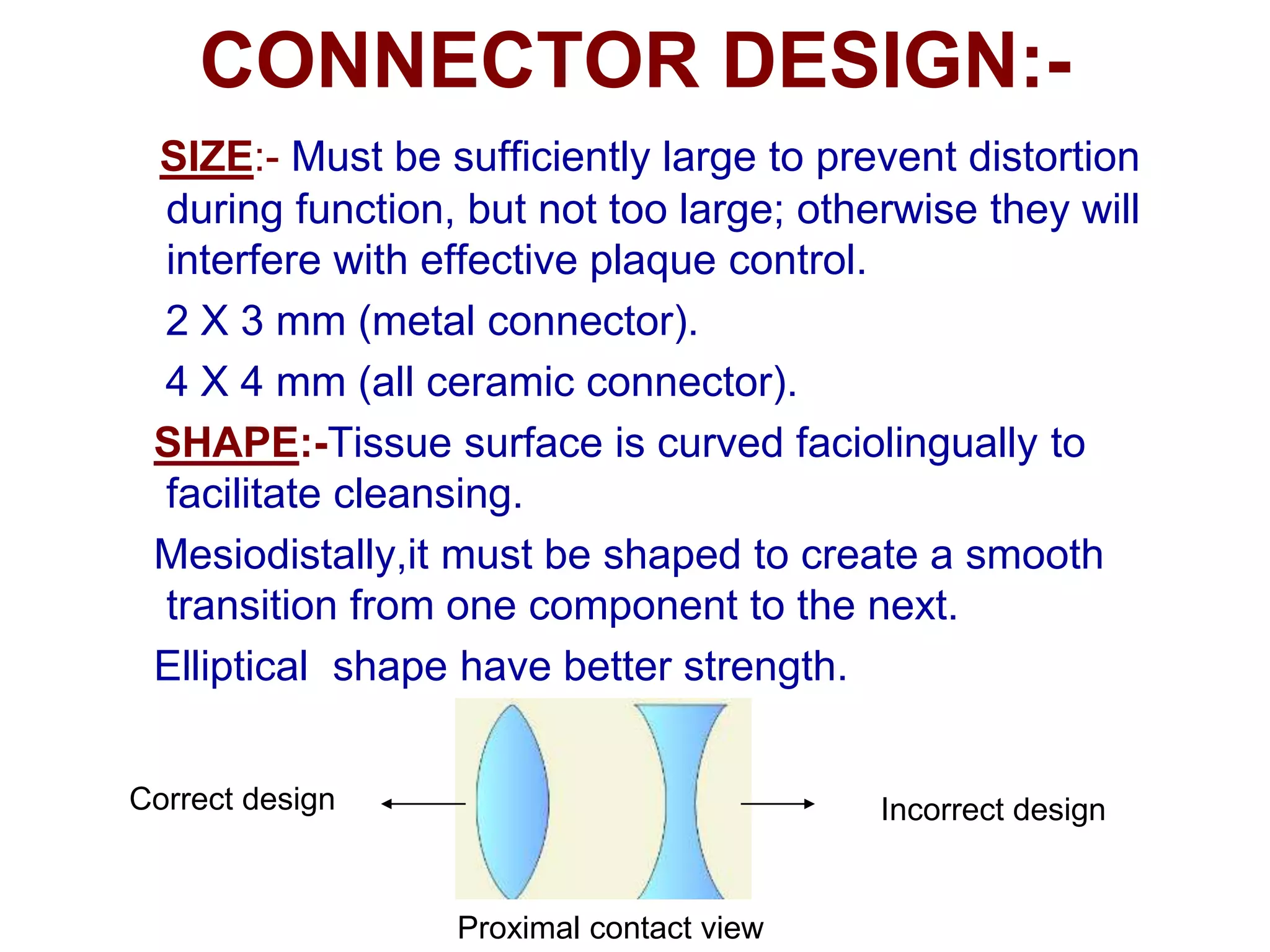

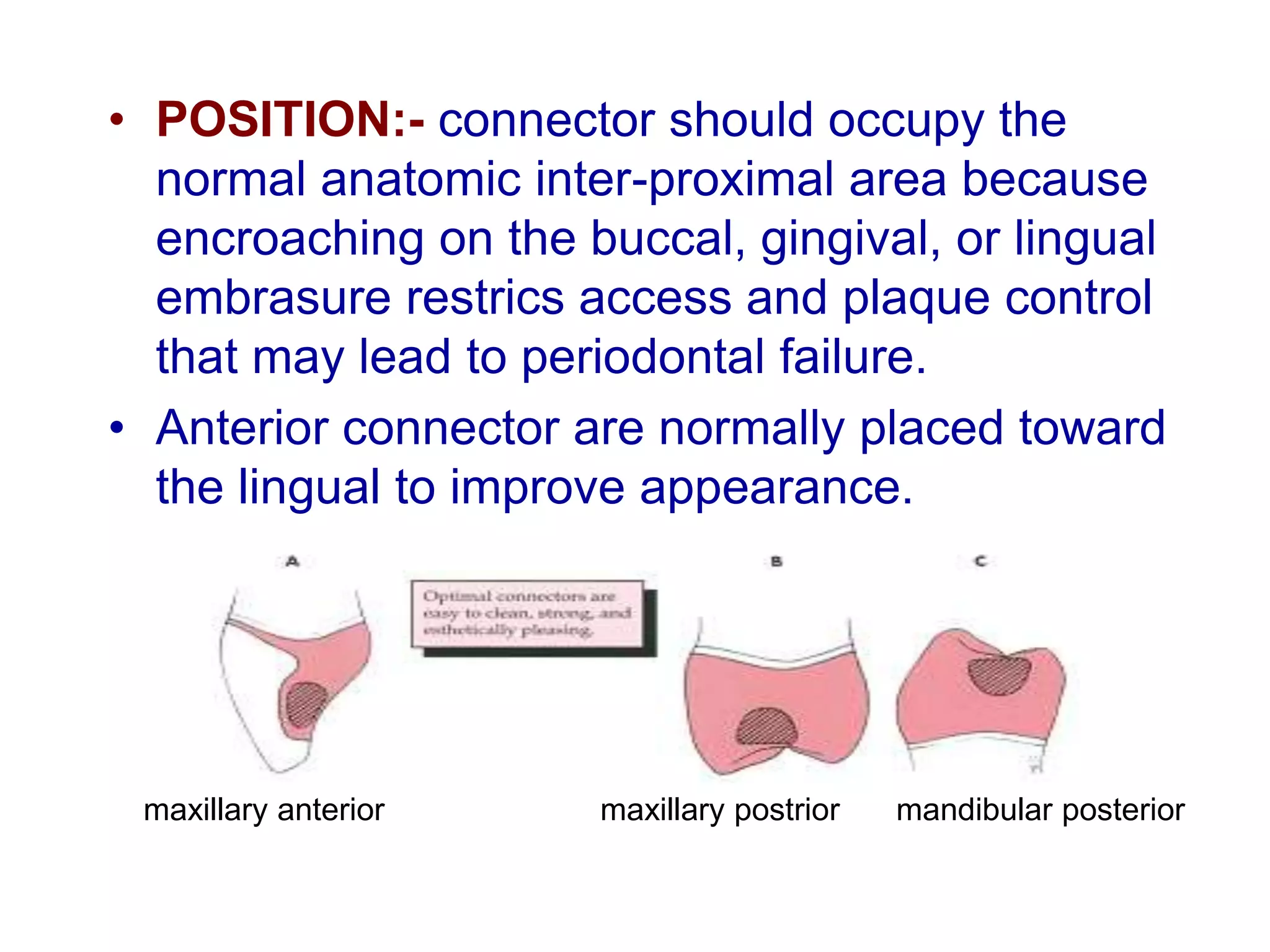

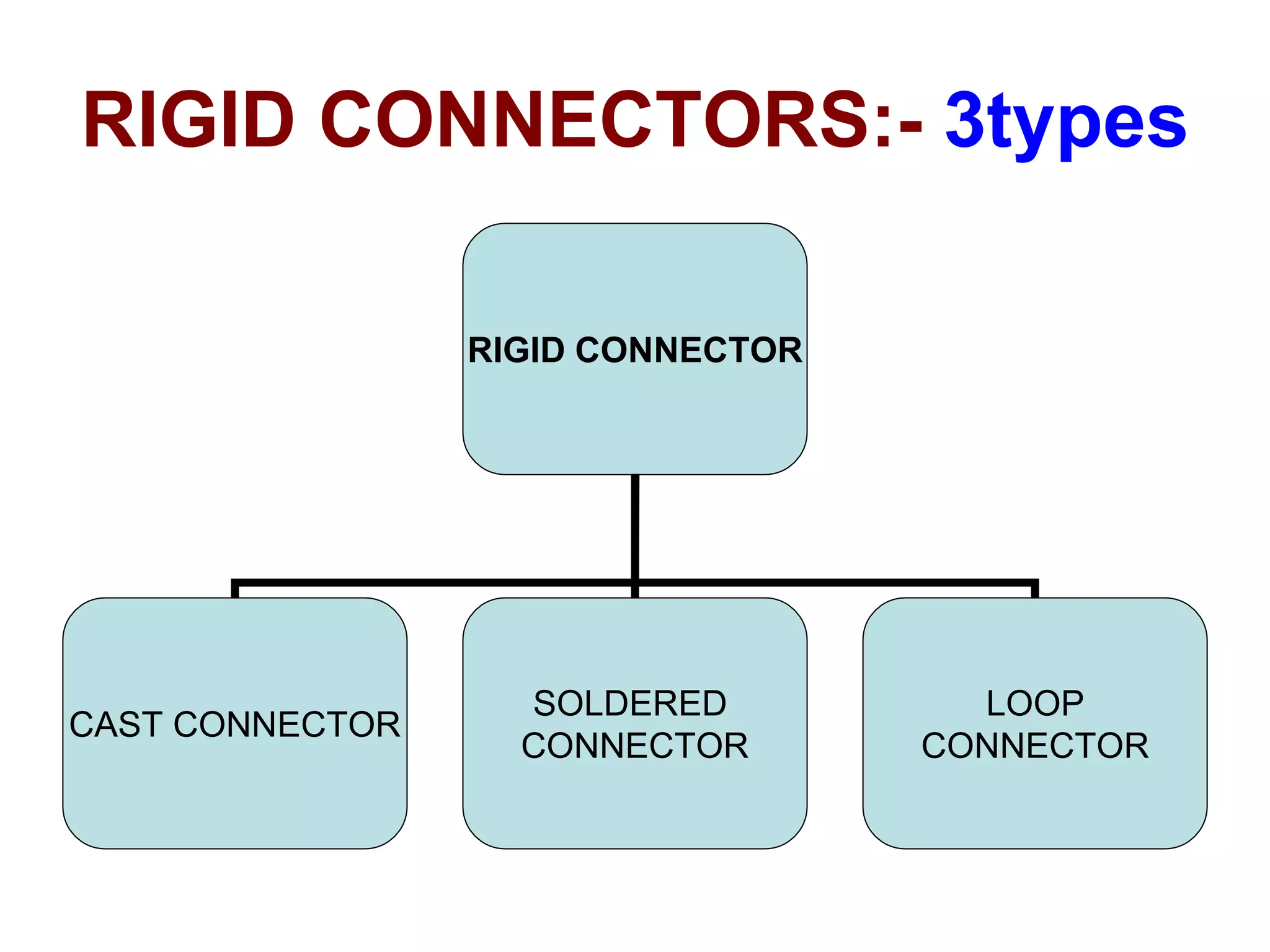

