Sensors being provided for Bardhaman Bridge health monitoring

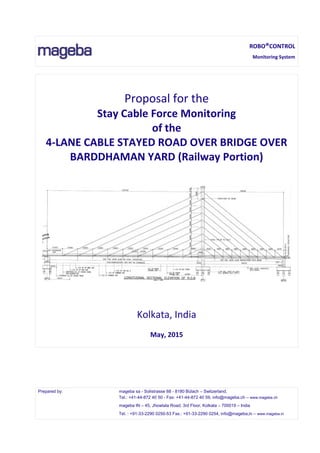

- 1. Prepared by: mageba sa - Solistrasse 68 - 8180 Bülach – Switzerland, Tel.: +41-44-872 40 50 - Fax: +41-44-872 40 59, info@mageba.ch – www.mageba.ch mageba IN – 45, Jhowtala Road, 3rd Floor, Kolkata – 700019 – India Tel. : +91-33-2290 0250-53 Fax.: +91-33-2290 0254, info@mageba,in – www.mageba.in ROBO®CONTROL Monitoring System Proposal for the Stay Cable Force Monitoring of the 4-LANE CABLE STAYED ROAD OVER BRIDGE OVER BARDDHAMAN YARD (Railway Portion) Kolkata, India May, 2015

- 2. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 2 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Table of Contents Table of Contents.............................................................................................................................. 2 1. Introduction.......................................................................................................................... 3 2. Description of the Monitoring System.................................................................................... 5 2.1 General .............................................................................................................................................5 2.2 Analysed structure ‘New 4-Lane Cable Stayed ROB at Barddhaman” .............................................6 2.2.1 Proposed sensor layout ........................................................................................................... 6 2.2.2 Monitored variables of the structural response. ................................................................................ 7 2.2.3 Frequency of measurements ..................................................................................................... 8 2.2.4 Sensor durability and protection rating .......................................................................................... 8 2.3 Detailed Sensor Description .............................................................................................................9 2.4 Power Supply of Sensors ..................................................................................................................9 2.5 Analogue Cabling..............................................................................................................................9 2.6 Digital Cabling...................................................................................................................................9 3. ROBO®CONTROL Data Acquisition and Transfer System........................................................ 10 3.1 Master Station................................................................................................................................10 3.1.1 Uninterruptible Power Supply – UPS ........................................................................................... 10 3.1.2 Software at master station...................................................................................................... 11 3.1.3 AD-Converters (stand-alone units) ............................................................................................. 11 3.2 Data transfer from data acquisition unit to the Web Interface .....................................................13 3.3 Control Room .................................................................................................................................13 4. ROBO®CONTROL Data Presentation..................................................................................... 14 4.1 ROBO®CONTROL Web Interface.....................................................................................................14 4.2 ROBO®CONTROL Web Interface Data Download...........................................................................16 4.3 Monitoring Cockpit and Live-view..................................................................................................17 4.4 iPad for Mobile Data Analysis.........................................................................................................18 4.5 Demonstration Login for Web Interface ........................................................................................18 5. Service Proposal.................................................................................................................. 19 6. Installation.......................................................................................................................... 21 6.1 General Sketch regarding installation and positioning ..................................................................21 6.2 Installation support requirement...................................................................................................21 6.3 Installation Methodology ...............................................................................................................22 7. Financial Offer and Conditions ............................................................................................. 24 7.1 Financial Offer for Permanent Monitoring System ........................................................................24 7.2 Additional Site Visits.......................................................................................................................24 7.3 Conditions.......................................................................................................................................25 APPENDIX A: Proposed Sensors APPENDIX B: References APPENDIX C: Terms & Conditions

- 3. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 3 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 1. Introduction This document provides mageba’s proposal for a Bridge Structural Health Monitoring System for the New 4-Lane Cable Stayed ROB at Barddhaman, India. The offer covers the design, supply, testing, and installation of the system. The purpose of mageba’s proposed monitoring solution is: To measure the parameters which have an influence on the structural performance and intended service of the bridge Assessment of factors that influence user safety The proposed mageba ROBO®CONTROL monitoring system is offered in a turnkey manner, i.e. mageba will be responsible for technical design, supply, and installation of the system as well as training of the operators. In addition, maintenance and operations support is offered to ensure smooth and reliable operation. The ROBO®CONTROL Web Interface will allow remote internet access to the data. An automated alarm system can be established to notify the responsible personnel in the event that any pre-defined threshold values are exceeded. The system will be implemented using industrial-grade components capable of continuous uninterrupted operation. The proposed system will monitor environmental factors and the bridge’s structural response, through high quality sensors especially selected for the New 4-Lane Cable Stayed ROB at Barddhaman project. Technical Capabilities mageba is one of the world's leading bridge equipment suppliers, with extensive experience in the design and supply of structural health monitoring systems, expansion joints, bridge bearings and anti-seismic devices. Durable components are used to ensure maximum service life. Where possible, the latest technologies are used. Examples are: Measurements at frequencies of up to 300 Hz Integration of alarm functions and alert message systems (e.g. SMS, email, etc.) where applicable and required Presentation of data on the Internet with instructions and data download functions Application for tablet computer (e.g. iPad, etc.) allowing mobile access to the monitoring data Experience This proposal is based on the experience of successful involvement on dozens of monitoring projects over many years around the world. Details and sample reference letters from a selection of projects carried out in the last four years are contained in APPENDIX B of this document.

