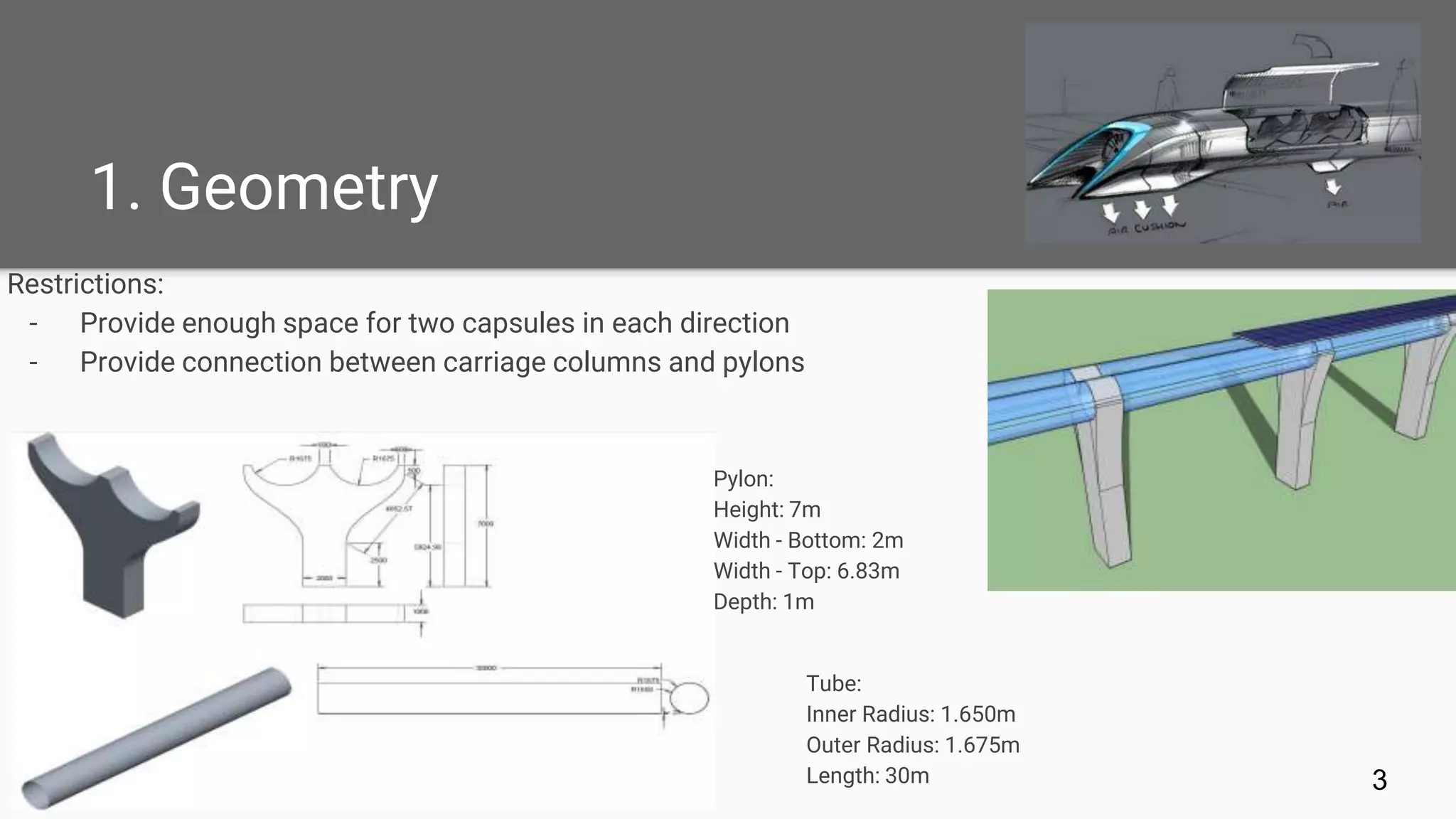

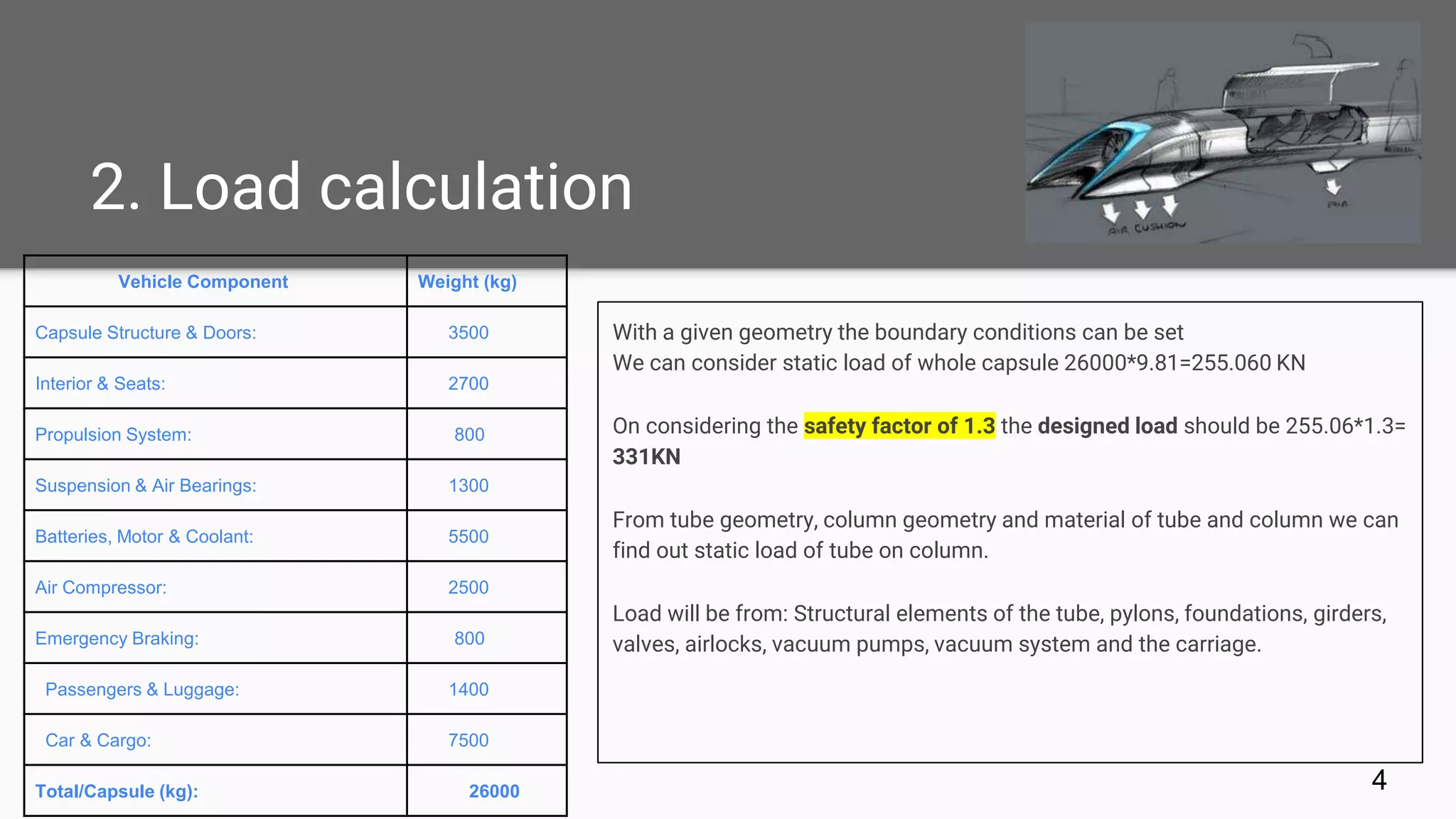

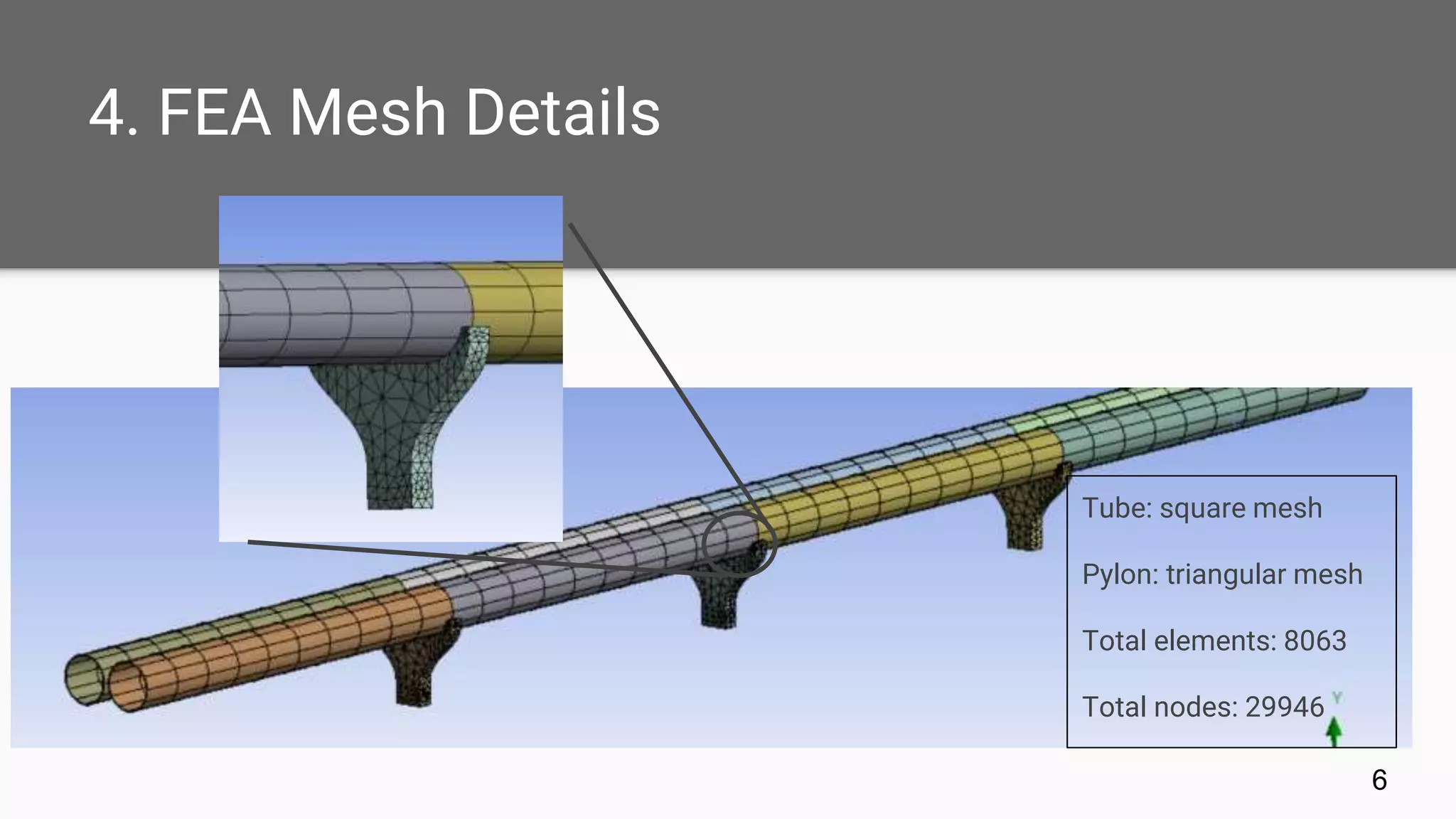

