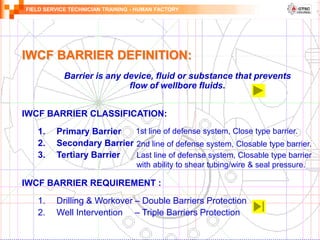

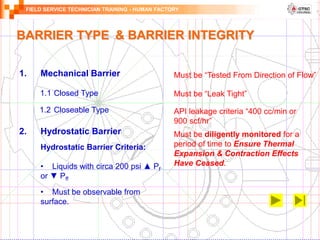

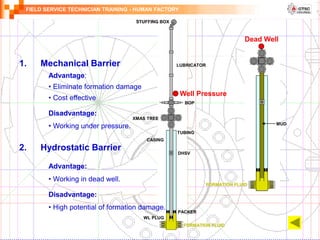

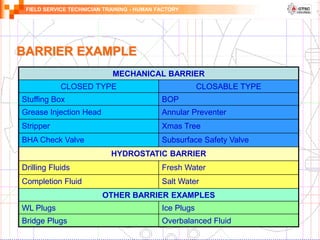

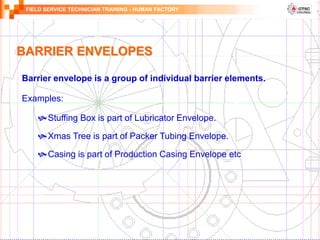

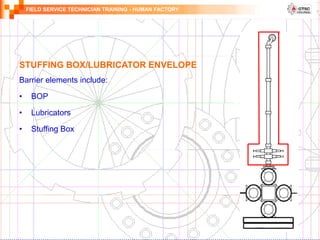

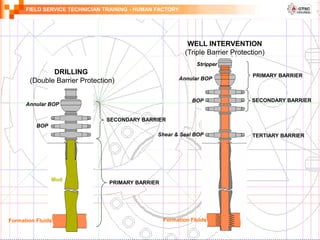

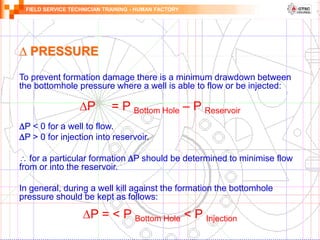

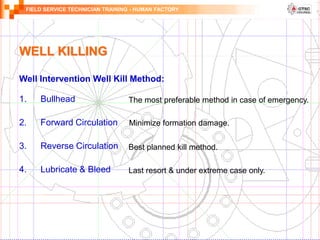

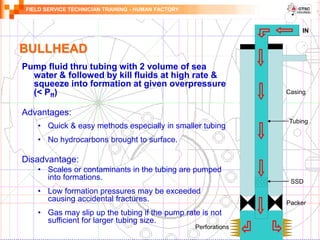

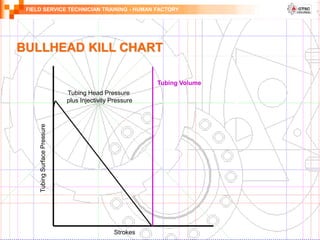

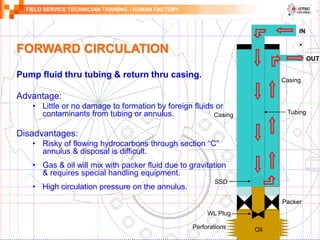

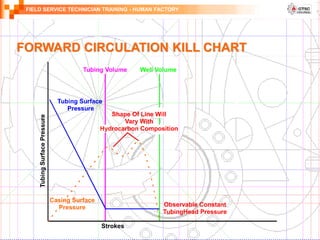

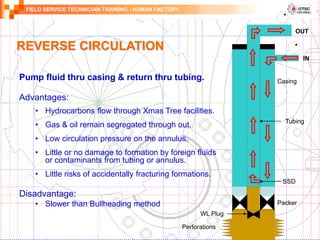

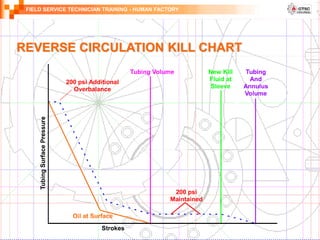

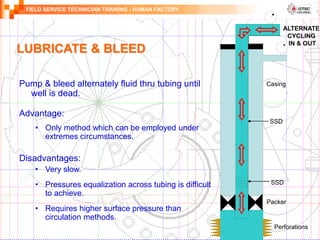

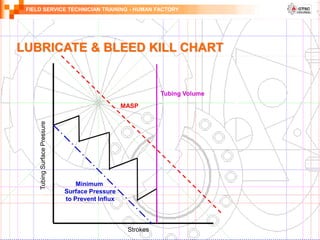

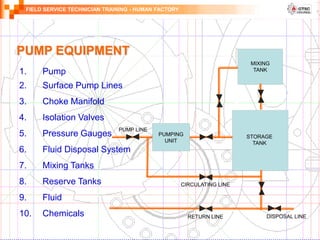

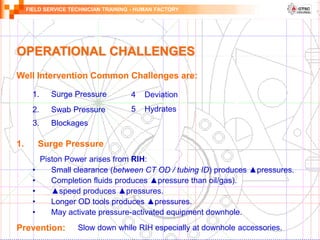

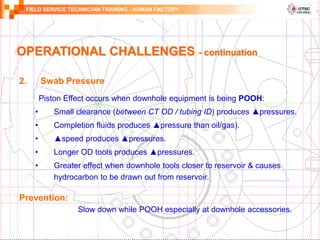

This document provides training on well control, barriers, and killing an intervention well. It discusses the three factors that govern well control: personnel, equipment, and plans/procedures. It defines barrier types and requirements for drilling and intervention wells. Methods for killing a well include bullheading, forward circulation, reverse circulation, and lubricate and bleed. Proper preparation, information, and pumping equipment are needed to kill a well safely while preventing formation damage. Common challenges include surge pressures, swab pressures, and blockages.