- 4. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 4 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Important Note The proposed system is based on the information provided: Main Bridge drawings GAD_ROB The monitoring system needs to be implemented by means of industrial-grade components capable to continuous uninterruptible operation during earthquakes or rough weather conditions. Proposed procedure: (1) Elaboration of a monitoring proposal. (2) Presentation of the proposal to the client. (3) Discussion with the client and elaboration of the final offer. (4) Negotiation with the client. (5) Manufacturing of the BSHMS (6) Installation and testing of the BSHMS. (7) Training of client’s staff handing over of the permanent system to the client. (8) Service and warranty for the permanent monitoring system (BSHMS).

- 5. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 5 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 2. Description of the Monitoring System This section describes our proposal for the permanent monitoring system of the New 4-Lane Cable Stayed ROB at Barddhaman. This entails a complete, turn-key monitoring solution which will be used for the purpose of comprehensive structural health monitoring. The sensor types required are listed in APPENDIX A of this document and are distributed across the bridge structure. 2.1 General Mageba’s monitoring systems have been developed specifically for applications in bridges. All components used are designed to sustain severe environmental conditions and perform reliably for the duration of the project. Design criteria are conservative to minimize failure risks and to guarantee an adequate lifetime. The data acquisition, transfer, and presentation are provided by mabeba’s ROBO®CONTROL system as further detailed and specified under Sections 3 and 4. The general requirements for a SHMS are fully met by this offer. These requirements are: (1) Solution shall be designed for bridge monitoring application and all components shall be of such design as to sustain severe environmental conditions and stand for several years of operation. Design criteria shall be highly conservative to maximize the mean time between failures (MTBF). (2) Hardware and sensors shall be available on open markets. Alternatively any proprietary components shall be replaceable with components available on open markets with reasonable modifications to the overall configuration. (3) Software operating system is to be based on Windows or other Software. (4) Software application packages shall be on open source or code available based programs in case vendor unavailability to support the solution at any time in the future (5) User interface shall be intuitive, showing “analogue instrument” display in the form of a “mimic panel” and it must be easy to use. (6) User interface is to be standard Web Browser based to ensure compatibility to any future operating environment. (7) Bridge structural health monitoring system is designed to sustain partial damage and the undamaged parts must remain operational and not lose real time and stored data. (8) Manuals are to be provided in electronic format (PDF) and paper copy. The user manual and all other manuals are to be in English. (9) The BSHMS shall be built on turnkey project basis. (10) The supplier shall be able to provide references of similar projects delivered and prove to be fully functional. Single sensor references will not be considered. References regarding the installation of a partial system (for example, stay cable monitoring only) will not be considered. (11) The supplier shall have on-line auto diagnostic, trouble shooting and support services for hard- and software. (12) Supplier shall provide a list of factors to be monitored, the scope of the monitoring for each factor and the sampling rate and accuracy of each sensor. Sampling rate shall refer to the frequency with which data is transmitted to the data processing unit from the sensor and specifically shall not refer to be maximum frequency of operation of the sensors.

- 6. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 6 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India (13) Archived data should have on-line controlled access such as password, Biometrics, etc. The Bridge structural health monitoring system consists of following integrated components: 1. Design, Installation, Commissioning of BSHMS 2. Operation, Maintenance, Data Recording, Analysing and Reporting 3. Sensors to measure environmental and structural response factors. 4. Signal acquisition solution including signal capture from the sensors, signal verification and temperature adjustment, conversion of signal to digital format using 18/24 bit architecture, 1/1000 sec. Signal time synchronization, signal transport to pre-processing data acquisition unit, signal pre-processing and buffering prior to transferring to data processing. 5. For data transforming from analogue to digital form, the system should have a converter to be installed as close as possible to each sensor. 6. Data Information processing to generate reports, to suggest control actions and alert/alarm, to provide data information distribution and storage, information analysis as applicable. Data storage, with no data loss, for a period of up to 20 years. 7. User friendly Interface to enable necessary operational intervention, maintenance optimization and support high level analysis such as finite element. 2.2 Analysed structure ‘New 4-Lane Cable Stayed ROB at Barddhaman” The main bridge is a cable-stayed bridge of 208m with a main span of 124m. The bridge structures carries 4 road lanes divided in two carriageways. The pylon consists of 3 steel towers connected with a beam. The mentioned structure is a good example of advanced civil engineering. The structural configuration is challenging, thus any miscalculation or mistakes done during construction can cause irreversible damages. To have a strong control on these critical issues, it is very convenient and helpful the use of a Structural Health Monitoring System. This kind of structure has to be instrumented with a sophisticated monitoring system. The proposed system is able not only to control the force distribution during construction of the bridge, but can also monitor all structural parameters during the service life. Important measurements are: cable forces. Additional parameters as accelerations, the opening of the expansion joints due to thermal expansions and unexpected deformations, temperature, humidity and wind sensors can be installed on the deck and pylon to detect the real structural behavior. 2.2.1 Proposed sensor layout The Bridge Structural Health Monitoring System (BSHMS) is divided into two parts: The on-structure instrumentation system The data acquisition system for operation and control The structural monitoring system issues alarms notification based on measurements by the on-structure instrumentation when pre-defined threshold values of structural loads are passed. The alarm criteria will be configured based on the structural design of the bridge according to the sensors indicated in the following figures and the sensors listed below. Sensors are included in the system as per the attached diagram below.

