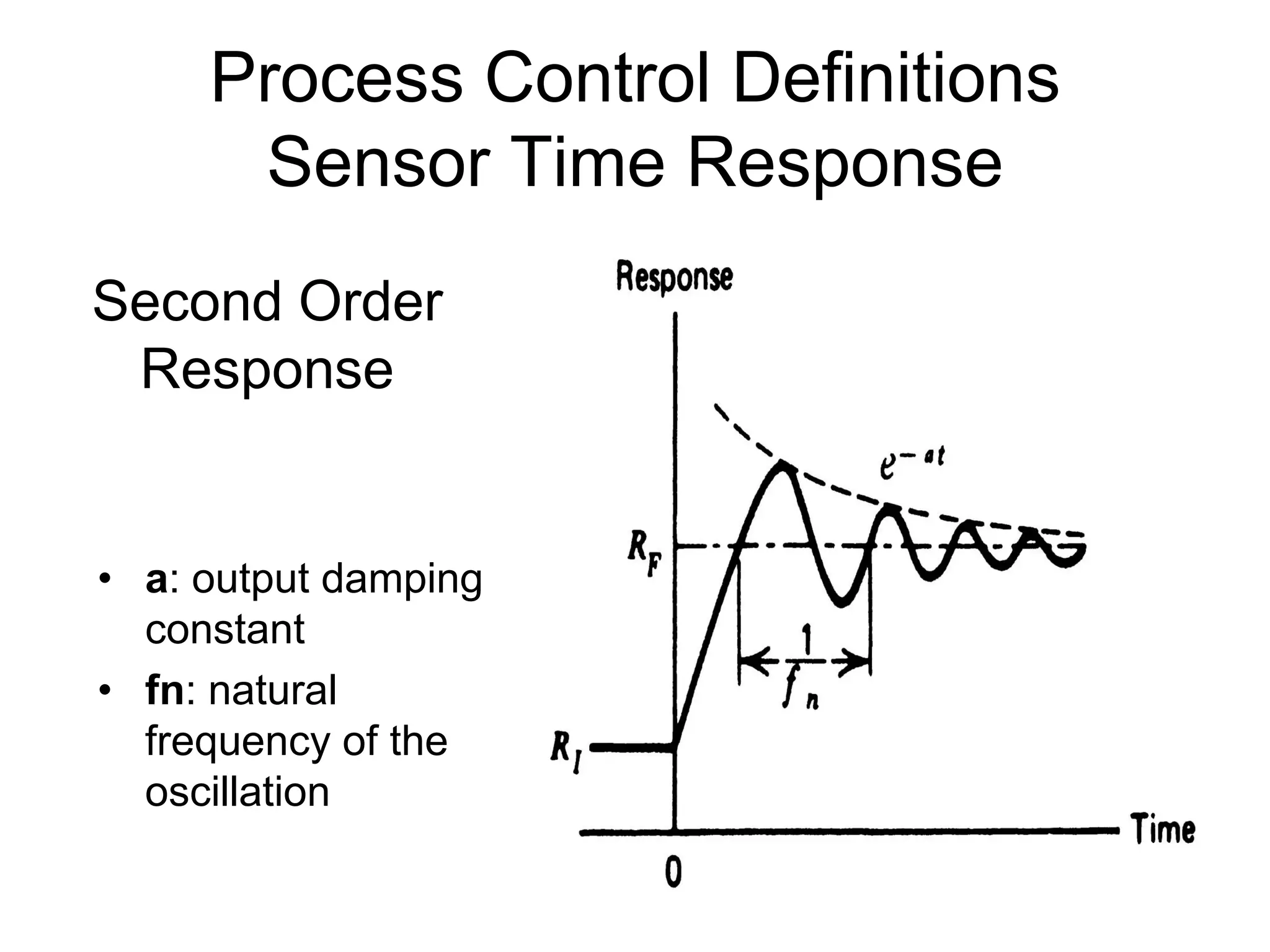

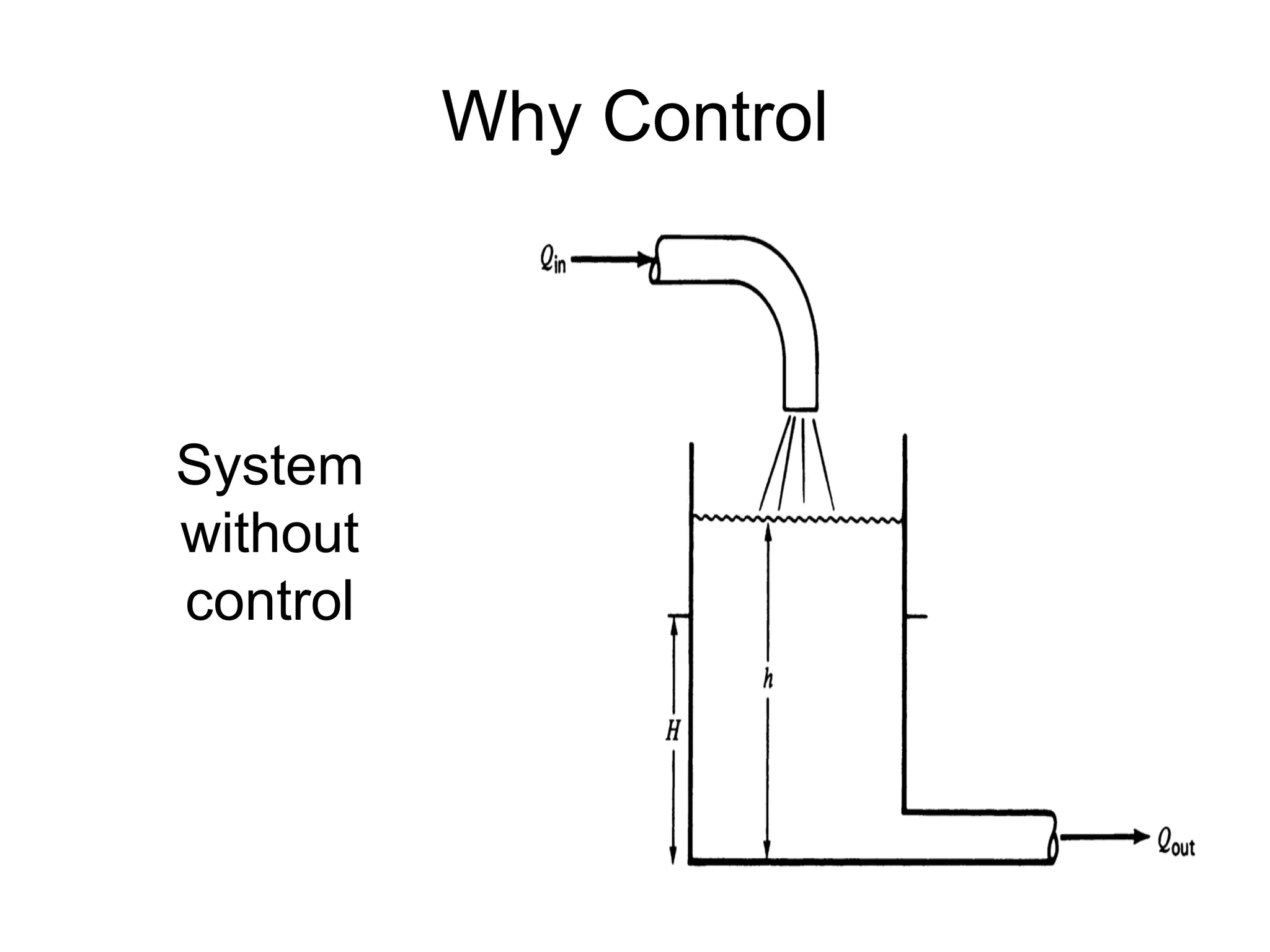

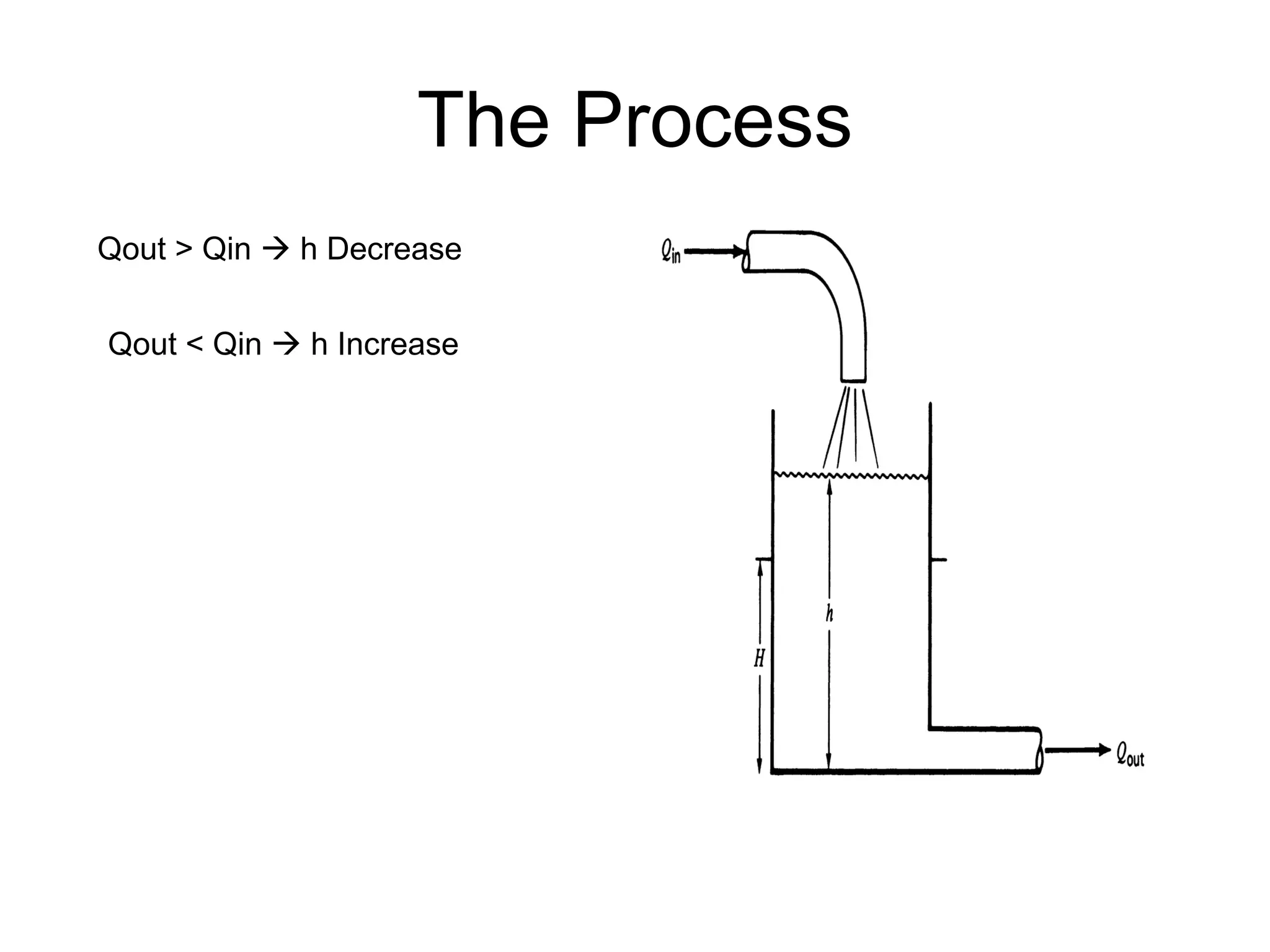

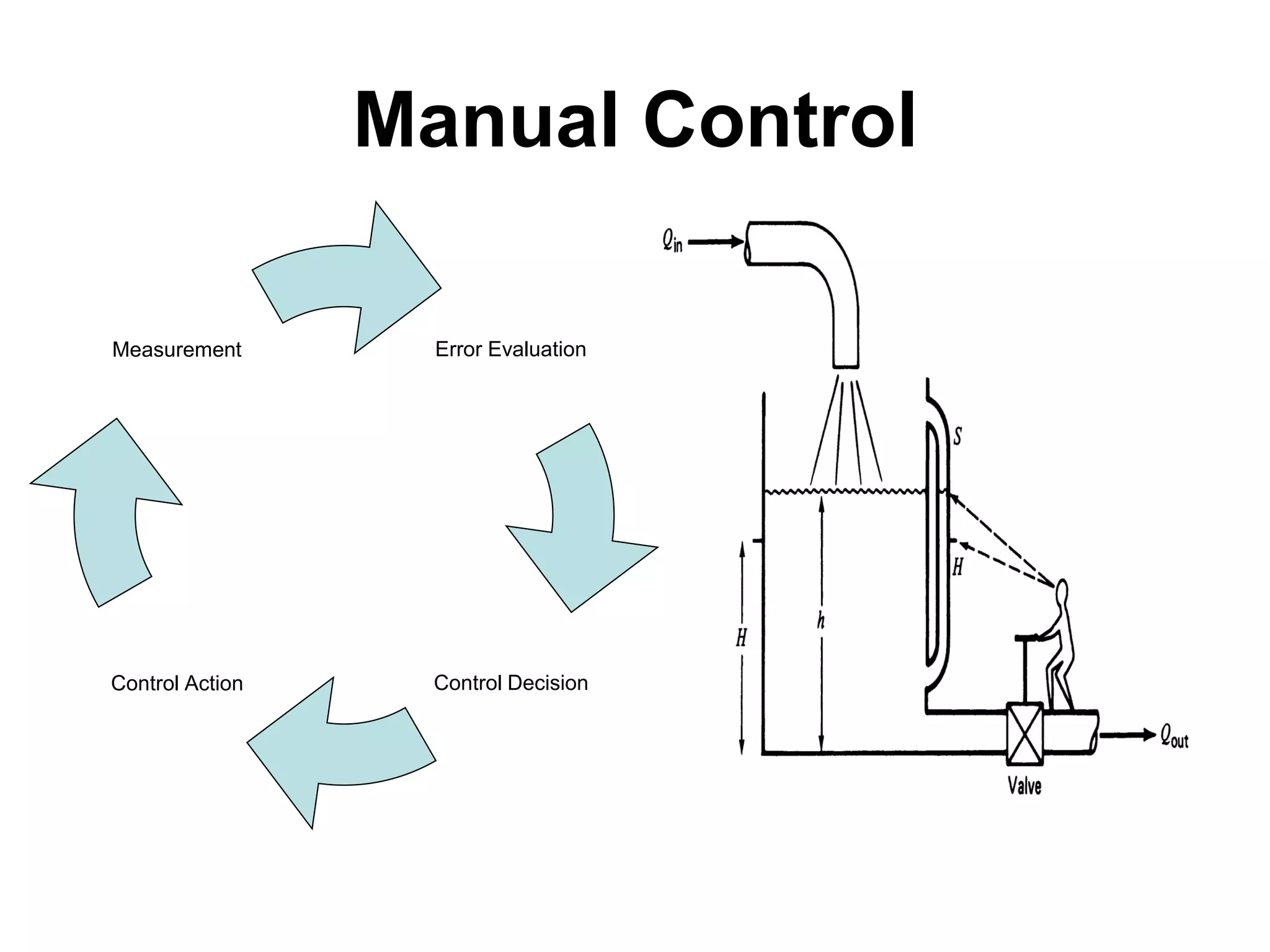

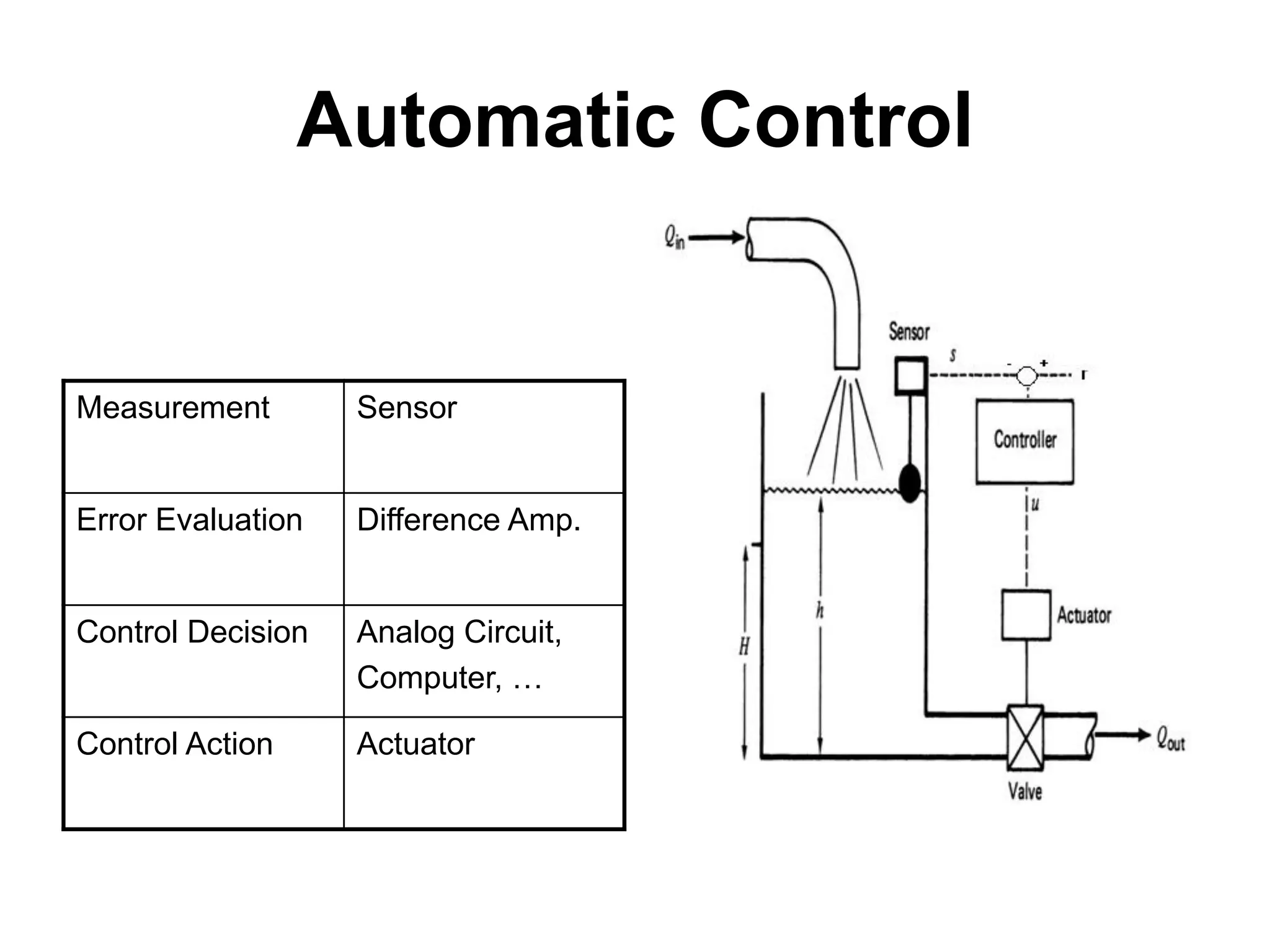