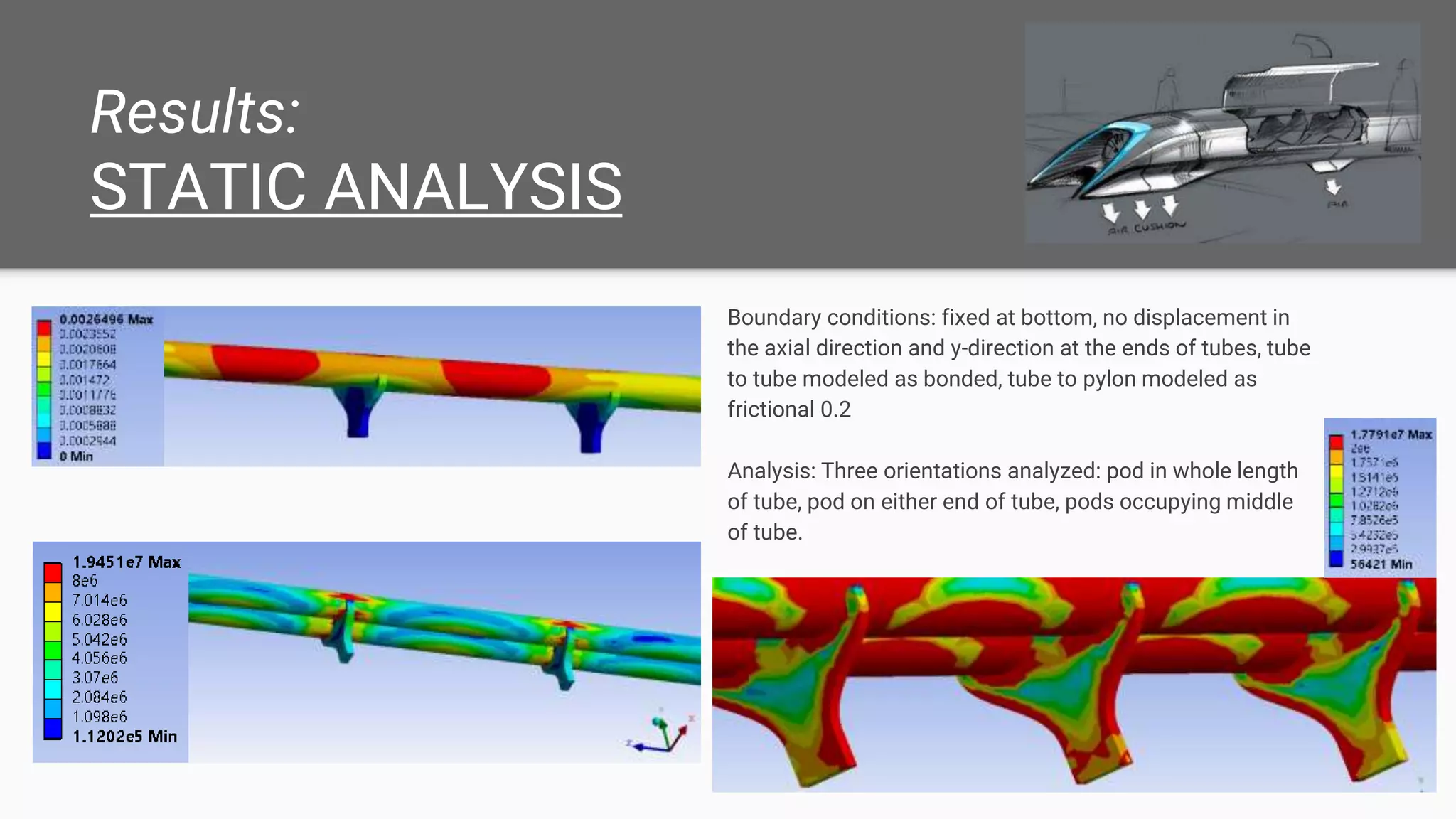

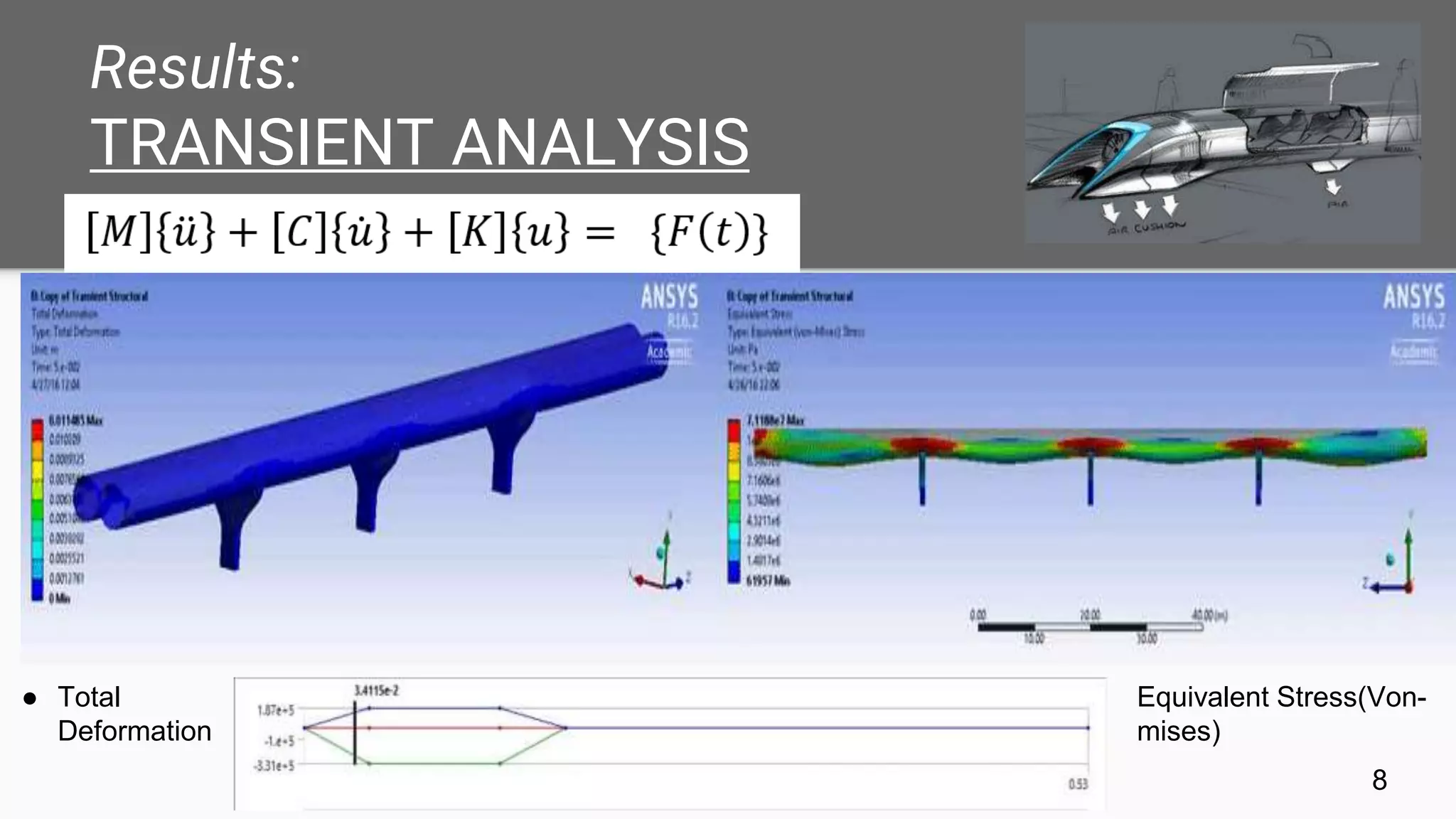

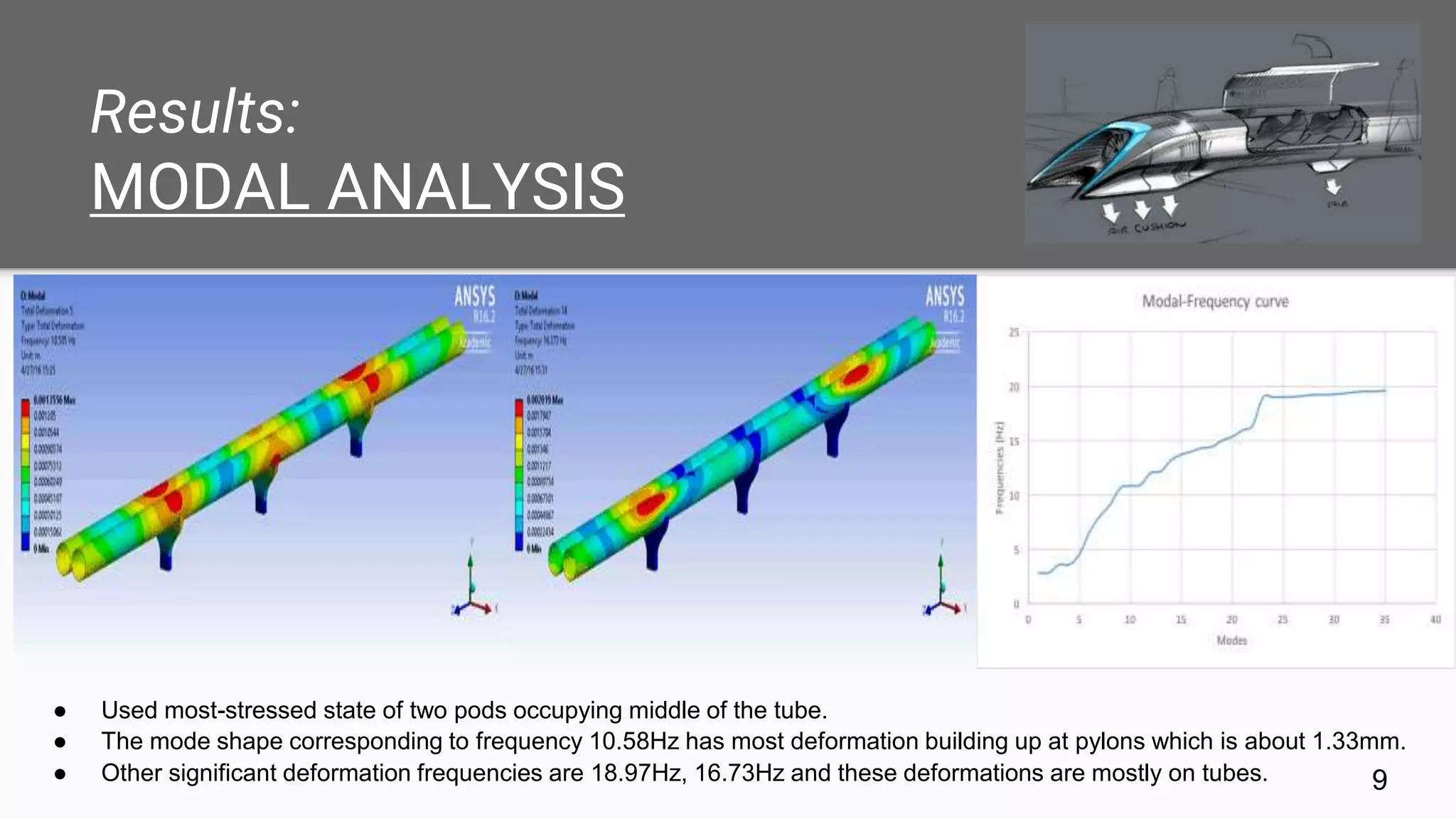