- 7. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 7 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India As per discussion at site the sensors would be installed at the pylon top end rather than the deck end as previously proposed by us. Exact positioning of the sensors will be done according to situations at site. The sensor which would be an annular sleeve would be installed inside the outer HDPE tube around the cable. It would be connected to the ROBO® Control Box via insulated wires. The ROBO® Control Box would be placed inside the hollow pylon. As mentioned by the consultant a 5 mm hole would be made available in the cable anchor plate for the wiring to be led out from the sensor to the ROBO® Control box. For visualisation, the below sketch could be used as a reference (not to scale). 2.2.2 Monitored variables of the structural response. Load cell will be provided 2nos in each pylon. From a Pylon, 9nos of Staycable will be fixed at Backspan side and 9nos of Staycable will be fixed at Main span side. Out of 9nos, 1 stay cable will be with load cell arrangement at backspan side and any 1 stay cable will be with load cell arrangement at main span side. Similar arrangement shall be in all 3nos of pylons. So total load cell requirement is (3x2)=6nos for stay cable monitoring purposes and load cell will be fixed during execution of stay cable. Sensor Logo Number of Sensors Number of channels Electromagnetical sensors: Load measurements EM 6 6 Other Equipment Amount Master Station (Central data server) 1 AD converters as required Cables as required System Software 1 Lightning Protection as required User Interface + Web user interface 1+1 Cabinet for processor and server, ventilated 1 Table 1: Proposed amount of sensors and required channels for NEW 4 LANE BRIDGE OVER BWN YARD

- 8. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 8 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India The positioning of all instruments follows the enquiry. OPTIONAL Sensors: Environmental factors (EC): Wind sensor measuring wind speed and wind direction Air humidity Barometric pressure Air Temperature to correlate all structural phenomena with environmental parameters (mageba offers optionally elaborated algorithms to eliminate the environmental effects and detect damage) Structural Temperature in 6 positions ultrasonic wind 3d Vibration and Seismic events (SE): Accelerometers to monitor seismic loads during an earthquake as well as traffic and wind load induced vibrations on the structure (3D or 2D – Seismic Accelerometers). Vibration measurements are taken on both decks but also onto the pylon to observe/compare the accelerations due to service loads and earthquakes on principal structural elements: Accelerometers to monitor cable vibrations and consequently forces o accelerometer, on chosen suspension cables Bridge structural response (BSR): Deformation measurements by displacement sensors at bridge’s deck to monitor accumulated/current deformations on the structure. o High precision measurement of the deck swing on longitudinal direction. o Alarm notification in case of defined threshold overpass. 2.2.3 Frequency of measurements General environmental factors such as wind, air temperature, humidity and luminosity are sampled with a measurement frequency of 1 Hz. For sampling of all other sensors sampling frequency of 1-100 Hz will be provided. This rate allows evaluation of dynamic events. All data will be stored at the master station and is continuously screened. The processed data will be sent to the ROBO®CONTROL Web Interface. The proposed sensors for dynamic measurements can be remotely controlled in order to enable changes of the measurement frequency. Setting of automatic frequency changes upon exceeding of defined threshold values is possible as well. 2.2.4 Sensor durability and protection rating Where possible, the sensors will be installed in hardware cabinets in order to ensure a protection rating of IP65. The cabinets are of high quality stainless steel and robust construction, capable of resisting accidental impact and damage. The cabinets are lockable and capable of resisting attempted theft.

- 9. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 9 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 2.3 Detailed Sensor Description A detailed description of the proposed sensors can be found in APPENDIX A. All parts required for fixation of sensors is included: Metallic sensor housings Metallic straps for fixation Cables Lightning protection Masts (GPS, Wind Sensors, Weather Station) 2.4 Power Supply of Sensors The sensors require an uninterrupted 220V (110V) power supply. The power supply network of the bridge will be used. All on-structure sensors are plugged into cabinet-sockets within the appropriately designed and installed cabinets. The cabinet sockets are fed from a power cable connected to the dedicated power supply. 2.5 Analogue Cabling The sensor will be connected to the local A/D converters by double shielded cables. 2.6 Digital Cabling The local will be connected to the nearest connection panel of the fibre optic network of the bridge. There is an electrical network on the bridge (not part of our offer). Our sensors will always be connected to the nearest panel using analogue cable and local stand- alone A/D converters. Our master station is in the control room and will be connected to internet there. All masts and fixing parts are included in the offer. High quality sensors (accelerometers) are used especially for the deck and seismic vibrations, because the bridge will have very low natural frequencies.

- 10. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 10 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 3. ROBO®CONTROL Data Acquisition and Transfer System The ROBO®CONTROL data acquisition system is divided into a master-station and several substations (local A/D converters). This centralized setup allows a reduction of cabling and increases signal quality because of shorter analogue signal cables. 3.1 Master Station The data acquisition unit is based upon industrial graded cPCI-Systems with high CPUs, running data acquisition and data calculating software. The A/D-conversion is done by multi-channel, 24-bit converter modules. The converters are placed to the sensors as close as possible. The master station is equipped with independent time-sources (GPS) to guarantee the highest possible self-sufficiency in the event of losing connection to the network. In such cases, full capability of preservation of evidence (traffic accidents, earthquakes) is given. The data acquisition unit is protected by an air-conditioned cabin to enhance reliability and durability. All master stations are connected together and can communicate with each other independently. The data is communicated in XML language. The master station is installed near the control room to allow easy access. The master station is protected by an isolated, air-conditioned/heated cabinet against the variable weather conditions on-site (-40°F to 176°F). Figure 1: ROBO®CONTROL Master Station 3.1.1 Uninterruptible Power Supply – UPS The master stations on the bridge can optionally be equipped with a UPS (uninterruptible power supply) in order to guarantee a power supply in the event of power interruption and to protect the equipment against fluctuation and voltage peaks of the public supply grid. The battery capacity will be adapted to the given power requirements in order to guarantee supply for up to 12 hours of interruption. The UPS will be charged from the power supply. Key features Lockable box Air-conditioned Compact design Redundant data storage PC-based system

