Garments in bangladesh

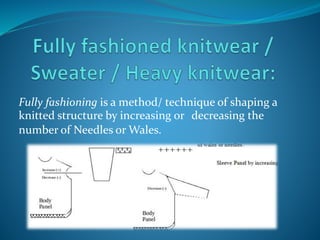

- 1. Fully fashioning is a method/ technique of shaping a knitted structure by increasing or decreasing the number of Needles or Wales.

- 2. Most common sweater machine in Bangladesh: Knitting Machine: Hand driven flat knitting machine. 3 Gauges, 5 Gauges, 7 Gauges, 10 Gauges, 12 Gauges, 14 gauges. Jacquard All gauges can be made in jacquard machine. Linking Machine: Dial linking machine 5 Gauges, 6 Gauges, 7 Gauges, 8 Gauges, 14 Gauges, 16 Gauges

- 3. Most common Yarn Basic Type: Fancy Type: 100% Acrylic Acrylic Mélange Blended Acrylic 100% Wool Mixed Wool 100% Cotton Blended Cotton etc. Chenille Angora tweed Nap yarn/ Slub yarn Mohair Tape yarn Cashmere Loop yarn Popcorn etc.

- 4. Most common Stitch Basic Stitch: Jersey stitch Rib Stitch Double Stitch Fancy Stitch: Shaker or half cardigan stitch, full cardigan Drop knit tuck knit Milano stitch pointelle zigzag stitch cable stitch diamond

- 5. FULLY FASHIONED MAKING PROCESS FLOW CHART Warehouse arrangement & yarn inspection Winding section Yarn cone distribution section Knitting section Knitted panel inspection. Linking section Linking inspection section Trimming section/ Linking continue Light check inspection Mending section Washing & drying section Pressing / Ironing section Finishing section

- 6. Warehouse arrangement & yarn inspection As per buyer requirement we will purchase the yarn from yarn supplier. It can be local or foreign yarn. Before purchase the yarn we must need clear idea regarding the wastage percentage of the each types yarn. Wastage consider in case of types of gauge and material quality: In case of normal gauge/ regular gauge (3G, 5G, 7G); 4% production wastage is considered except chenille yarn. In case of fine gauge (10G, 12G) add 1% more wastage for any fine yarn except chenille yarn. So production wastage is 4%+1%=5%. In case of chenille yarn add 1% more wastage to the normal gauge and fine gauge. So for normal gauge of chenille yarn wastage is 4%+1%=5% and fine gauge of chenille yarn 5%+1%=6%. After in-house the yarn we should store yarn by their types & count. And check or inspect the yarn: Color with swatch card, Quantity with order sheet.

- 7. Winding Section Winding section the yarn should be formed Hanks to Cone / hard cone to soft cone. After receive the yarn from supplier we need to wind these yarn by coning machine for knitting production. Winding machine

- 8. Yarn cone distribution section After winding the yarn it goes to yarn distribution section for distribution the yarn to the knitting floor. Here we must ensure that, the correct yarn is being distributed for correct gauge knitting machine. The distributor must distribute the yarn by weight basis and also the knitted panel should be returned accordingly to the distributor.

- 9. Knitting section In knitting section we should knit the body, sleeve etc of the sweater by knitting machine. The operators of knitting machine are called as knitting man. If the sweater is with placket then we will make the placket by auto placket machine. The decision to make by computer or hand machine is depended on the complexity of the design. Sometimes, intarsia design will be done. Hand driven flat knitting machine Jacquard machine.

- 10. Knitted panel inspection After knitting the body parts, it will be inspected by the Q.C team in the inspection section.

- 11. Linking section After pass the Q.C check, the body parts will be goes to the Linking section. In this section we join the front part, back part, sleeve etc with the Linking machine. Loop to loop connection is done manually for high quality garment. Linking process Linking machine

- 12. Linking inspection section Trimming section/ Linking continue After linking the body parts, it will be inspected by the Q.C team in the inspection section. In this section the body will be trimmed.

- 13. Light check inspection After linking the body parts, it will be inspected by the tubular light check machine.. And also marked the mending hole.

- 14. Mending section From trimming section it will go to mending section for mending on which hole has been marked in trimming section.

- 15. Washing & drying section In this section we wash & dry the sweater. Then we send it to the Iron section.

- 16. Pressing / Ironing section Here iron the body to fit the measurement and shape.

- 17. Finishing section After ironing the body we inspect the iron quality. After iron check we attached the label with the body by sewing machine also button and zipper can be join with body if those require. After attached the label with sweater, quality team check all over quality. It’s called final quality. After the final check we sent the sweater to packing section for poly & carton.

- 18. Conclusion From above presentation we understand that every step of manufacturing sweater is so important. Because if we don’t give strong follow up on every stage then bottle neck can be risen. So we should keep potential follow up on all stage.

- 19. Question?????

- 20. THANK YOU…….!