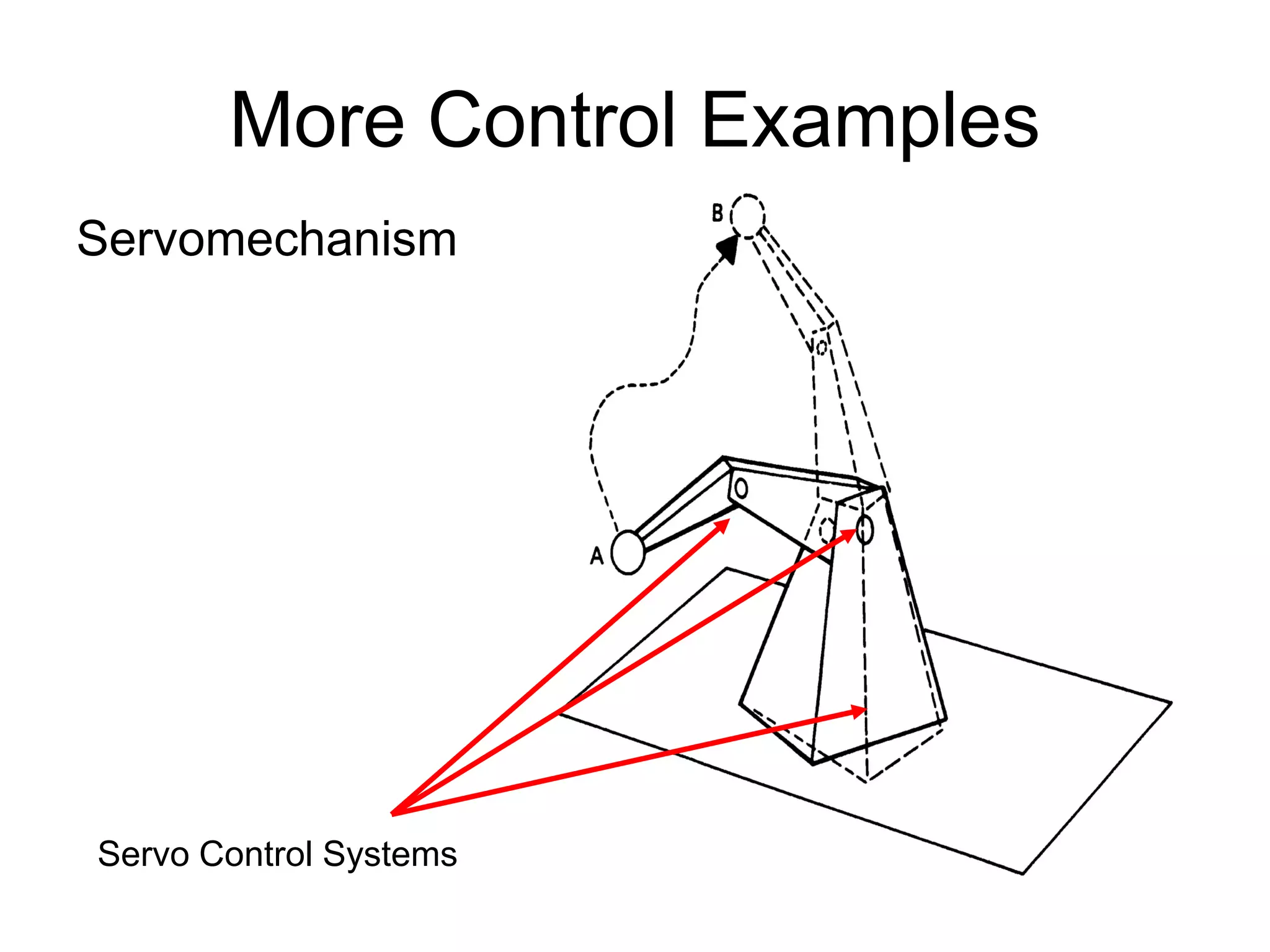

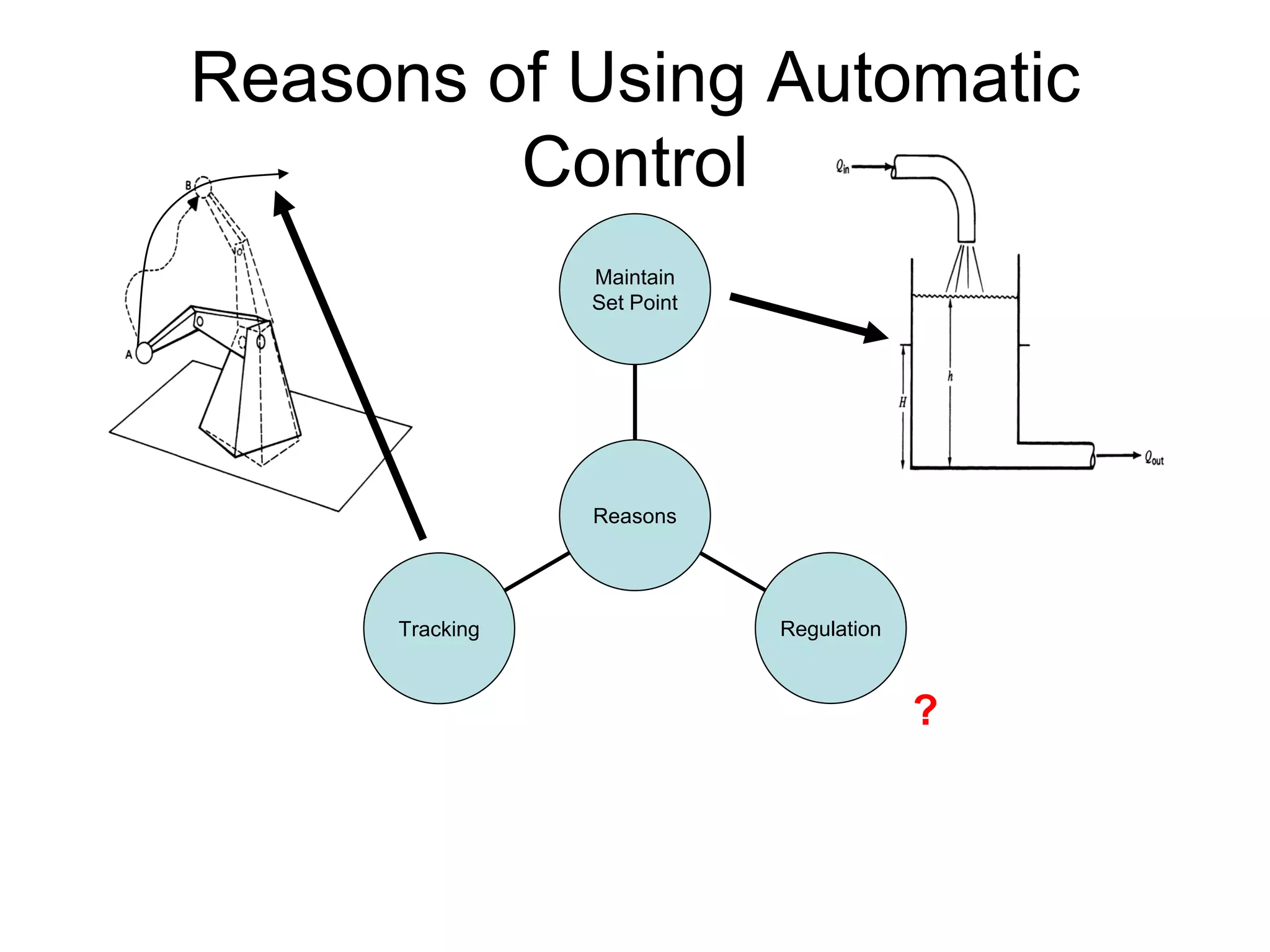

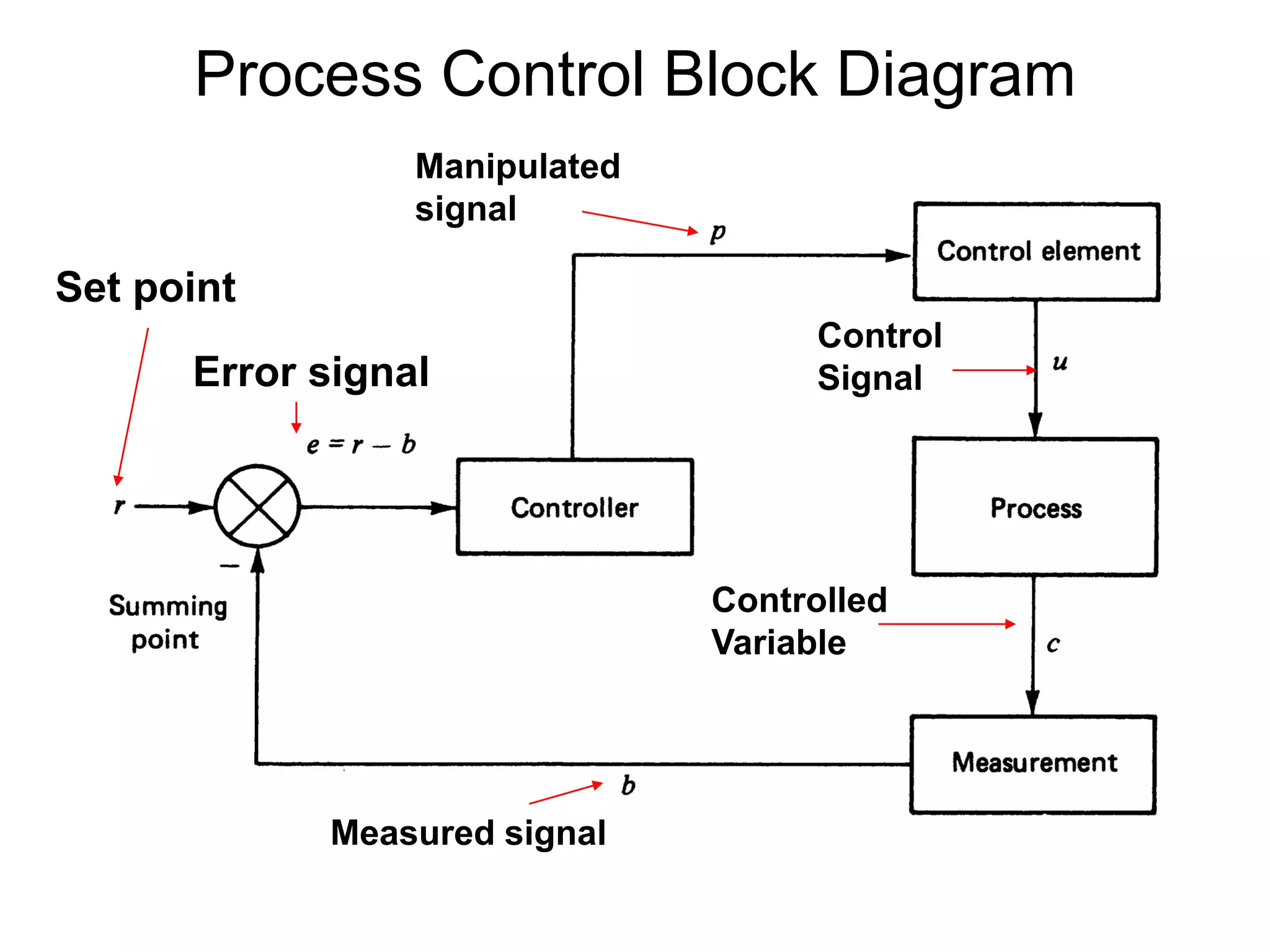

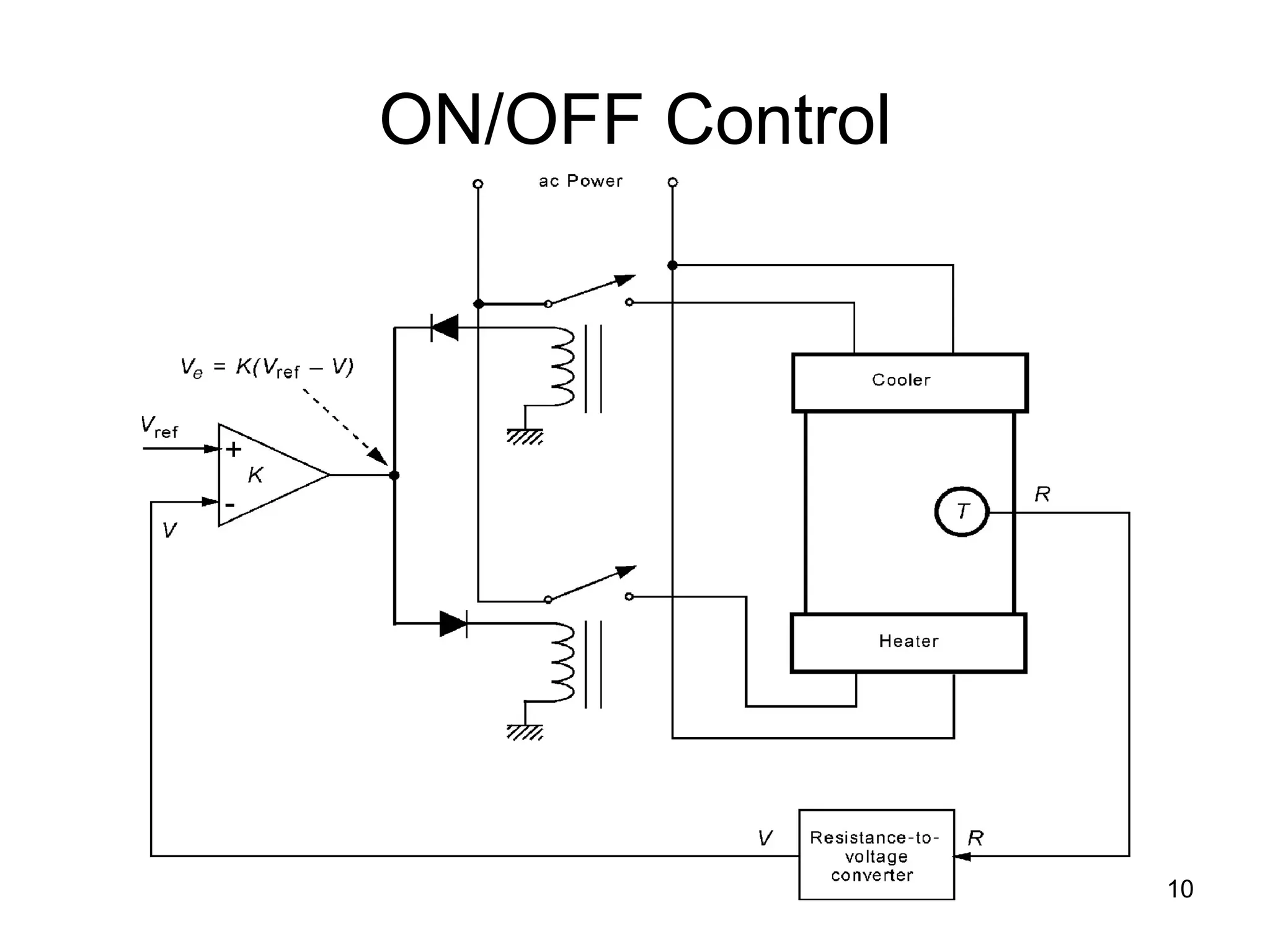

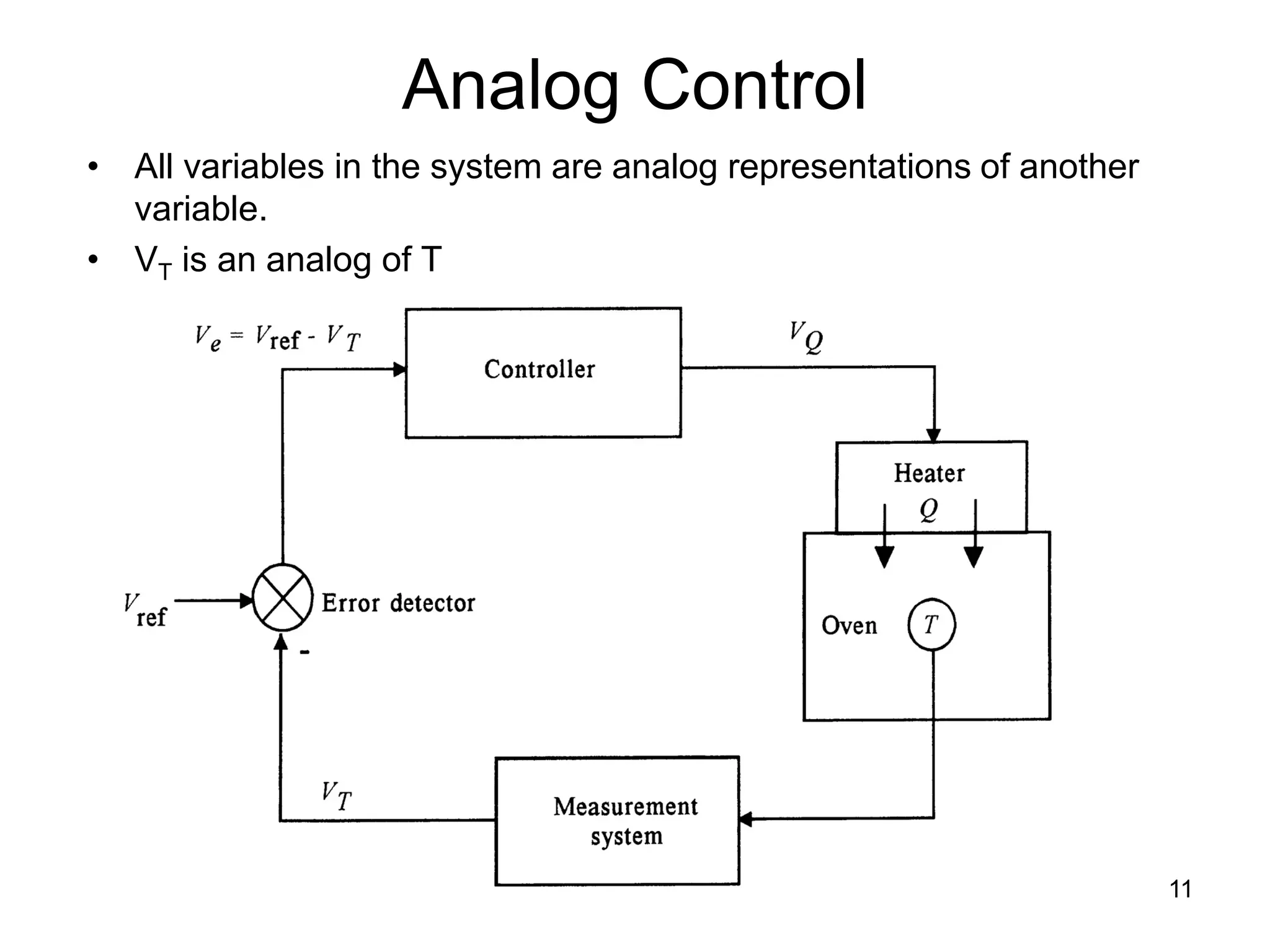

