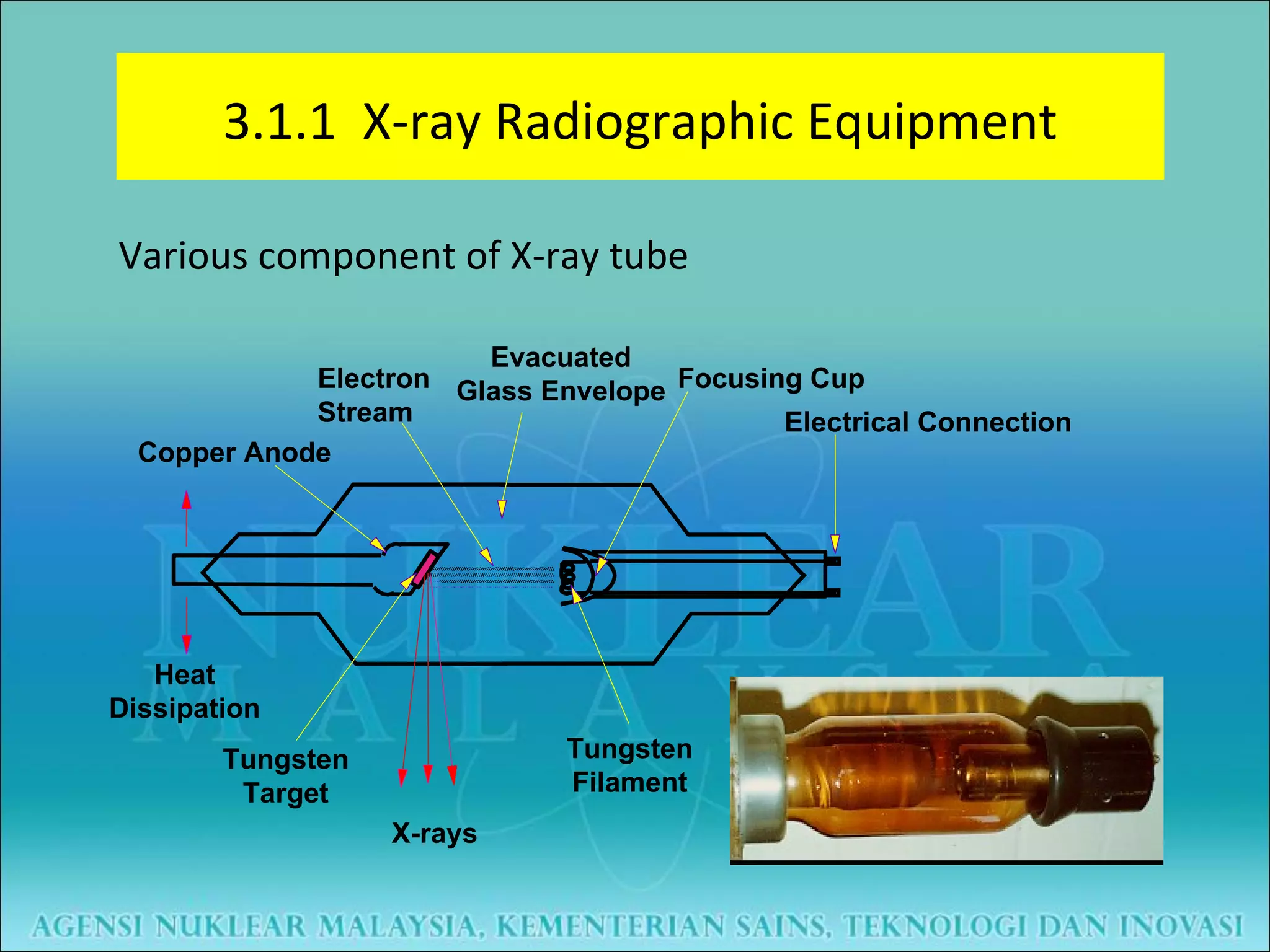

The document discusses safety and security in industrial radiography. It describes the basic principles and applications of radiography techniques using radiation sources like x-rays and gamma rays. It also discusses the equipment used including radiation devices, safety equipment, and procedures to control external radiation exposure through principles of time, distance and shielding.