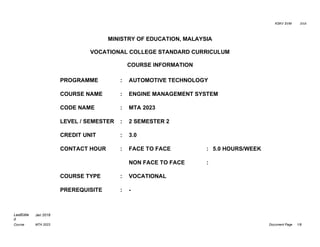

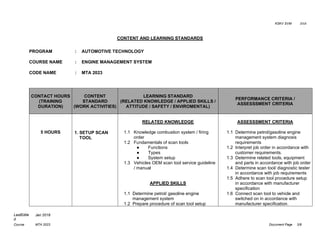

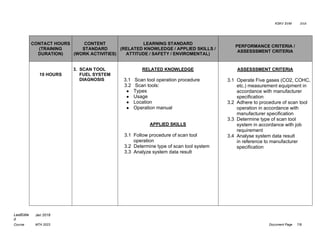

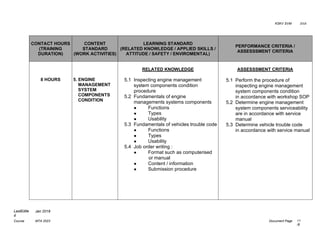

This document provides information on the Engine Management System course offered at the Ministry of Education, Malaysia Vocational College. The 3-credit, semester 2 course aims to teach students to detect defects in engine management systems and assess problems to assign required repairs. Key topics covered include setting up scan tools, performing fuel pressure tests, using scan tools for fuel system diagnosis, analyzing oscilloscope patterns, and checking engine management system components. The course is comprised of 5 hours per week of face-to-face instruction over various topics, with assessment based on competency in tasks like operating diagnostic tools according to specifications.