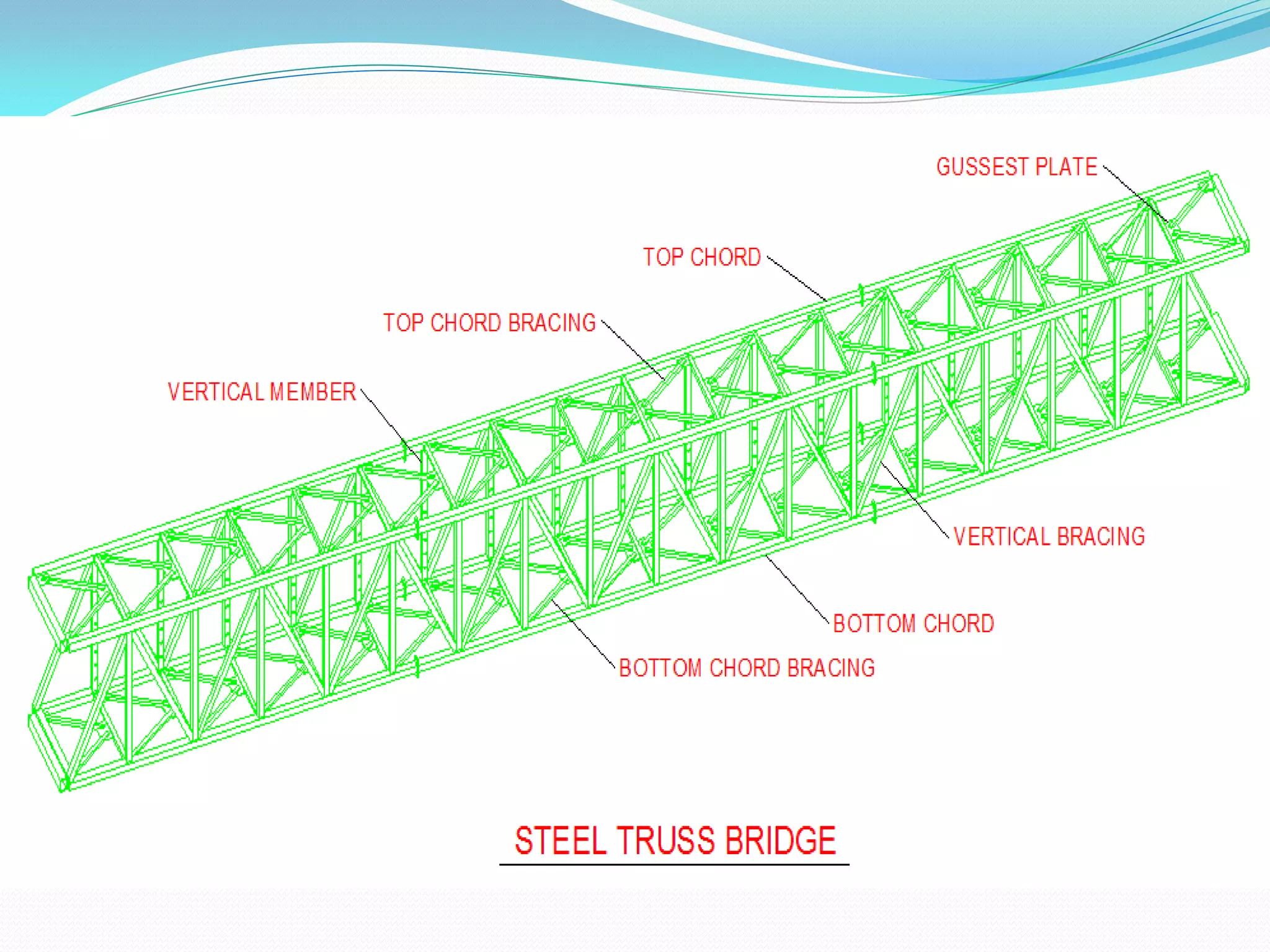

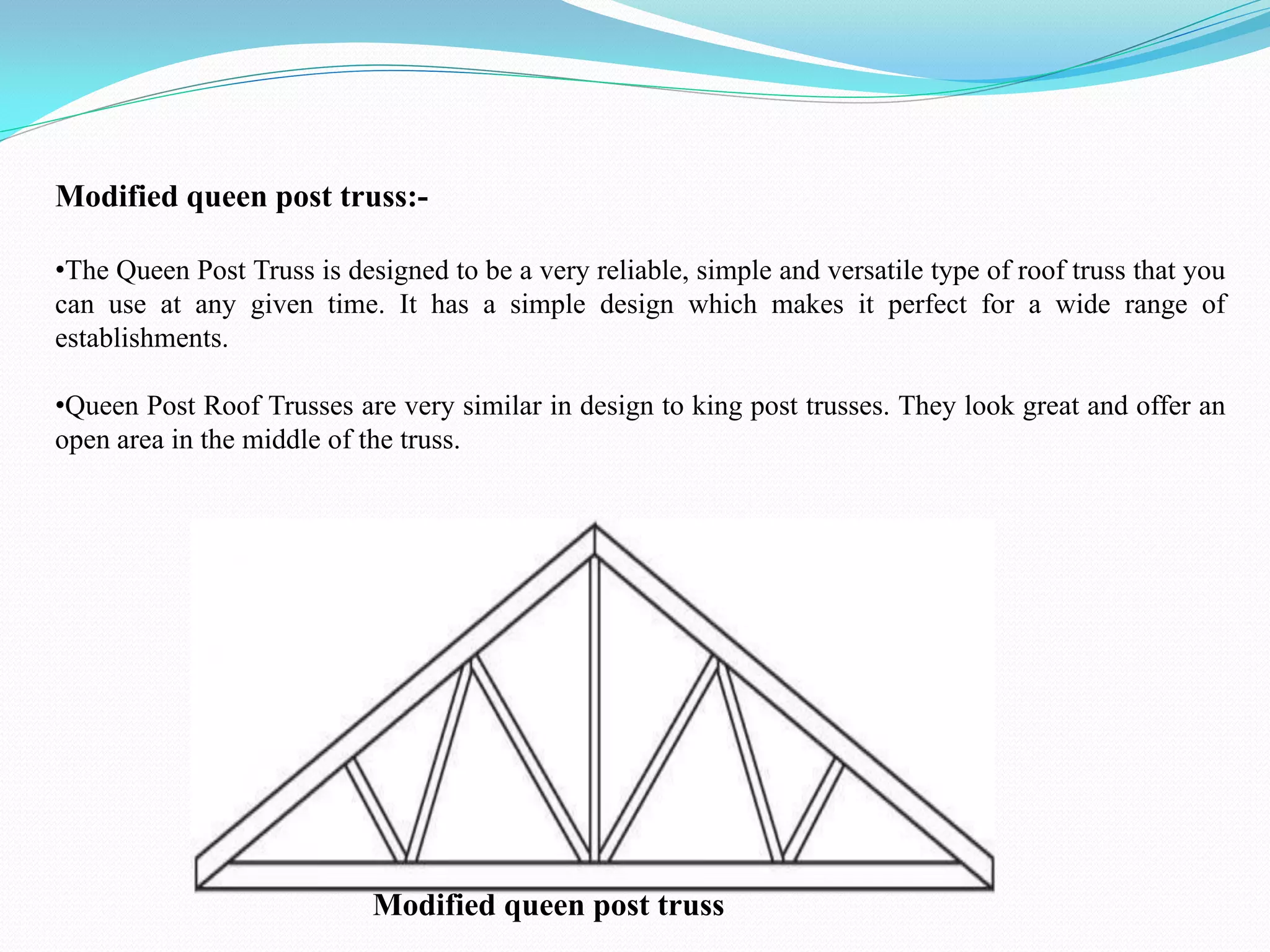

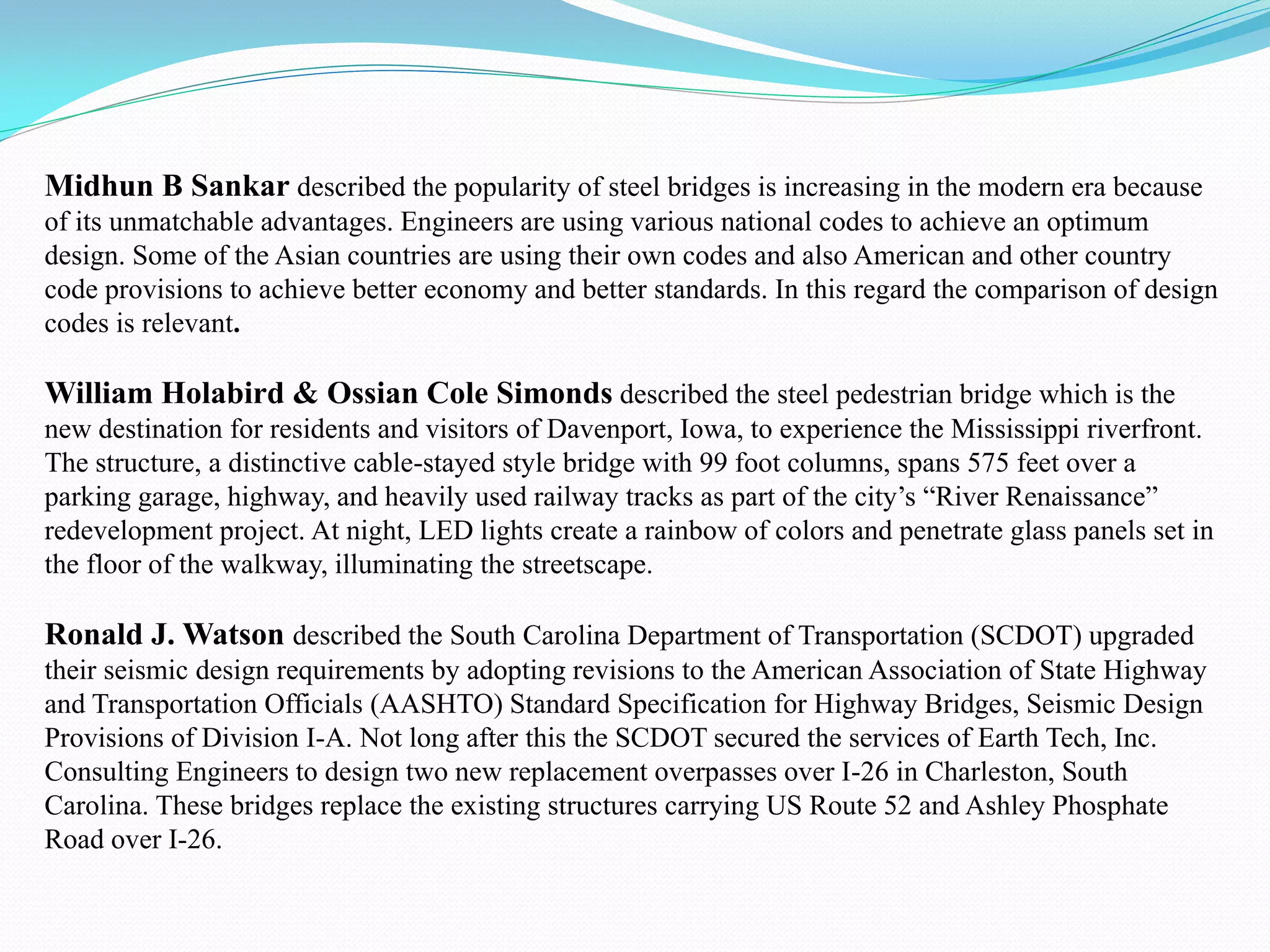

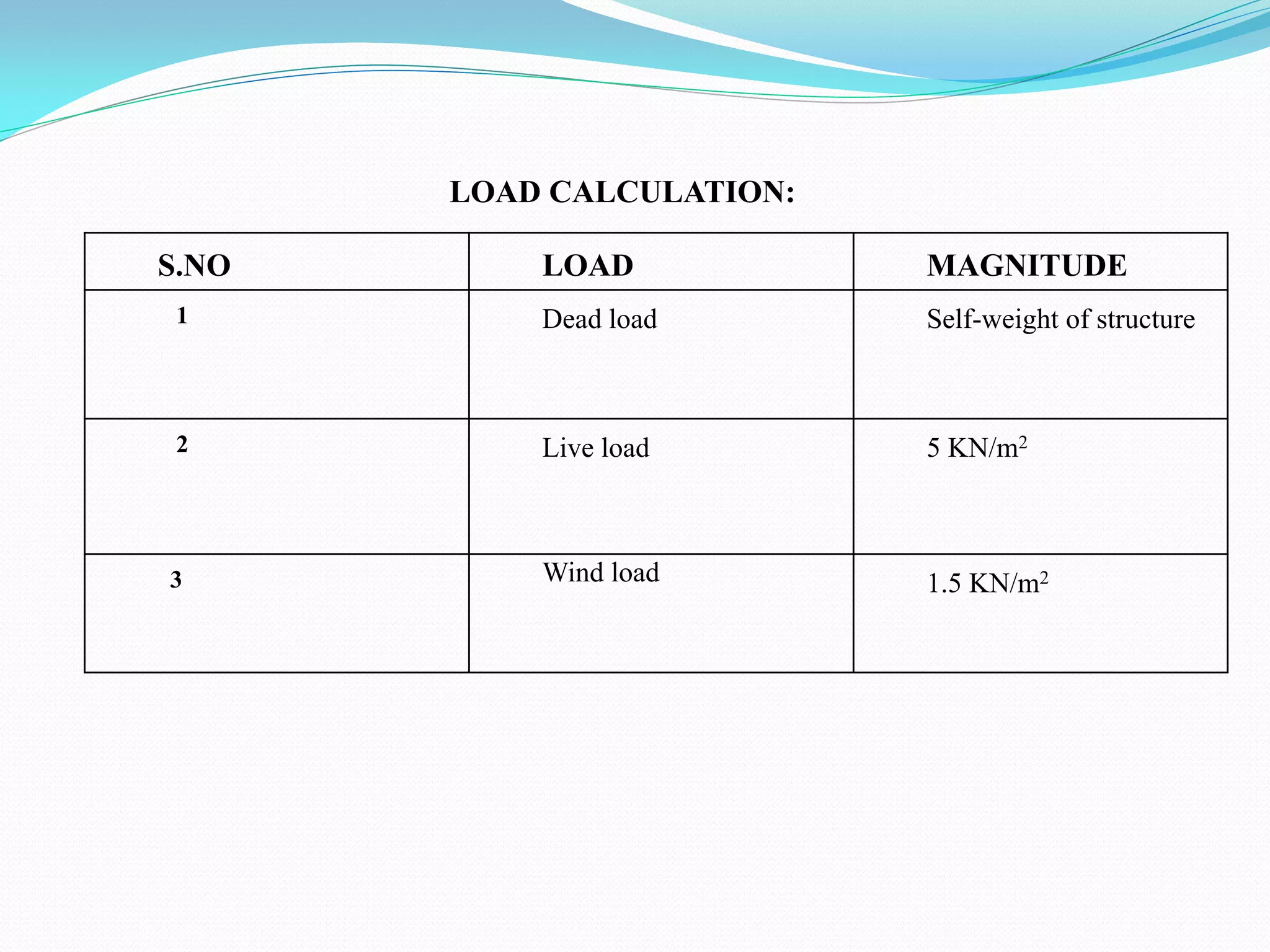

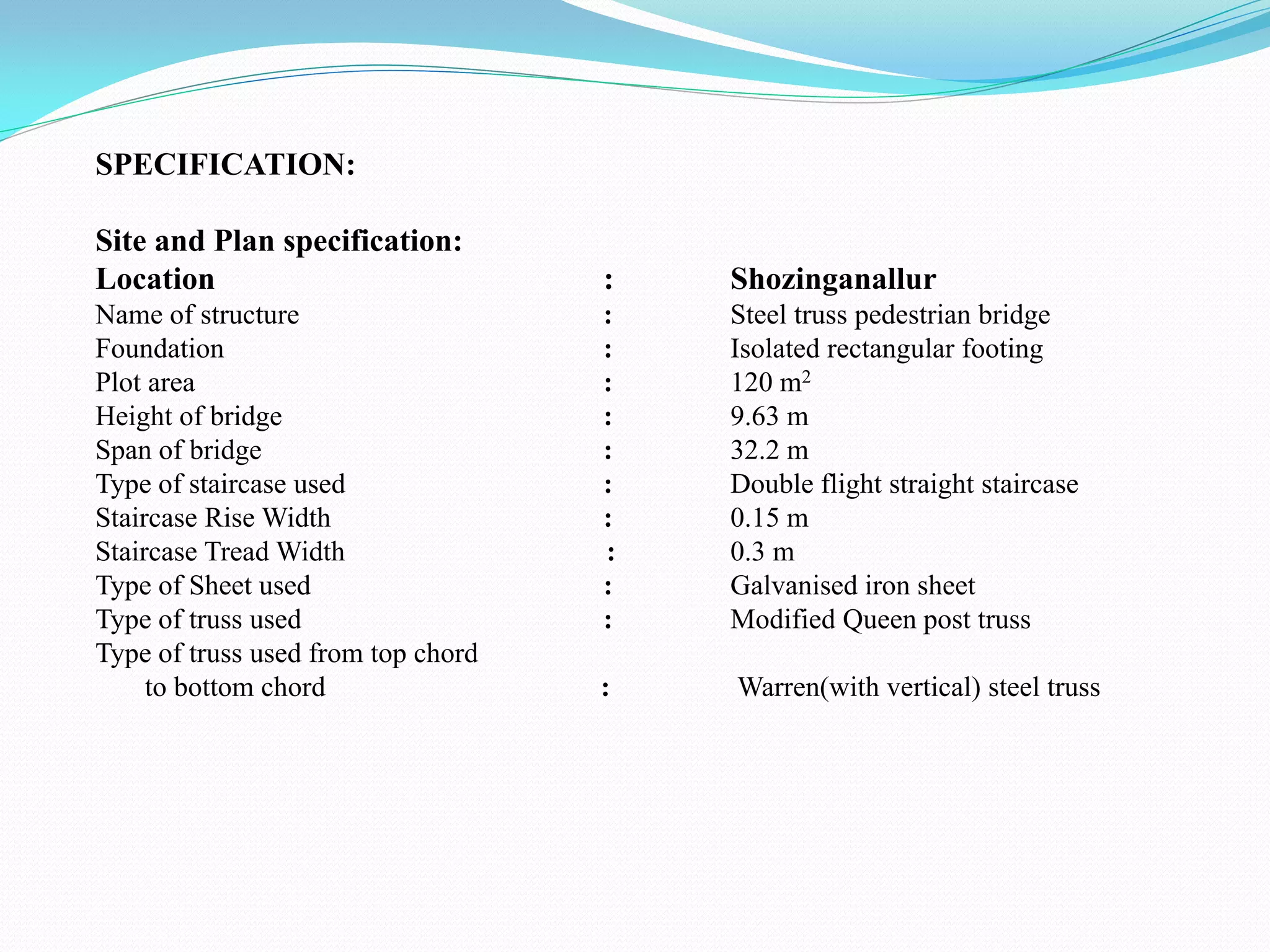

