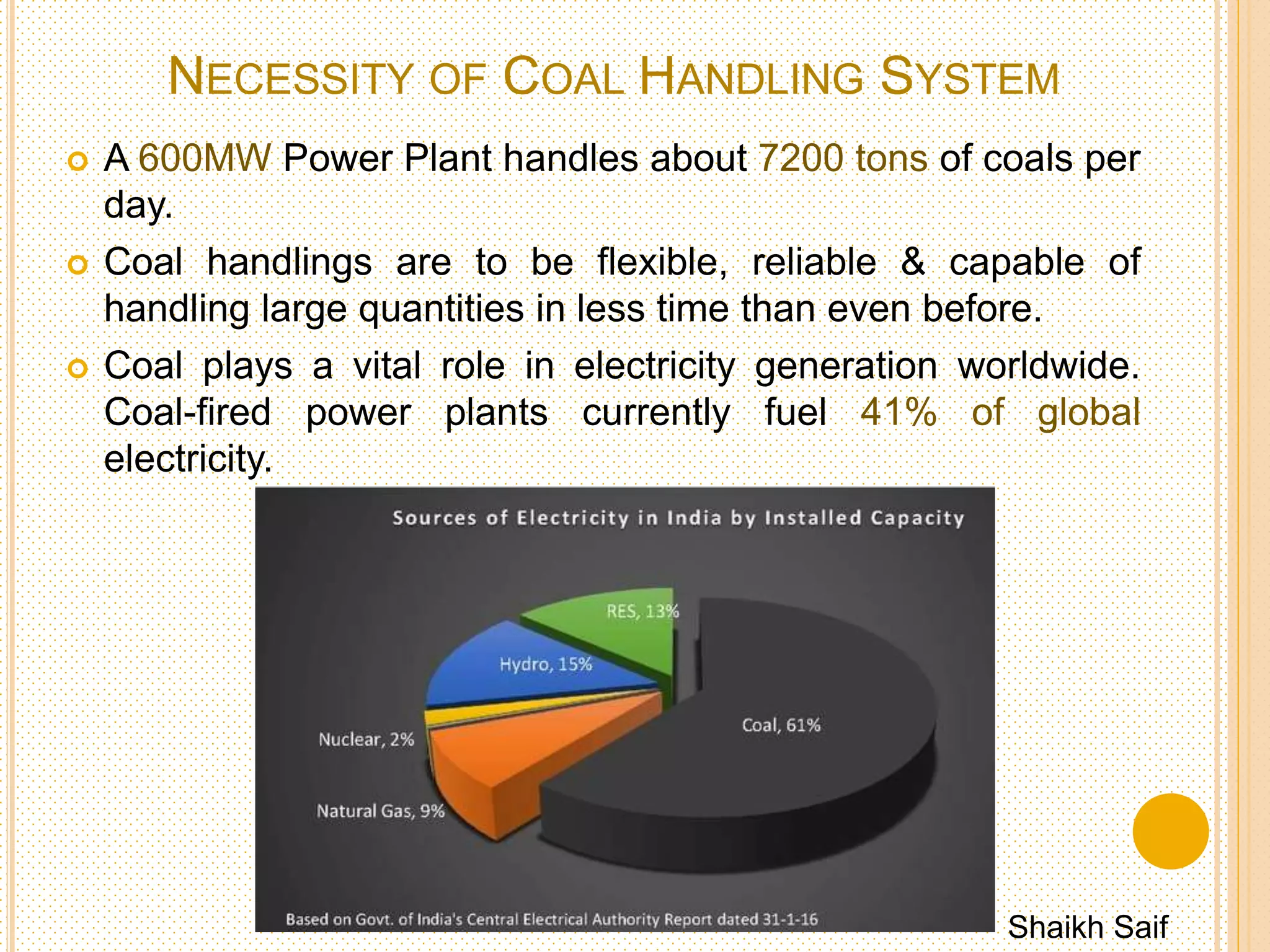

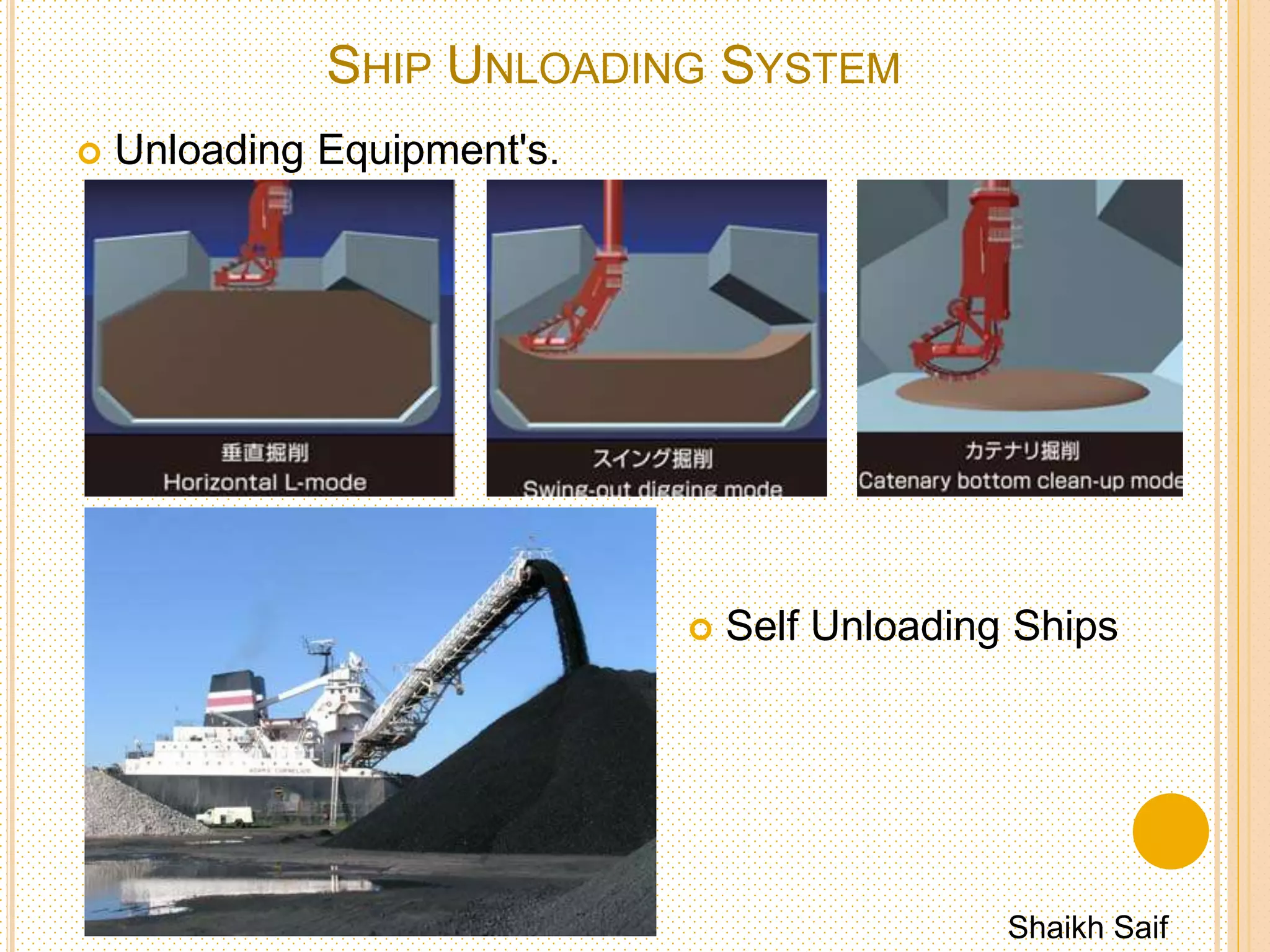

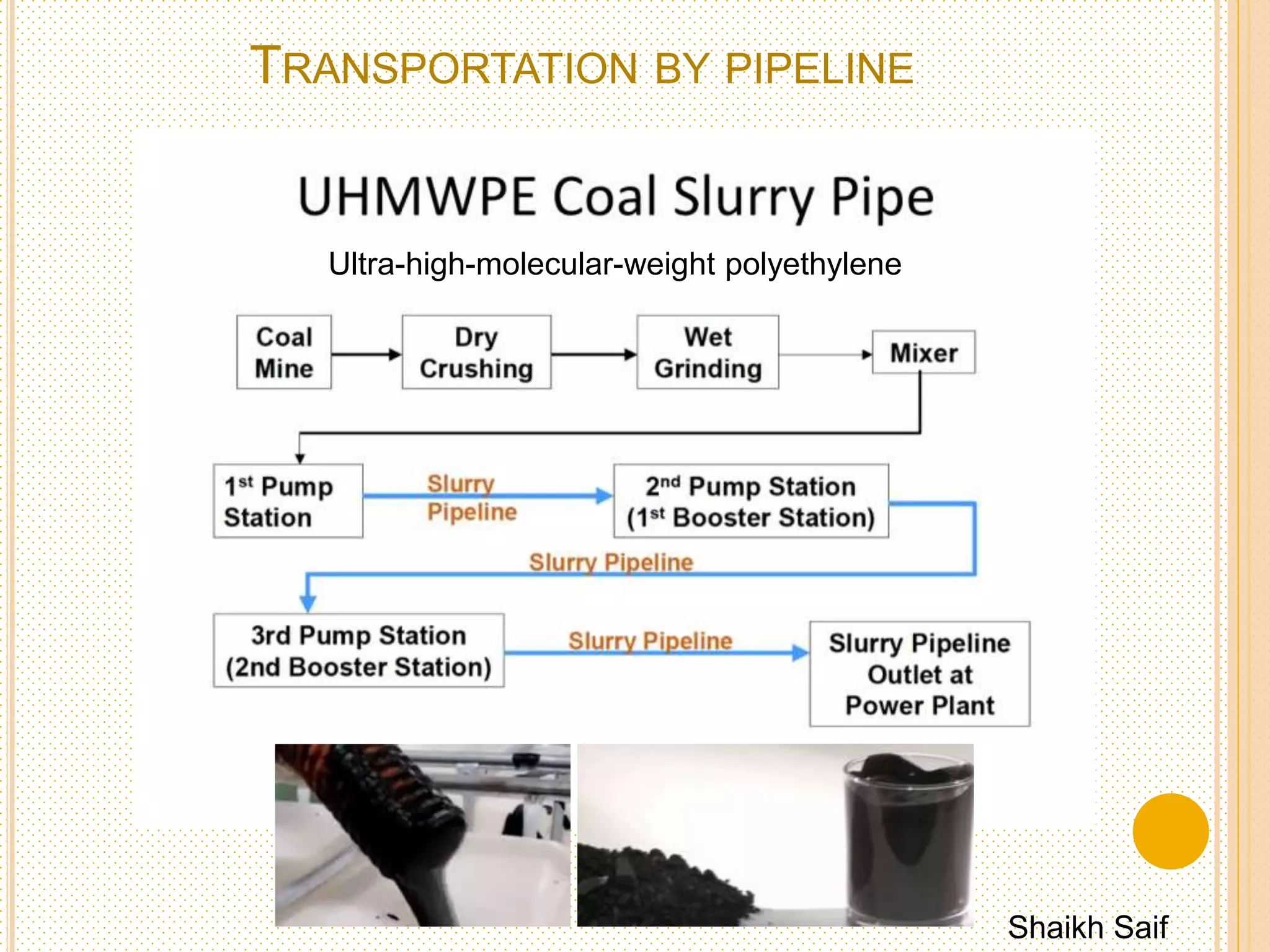