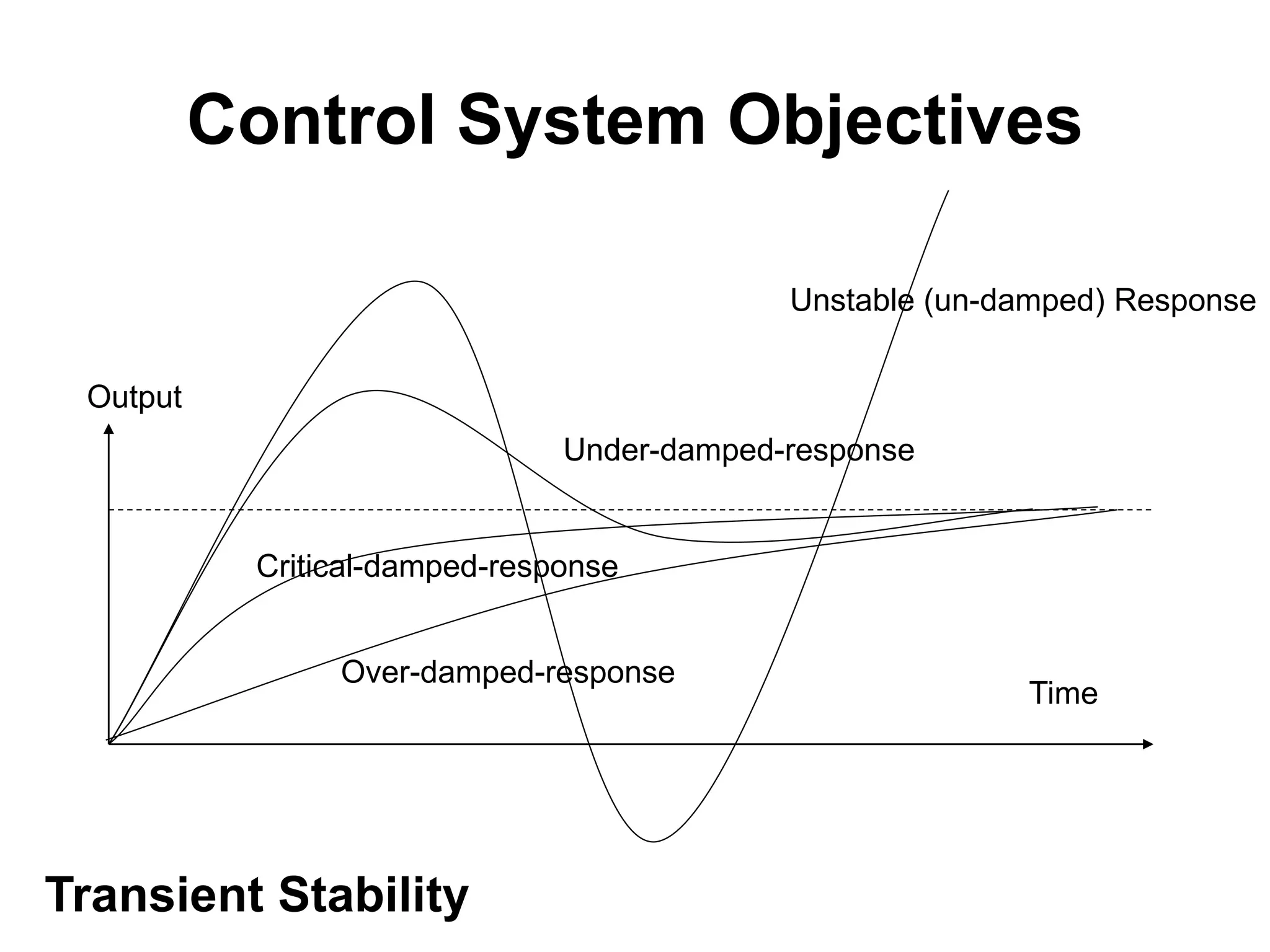

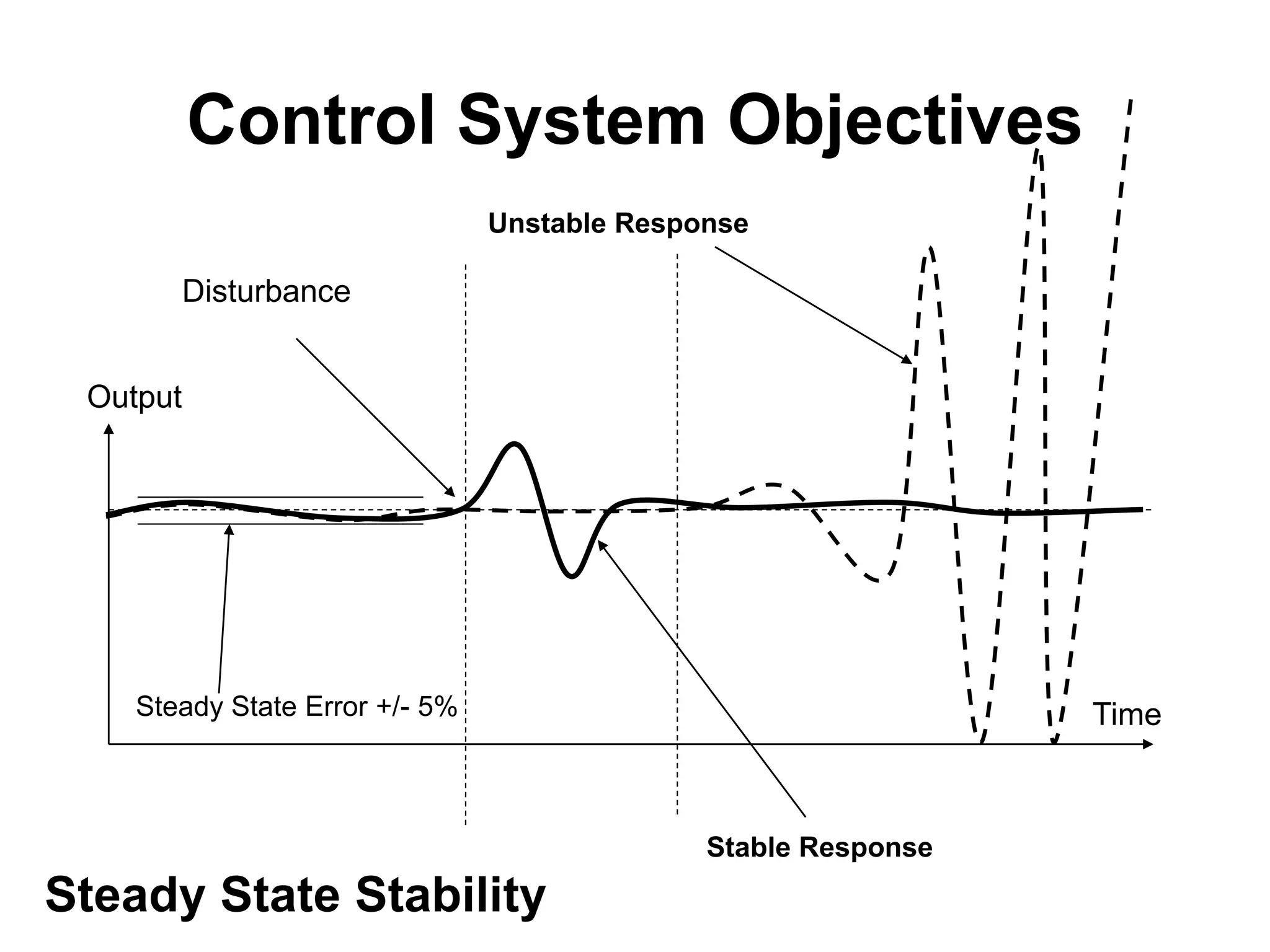

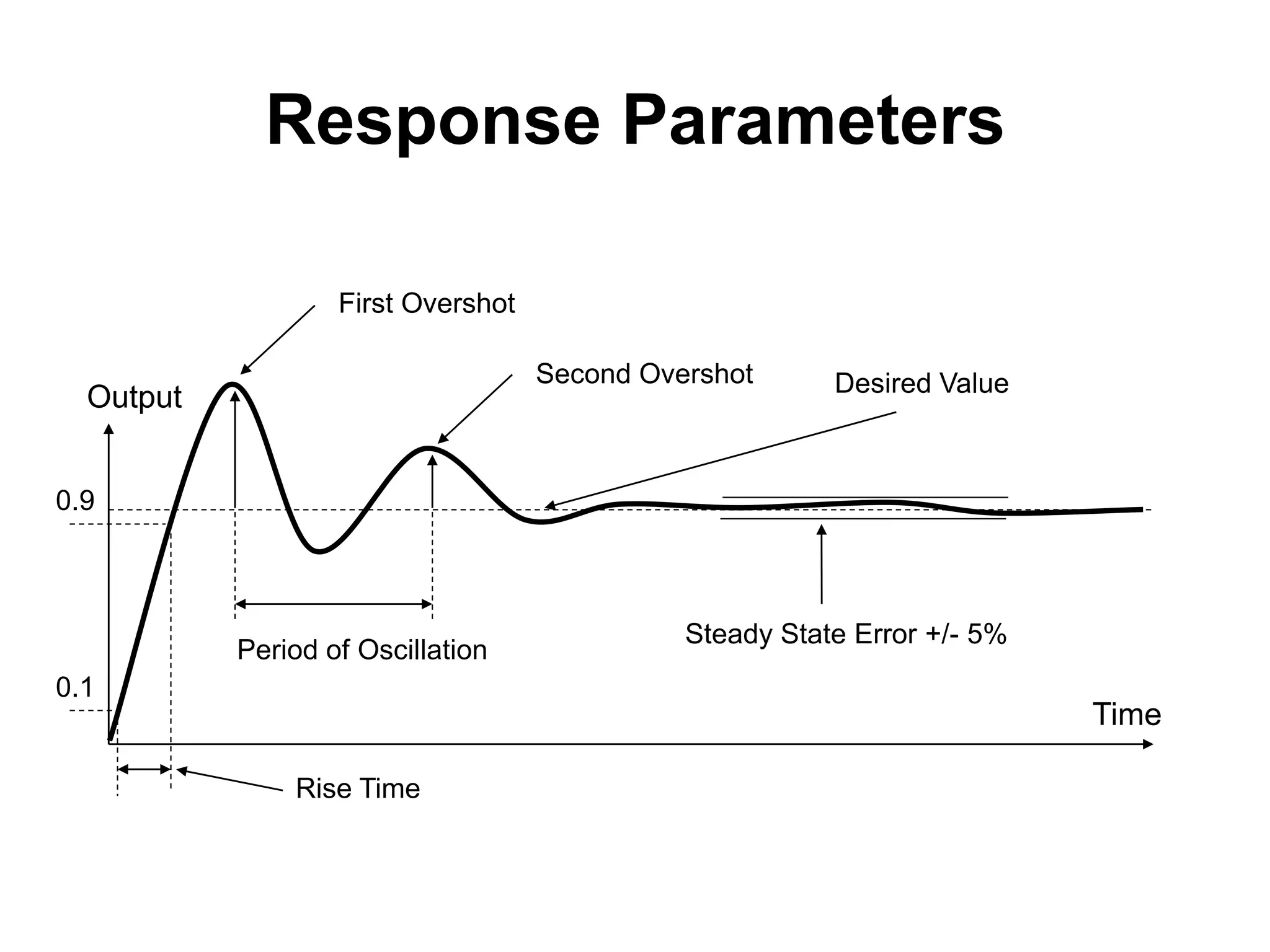

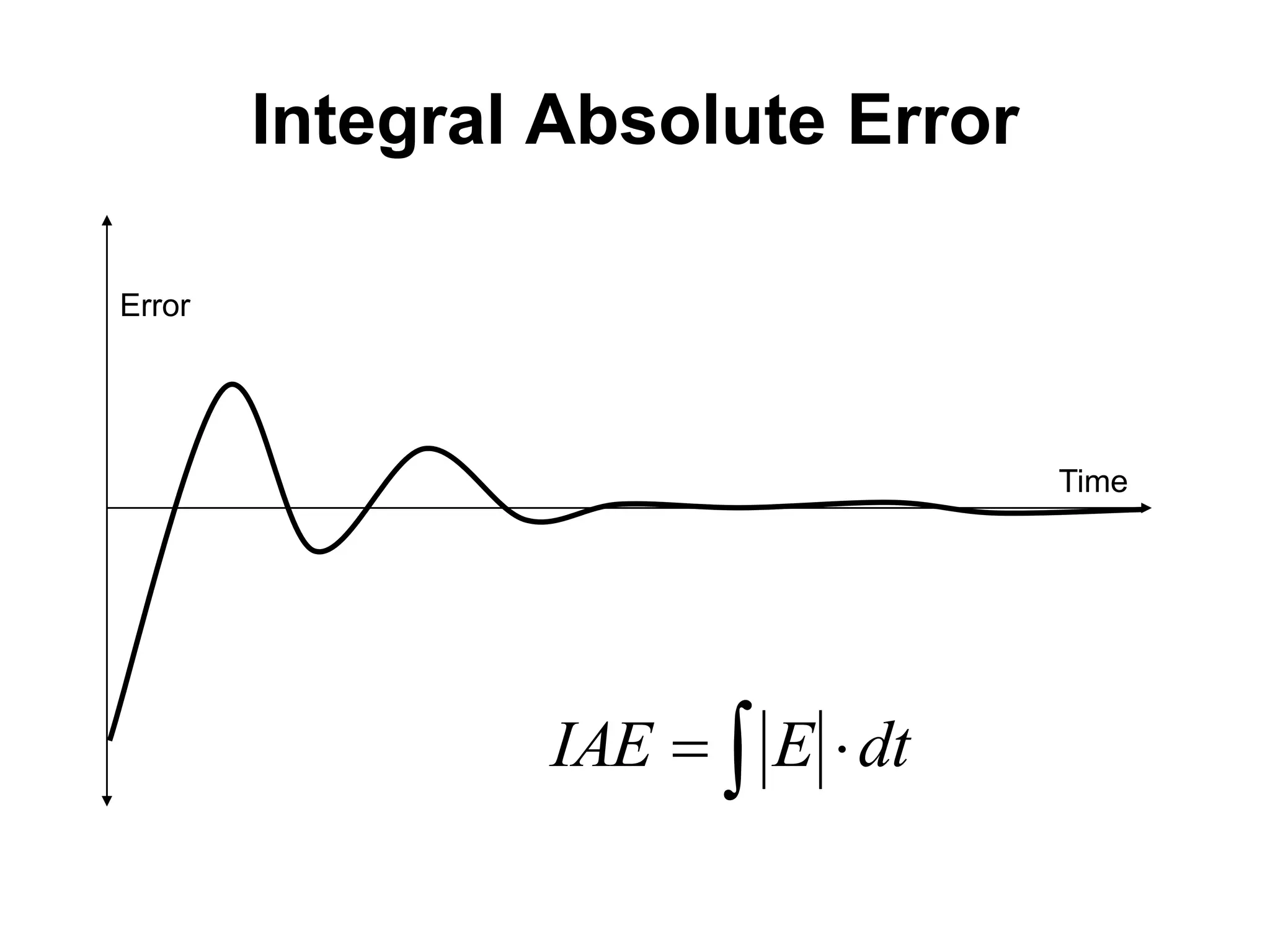

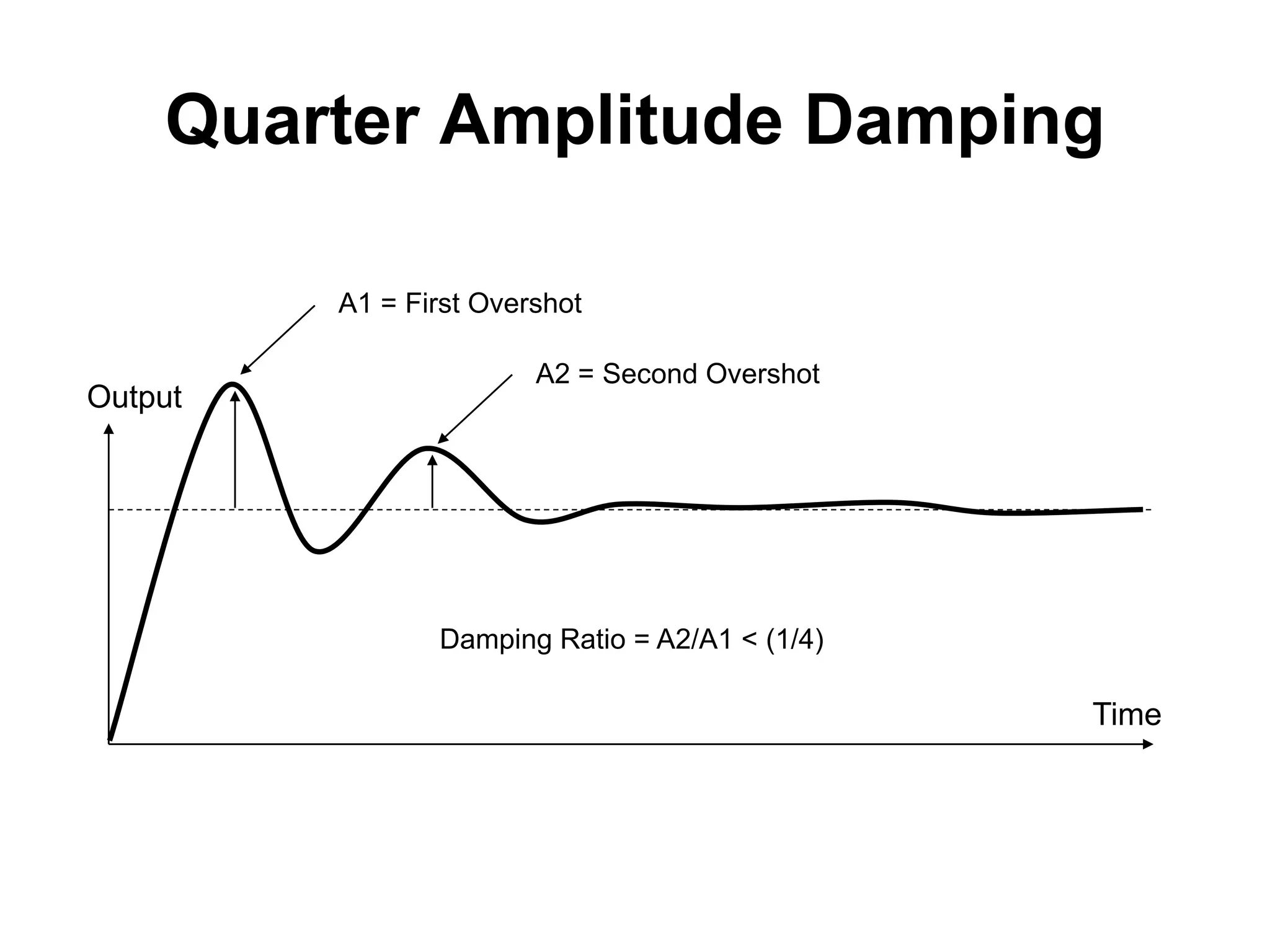