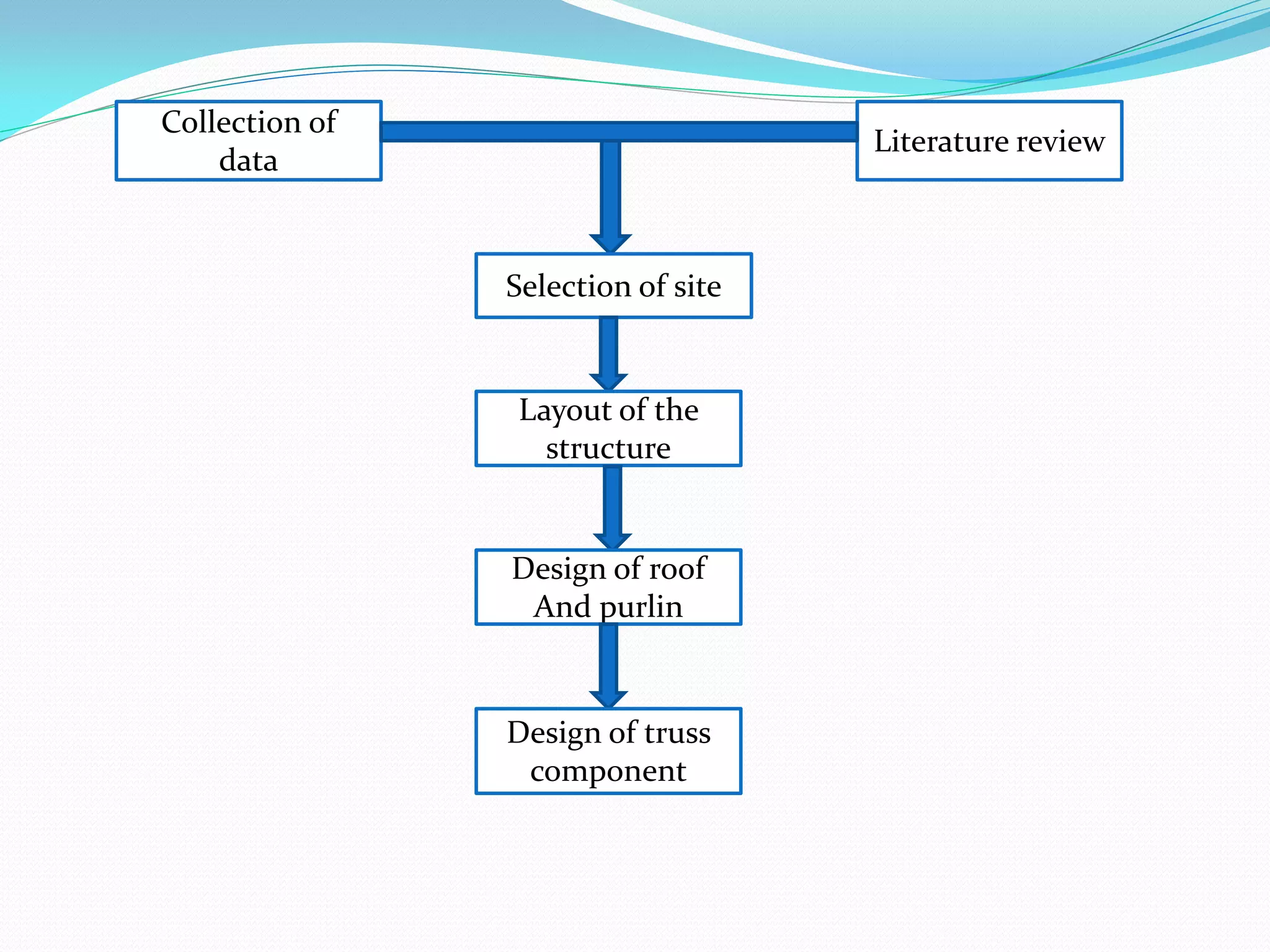

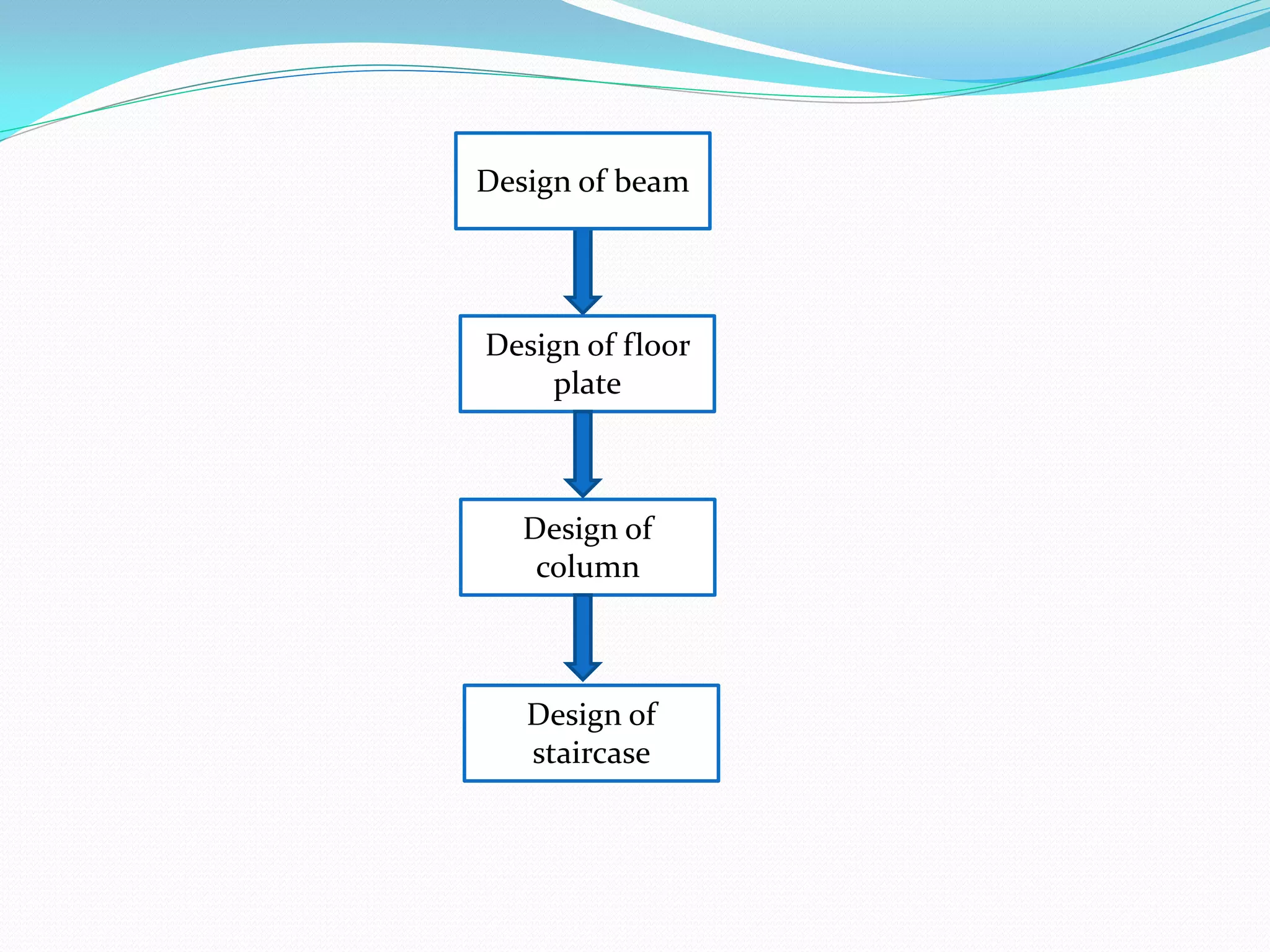

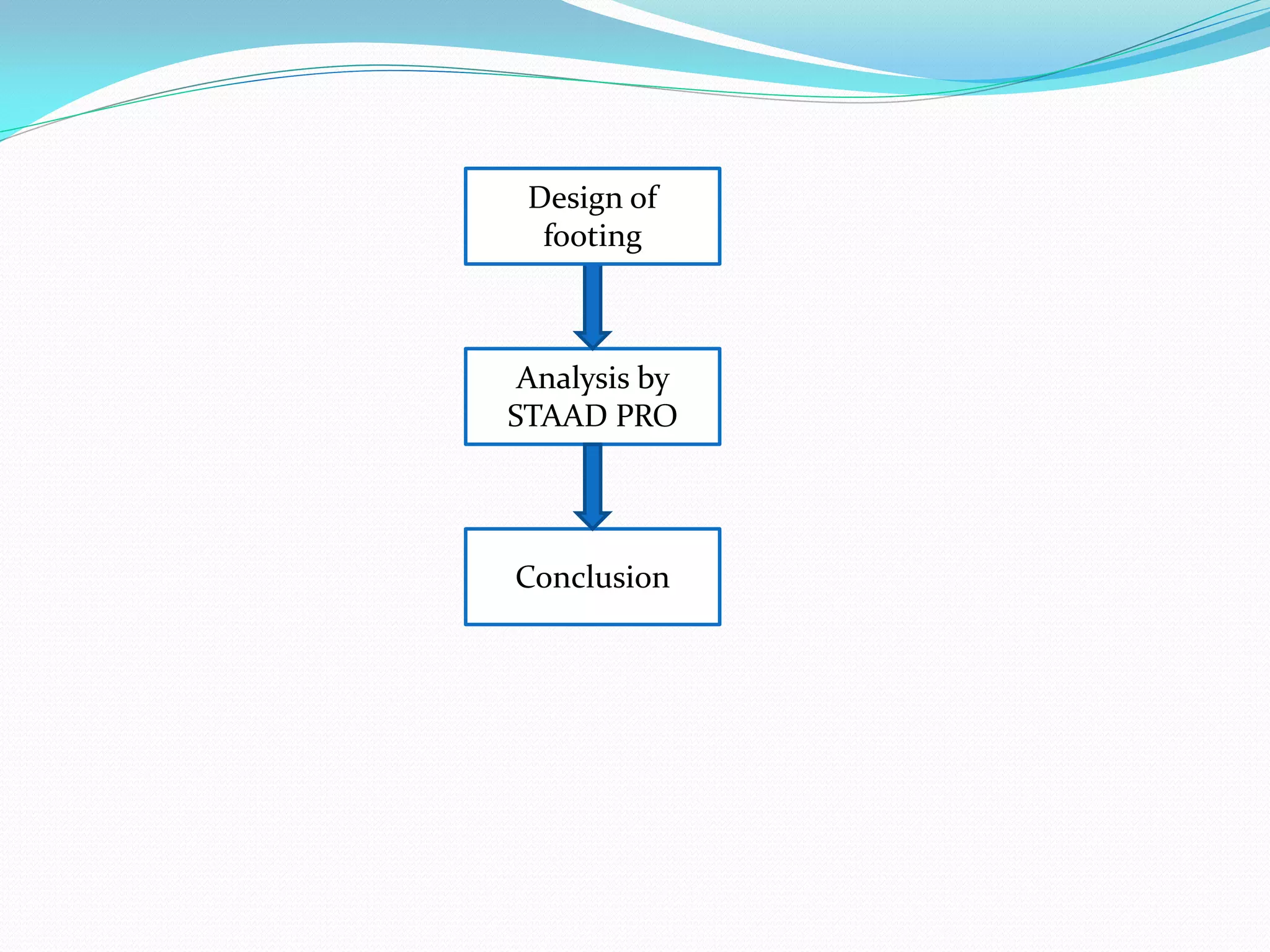

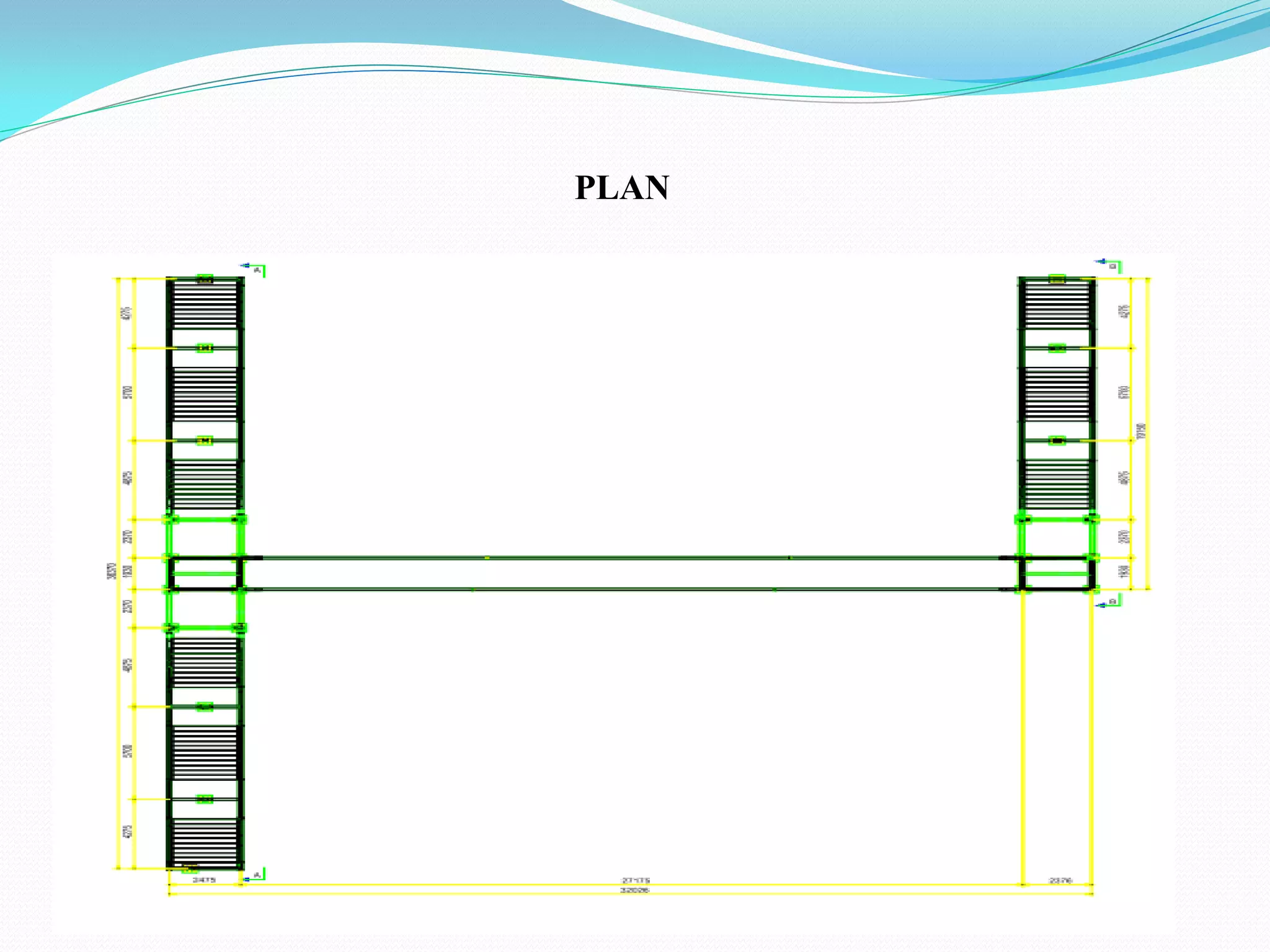