- 11. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 11 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Figure 2: UPS unit 3.1.2 Software at master station The software in the data-acquisition unit also controls the sensor functions and provides all measurement data with source code (name and position of sensor) and time stamp to allow accurate time synchronization. The raw data taken by all sensors of the monitoring system is stored on-site on 2 independent hard-discs to prevent data loss in case of disc failure. The measured values are organized in separated, compressed files; the administration and organization is done by a database system. The pre-processing of the monitoring data takes place at the master station. System identification algorithms are provided. Duhamel algorithm included. 3.1.3 AD-Converters (stand-alone units) The National Instruments NI 9205 is a C Series analog input module for use with NI CompactDAQ and CompactRIO chassis. It features 32 single-ended or 16 differential analog inputs, 16-bit resolution, and a maximum sampling rate of 250 kS/s. Each channel has programmable input ranges of ±200 mV, ±1 V, ±5 V, and ±10 V. To protect against signal transients, the NI 9205 includes up to 60 V of overvoltage protection between input channels and common (COM). In addition, the NI 9205 includes a channel-to-earth ground double-isolation barrier for safety, noise immunity, and high common-mode voltage range. It is rated for 1,000 Vrms transient overvoltage protection. Key features Power supply during power outage Protection against fluctuation of electric tension and voltage peaks

- 12. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 12 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Figure 3: AD-converter type NI 9205 An example of the distributed architecture of the data acquisition scheme is illustrated below. Figure 4: Data acquisition scheme

- 13. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 13 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 3.2 Data transfer from data acquisition unit to the Web Interface 3.3 Control Room The master station will be connected with the SCADA system. All data can be transferred in this way. The communication between the data acquisition unit and the Web Interface is wireless, using GPRS/UMTS telecommunication network. Figure 5: Data flow for ROBO®CONTROL Monitoring system (Example) In case of GSM/GPRS network failure, the data is stored locally in the ROBO®CONTROL Box and will be sent to the Web Interface after re-commissioning of the network. Data loss can therefore be prevented.

- 14. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 14 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 4. ROBO®CONTROL Data Presentation The Web Interface can be seen as the end node of the monitoring system, providing the interface for the operator and feeding the graphical display with condition and event values and – if necessary – instructions for the bridge personnel (in case of a predefined alarm notification event). 4.1 ROBO®CONTROL Web Interface The operator-chosen information is presented in a user-friendly and simple to understand format. All measured data, together with all data provided from the weather station, is displayed in clear and easy to understand graphics (e.g. mimic panel format). Further, the monitoring system includes an alarm system that actively informs the client if pre-defined threshold values (e.g. max. displacements) are exceeded. The threshold values can be set and modified by the client via the Web Interface. The Web Interface is protected against unauthorized access by a secure login. Data transfer from the bridge to our server is by VPN connection. User-name and password for three different users will be provided. The duration of the access to the Web Interface is depending on the Guaranty chosen. More extended web access can be offered upon request. The Web Interface is accessible via internet web browser (e.g. Internet Explorer or Mozilla Firefox). Figure 6: Login of web interface

- 15. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 15 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Figure 7: Overview of some currently monitored structures Figure 8: Dashboard of web interface

- 16. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 16 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Figure 9: Monitoring results –graphical format 4.2 ROBO®CONTROL Web Interface Data Download The ROBO®CONTROL Web Interface allows the download of the measured data and results for a user- specified time period. Tables and pictures can be downloaded and elaborated into Excel spread sheets. Figure 10: Monitoring results download.

- 17. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 17 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 4.3 Monitoring Cockpit and Live-view The Web Interface also offers a so-called “Monitoring Cockpit” which shows the most current measurement values for each sensor in an easily understood format. Figure 11: Monitoring cockpit with current monitoring values for each sensor (sample taken from an actual current mageba monitoring system)" The “Live-View” function allows real time access to the high frequency measurements. Figure 12: Live-View (real-time)

- 18. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 18 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 4.4 iPad for Mobile Data Analysis For the client’s convenience and flexibility, mageba also developed an application that allows accessing the Web Interface by iPad or tablet computer, offering maximum mobility. All data can be viewed in real time on a tablet (not included). Figure 13: Access to web interface using an iPad / tablet 4.5 Demonstration Login for Web Interface The client is given the possibility to temporarily access the Web Interface of an operating bridge structural health monitoring system. The following login and password provides viewer access the dashboard for the systems of the River Suir Bridge, Ireland, during a term of 90 days from the date of tender submittal. Please note that data download is not possible with this demonstration version. Internet: ChambelKota Chambel2Kota3 http://www.mageba.ch/htm/870/de_CH-1996/ROBO-CONTROL.htm

