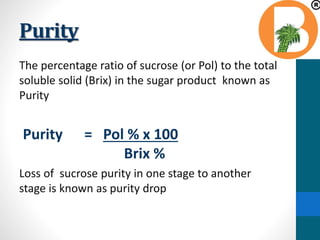

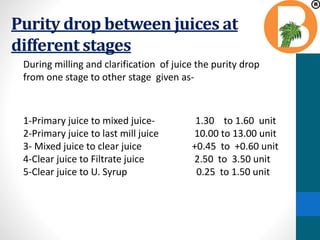

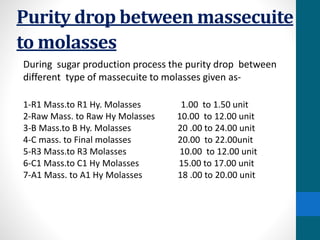

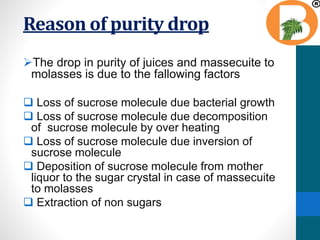

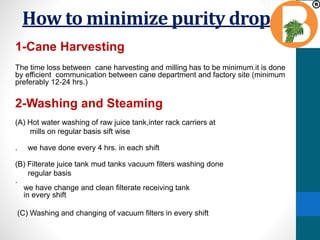

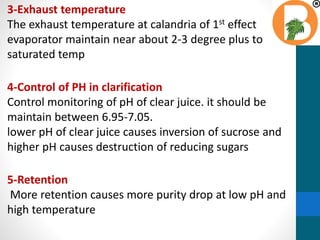

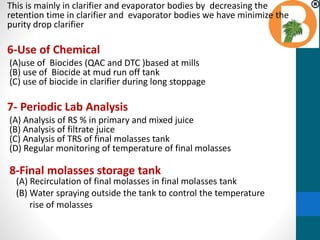

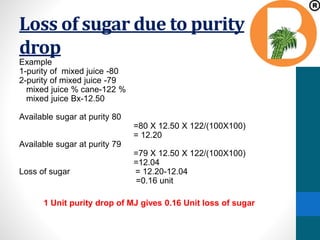

The document discusses purity drop that occurs at various stages of sugar production such as during cane harvesting, milling, clarification, evaporation, and crystallization. It provides typical ranges of purity drop between different process stages. For example, purity may drop 1.3-1.6 units from primary juice to mixed juice, and 10-13 units from primary juice to last mill juice. Factors that influence purity drop include bacterial growth, sucrose inversion, and non-sugar extraction. The document also discusses ways to minimize purity drop such as proper sanitation, pH control, and minimizing retention times.