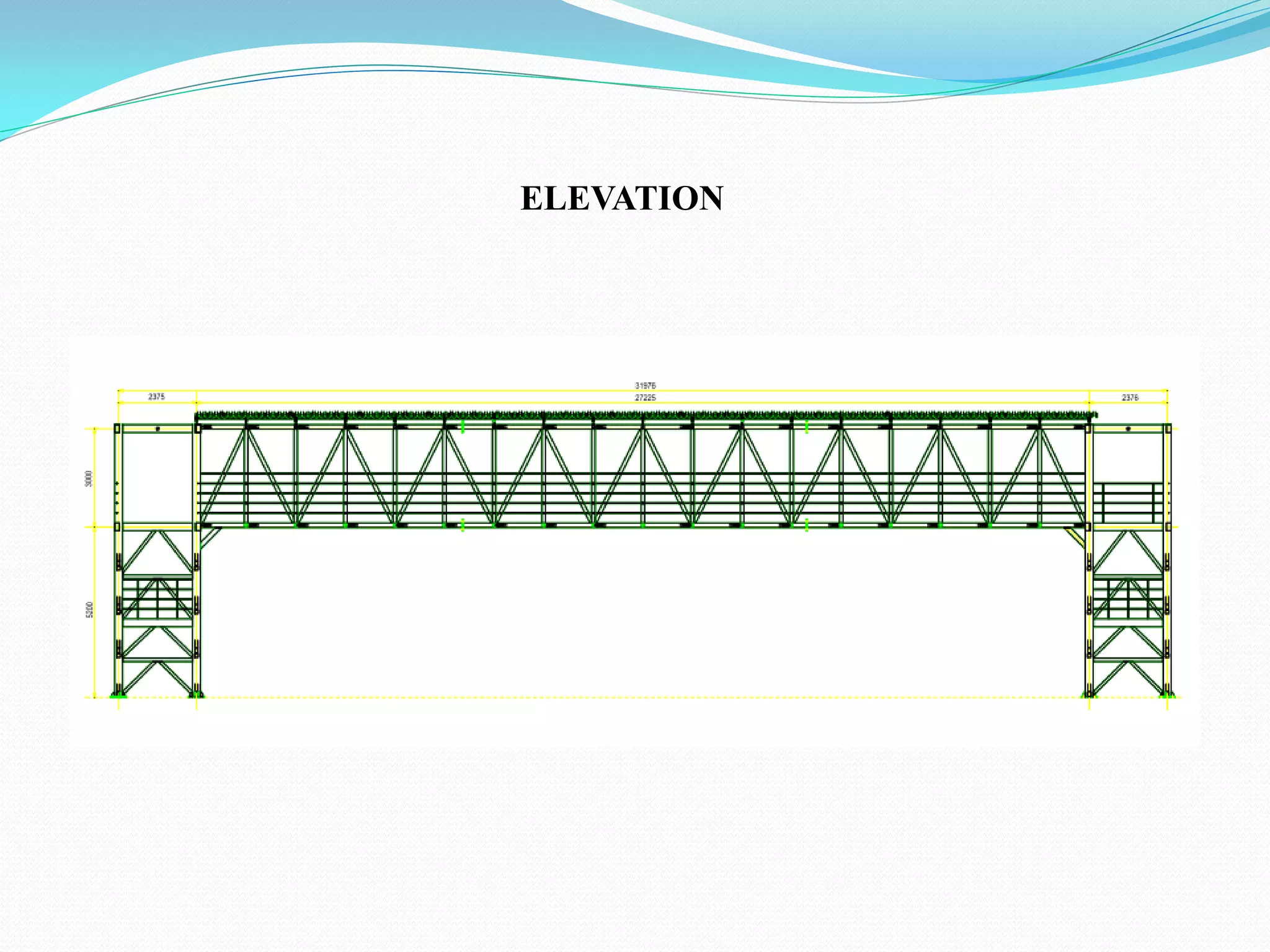

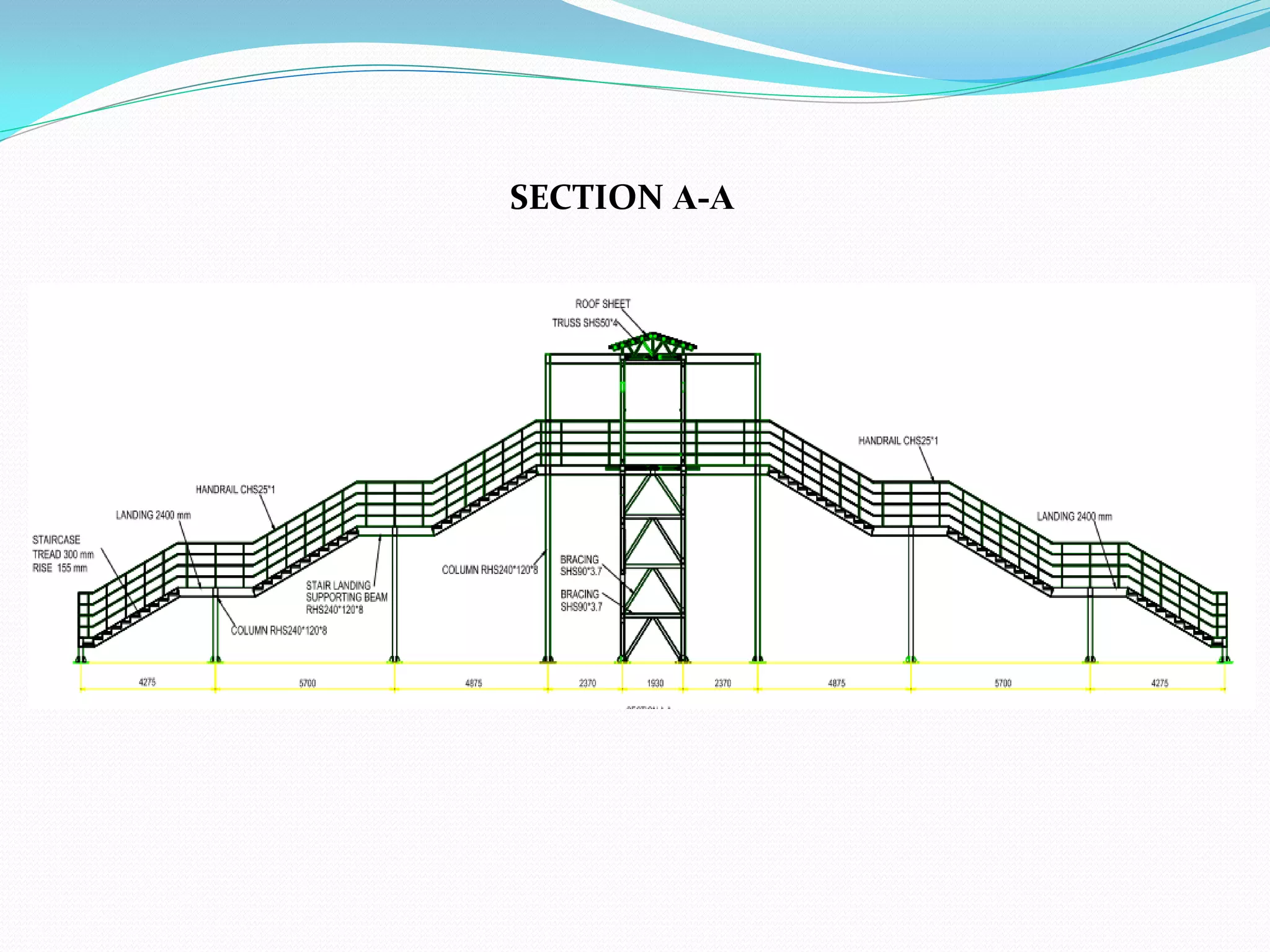

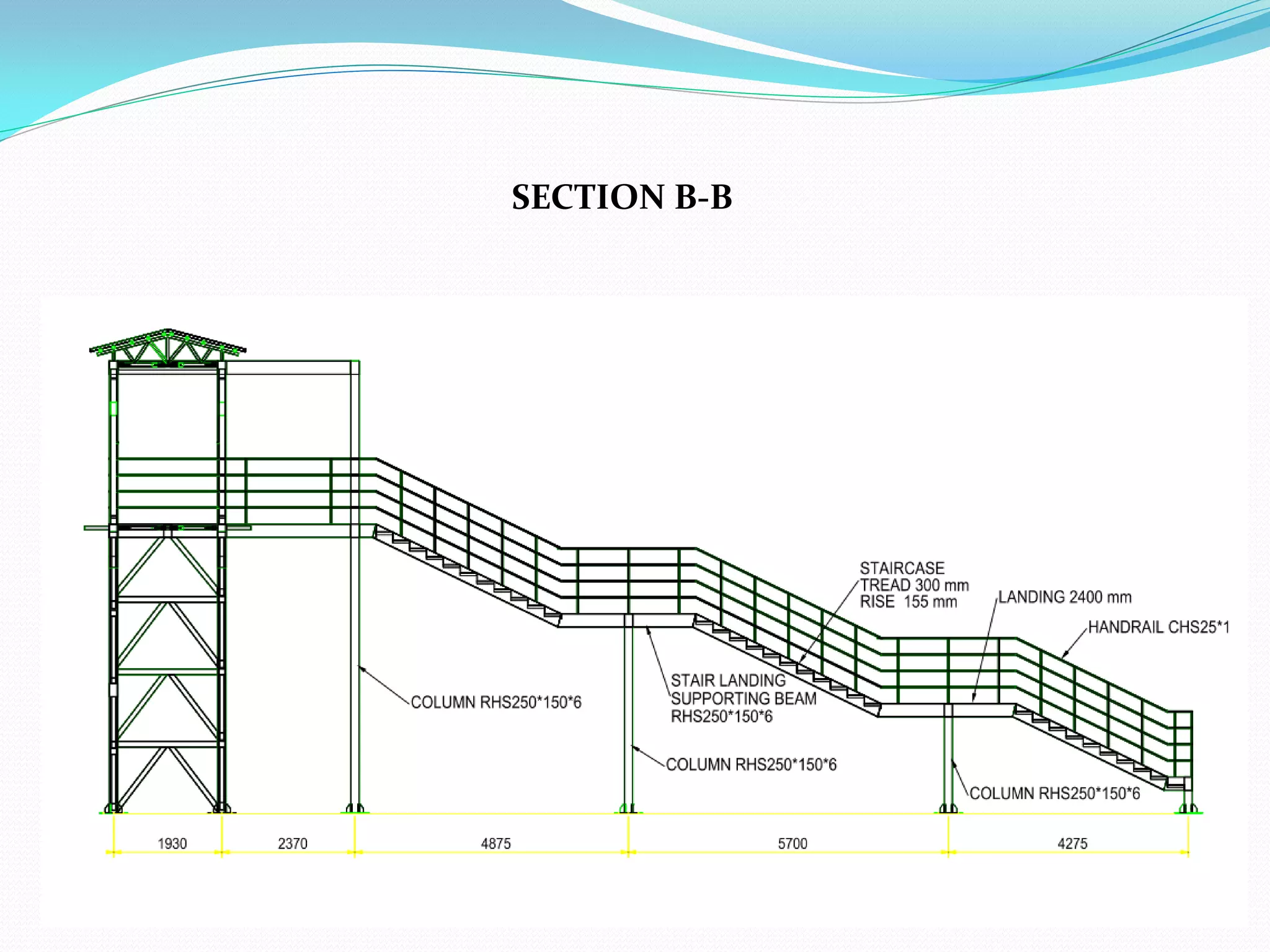

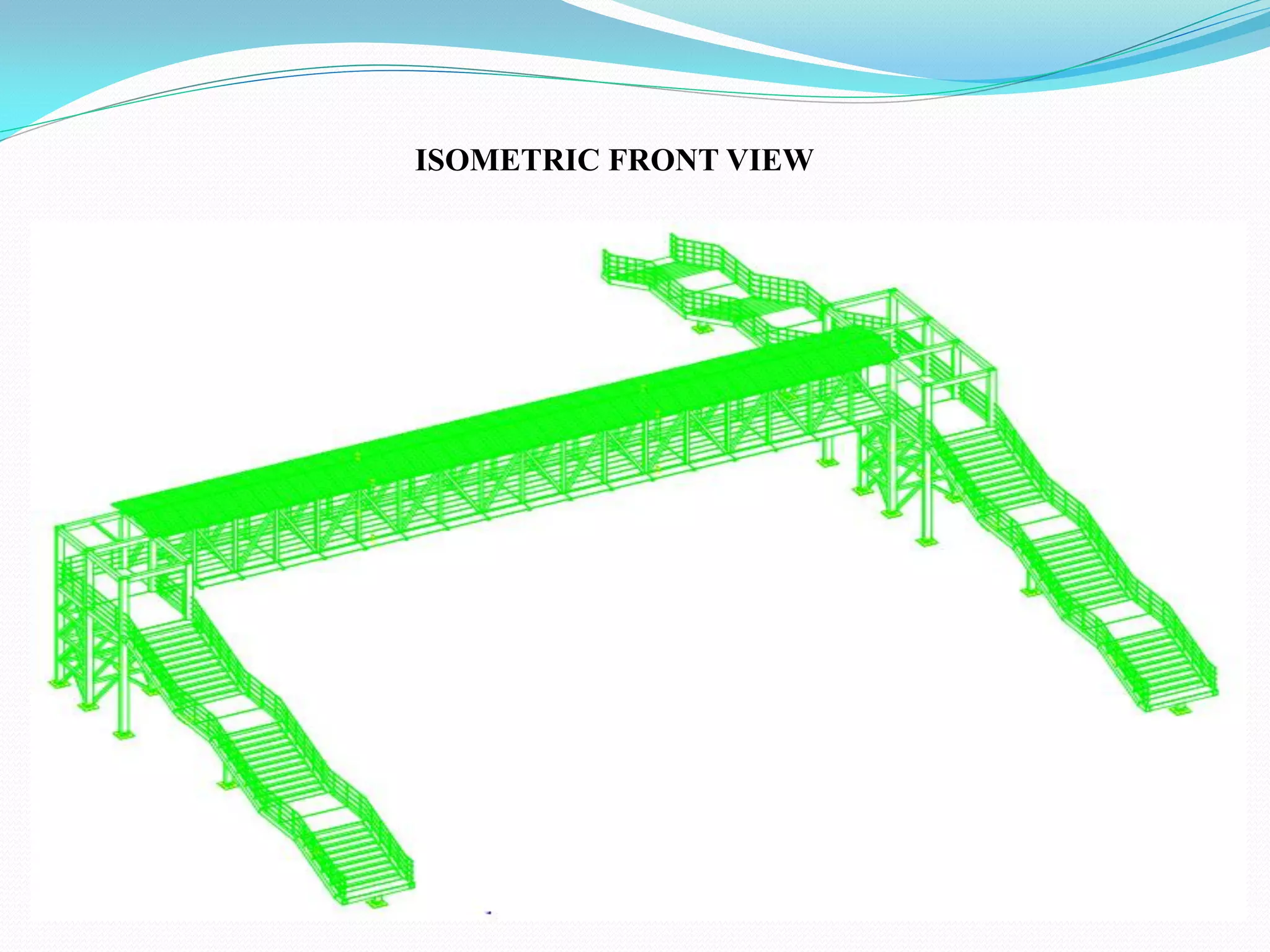

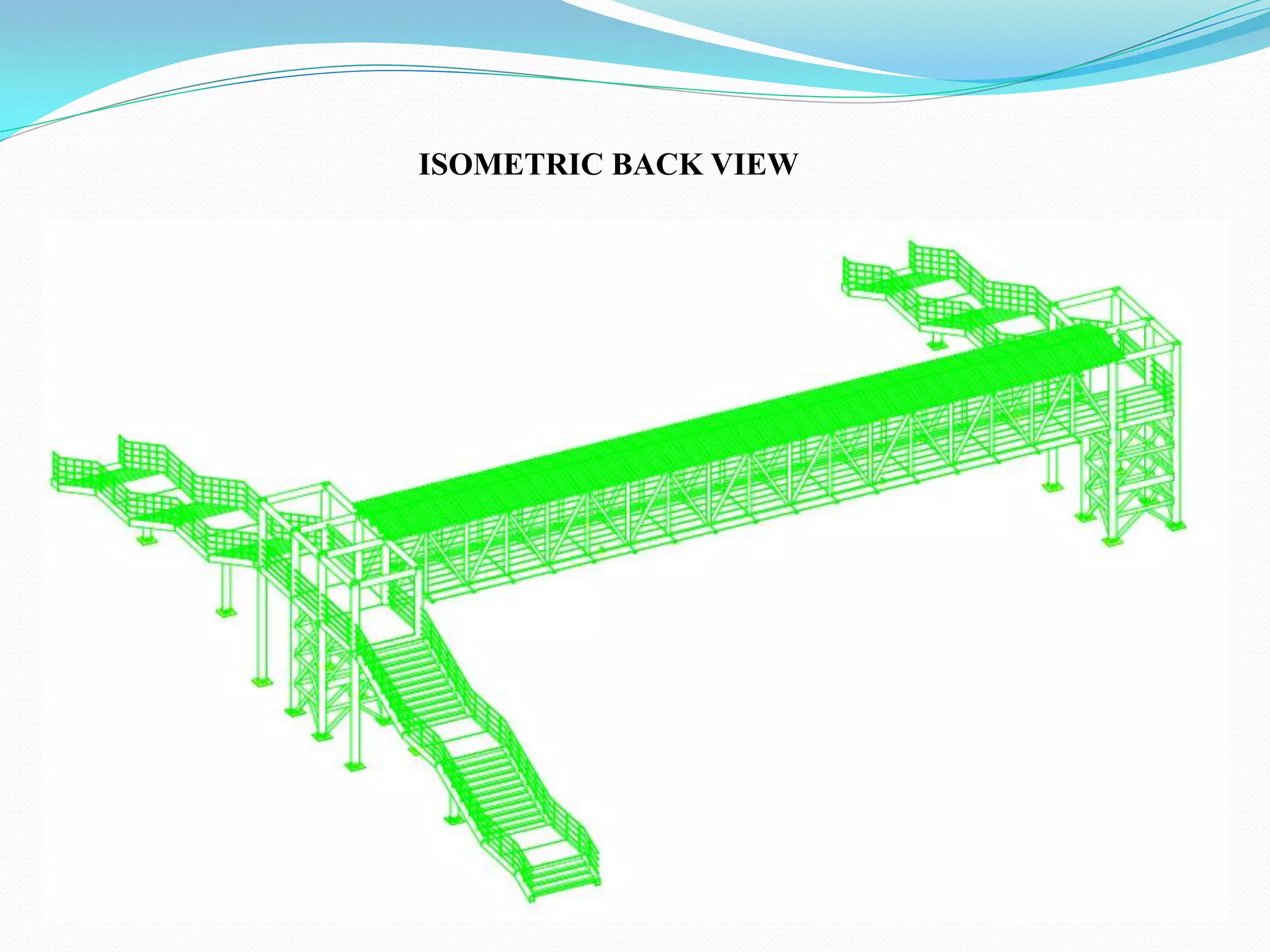