- 19. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 19 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 5. Service Proposal mageba’s service proposal covers the following areas: (1) Detailed SHMS design: Detailed system specifications, sensor specification and system design drawings will be prepared and submitted based on the client’s specifications. The design of sensor housings will be done in accordance with the client’s needs and under consideration of the environmental and visual aspects. (2) Site visit for coordination prior to installation: A site visit of a monitoring engineer is foreseen to coordinate technical and organizational details with a representative of the client and the executing contractor. A plan for the required support activities (i.e. power supply and communication, etc.) will be made and interfaces between the contractors and employer will be clearly agreed and documented. Any deviation from the design due to different site conditions will be sorted out and agreed. It shall be made sure that there are no gaps in the process. Details such as cabling management, power availability, fixing positions for antennas, poles, cameras, etc. will be discussed at this visit. Also questions concerning equipment storing whilst installation and safety themes will be clarified. (3) Configuration of the permanent system: The system will be assembled in the factory. A test of each single component and the whole system is included. This task also includes the correct calibration of the sensors, the set-up of the documentation for quality control as well as the last updates of pre-installed PC -and server-operating systems. All components will be shipped to the bridge site after proper packing. The INCOTERMS in their current version apply. The shipment will be received by the local contractor responsible for the construction of the bridge and required import activities and duties will be obeyed. The transport insurance covers transport only. (4) Installation of the SHMS: mageba estimates that the installation will require about 2 weeks, distributed in 6 visits. The installation team consists of mageba specialists as well as local support staff (e.g. technicians, electricians, drivers, etc.). The installation progress will be documented. In this way, possible delays will be identified and adequate measures defined. (5) Calibration and testing of the SHMS: Calibration of all sensors and a function test of the complete installed system are included. A bridge’s owner representative is invited to join the testing procedure. In this context, calibration means the checking of the horizontal fixation of tilt-sensors, subtraction of static offset-values of accelerometers and the like. (6) On-site maintenance training: Operation training included directly after installation. The training consist of operation training for the monitoring system, operation training for the user interface in the monitoring office and operation training for the web interface. As the system and the interfaces are mainly self-sufficient the training can be limited to half a day. Additional information and a helpline are offered permanently. (7) Operation and maintenance manual: All drawings and manuals for the monitoring system will be delivered according to the technical specifications. The package includes hardcopies and digital versions (e.g. PDF) in English. (8) Remote support: A support hotline via telephone and e-mail is also part of the included services. Support is provided by mageba’s service hotline. For the contact details refer to the login page of the web interface. A

- 20. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 20 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India routine check will be performed whenever the system indicates a malfunction or any of the thresholds is exceeded. (9) Additional maintenance and training visits: After 12 months of installation of the BSHMS one site visit (including travel) of a monitoring specialist is recommended. The purpose of the visit is to answer questions of the operators and to provide additional training. The system will be adjusted considering the experience made during the monitoring period. Eventual items of interest will be discussed with the operator and implemented in case it comes without additional costs and is covered by the contract.

- 21. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 21 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 6. Installation The installation of the system will be done by mageba. We would need to be informed of the cable erection sequence at least three month in advance to allow us to make system ready for implementation. 6.1 General Sketch regarding installation and positioning 6.2 Installation support requirement The following items are to be provided by the Employer (See Appendix C). They have to be made available to the installation crew free of charge and ready for use at arrival: Permanent electrical power supply for the permanent system Cable trays from the sensors to the master station. Ladders and crane, man lift or similar to reach all the installation points (especially at the cables and at the pylons). Local support for customs formalities. Local storage for equipment. Connection of control room to internet (also by SIM card).

- 22. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 22 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 6.3 Installation Methodology Monostrand diameter = 15.7mm Outer diameter of the coated strand = 19.5 mm The sensors have to be installed over the HDPE envelope. Cable vise sensor distribution 7001 – 1 Sensor 7002 – 1 Sensor 7003 – 1 Sensor 7016 – 1 Sensor 7017 – 1 Sensor 7018 – 1 Sensor

- 23. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 23 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India

- 24. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 24 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India 7. Financial Offer and Conditions 7.1 Financial Offer for Permanent Monitoring System Price per Position INR Detailed Design of Monitoring System including master station, substations, sensors and cables. One site visit for optimal design prior to design. As-built drawings and report. Management and coordination for Load tests, measurements and Permanent monitoring. User and maintenance Manuals. Monitoring Master Station (ROBO®CONTROL Box ), substations Hardware and Sensors, Cables, converters, consoles and other equipment. System preparation prior to on-site visit (Programming, configuration and operation). Testing and calibration in home office. 4 System Software. Data recording and Analysis software for monitoring, User web Interface. 1 LS 5 Transport, insurance and packing ofall equipment. 1 LS 6 Installation on-site. 6 site visits for the installation ofthe complete system (minimum 1 Specialized Engineers per visit); Finalization ofinstallation, Operation trainig 6 visits 7 Installation expenses: installation equipment, local support, travel and accommodation are included. Training in site. Testing ofsystem. Software and hardware test ofeach individual component and the whole system is included. All other expenses are excluded.* 1 LS 8 On-site repair and replacement of sensors guarantee year. Guarantee and maintenance for 1st year of operation. Includes travel costs, transport costs, travel time, working time. 1 LS Analysis of measurement data, not included Report on measurment data, visible online. INCLUDED Total INR 45,00,000.00 Hardwareand Software Preparation works 45,00,000.00 LS 9 1 n.a. Barddhaman ROB Installation and direct travel costs 3 1 LS Position Description ofthe Monitoring Offer for Barddhaman ROB Quantity Unit 1 1 LS 2 1 *Daily travel from accommodation to site has to be provided by client. Cable trays and installation of cable trays is not included. Installation of electromagnetical sensors only possible if cables have not been installed and doable during installation of stay cables. 7.2 Additional Site Visits The above prices include the specified site visits for the installation of the complete system. The site visit for the removal of the complete system can be offered as an option. Any interruption of installation process (traffic on or below the bridge, construction works, missing of permanent electric power supply, missing cable trays, missing man lift, missing SIM cards etc.) will be charged separately. In case additional site visits are required, the following prices apply: o Visit from mageba India for coordination meetings and / or technical support (1st level):