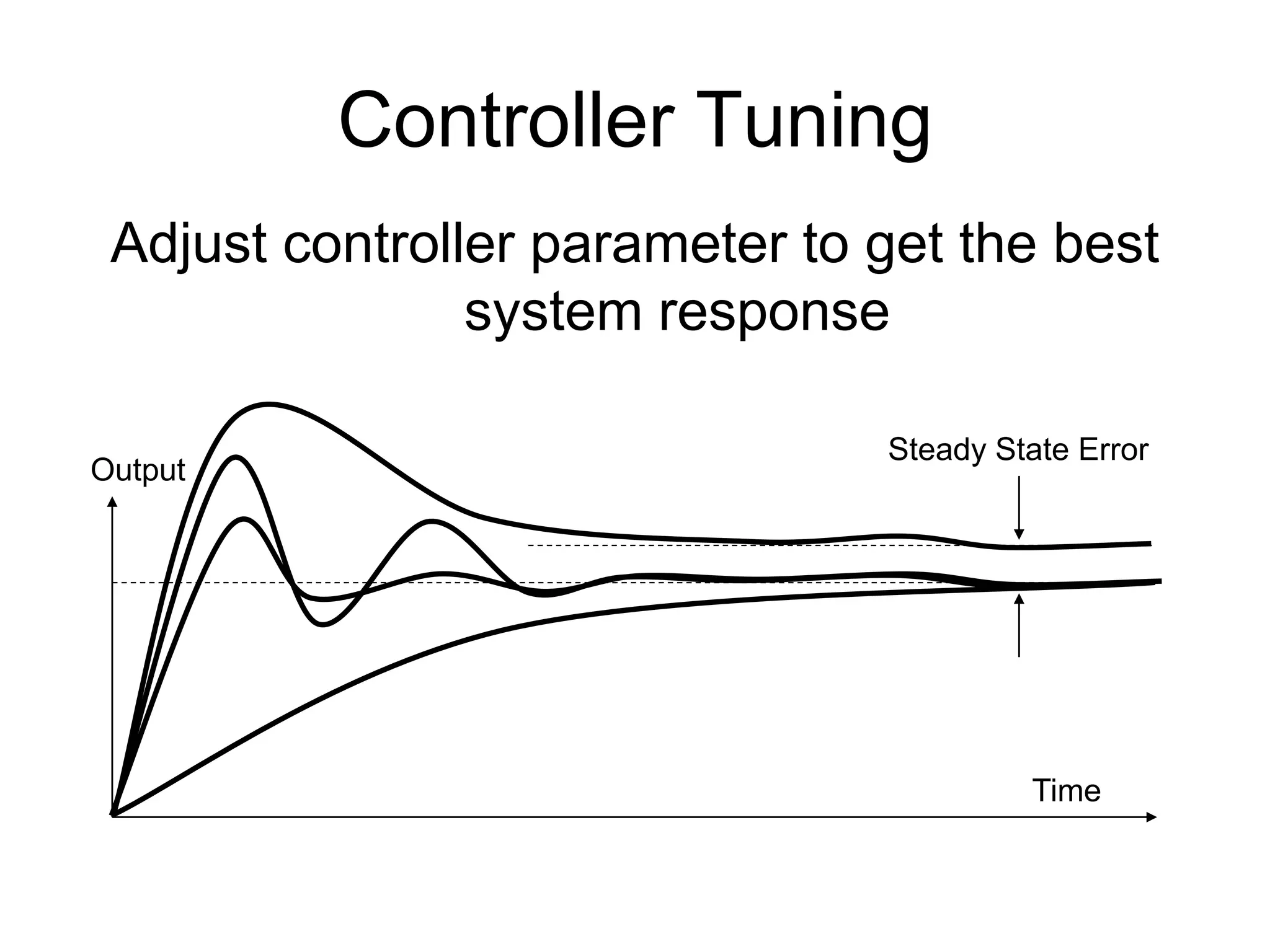

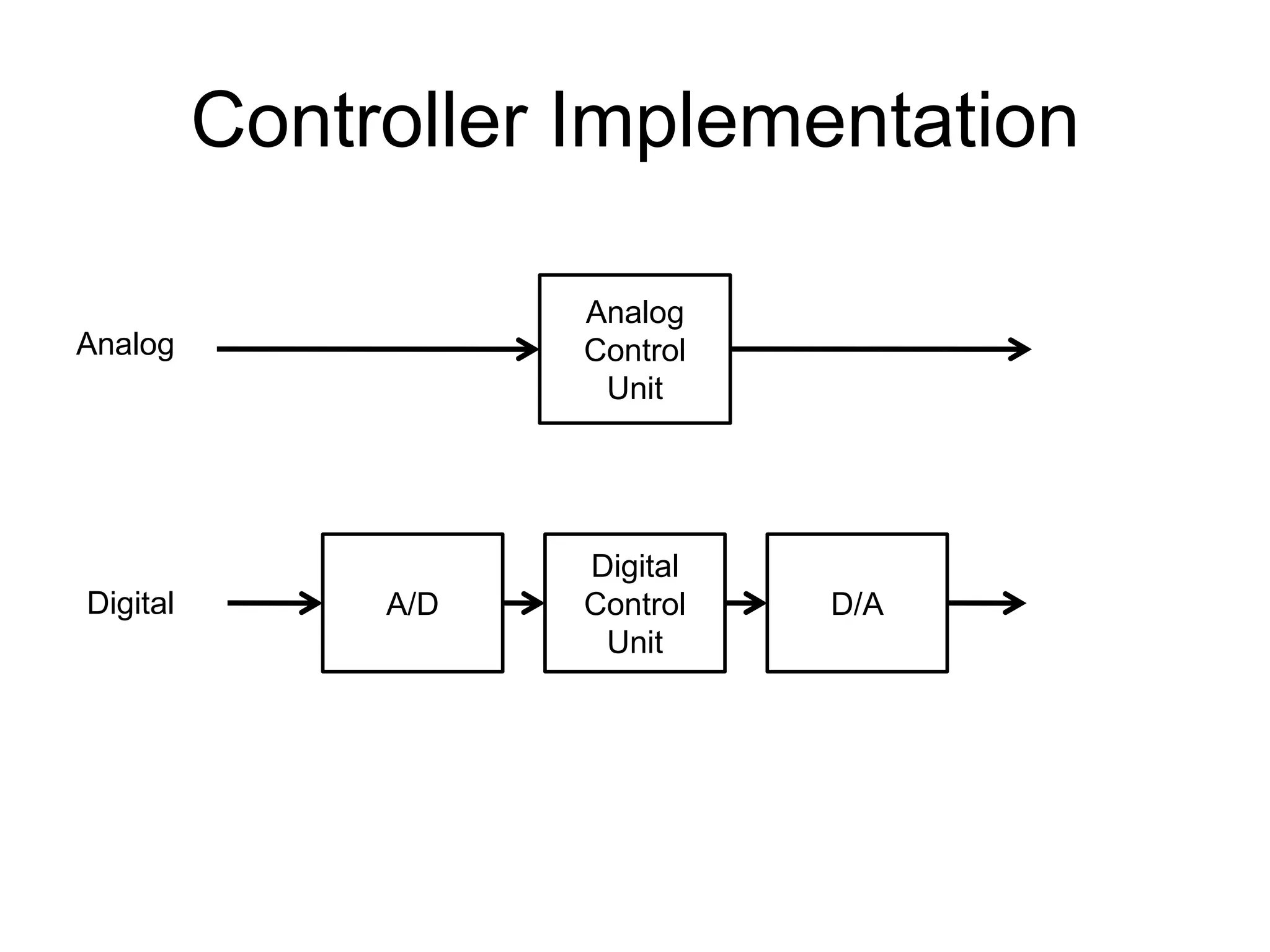

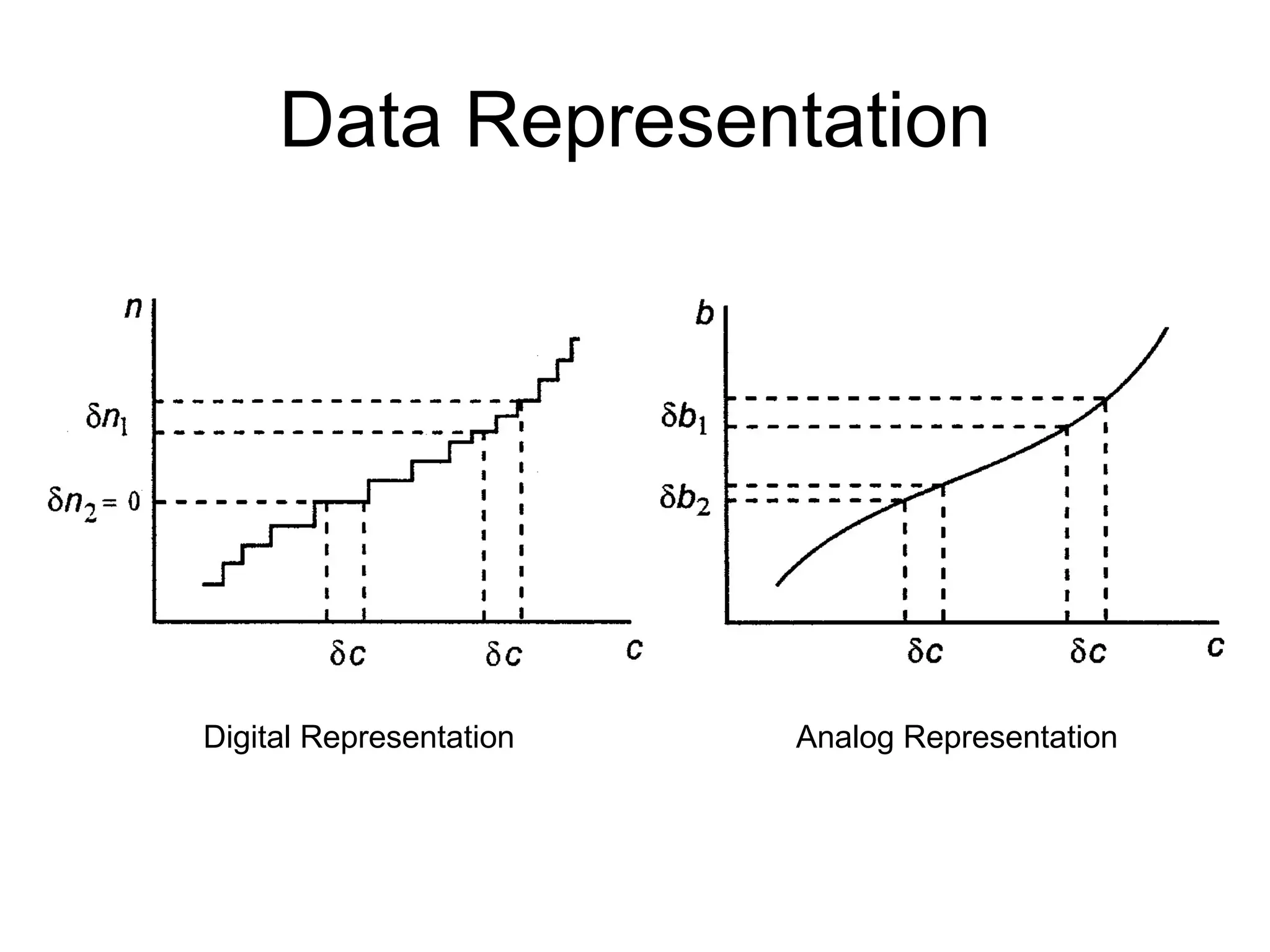

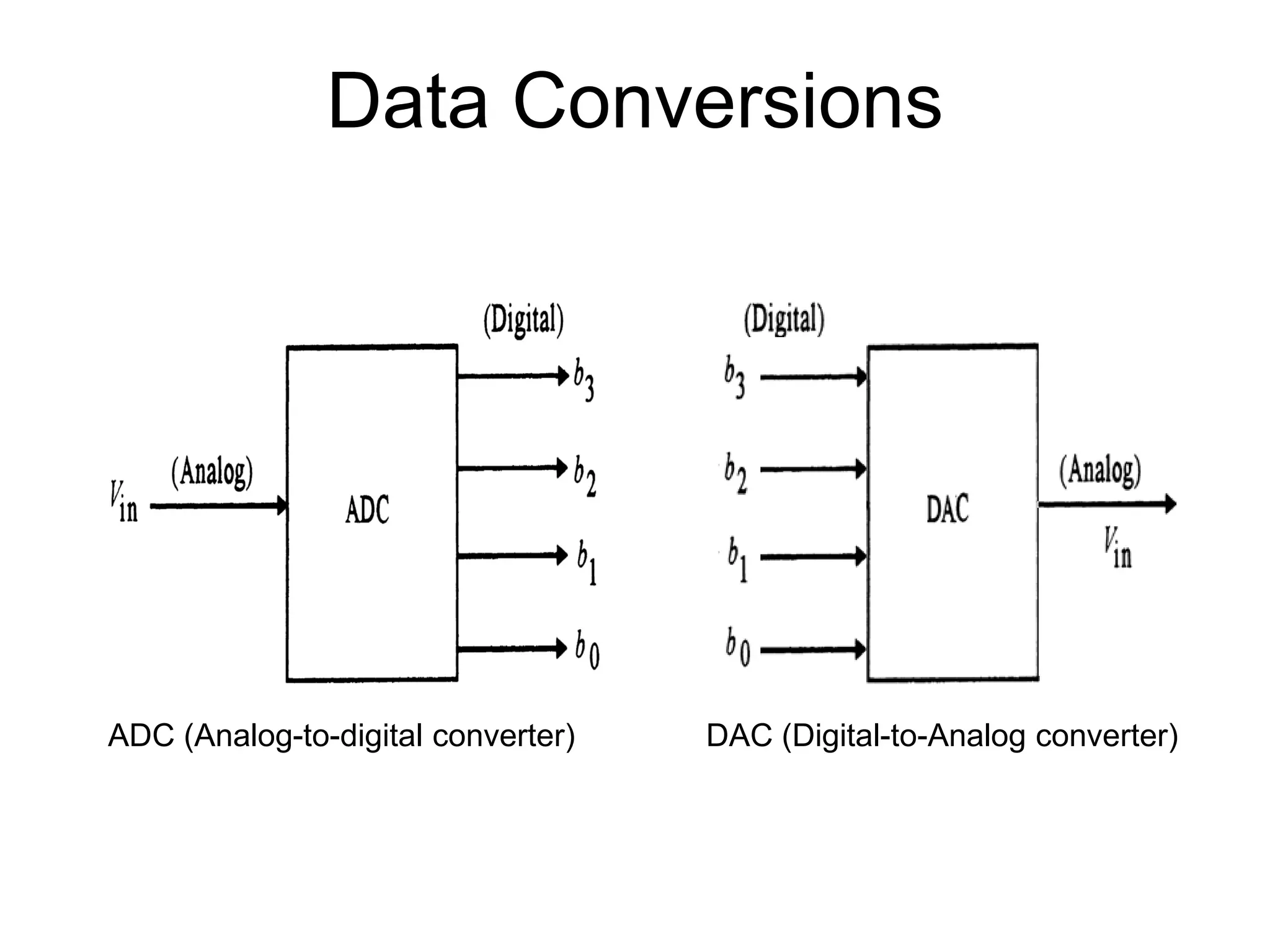

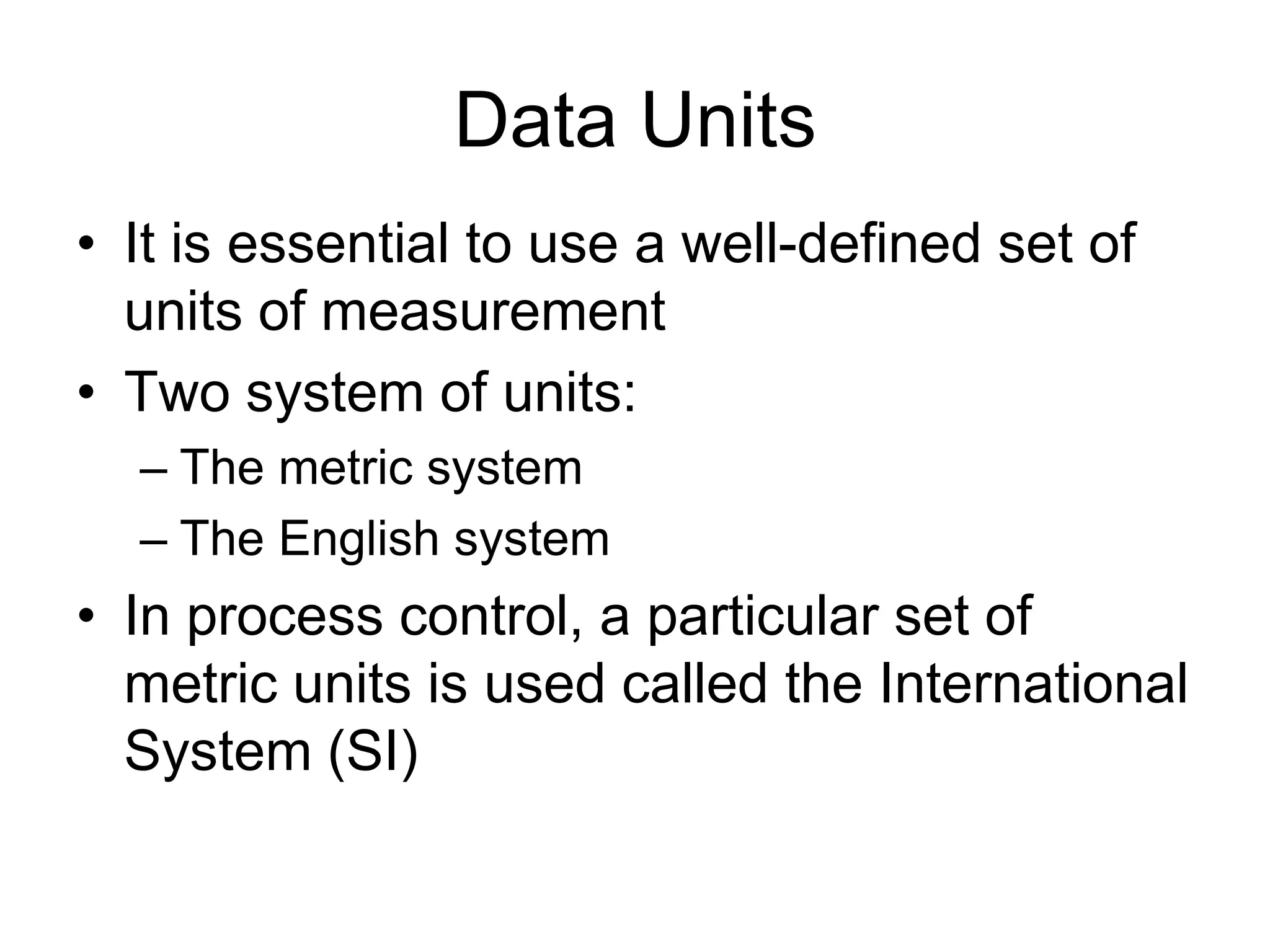