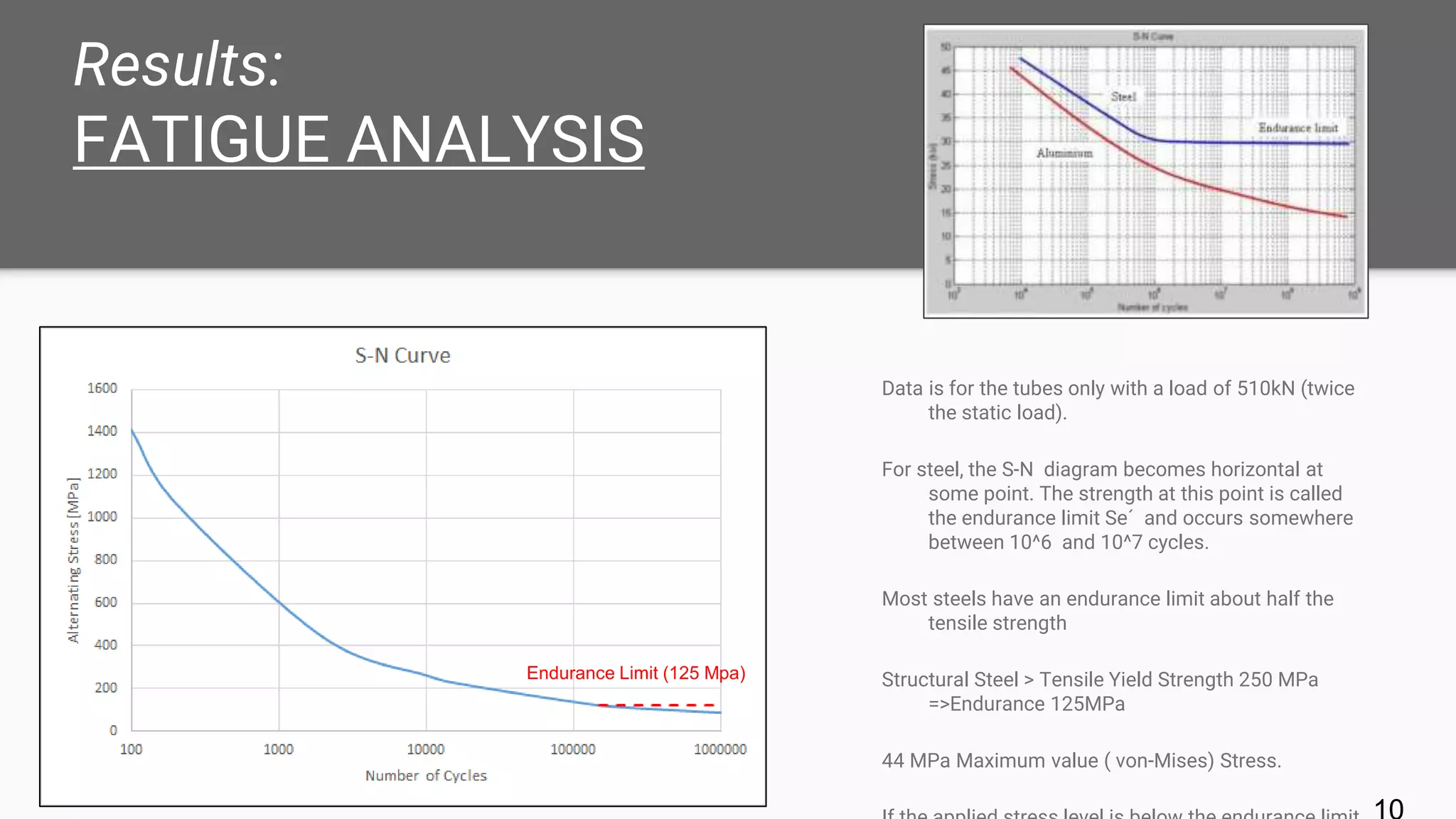

The structural analysis of pylons, columns, and carriages for a Hyperloop system was conducted using finite element analysis. The geometry of the tube and track was determined, including pylon dimensions of 7m height, 2m bottom width, 6.83m top width, and 1m depth. Loads from the 26,000kg capsule were calculated, and material properties of concrete for pylons and steel for the tube were defined. A finite element mesh with 8063 elements was generated. Static, transient, modal, and fatigue analyses showed peak stresses below yield strengths and minimal deformations, indicating the design would withstand expected loads without failure.