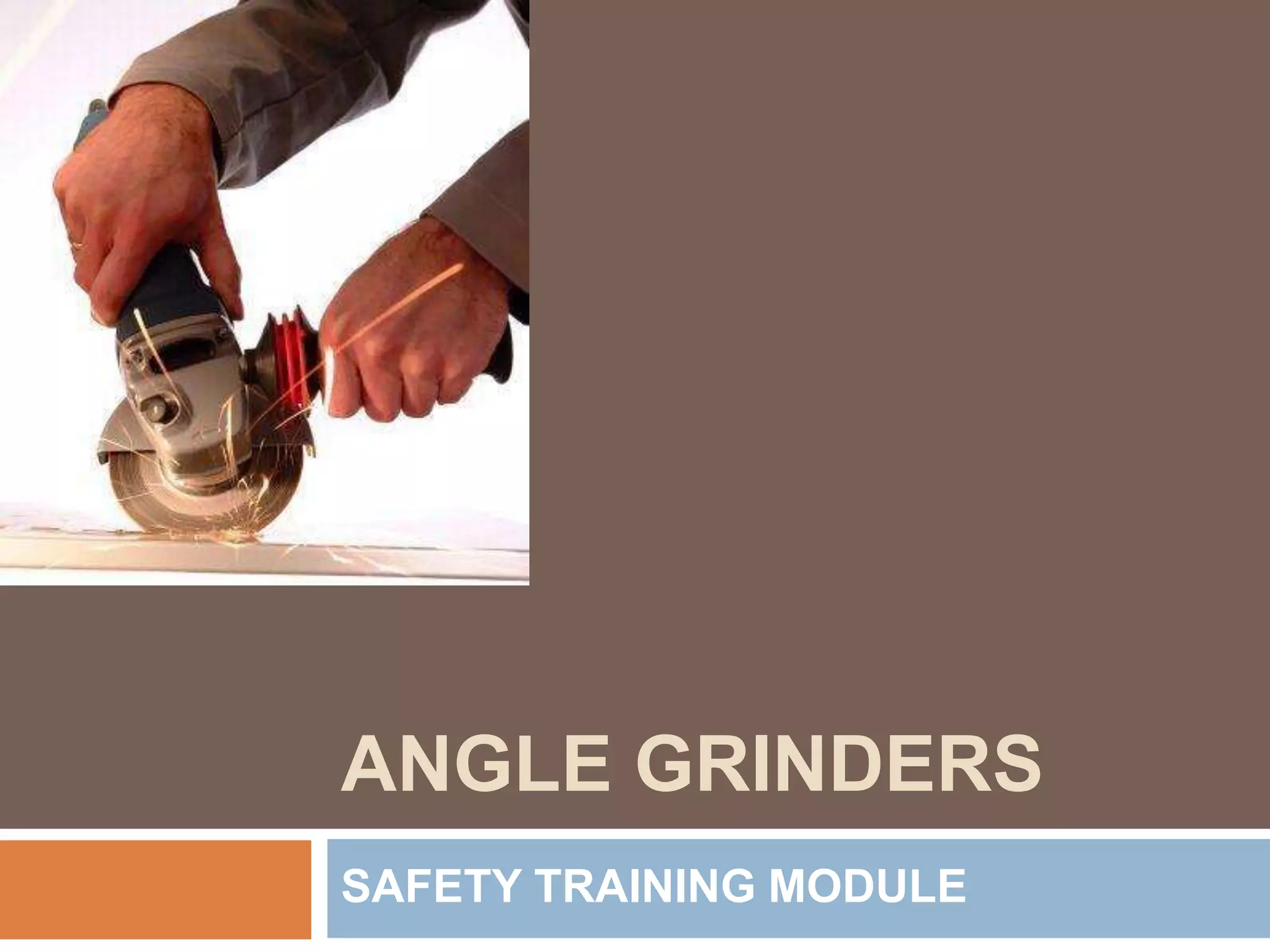

This document provides safety information for operating angle grinders. It identifies several risks such as kickback, disc shattering, and eye injuries from metal particles. It emphasizes the importance of using both hands, wearing proper protective equipment like face shields, and ensuring the guard and handles are securely in place. Operators should receive training and carefully inspect the tool, disc, and work area before operating.