are

fixed to the strip through nut and bolts.

Initially 200 grams of Bamboo Fibres is taken in a beaker. After that paste of Ethylene

Glycol, Epoxy Resin and Hardener of around 300ml is being prepared and added to

the Bamboo Fibres of taken quantity.

First a layer of paste is poured into the mould and then a layer of Glass Fibre [13]

weighing around 20 grams is being kept above it and then another layer of paste is

poured. After that Bamboo Fibre is added and then again one layer of paste is poured

and again a layer of glass Fibre is added.

Dried in Oven at 100 degree to remove Moisture

Cut Fibres length of 10mm

Fibres dried in sun for 1 day

Hand Peeling of Fibres from wet sticks

Soaked Bamboo Sticks in NaOH Solution for a day

Collecting Bamboo Sticks](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-21-320.jpg)

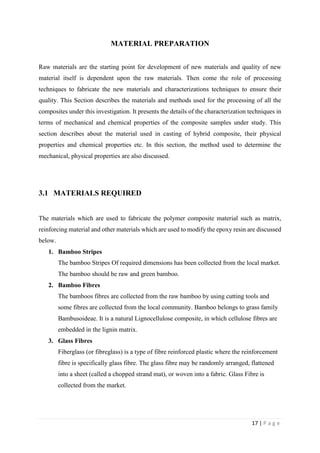

![26 | P a g e

Load

(Kn)

Area

(mm2

)

Stress

(Mpa)

Displacement

(mm)

Strain

(×10m3

)

(mm/mm)

0 104 0 0 0

0.88 104 10.2 0.03 0.12

1.76 104 17.4 0.04 0.14

2.64 104 24.6 0.06 0.25

3.52 104 31.8 0.08 0.33

4.4 104 39 0.09 0.37

5.28 104 46.2 0.14 0.57

6.16 104 53.9 0.16 0.65

7.04 104 61.6 0.17 0.69

7.92 104 69.3 0.21 0.86

8.8 104 76.8 0.24 0.9

Table 3: Stress vs. Strain of Wood Fibre

One year old bamboo had the lowest of 16.1 Mpa compressive stress and a five year old

bamboo had the highest compressive stress and in terms of highest compressive stress and

highest Young’s` modulus than the middle and bottom . As a result it was noted that

compression properties parallel to the longitudinal direction were significantly higher than that

perpendicular to the longitudinal direction and vascular bundles distribution had the highest

concentration in the outer layer of bamboo. University of Southern California Los Angeles,(

CA 90089-2531 ) by [14] Andrea Carrasco, Jojn Fronda and Brain Macrae on the mechanical

properties , define bamboo as a lightest material and strengthen extreme product of nature

which is stable and because of its cavities an extreme light and elastic building materials ,noted

that the lignifying cell construction of the bamboo texture and its technical conditions are

similar to the original texture of wood whereas wood has got a hard centre and becomes weaker

toward the outer parts.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-26-320.jpg)

![38 | P a g e

REFERENCES

[1] J. Van Suchtelen (1972). Philips Res. Rep., 27, 28. T.S Srivatsan and E.J. Lavernia (1992).

J. Materials Sci., 27, 5965. N.S. Stalaff (year). In Advances in composite Materials Applied

Sci. Pub., London, P. 247

[2] U.C.Jindal, (1986) Development and testing of bamboo fibres reinforced plastic

Composites. Journal of Composite material, Vol. 20, pp. 19-29.

[3] Seema Jain, Rakesh Kumar (1992) Mechanical behaviour of bamboo and bamboo

composite. Journal of Material Science, Vol.27, pp.4598- 4604.

[4] Jain et al, U C. Jindal, Rakesh Kumar (1993) Development and fracture mechanism Of

bamboo /polyester resin composite. Journal of Materials Science Letters, Vol. 12, pp. 558-560.

[5] H. Kumar, Siddaramaiah, 2005, “Study of Chemical and Tensile Properties of PU and

PU/PS Coated Bamboo Fibres”, Polymer-Plastics Technology and Engineering, Vol. 44,

pp.1369–1377.

[6] Tokoro et al, P Reichert, H Ro Mling, and R.Mulhaupt (2000) Influence of compatibilizers

on the surface hardness, water uptake and the mechanical properties of poly(propylene) wood

flour composites prepared by reactive extrusion. Macromolecular Material and Engineering,

Vol. 276/277, pp.51-58.

[7] Tajvidi et al and Yohie Ichihara (2004) Effect of fibre length on mechanical properties of

green composites using starch based resin and short bamboo fibres. ISME International

journal, Series A Vol.47, No.4, pp.551- 555.

[8] S Panthapulakkal, M Sain (2007) Injection-Molded Short Hemp Fibre/Glass Fibre-

Reinforced Polypropylene Hybrid Composites- Mechanical, Water Absorption and Thermal

Properties. Journal of Applied Polymer Science, Vol. 103, pp. 2432-2441.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-38-320.jpg)

![39 | P a g e

[9] R M Rowell, A M Tillman, R Simonson (1986) A Simplified Procedure for the Acetylation

of Hardwood and Softwood Flaxes for Flake board Production. Journal of Wood Chemistry

and Technology, Vol.6, pp.427- 448.

[10] Kazua Okubo, Toru Fuzii, Naoya Yamashita (2005) Improvement of interfacial adhesion

in bamboo Polymer composite enhanced with micro fibrillated cellulose. JSME International

journal, Series A, Vol.48, No.4, pp.199-20.

[11] J. M. G. Martiner, J. Taranco, O. Laguna, and E. P. Collar (1994) Modification of

polyolefin, and polystyrene, polyester and epoxy resins. Study on the Reaction Conditions

Using a Batch Process. International. Polymer. Processing IX, Vol. 3, pp.246-251;

[12] Thwea and Liao (2003) Natural fibres: can they replace glass in fibre reinforced plastics.

Composites Science and Technology, Vol.63.

[13] P. Wambua, J. Ivens, and I. Verpoest, "Natural fibres: can they replace glass in fibre

reinforced plastics?" composites science and technology, vol. 63, 2003.

[14] Andrea Carrasco, Jojn Fronda and Brain Macrae, University of Southern California Los

Angeles, (CA 90089-2531) “Fibre Texture and Mechanical Graded Structure of Bamboo”,

Composites Part B, Vol.288, 1997.](https://image.slidesharecdn.com/3-160725152353/85/3-chapter-1-39-320.jpg)