- 25. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 25 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India Cost for 1 visit (Kolkata, 1 full man day of work): INR 10,000; every additional day is charged at INR 8,000 o Visit from mageba Switzerland for technical support (2nd level): Cost for 1 visit (incl. travel time from Switzerland, flight cost, and 1 full man day of work): 2,500 EUR; every additional day is charged at 900 EUR; waiting day 600 Eur. o Above prices do not include costs for local transport, accommodation, or meals. 7.3 Conditions Please find attached mageba’s Terms & Conditions in APPENDIX C. In addition to these conditions, the following apply: Delivery of the system can be expected about 12-15 weeks after receipt of a written order, depending on the availability and delivery of the devices by the manufacturers Installation of system is included (with local support staff provided by the owner of the bridge) All prices exclude customs, taxes, import fees, local insurance, etc. The price calculation is based on conditions as of November, 2014. This offer is valid for two months. If this proposal meets your requirements, we are open for any further discussion on this proposal, especially on the sensor layout and on technical details. After this next step, we would be pleased to work out a revised version. Yours sincerely Kleidi Islami Manager SHM mageba Switzerland Chinmoy Ghosh Chief Operating Officer mageba India

- 26. ROBO®CONTROL Monitoring System Service provided: Monitoring Offer no – Q703892 5/30/2015 Page 26 of 37 Proposal for the Stay Cable force Monitoring of the Cable Stayed ROB at Barddhaman, India APPENDIX A: Proposed Sensors

- 27. ROBO®CONTROL Monitoring System Service provided: Safety Monitoring Offer nr. VOA000200 5/30/2015 Page 27 of 37 Proposal for the Permanent Monitoring of the 1. Stay cable forces (installable only if cables are not erected) Type of sensor: DynaMag Total Number: 12 Figure 14: Electromagnetic Sensor for Cable Forces Magneto elastic dynamometer DynaMag is intended for non-contact mechanical tension measurement in pre-stressed steel parts of suspended bridges and ground anchors. Pre-stressed steel parts are used as a sensor component of DynaMag system. Dynamometer DynaMag is designed for monitoring of supporting members in structures during their construction as well as for long-term monitoring during their entire lifetime. This sensor has to be installed during stay cable installation because the strand has to be pushed through the sensor. The position of the sensor is close to the upper stay cable anchor. Dynamag main features are as follows: simple and clear principle It is a direct measuring method utilizing the changes of physical properties of ferromagnetic materials after their mechanic load. Pre-stressed parts of constructions are a component of magnetoelastic circuit of the sensor. non-contact and non-destructive method Direct physical contact between the sensor and the measured element is not required. Allows measurement of mechanical stress through anti-corrosive protection of prestressed elements without damaging them. The link between the measured element and the sensor is provided purely by means of magnetic field. high accuracy and long term reliability Sensors include neither moving parts nor parts that are liable to material ageing and performance reduction Key features: Non-destructive method High accuracy and long-term reliability. Direct measuring method, pre-stressed parts of construction are direct component of the sensor High resistance to dust, shocks, vibrations, water, salt water, chemicals Simple installation

- 28. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 28 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India high durability of sensors Sensors are resistant to dust, shocks, vibrations, water, salt water, water under pressure, chemicals and radioactive radiance. unlimited lifetime of sensors The life span of sensors exceeds the life span of standard constructions. simple installation The dynamometer DynaMag is designed for monitoring of supporting members in structures during their construction as well as for long-term monitoring during their entire lifetime. The sensor will be attached to one single strand whilst its installation. It is connected via e special readout unit with the monitoring system. For clear identification of sensors, all DynaMag sensors are equipped with electronic identifier and accurate thermometer, which measures the temperature of a construction in the sensor’s area. mageba assume that the installation works for these sensors will take place in close coordination and cooperation with the stay cable supplier. 2. Signal cables (for analogue signals) Figure 15: Double shielded signal cables The signal cables connect all sensors with the digital conversion unit. To guarantee best signal quality the signal cables are double-shielded, have a cable attenuation of 9 dB/km@100 kHz and are therefore the best choice for completing an ambient vibration-based monitoring system. As the A/D- conversion takes place as close as possible to each sensor, the potential of interference is eliminated. In this way effective real-time data acquisition is possible. Key features: Cable attenuation 9 dB/km@100kHz Double-shielded cables

- 29. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 29 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India APPENDIX B: References

- 30. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 30 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India mageba with HQ in Switzerland, and companies in Germany, Austria, Turkey, USA, India, China and Korea… 9 companies 47 agencies 8 licensees Markets supplied with mageba products … with a worldwide network of 47 exclusive distributors mageba (Shanghai) Bridge Products Co., Ltd. HQ: mageba sa Switzerland mageba (India) Bridge Products Co., Ltd. mageba Ges.m.b.H. Austria mageba GmbH Germany MagebaYapı Turkey mageba (Korea) Co. Ltd.mageba LLC - Division West mageba LLC - Division East mageba Russia Reference projects

- 31. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 31 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India

- 32. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 32 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India

