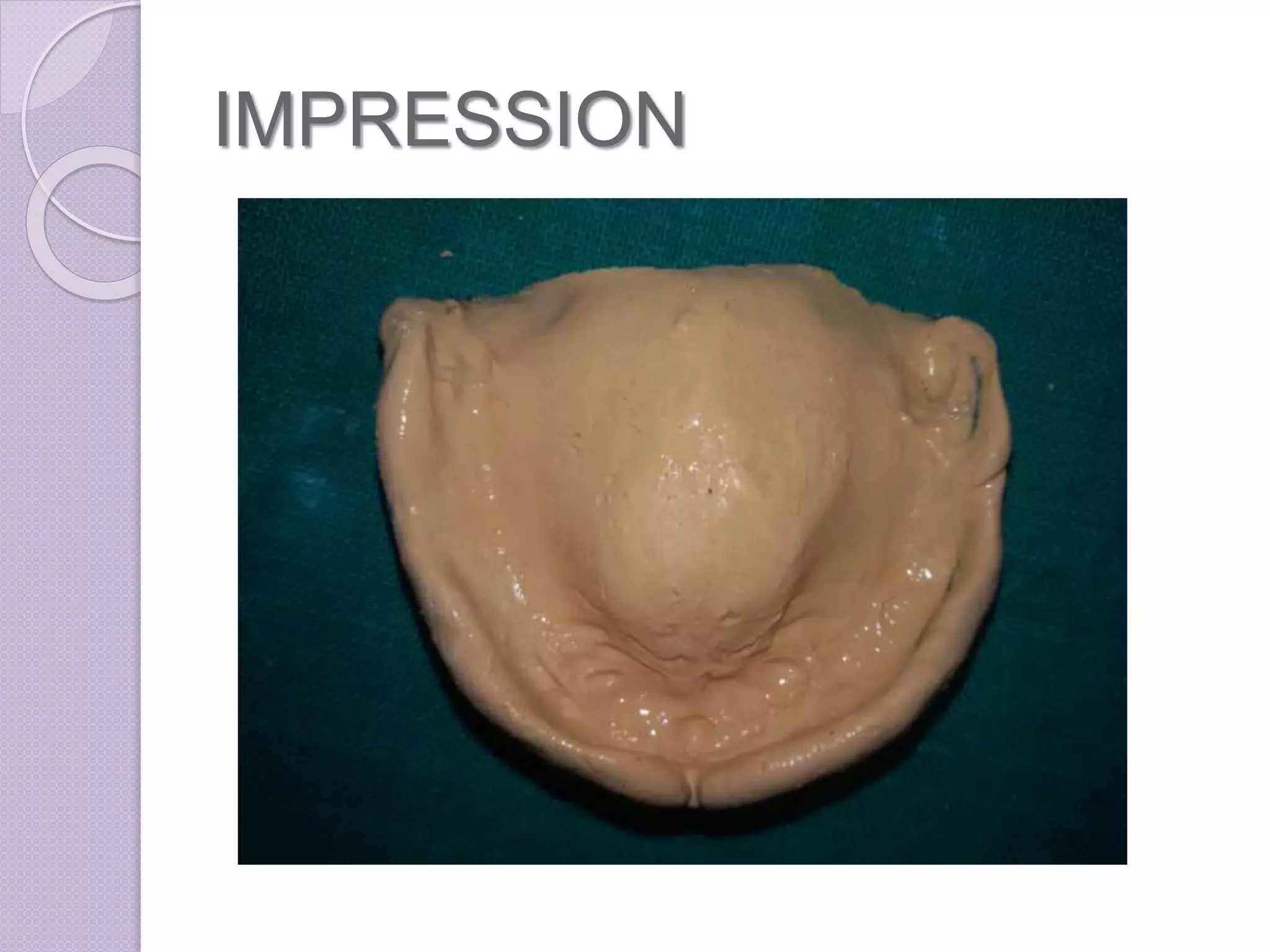

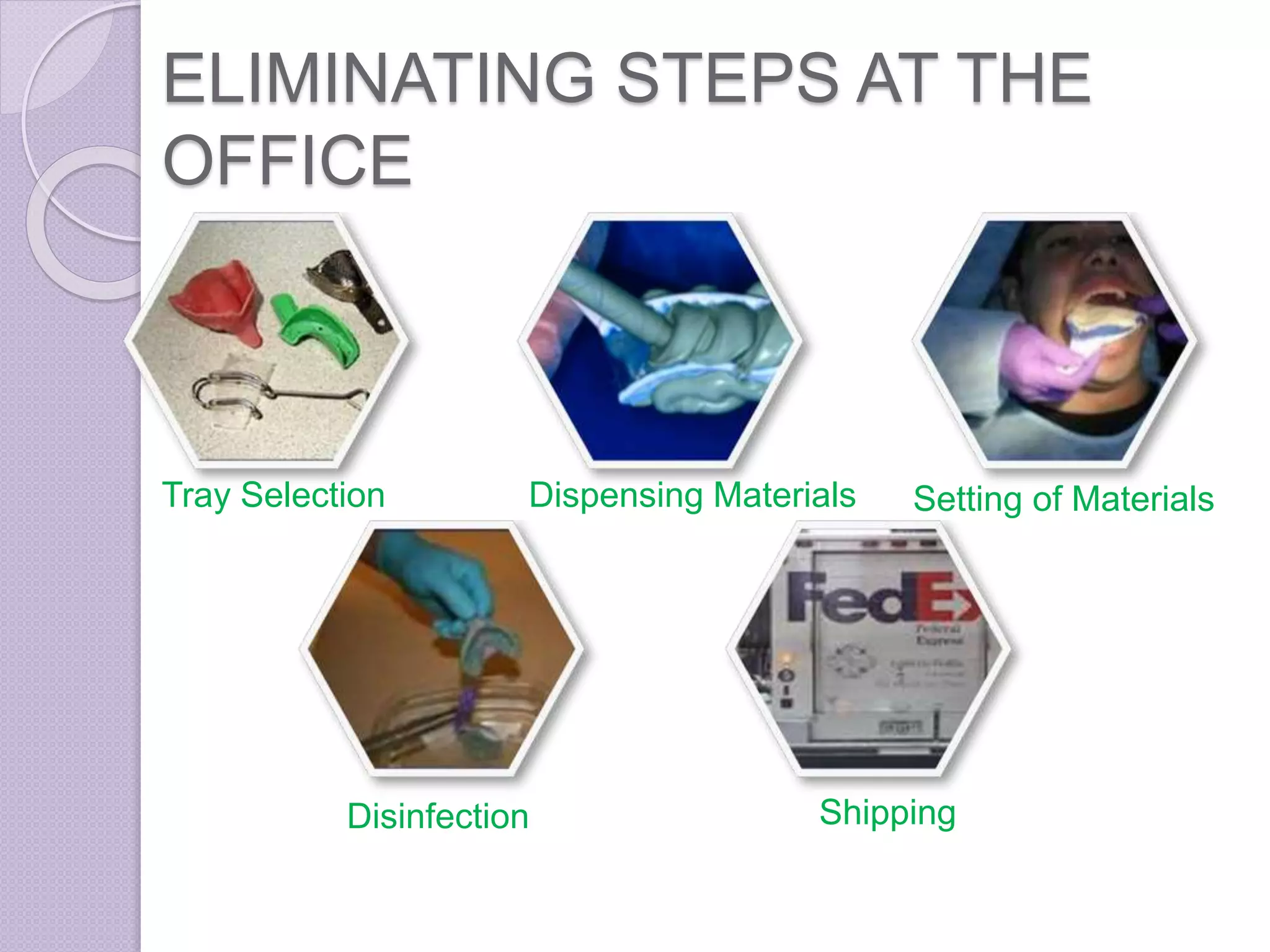

This document discusses virtual impressions and stereolithographic models in dentistry. It provides a brief history of dental impressions, describes recent digital impression technologies like iTero and CEREC, and discusses how digital impressions can eliminate lab steps and provide benefits like accuracy. It also covers virtual model technologies like stereolithography, how they work using layer-by-layer additive manufacturing, and their applications in areas like implant planning and prosthodontics. The conclusion reiterates that while digital technologies provide benefits, traditional impressions still have roles and digital methods have limitations like equipment costs.