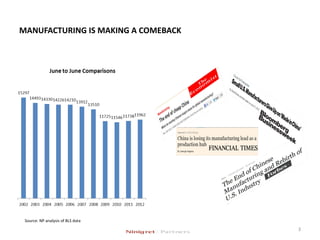

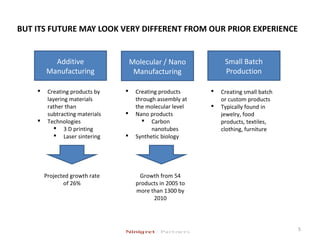

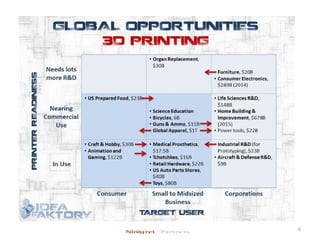

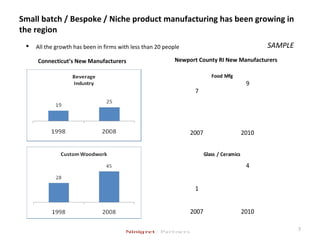

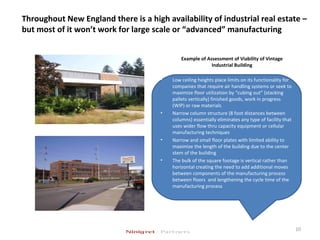

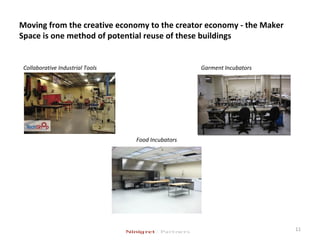

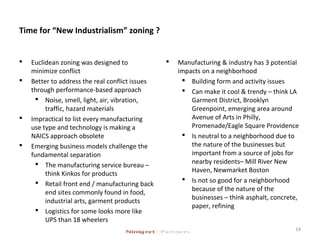

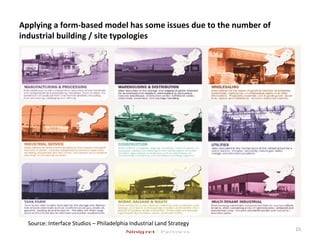

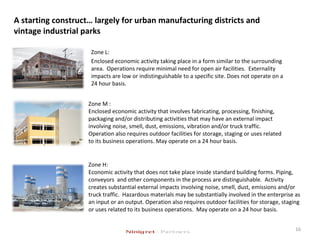

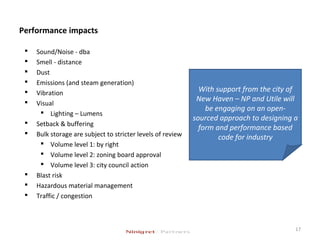

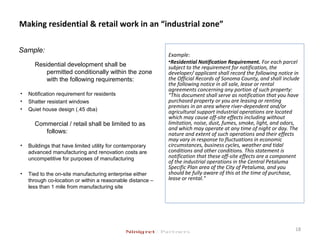

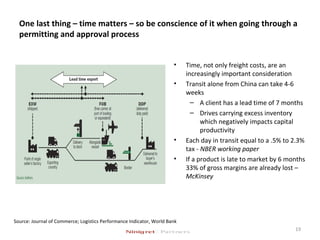

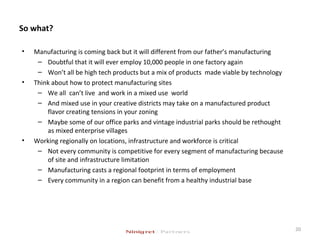

This document discusses strategies for local economic development to support the resurgence of manufacturing. It notes that while manufacturing jobs are increasing again, the future of manufacturing will likely be different than the past with trends like additive manufacturing, nano-manufacturing, and small-batch production. It also discusses challenges like outdated industrial real estate, integrating maker spaces and incubators into communities, and ensuring zoning allows for diverse new models. The document advocates for performance-based industrial zoning, protecting manufacturing sites, and taking a regional approach to workforce development and infrastructure to support modern manufacturing.