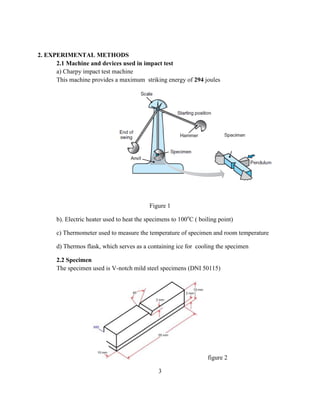

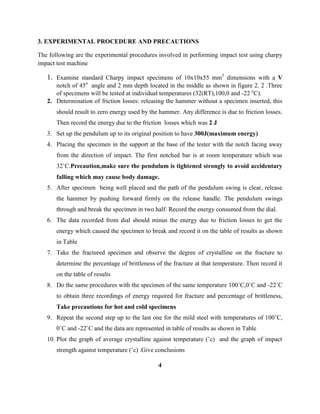

This technical report details an impact test conducted on three types of steel (hot, cold, and steel alloy) using the Charpy method at various temperatures to analyze ductility and brittleness transitions. The experiment determined a ductile-to-brittle transition temperature of around -18°C, with additional insights into the relationship between temperature and material toughness. Despite some experimental errors impacting the results, it was concluded that lower temperatures increase brittleness in mild steel, while higher temperatures enhance ductility.