- 33. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 33 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India Details of BSHMS works in cable stayed bridges/suspension bridges/box girder bridges commenced since 2005 No Name of project Date of commencement as per contract Stipulated date of completion Name & address / telephone number of officer to whom reference may be made Remarks 1 Sko Energo Czech Republic 01st May 2007 30th November 2008 Miroslav Hubka, Peluskova 1407 19800 Praha 9-Kyla +420 7773 47 500 Installation of Permanent Monitoring System, Data Analysis and Interpretation 2 ABA Rinterzelt Vienna, Austria 03rd December 2009 31st January 2010 Karl Schwaiger Stadlauerstraße 41a 1220 Vienna +4312836220111 Operation Period ongoing until December 2025 3 Weyermanns-haus Viaduct Switzerland 01st August 2009 31st December 2012 Andri Sinzig Uttigenstrasse 54 CH-3600 Thun +41332282459 Monitoring System installed, Service Contract ongoing 4 River Suir Bridge Waterford, Ireland 17th July 2009 17th November 2009 Andrew Ladysz Mekano4 Ctra. Rubi 72-74 Edificio Horizon 08173 Sant Cugat del Valles, Barcelona +34686599282 Installation of Permanent Monitoring System, Data Analysis and Interpretation, Web Interface 5 Europa Bridge Tirol, Austria 01st August 2004 ongoing Josef Fink Innpark Center, Dr.-Franz- Werner-Straße 30, 6020 Innsbruck +436643302395 Installation of Permanent BSHMS with ongoing service contract 6 Beska Danube Brige Serbia 01st January 2009 30th September 2011 Taimur Tadros Oberlaaer Straße 276 1239 Vienna + 436648147659 Installation of Permanent BSHMS with ongoing service contract 7 Schaffhausen Switzerland 01st February 2010 31. December 2013 Erwin Ronner Hochbauamt Stampfenbachstr. 110 CH-8090 Zürich +41432592864 Installation of Permanent BSHMS with ongoing service contract 8 Ponte Nanin Mesocco Switzerland 01st December 2005 31st December 2014 Cedric Pagani Via c. Pellandini 2 CH-6500 Bellinzona +41918206833 Installation of Permanent BSHMS with ongoing service contract 9 Obermattbrück Switzerland 01st January 2011 01st January 2014 Andrea Müller Berner Fachhochschule Solothurnstrasse 102 CH-2504 Biel +41323440319 Installation of Permanent BSHMS with ongoing service contract 10 Incheon Grand Bridge Seoul Korea 01st June 2009 01st June 2019 (on going) Mageba SA Solistrasse 68 CH-8160 Bülach +41448724050 Installation of Permanent BSHMS with ongoing service contract 11 Europa Bridge Zürich Switzerland 01st August 2009 31st July 2010 Manuel Schmid Ewp AG Effretikon Rikonerstr. 4. CH-8307 Effretikon +41523542215 Installation of Permanent Monitoring System, Data Analysis and Interpretation, Web Interface 12 Gleisbogenbrücke Zürich Switzerland 01st July 2010 30th September 2010 Markus Aerni Rotbuchstrasse 32 CH-8037 Zürich +41443652865 SHMS and mobile measurements activities 13 Taichung Taiwan 01st September 2008 30th April 2009 Boris Wiessler 6 Floor, No. 7 Tun-Hwa South Road Section 1, Taipei, 105, Taiwan, R.O.C. +886 2 2570 8338 Installation of Permanent Monitoring System, Data Analysis and Interpretation

- 34. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 34 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India Please refer to the separate document provided: reference datasheets of Monitoring Projects 14 YH-1 Austria 24th July 2008 24th July 2010 Norbert Friedl Vivenotgasse 10 1120 Vienna +4319300045920 Installation of Permanent Monitoring System, Data Analysis and Interpretation 15 L110 Austria 28th September 2010 31st December 2012 Hannes Kari Vivenotgasse 10 1120 Vienna +43 1 93000 45914 Installation of Permanent BSHMS with ongoing service contract 16 Älvsborgbron Gothenburg Sweden 17th May 2011 16th May 2012 COWI Matthew L. Bloomstine Parallelvej 2 DK – 2800 Lyngby +45 45 97 22 11 Installation of Permanent BSHMS with ongoing service contract 17 Dintelhaven bridge Rotterdam The Netherlands 29th November 2011 31th December 2012 Rjikwaterstaat Mr. Cor Kuilboeur Afdeling civiele techniek Postbus 20.000 3502 LA Utrecht Installation of Permanent BSHMS with ongoing service contract 18 High speed rail Taichoeng Taiwan 20th July 2012 30th September 2013 Pan Asia Coorperation 7F, No. 219, Sec. 4 Chung- Hsiao E. RD Taipei Crack, vibrational and environmental Monitoring 19 Angus L. Macdonald bridge A. Murray MacKay bridge Halifax, NS Canada 31th March 2012 31th August 2013 Buckland&Taylor Mr. Daniel Grant 101-788 Harbourside Drive, North Vancourver, BC Permanent Monitoring of Deck movement and rotation at 4 towers of the bridge 20 TaiZhou Bridge China 15th August 2012 Ongoing mageba bridge products Mr. Pascal Savioz No. 388,Bei Huan Road Wu Qiao District, Fengxian Shanghai 201402 Permanent Monitoring of Expansion Joint behaviour 21 Viaduc Sernigerbaach Luxembourg 15th September 2012 Ongoing Ministere du Development Mr. Jean-Claude Heyard 43, bvd Gd Charlotte B.P. 880 Permanent Monitoring of Deck movement and rotation 22 Hunter Expressway Queensland Australia 1st July 2013 31st July 2014 Thiess PTY Ltd. Level 5, 179 Grey Street 4101 Queensland South Bank, Australia Permanent settlement monitoring and EJ monitoring of 4 highway bridges 23 Wazirabad Signature Bridge New Delhi, India 1st May 2014 May 2019 Delhi Tourism & Transportation Development Corporation, Outer Ring Road New Delhi 54, India Monitoring of 575m long deck and 150m high pylon, with more then 120 sensors. 24 Kawarau Bridge, New Zealand 1 August 2014 30 August 2016 Fulgan Hogan Limited, 113 Dunstan Road, Alexandra, New Zealand Permanent monitoring of displacement and pressure at the 8 dampers installed by mageba 25 Stavros Niarchos Cultural Center, Athens, Greece 1 January 2015 31 December 2020 JV Impregilo – Terna SPA, 85 Mesogeion Ave. Athens Greece Monitoring of liftable roof of the 500 Mil€ project. 240 sensors, online control.

