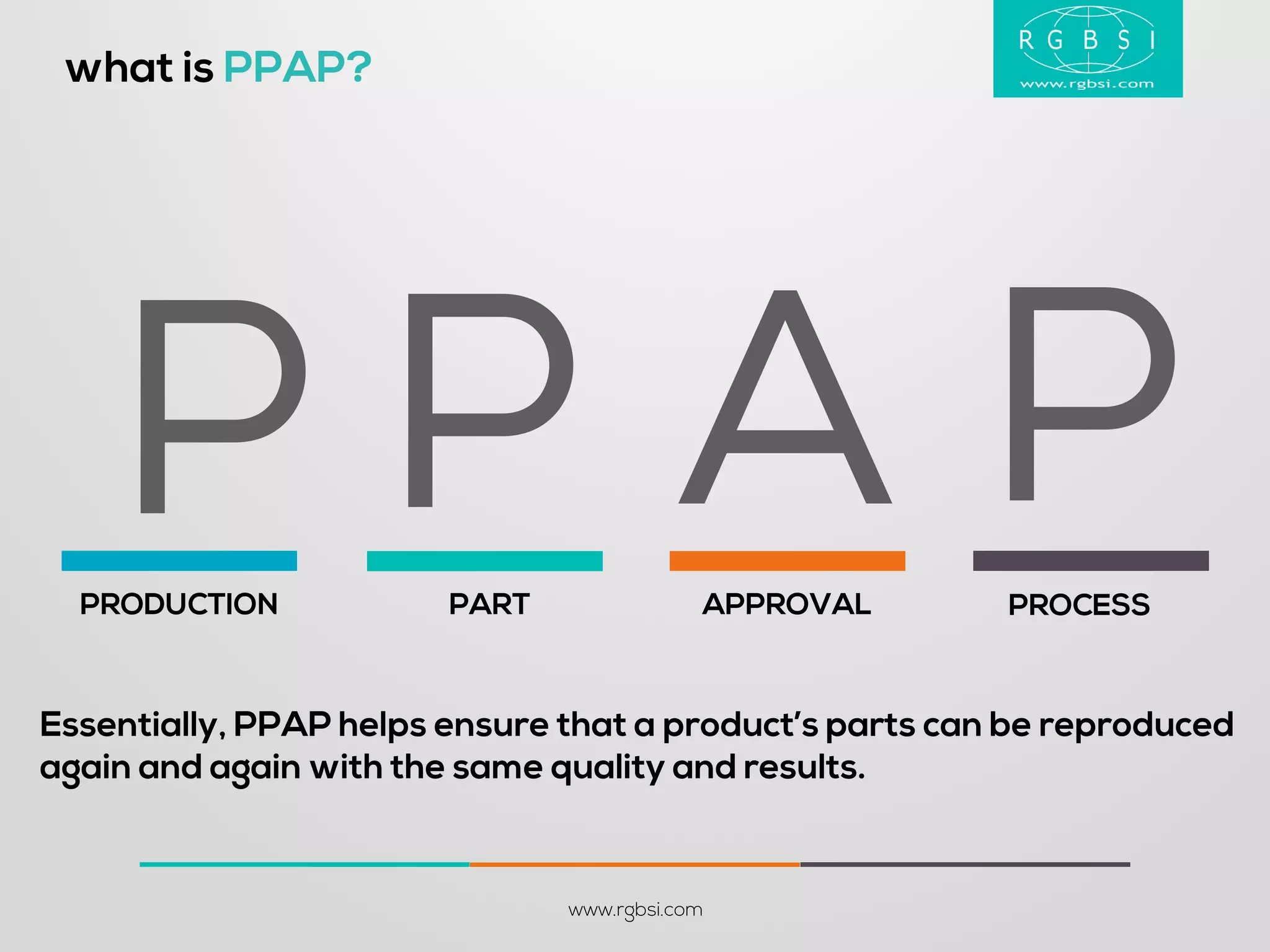

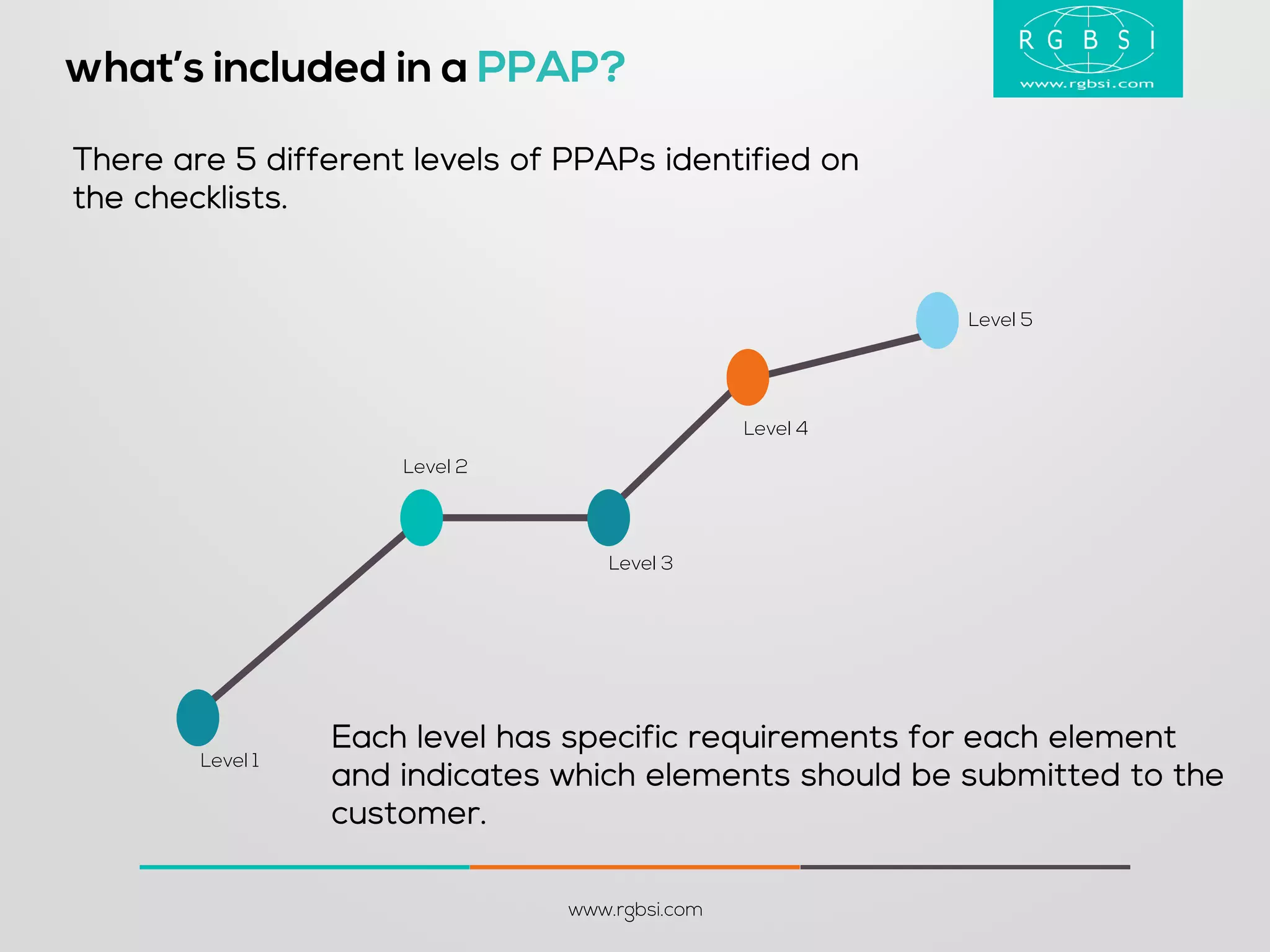

The document outlines the production part approval process (PPAP), which is a standardized method in the automotive and aerospace industries that ensures manufacturers and suppliers can consistently reproduce parts with the same quality. It details the requirements, elements, and negotiation strategies involved in PPAP, noting differences between automotive and aerospace requirements. Additionally, it emphasizes the importance of PPAP in protecting customers and maintaining product quality.