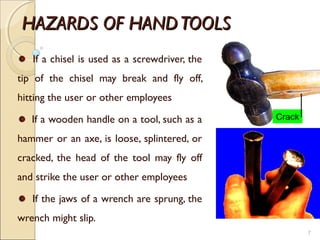

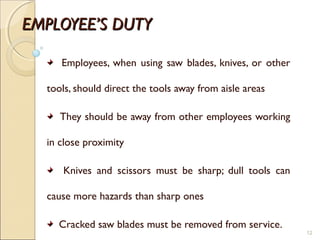

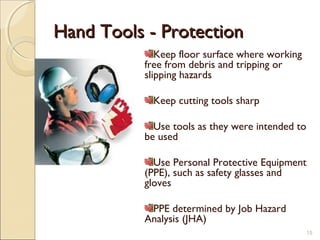

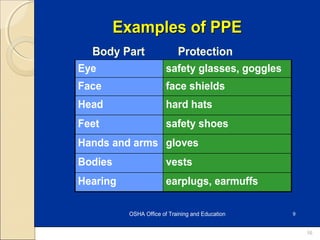

This document provides information on safety practices for hand tools and grinding tools. It discusses hazards associated with both types of tools and outlines safety precautions and regulations. For hand tools, common hazards include tool misuse, improper maintenance, and loose or damaged parts. Grinding tools can cause injuries from contact with abrasive surfaces or failure of grinding wheels. The document recommends personal protective equipment, proper tool use and maintenance, guarding, training, and following manufacturer guidelines to prevent injuries when using hand and grinding tools.