- 35. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 35 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India APPENDIX C: Terms&Conditions Particular Terms & Conditions for mageba SHMS Projects DISCLAIMER: Structural Health and Safety Monitoring Systems (SHSMS) are tools to support the client and parties related to the client in the understanding of the behaviour of a structure. However, SHSMS shall never replace human intelligence and the related critical interpretation and visual and physical verification of facts. As for any system, SHSMS are not 100% fault-fee. mageba cannot be held liable for the content measured and displayed by the SHSMS system as well as the interpretation of such content by the client and parties related to the client and the material, financial or legal consequences arising from such interpretation. Furthermore, mageba cannot be held liable for any

- 36. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 36 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India material, financial or legal consequences arising from failed data acquisition and/or faulty content due to but not limited to system malfunction, undetected equipment defects, detected but not rectified equipment defects or improper operation of the SHSMS by the client and parties related to the client. The General Terms & Conditions (T&C) of mageba SA apply. The valid version of the T&C is accessible through the website www.mageba.ch. The following terms apply in addition to the above mentioned T&C and where applicable overrule these: §1 Price and Offer Validity: Price basis is CIF, including packaging and without deductions or discounts. All additional costs such as local taxes, duties, fees and custom and agent charges are to be bore by the client. §2 Terms of Payment (changeable): 50% of contract value after issuing of purchase order, 10 days net 30% of contract value after confirmation of detailed design, 10 days net 20% of contract value after installation of complete system (if installation is split into stages, on a pro-rata value basis), 10 days net. The issuing of a bank guaranty is necessary. §3 Guarantee: The warranty period for permanent systems for the proposed system shall be 24 months from the date of handover of the operating system to the client. mageba undertakes to either repair or replace at its own choice, as soon as possible, at the customer’s written request, all equipment and software contained in the scope of delivery which, during the warranty period, prove to be defective or unfit for use on account of faulty materials or incorrect workmanship at installation. The warranty does not include losses caused by the following reasons: Manipulations of the system performed by the client or a 3rd party without mageba’s written consent Improper power supply and setup of the site supply grid (e.g. electrical surge, missing electrical grounding) Indirect damage (e.g. damage by falling bridge parts and other foreign objects) Damage trough falling or agglomerating snow, ice and water due to insufficient protection of the sensors other than the protection specified in the scope of delivery Vandalism and theft Other hazards (fire, explosion, earthquake, hurricane, tornado, direct and indirect effects of lightning strike, animal attack, etc.) §4 Data Generation: Monitoring data is made available to the client trough the specified interface (“Web Interface”)

- 37. ROBO®CONTROL Monitoring System Service provided: Global Monitoring Offer nr. VO138293 5/30/2015 Page 37 of 37 Proposal for the Permanent Monitoring of the Kota Bypass Cable stayed bridge, India Data provision in alternative format and trough alternative channels (i.e. untreated “raw” data or the like) is not part of the project scope and will be charged separately under a separate agreement §5 Items to be Provided by the Client: System design & preparation: Upon signing of contract, provision of relevant drawings specified and required by mageba for the system detail design. Provision of detailed delivery instructions (i.e. physical address, contact person, etc.) 15 working days prior to the first material shipment. System installation: Lockable and water protected storage for the materials and tools before and during installation. Free of charge and safe access to all installation points through appropriate means such as ladders, scaffolding, cherry picker, crane, car lift etc. Cable trays and other fixings to all sensor positions installed prior to the sensor installation. Installation of mechanical equipment (e.g. masts for GPS and Wind sensors). Drilling, welding, corrosion protection wherever required for and after installation. Where applicable, free of charge site safety training and gear. In the event that such training requires more than ½ working day per person, the additional time required for such training is separately charged by mageba to the client at a rate of EUR 350 per half day and person. If such training is to take place before the installation the travel cost is to be bore by the client. Uninterrupted electric power supply during installation works with sufficient power to operate electrical tools. Local transports of mageba’s installation staff between site and accommodation (minibus + driver permanently during installation). System operation: Identification and communication to mageba of person-in-charge for on-site system operation and maintenance acting and as a counterpart to mageba. Permanent 240 V (110 V) electrical power supply for operation of system. The power supply has to be tested by the client prior to connection to the system and must be grounded. SIM card and subscription for uninterrupted data transmission [Transmission rate: 2.5 GB/month] at the beginning of the installation works. Cost for electrical supply Cost for data transmission System maintenance/updates/rectification: Designation and delegation of an electrical engineer being present during the installation for on- the-job instruction by mageba installation staff and system familiarisation Designation and delegation of an electrical engineer acting as a counterpart to mageba during the operation of the system for possible system maintenance, update and/or rectification works.