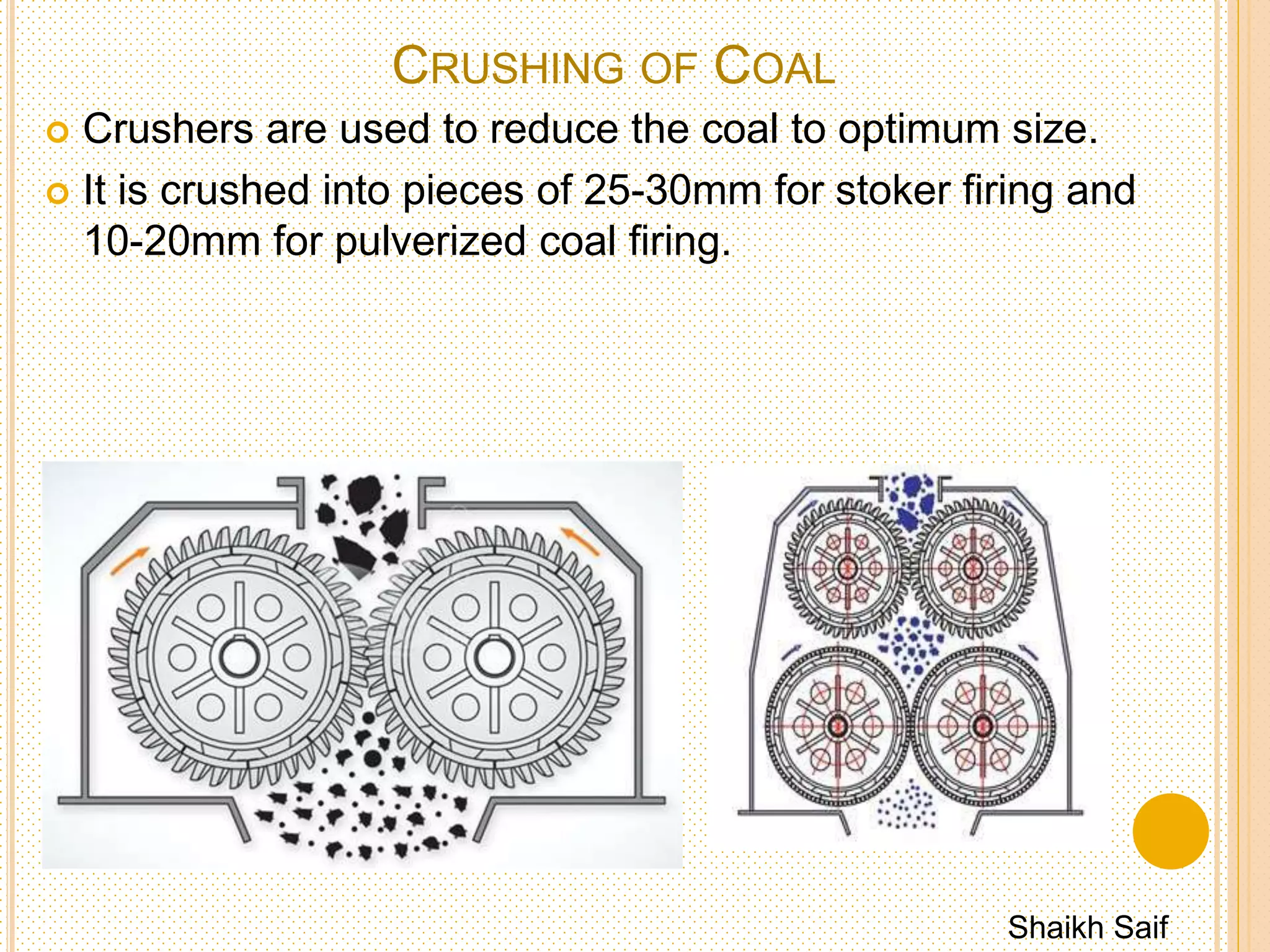

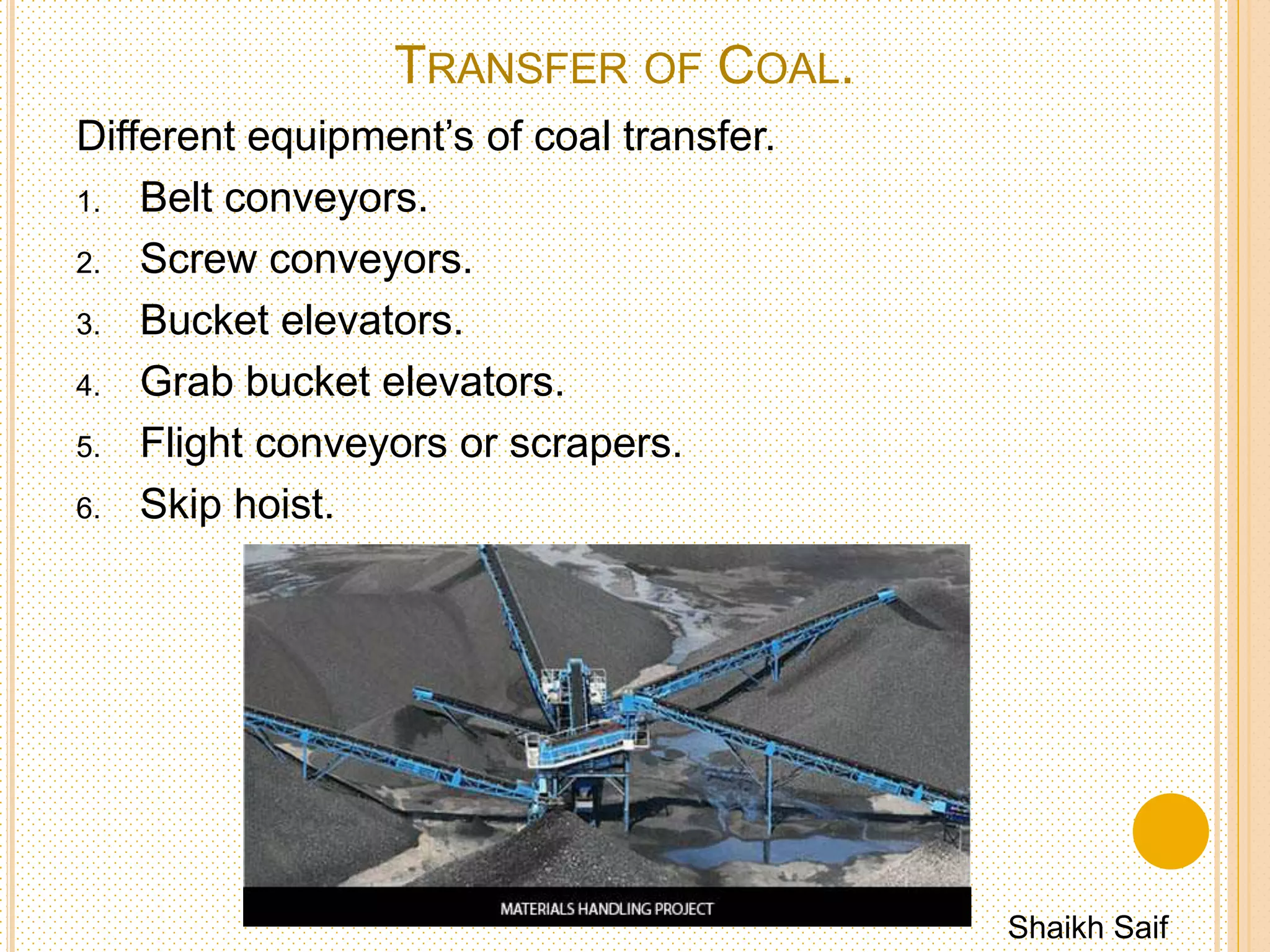

