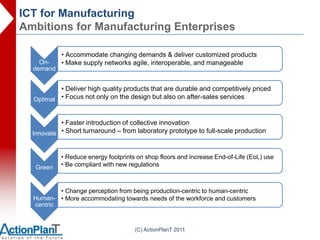

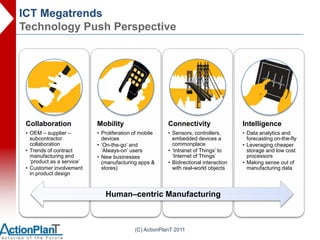

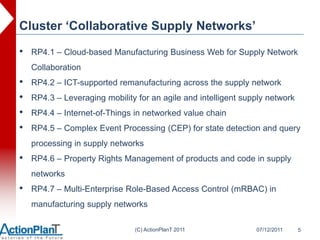

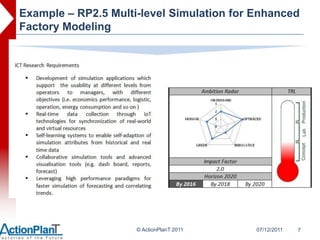

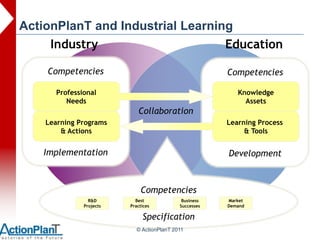

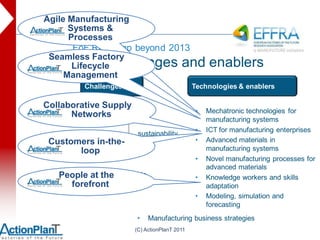

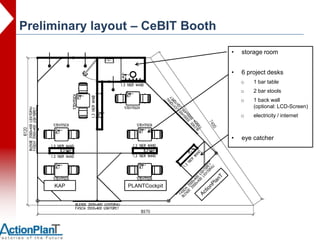

The document outlines the ambitions and strategies for integrating ICT in manufacturing enterprises to meet evolving demands through customization, agile supply networks, and sustainability. It discusses collaboration and technology trends such as the Internet of Things and mobile solutions to enhance manufacturing processes and innovation. Additionally, it presents research priorities and plans for future conferences focused on advancing manufacturing practices and education in digital technologies.