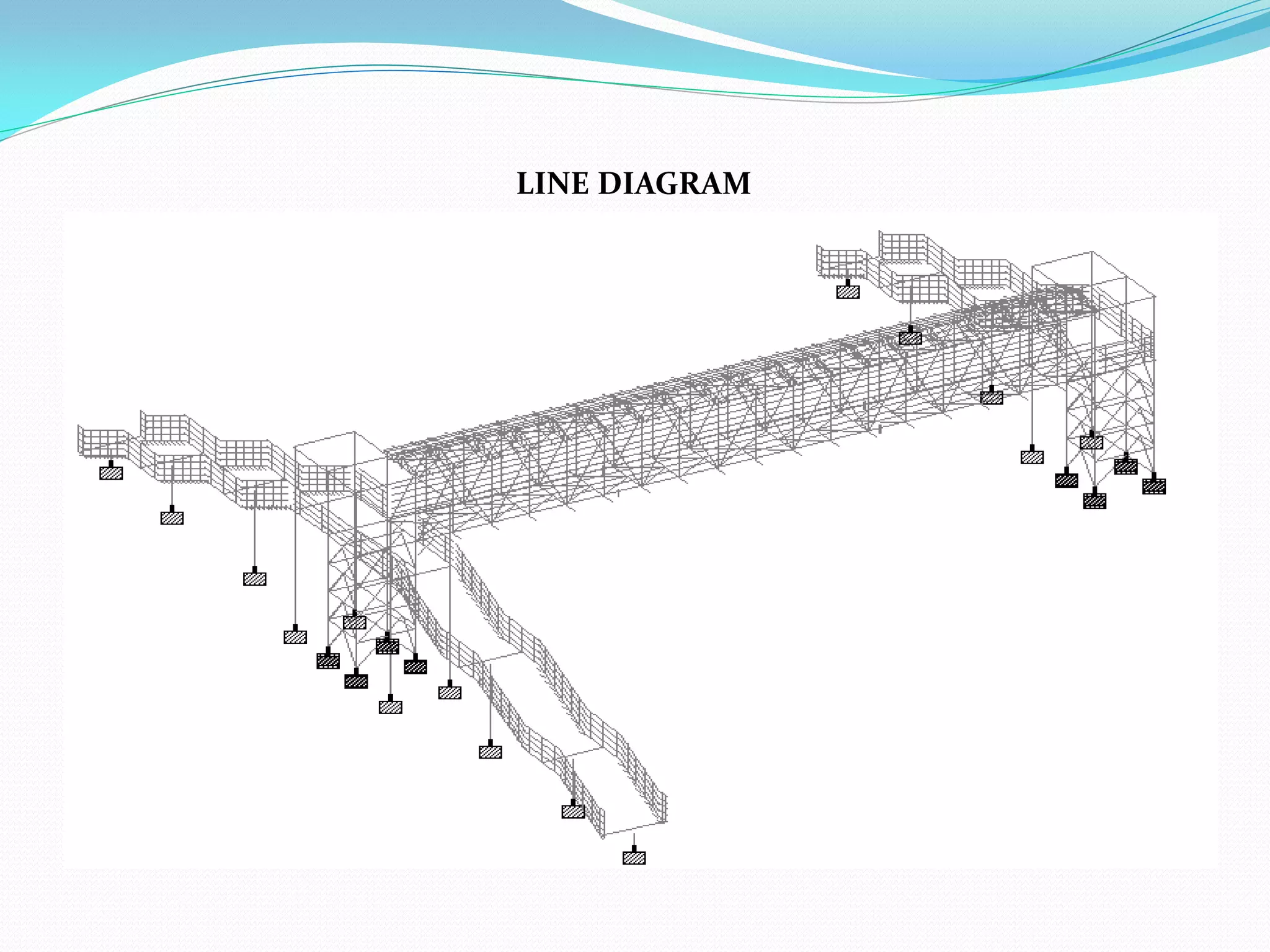

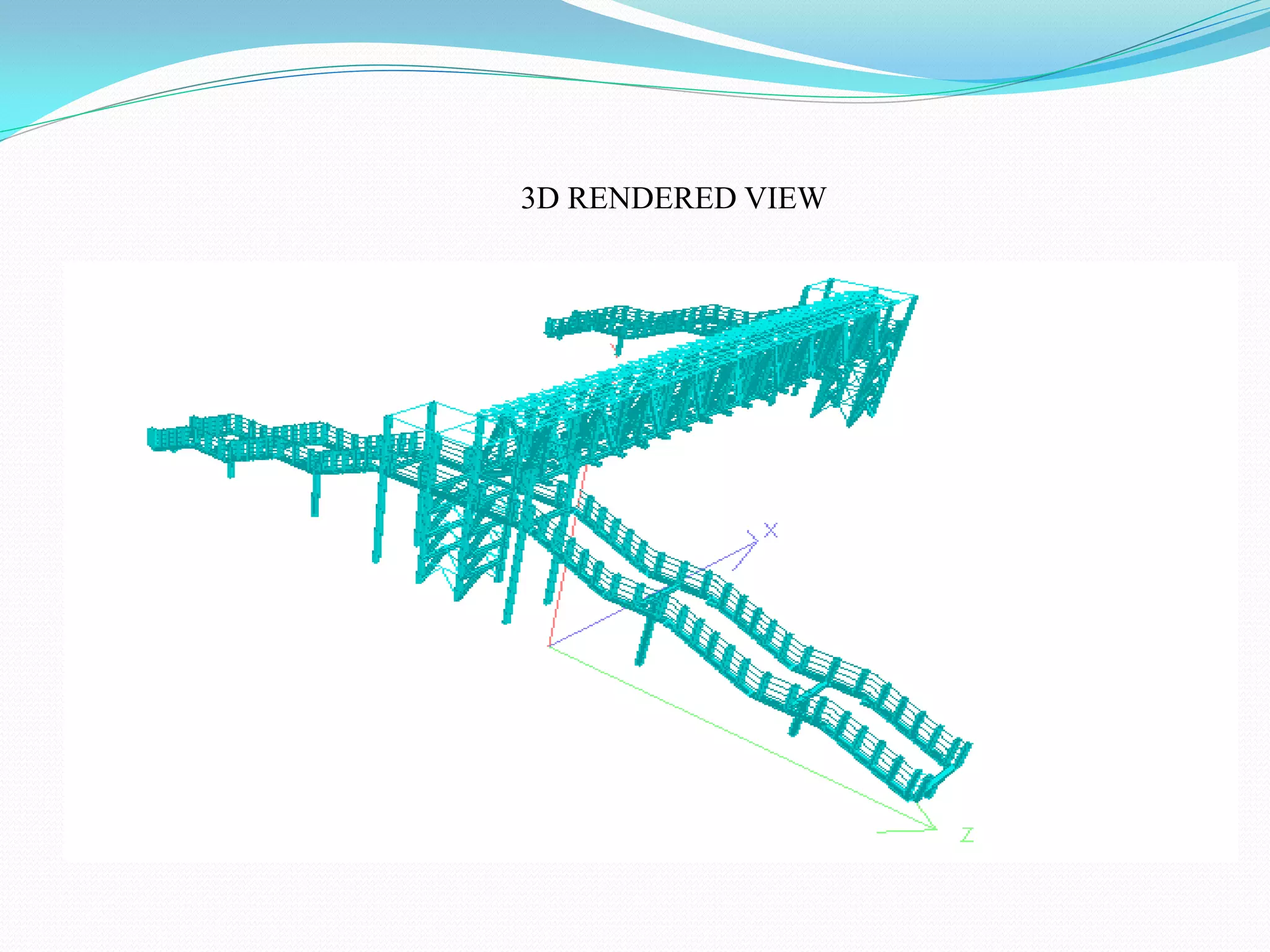

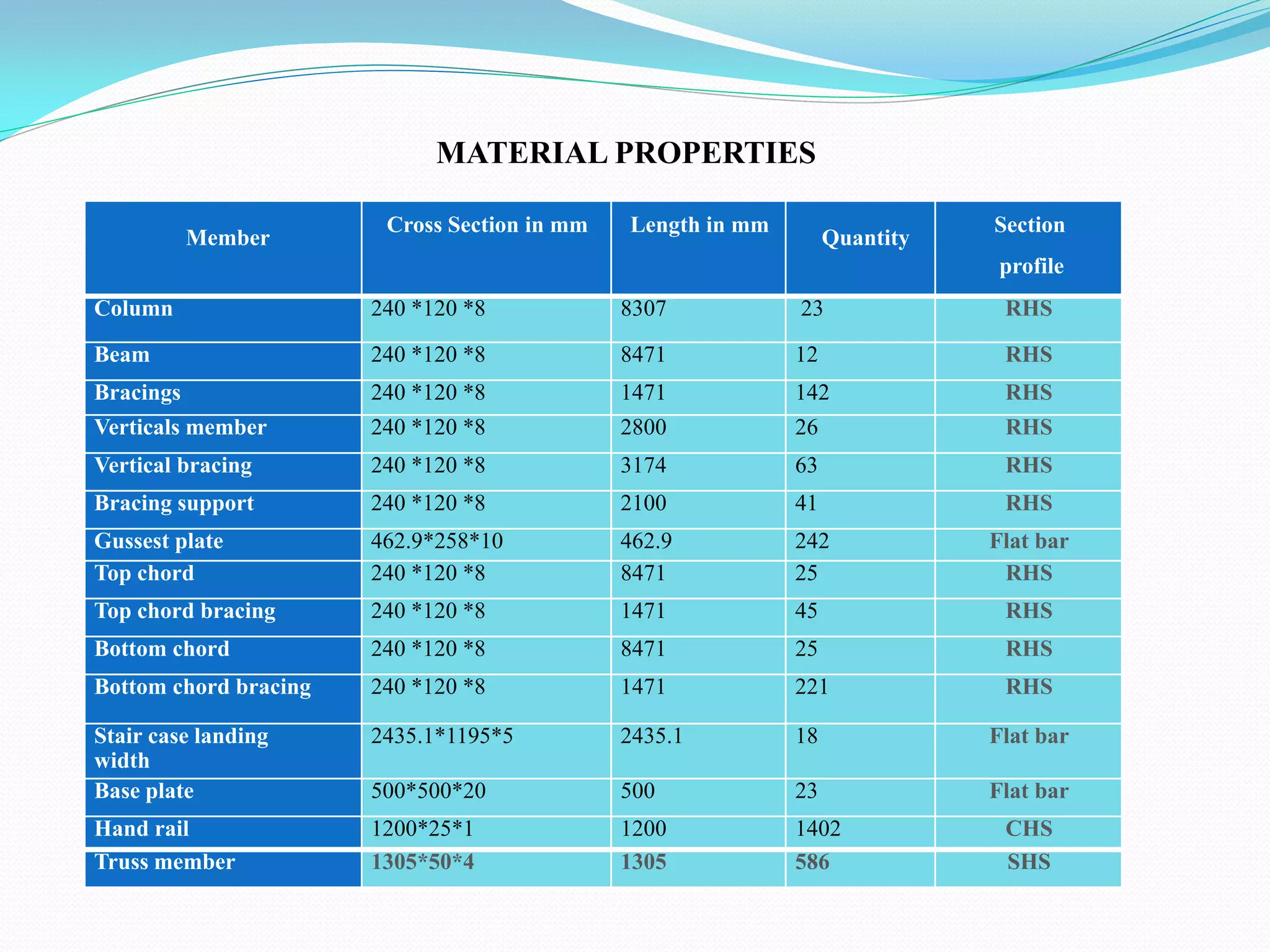

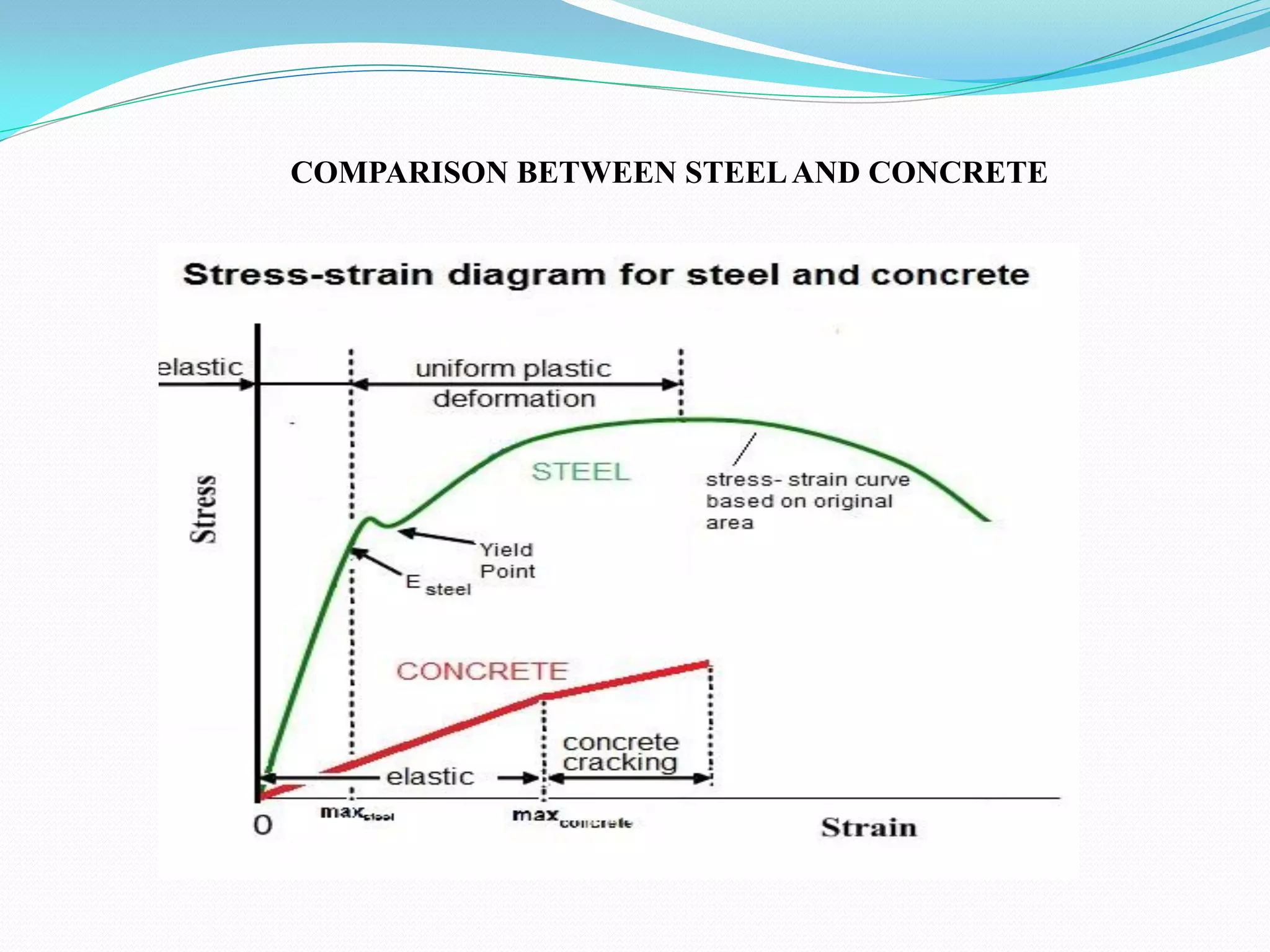

