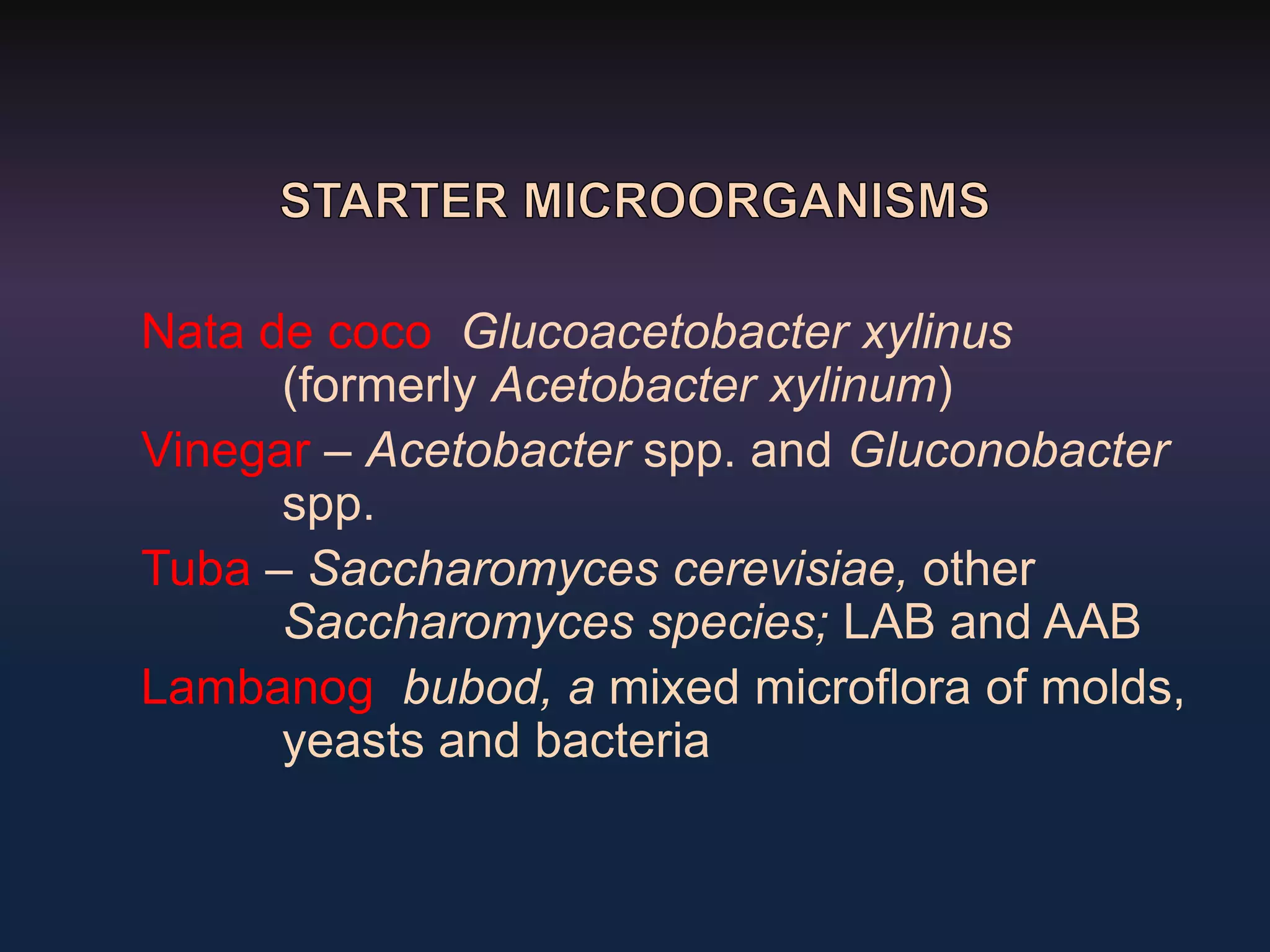

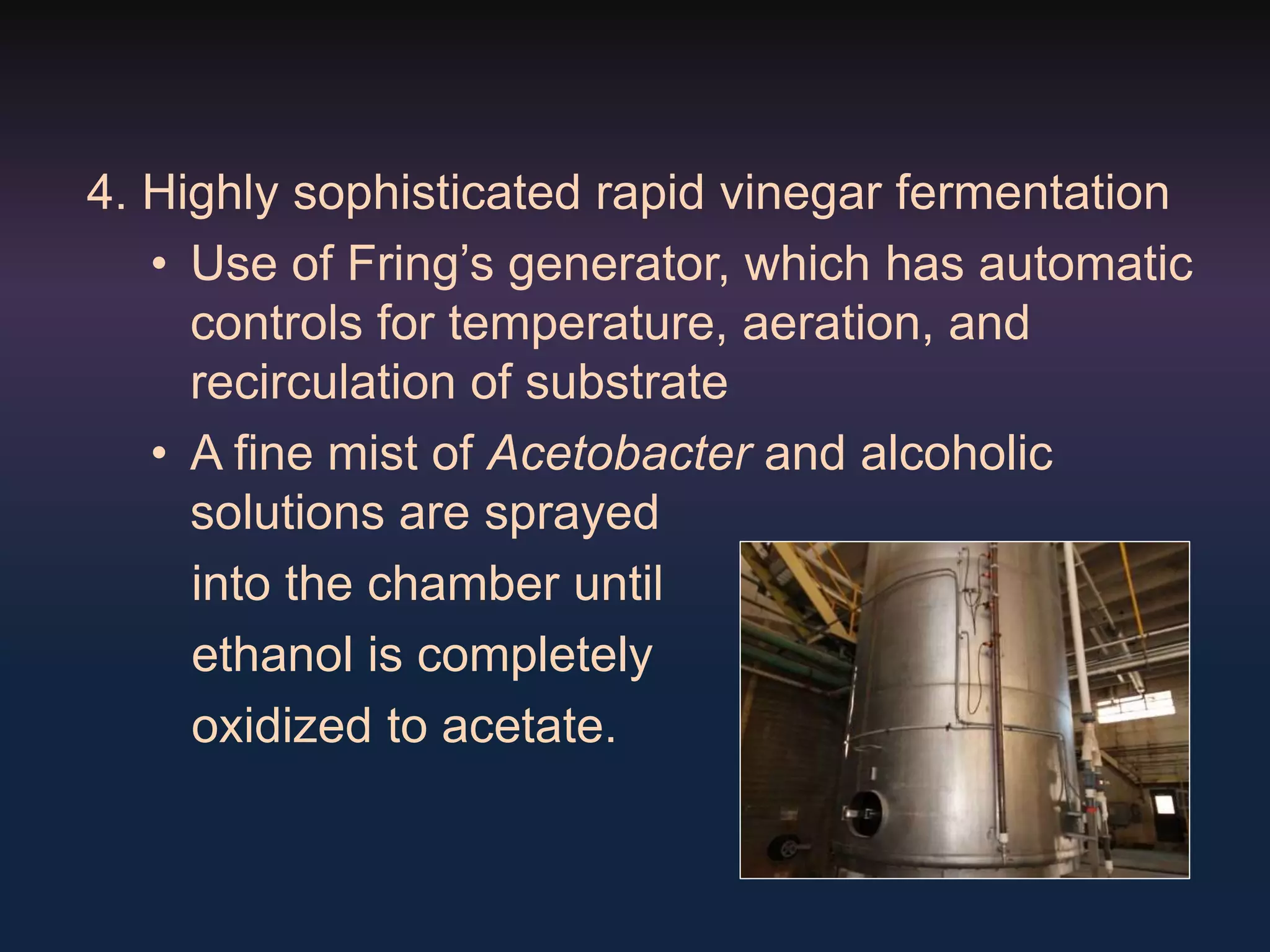

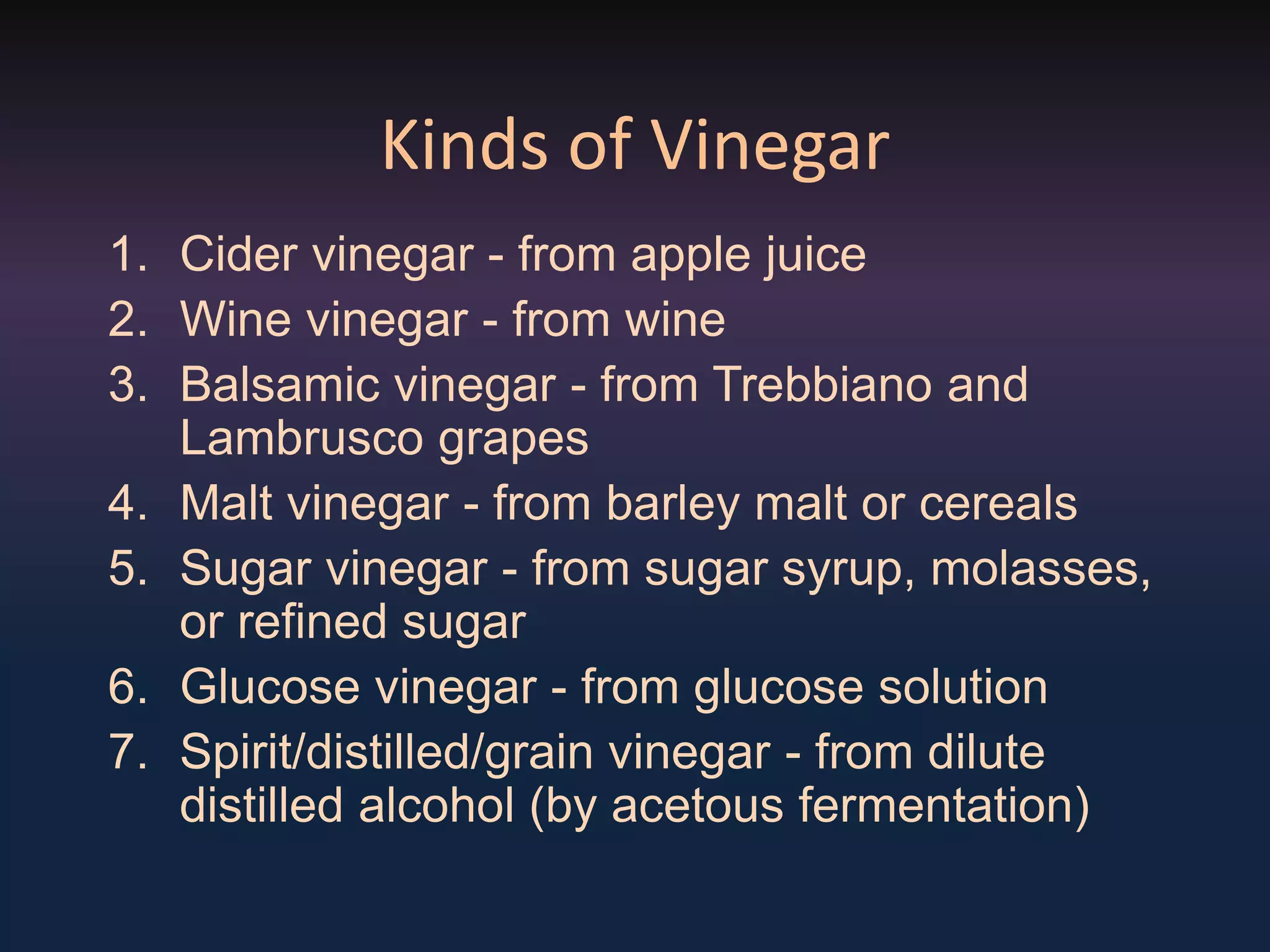

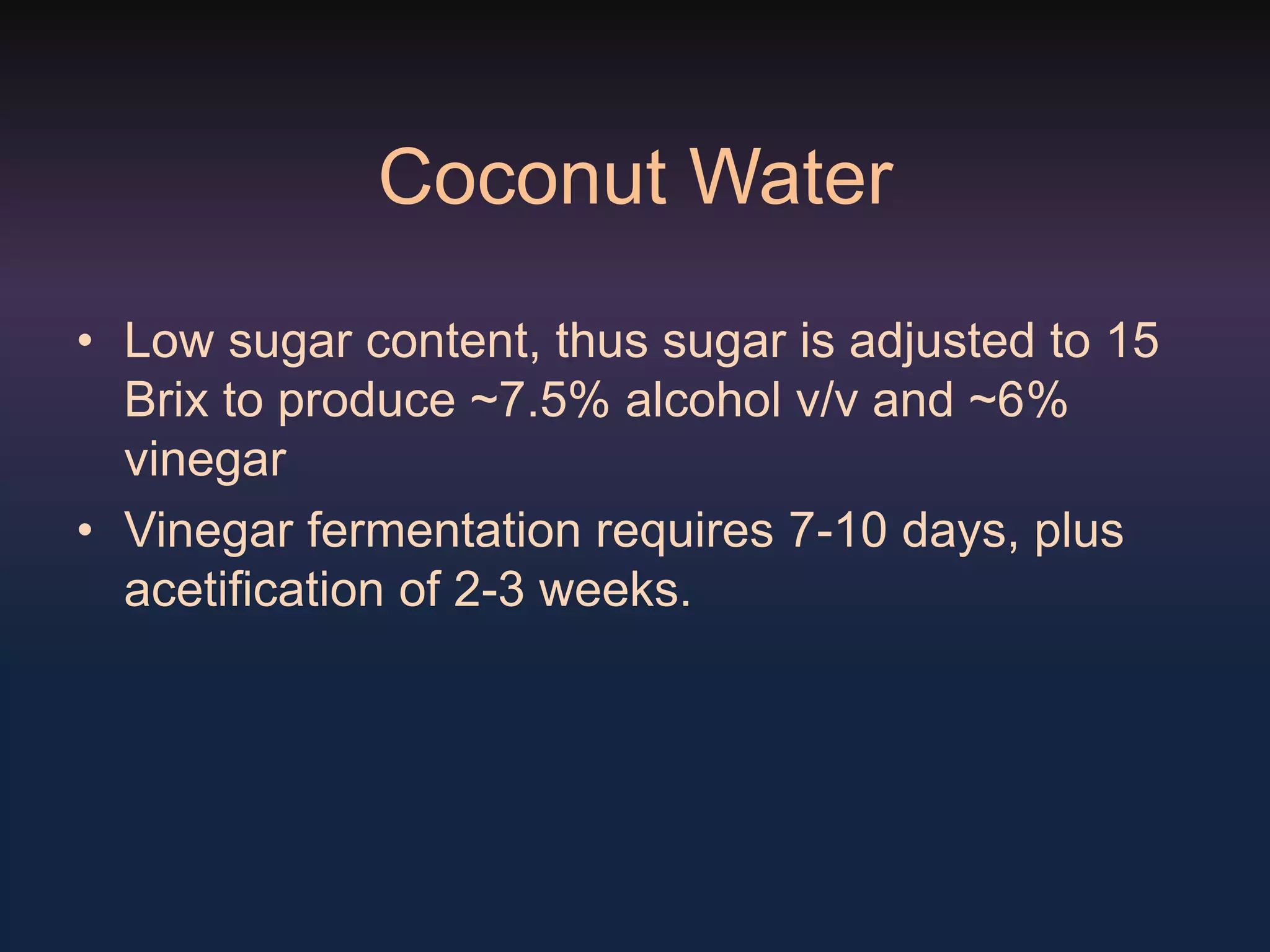

This document discusses several types of fermented products from the Philippines including nata de coco, vinegar, tuba, and lambanog. It provides details on the microorganisms involved in fermentation for each product and describes the production processes. Specifically for vinegar, it outlines the chemical process, methods of production including Orleans and submerged fermentation, common types of vinegar from different substrates, and notes on quality control during fermentation.