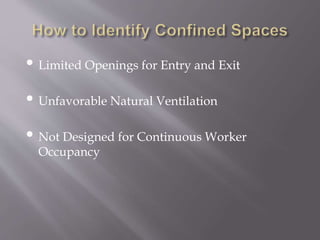

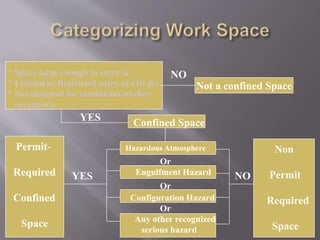

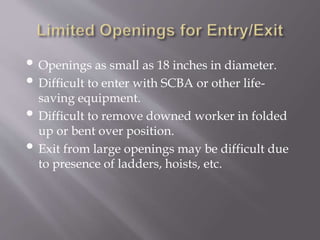

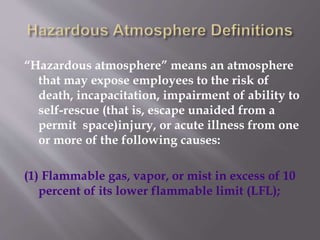

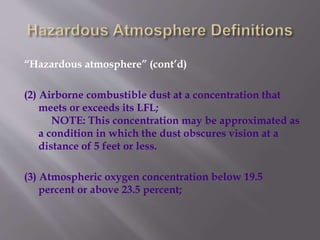

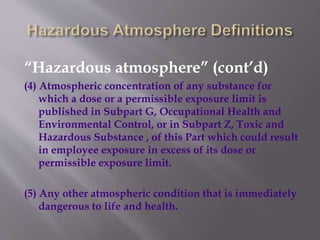

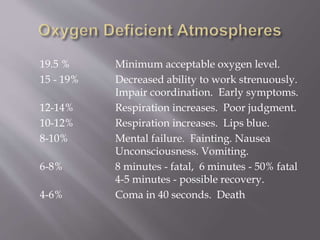

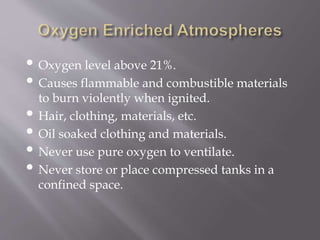

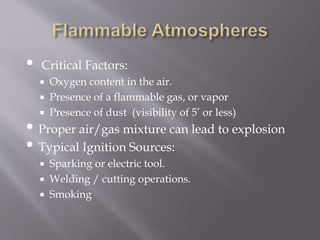

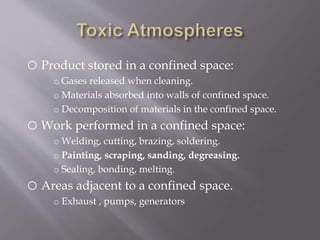

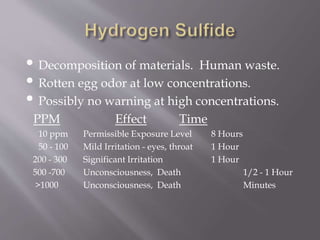

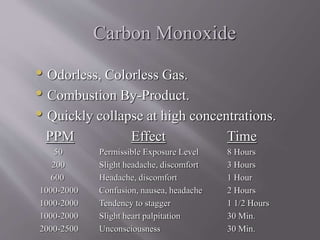

This document provides an overview of OSHA standards and confined space hazards. It defines a confined space as having limited openings for entry/exit, unfavorable natural ventilation, and not being designed for continuous occupancy. Hazards include hazardous atmospheres from gases, vapors, dusts or oxygen deficiency; engulfment from materials like grain; and configuration hazards due to limited space. Proper precautions include testing the atmosphere, ventilation, lockout/tagout of hazards, use of permits and attendants, and rescue procedures. All workers entering confined spaces must be trained.