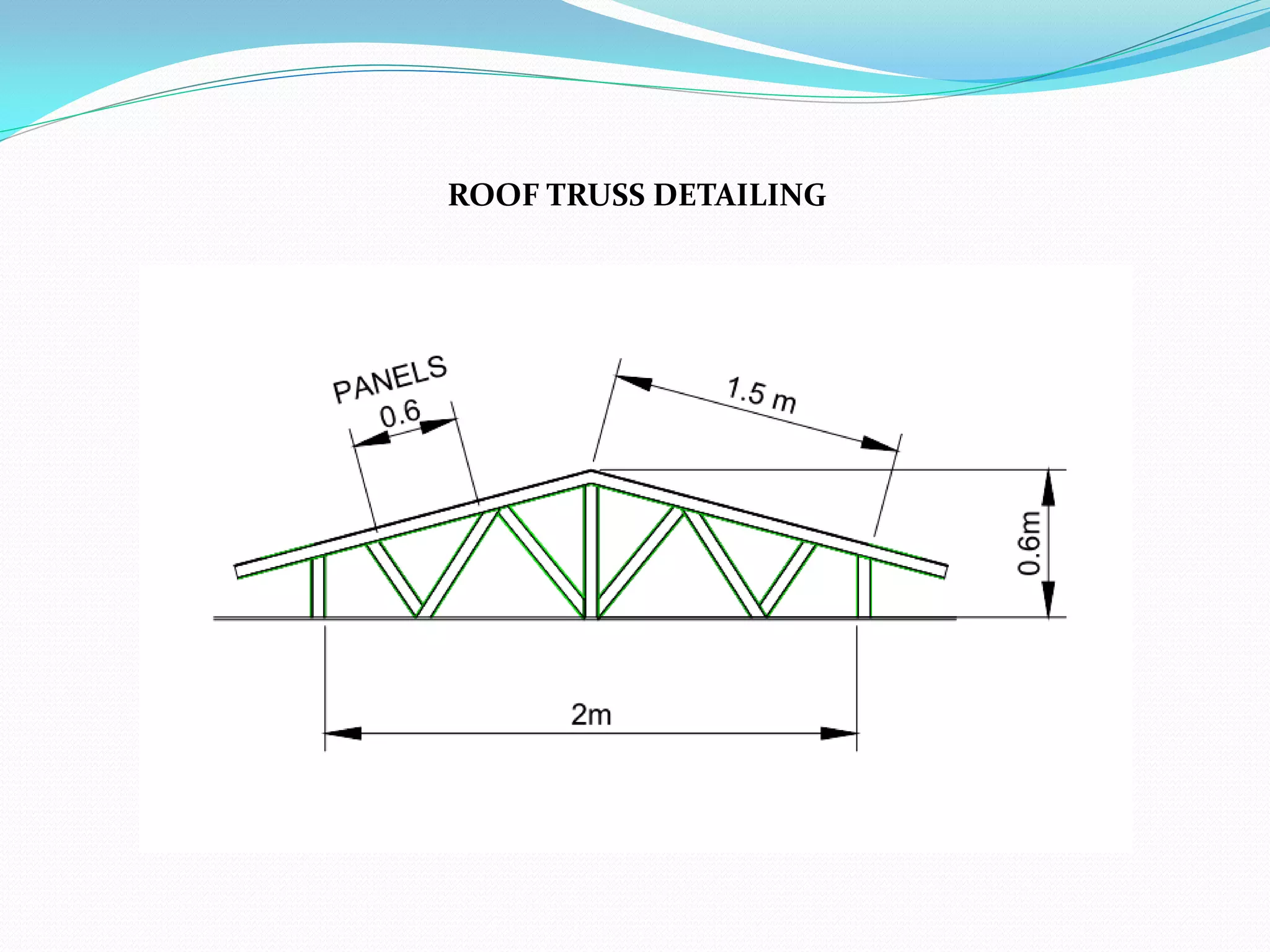

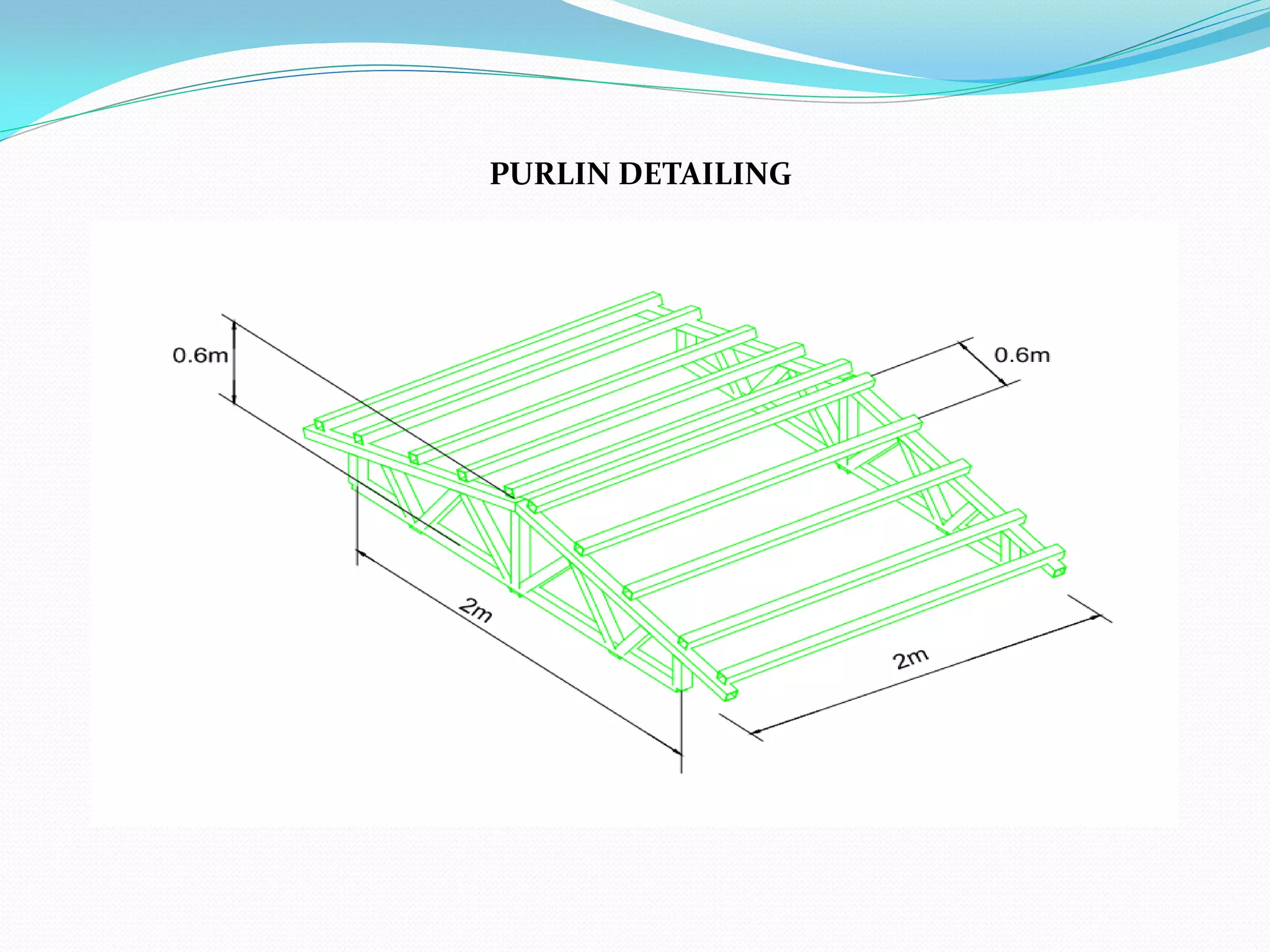

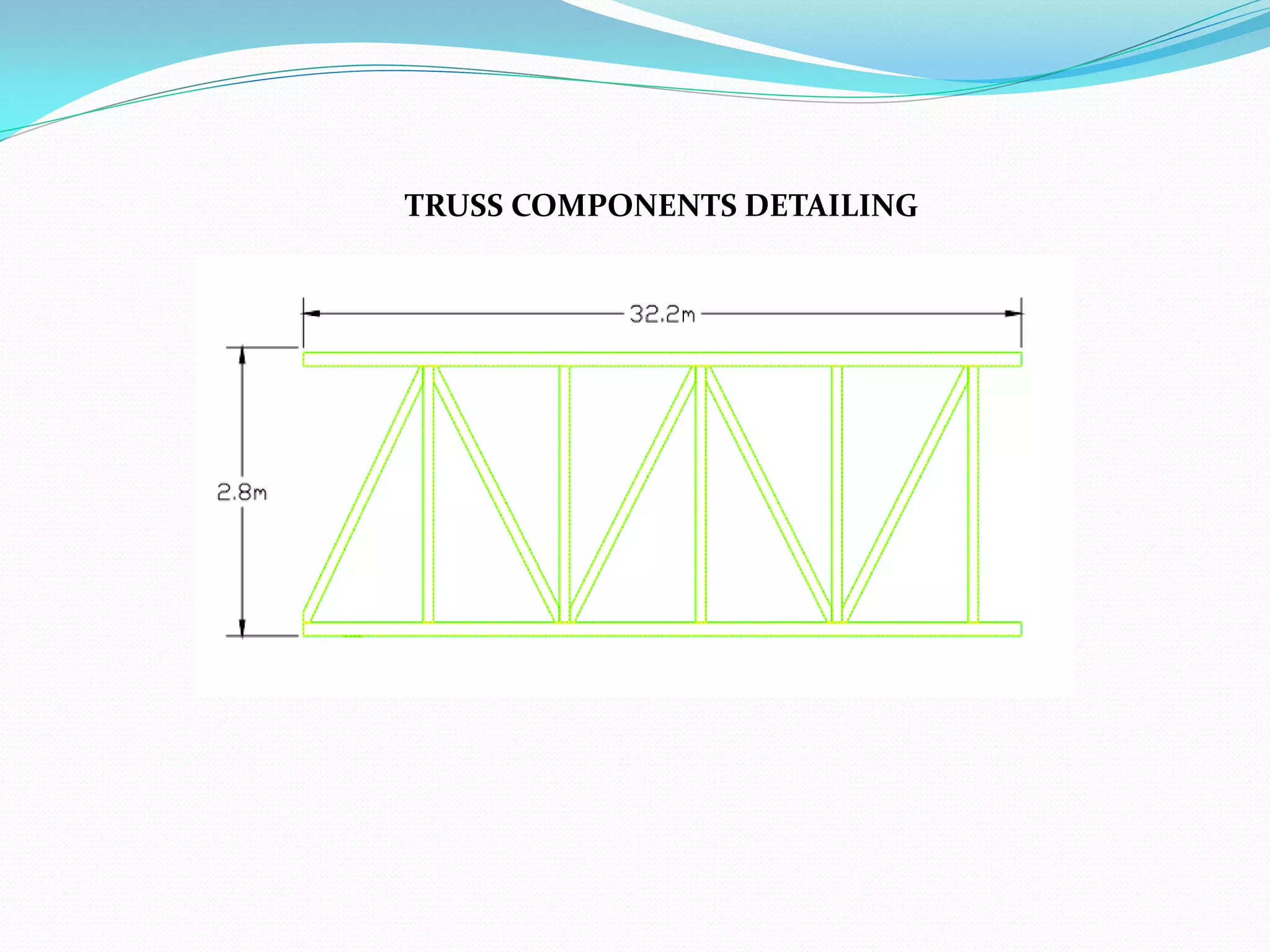

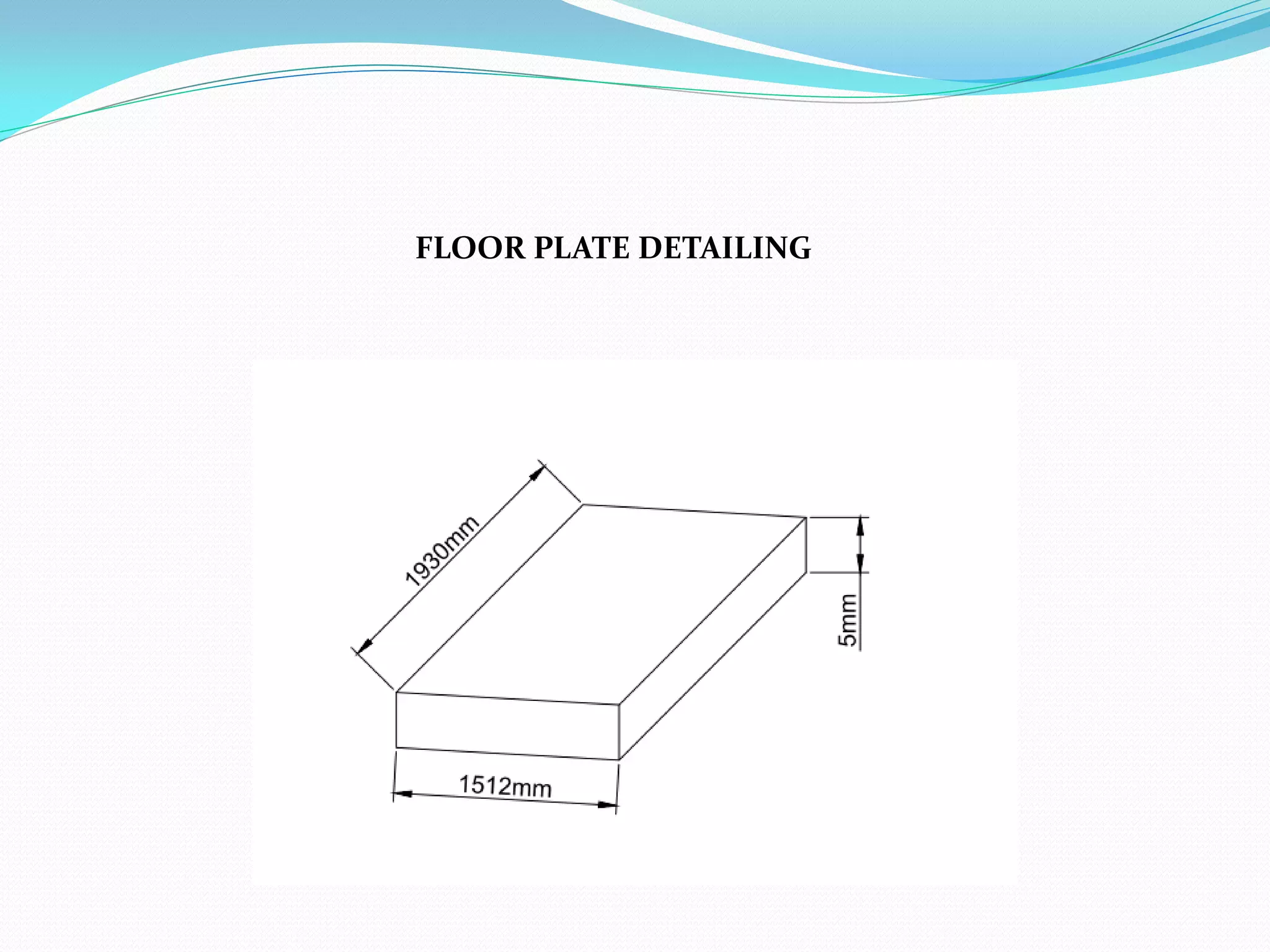

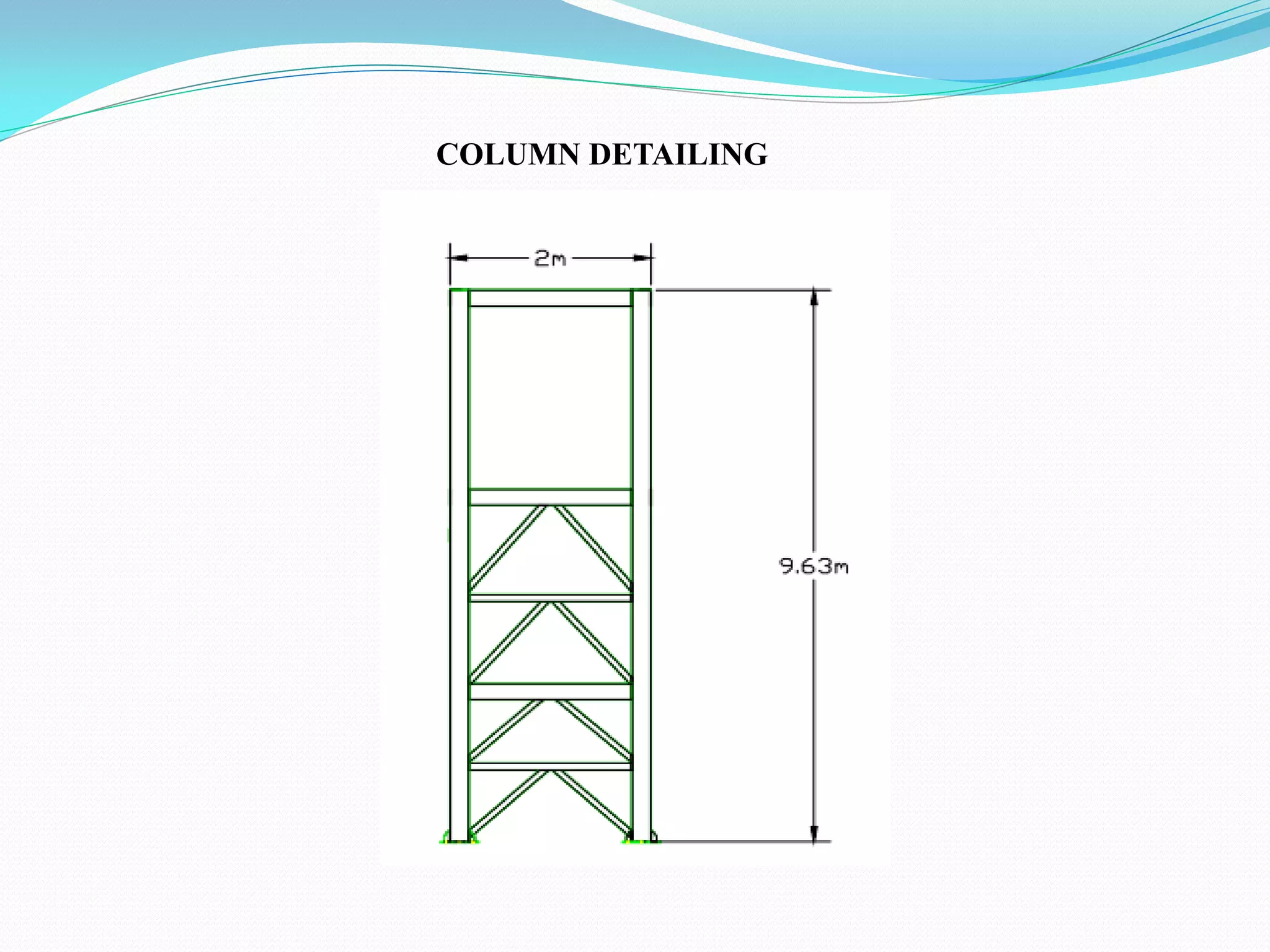