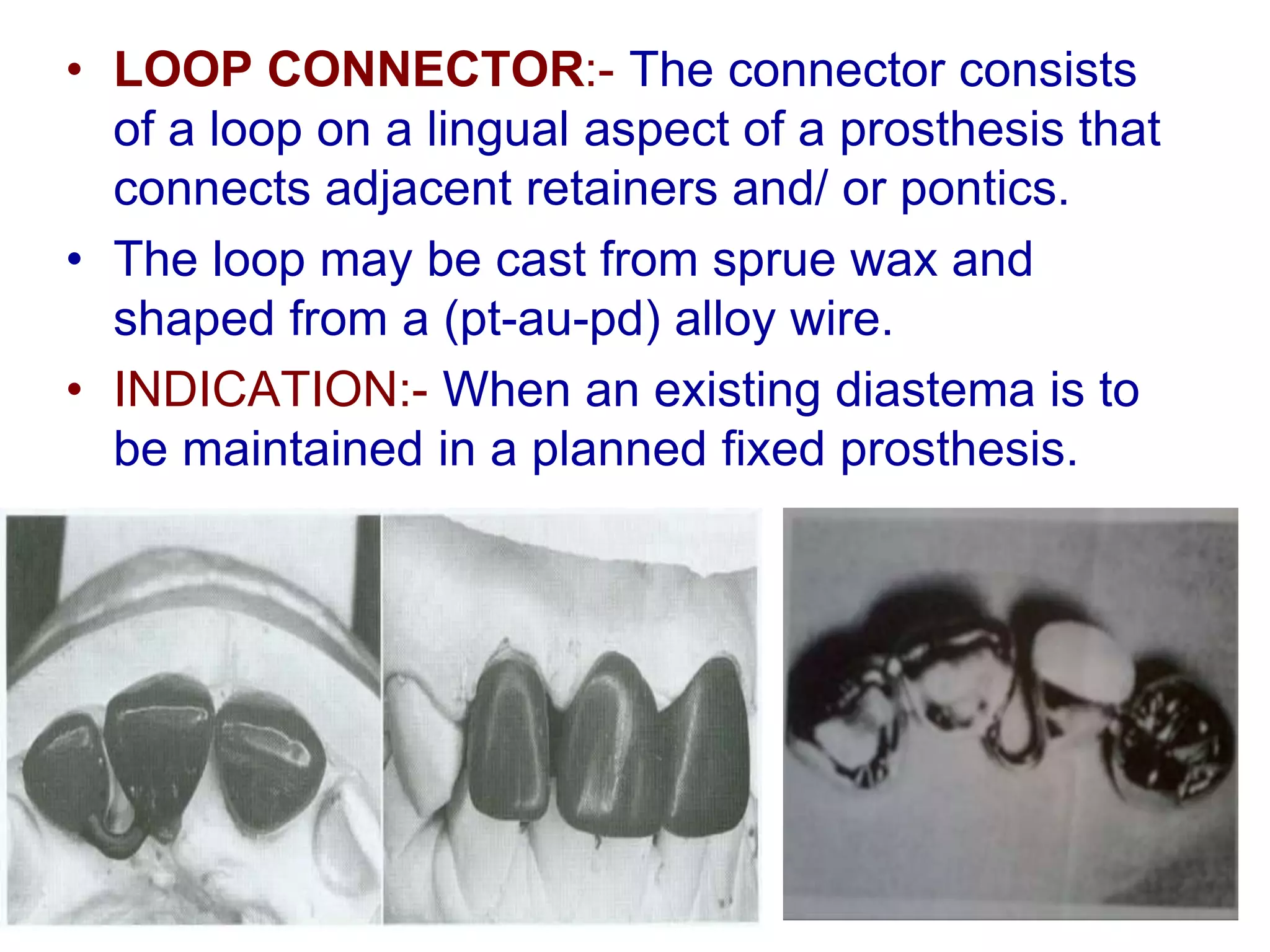

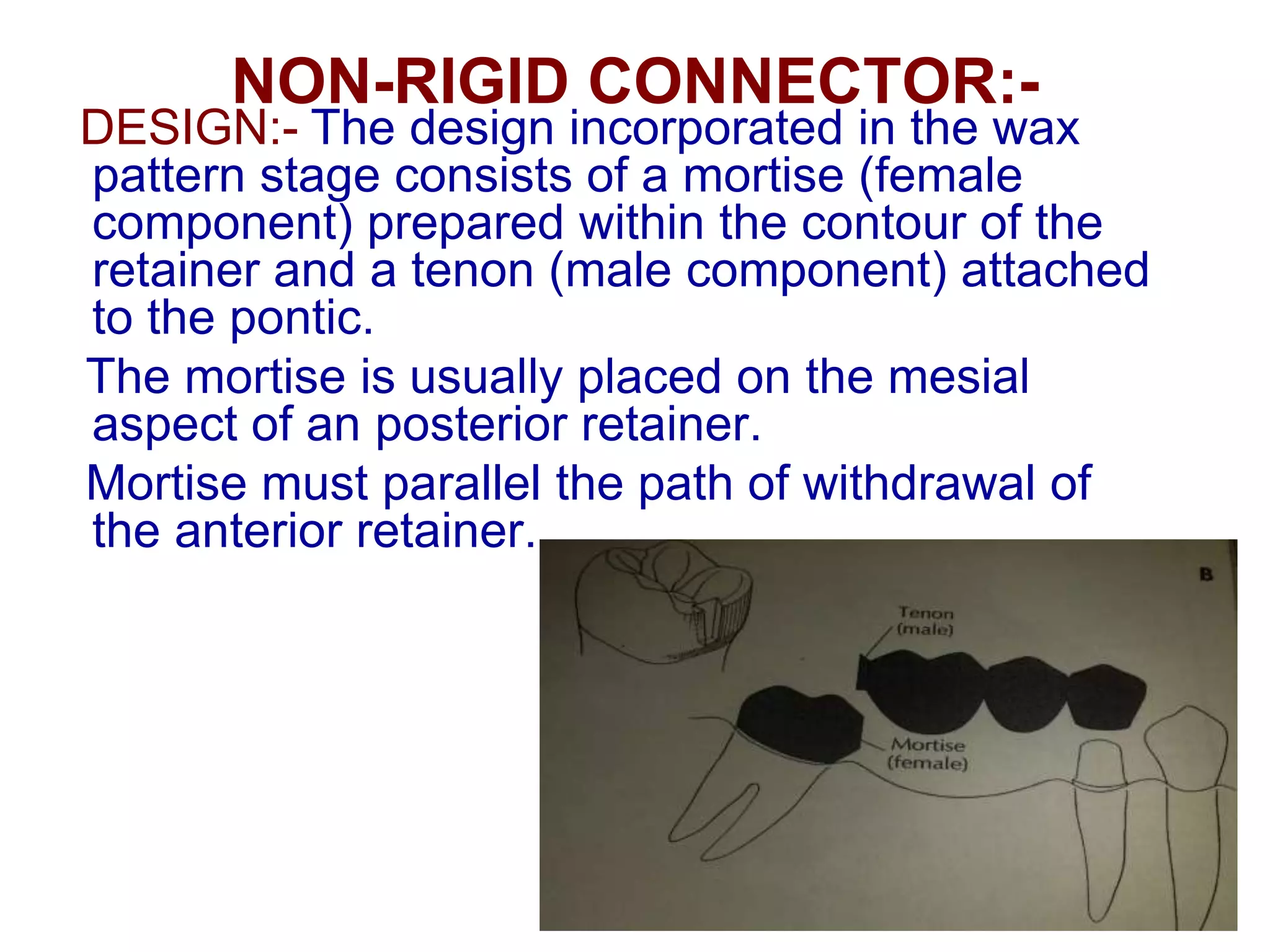