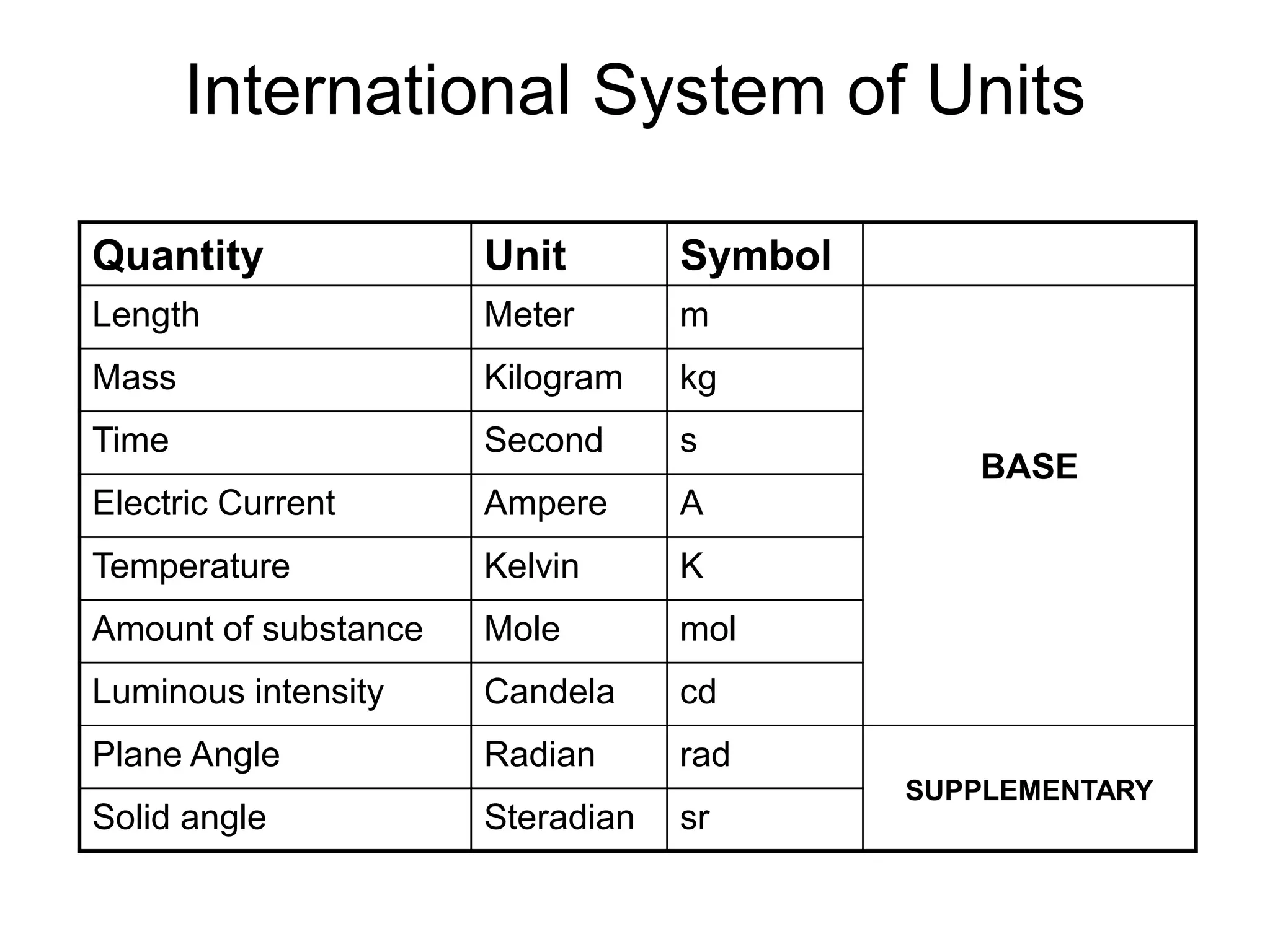

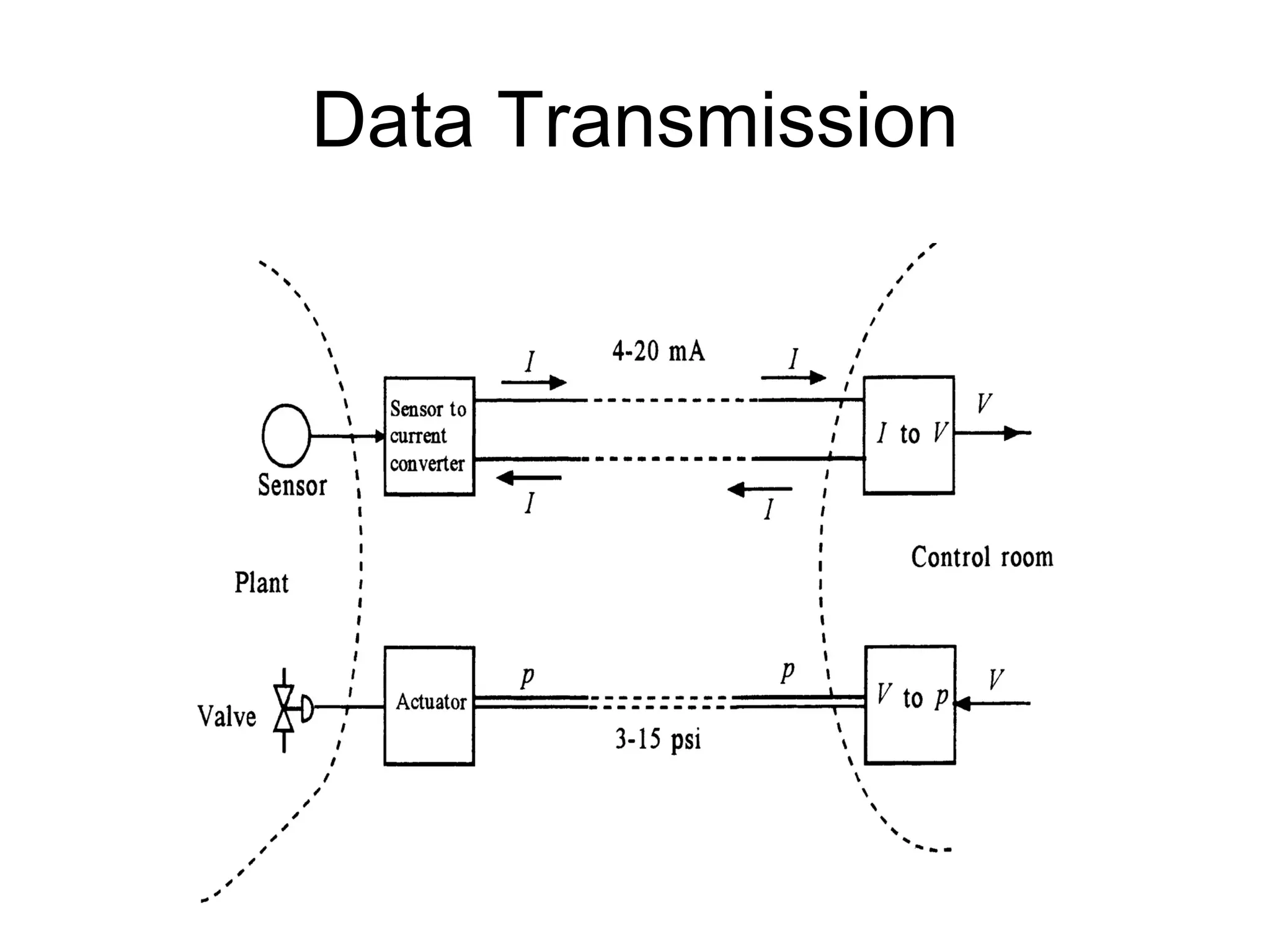

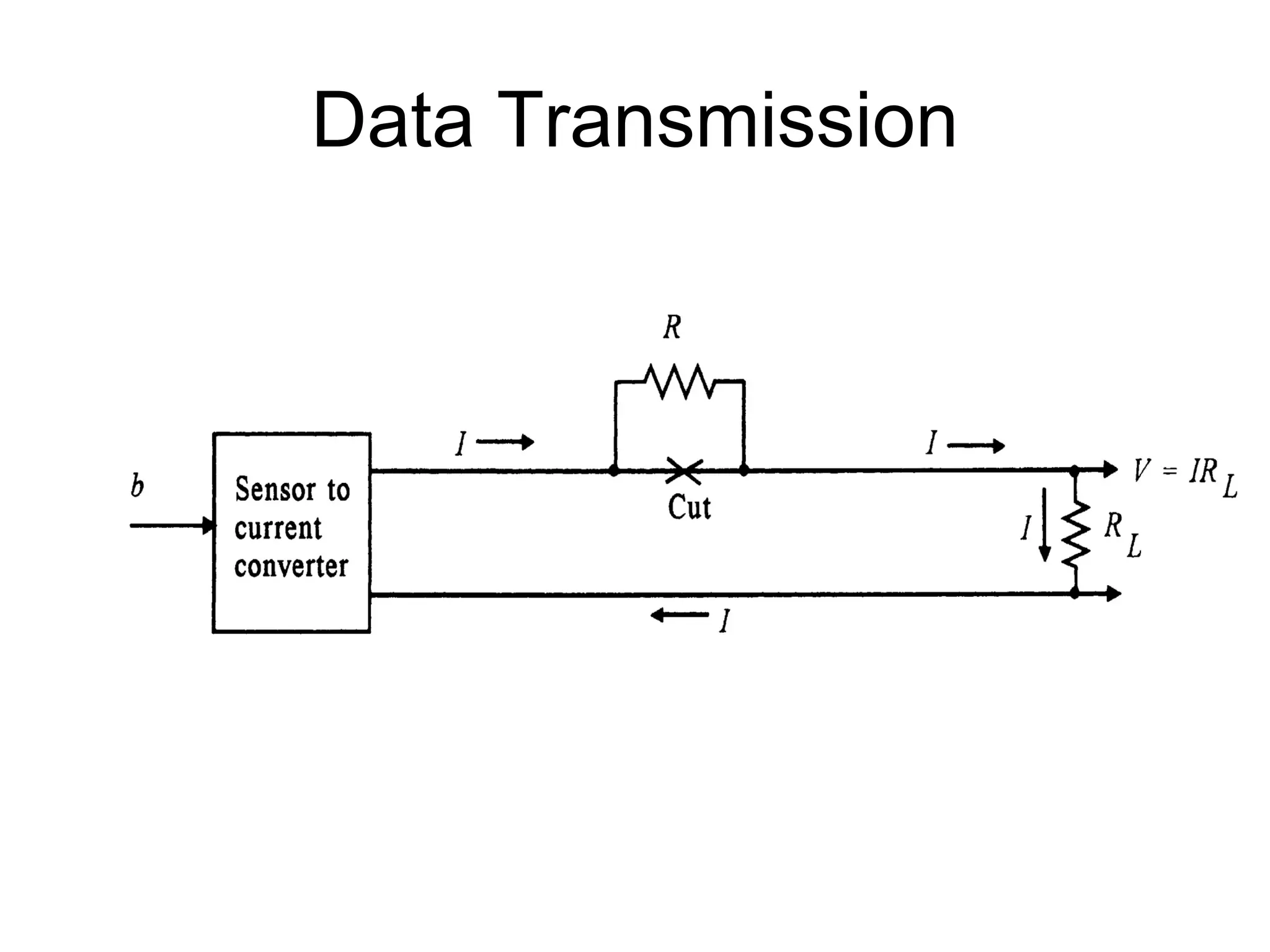

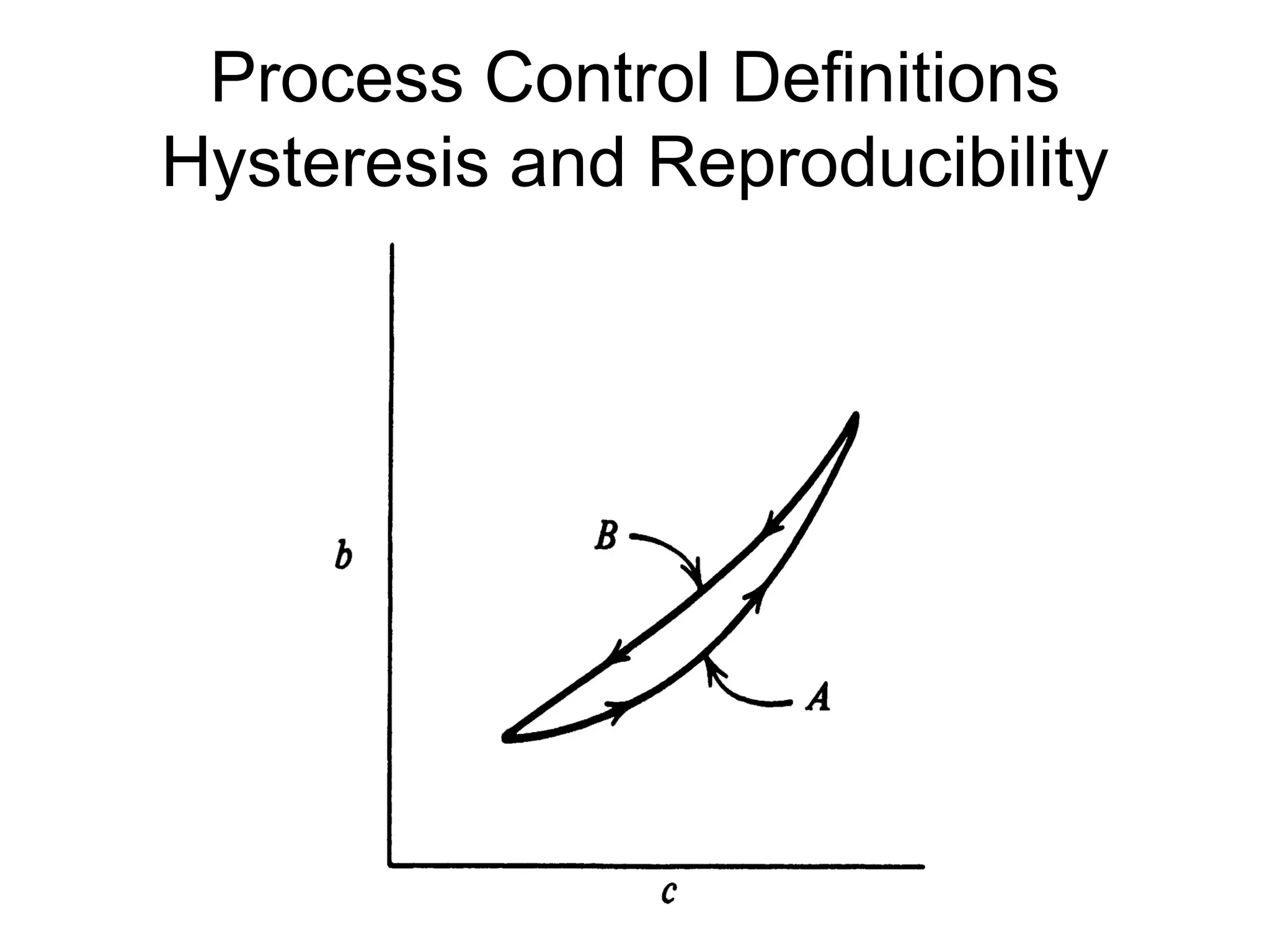

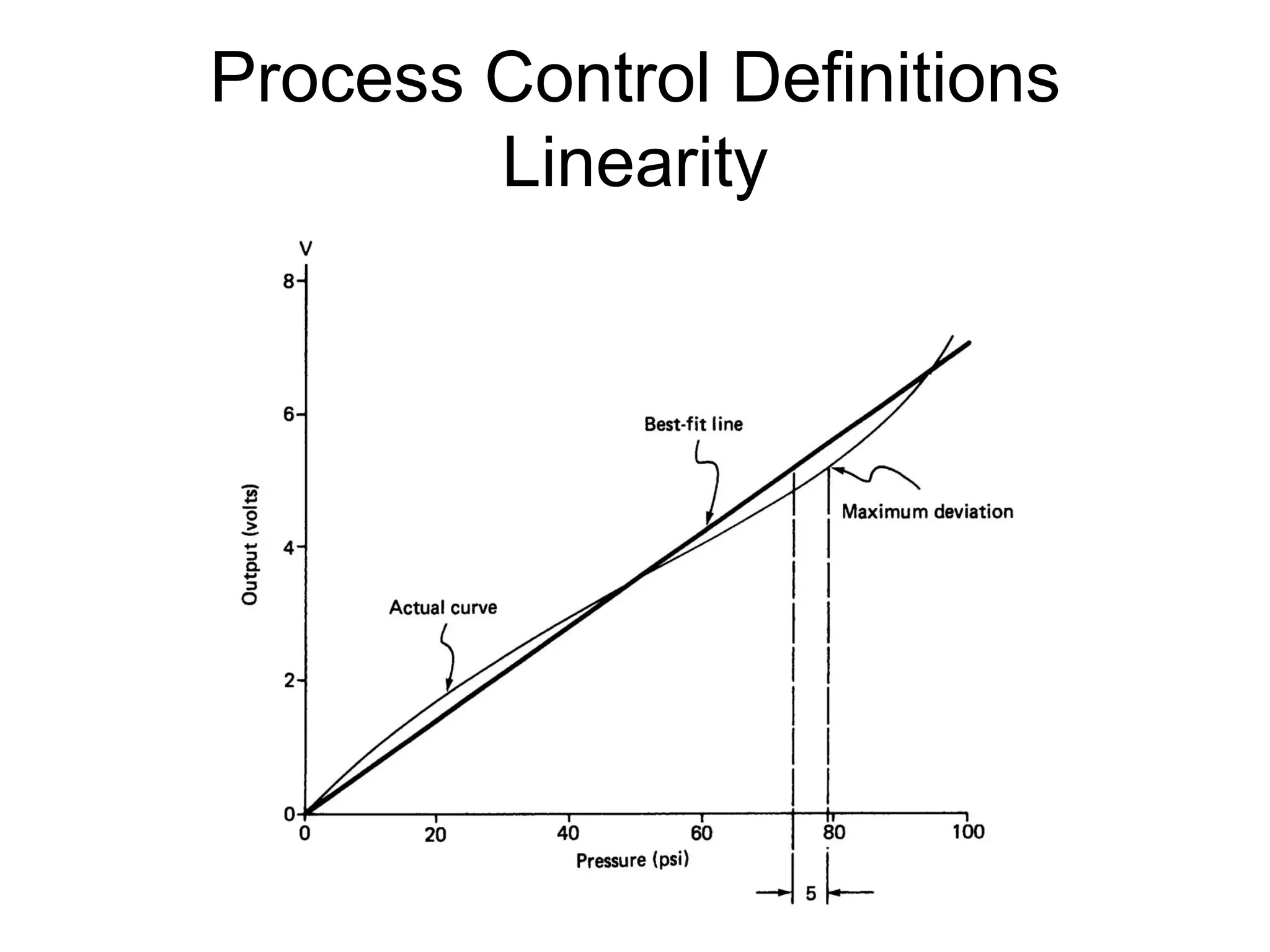

The document discusses process control components, definitions, and concepts. It introduces automatic and manual control systems, control objectives like stability and regulation, and control fundamentals such as sensors, actuators, controllers, errors, and transfer functions. It also covers data representation, conversions between analog and digital signals, and important metrics for control elements like accuracy, sensitivity, resolution, and time response.

![Process Control Definitions

Sensor Time Response

b(t) = bi+(bf – bi)[1 – e-t/]

First Order

Response](https://image.slidesharecdn.com/chapter1-120501220235-phpapp02/75/Chapter-1-38-2048.jpg)