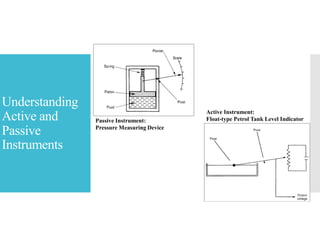

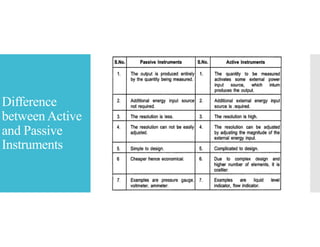

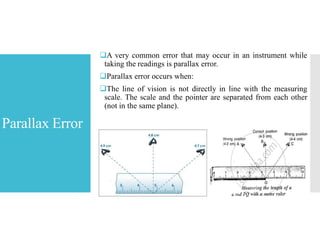

This document provides an overview of measurement and instrumentation topics. It defines measurement as the act of comparing an unknown quantity to a standard. Instruments are defined as devices used to determine the value of a quantity, while instrumentation refers to using instruments to measure properties in industrial processes. The document discusses types of instruments, including active vs passive, as well as different methods and standards used for measurement. It also covers sources of error in measurement, such as systematic, random, alignment, and parallax errors.