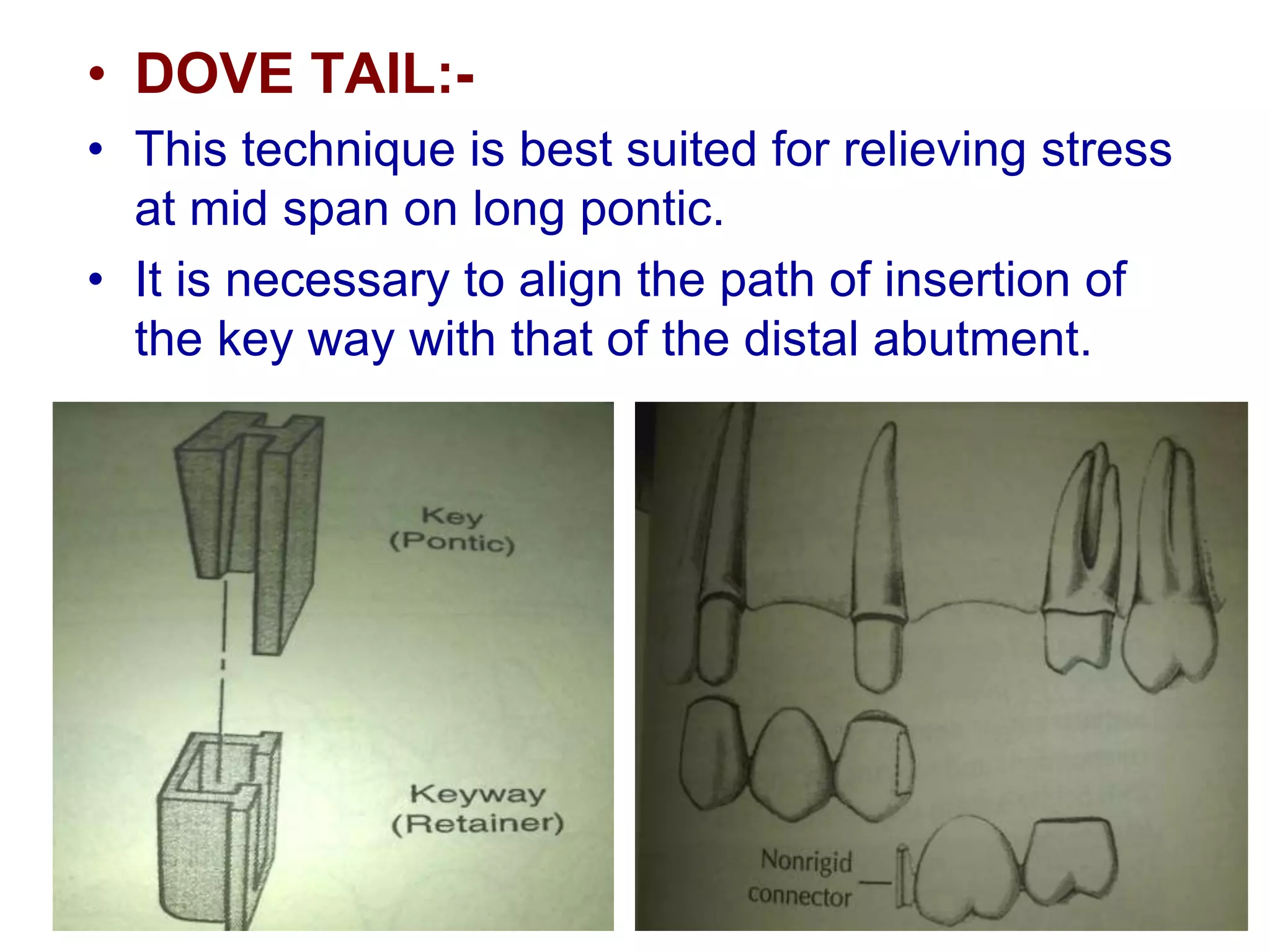

This document discusses different types of connectors used in fixed partial dentures. It describes rigid connectors which provide a cast, soldered, or fused union between retainers and pontics. Non-rigid connectors allow limited movement and include dove-tail, split pontic, and tapered pin designs. The document outlines appropriate sizes, shapes, and positions for connectors and provides illustrations of different connector designs.