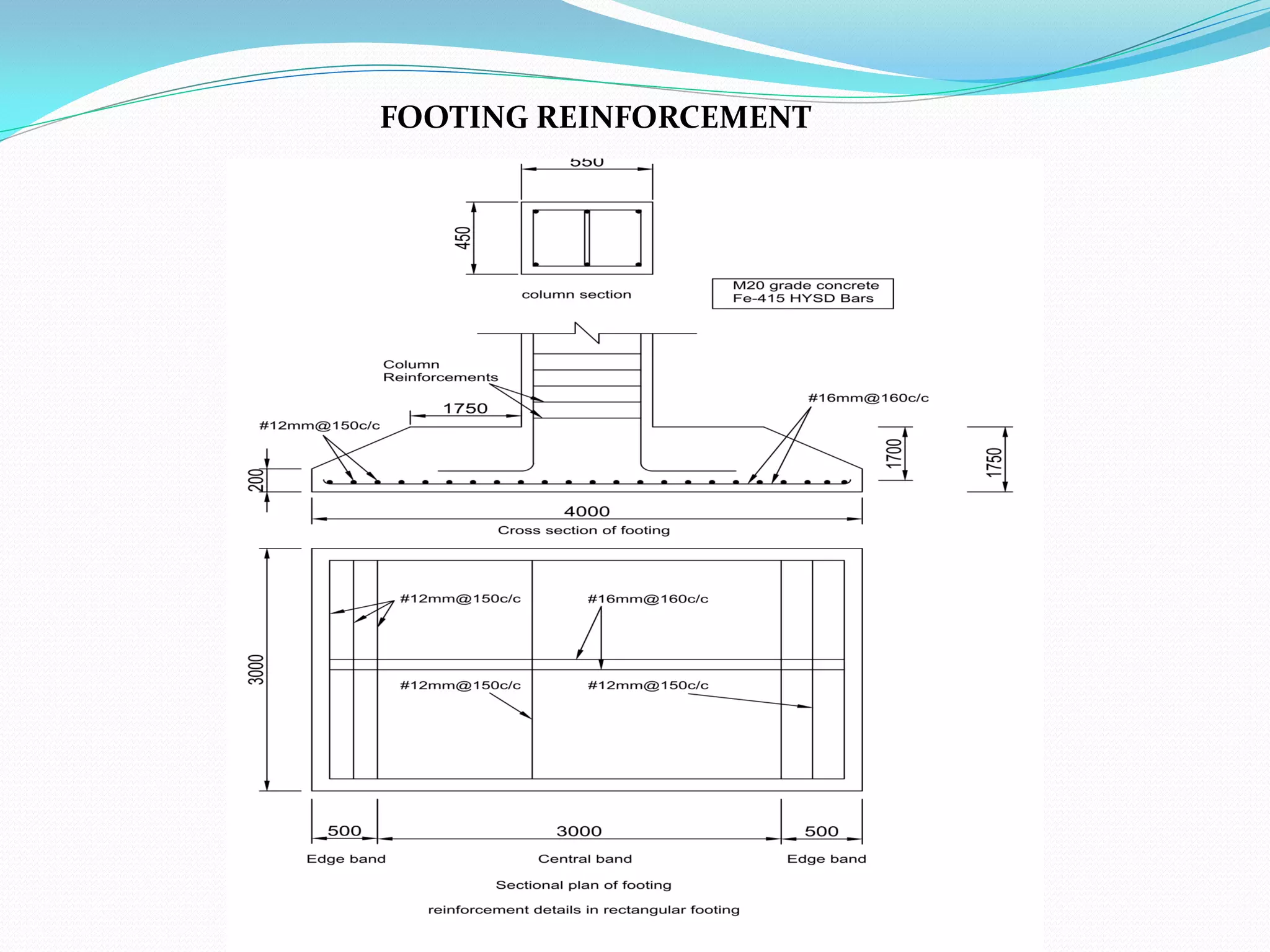

The document describes the analysis and design of a steel truss footbridge with an isolated foundation. It discusses modeling the superstructure in STAAD PRO and Tekla Structure software. The bridge is a 9.63m high steel structure. Methodology includes drafting plans in AutoCAD, modeling in Tekla Structure, analysis in STAAD PRO, material properties, design of truss components, fabrication of steel, and conclusion. A modified queen post steel truss is analyzed and designed to be economical, safe, and easily assembled for pedestrian use.