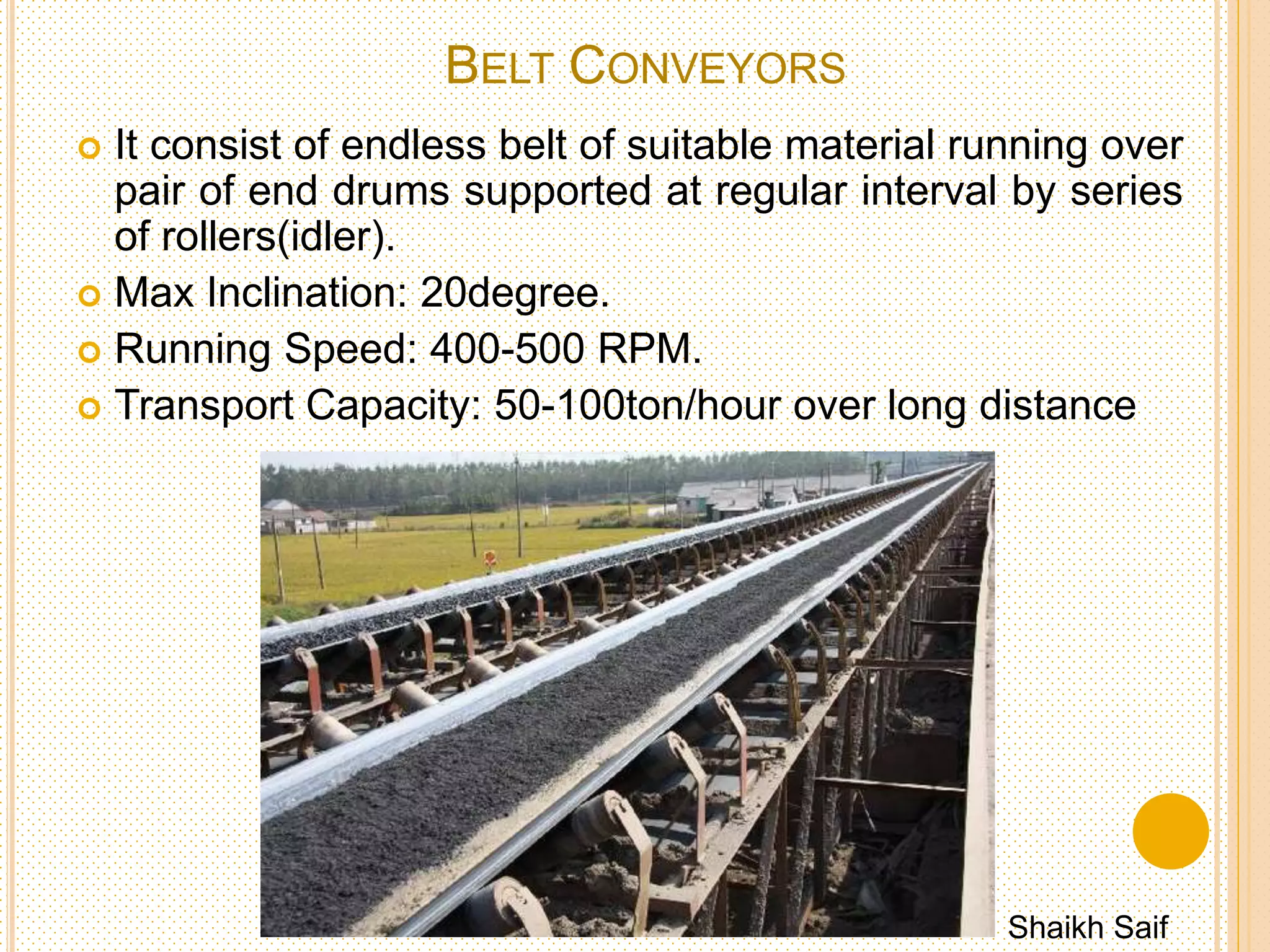

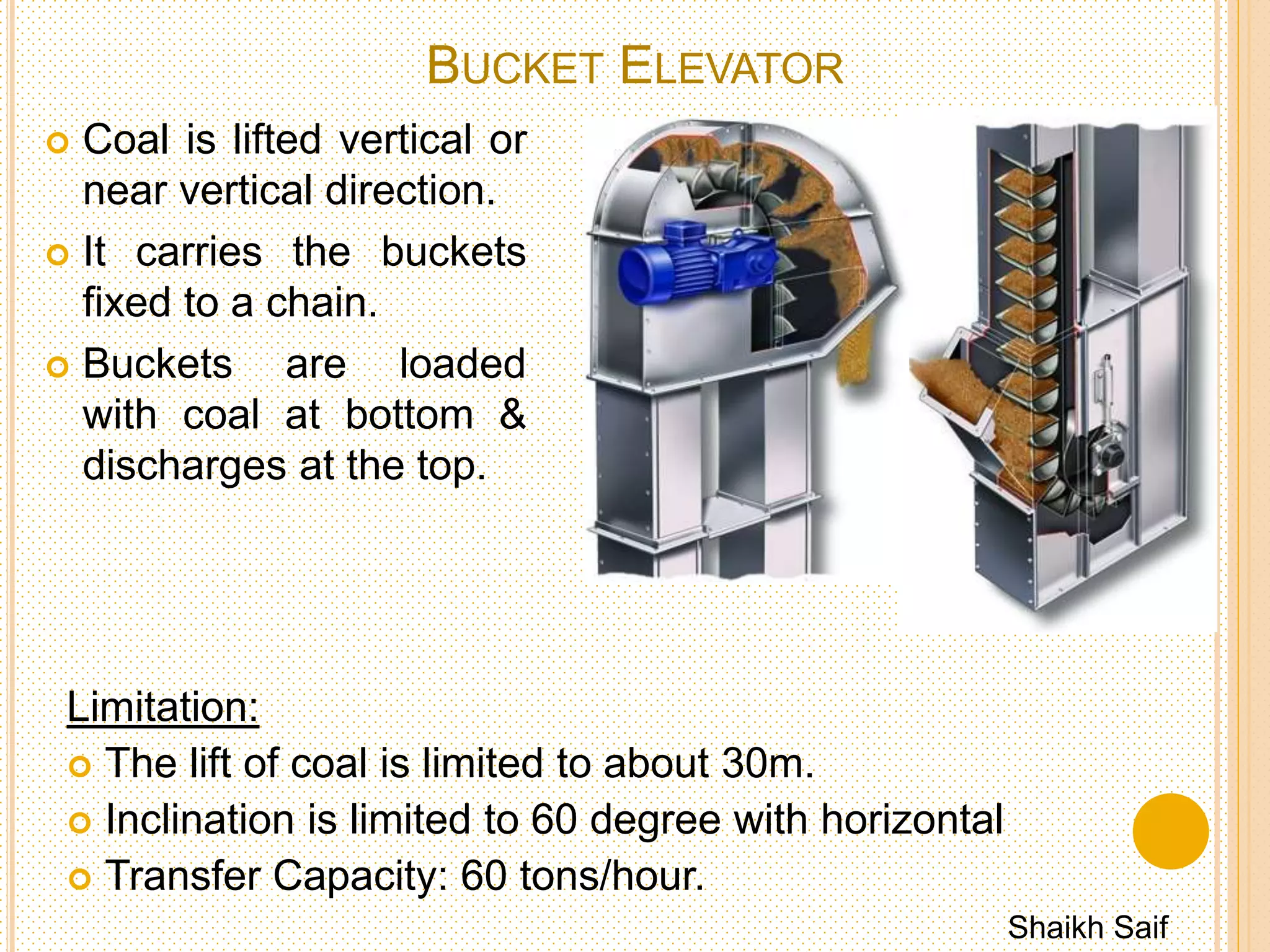

The document discusses the coal handling system for a 600 MW power plant that processes approximately 7200 tons of coal per day, emphasizing the need for flexibility, reliability, and efficiency in coal management. It covers various transportation methods, unloading systems, storage strategies, and the equipment used for coal transfer and preparation. Key points include minimizing maintenance, achieving optimal coal size for combustion, and utilizing efficient technologies for coal weighing and handling.