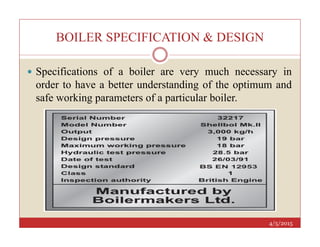

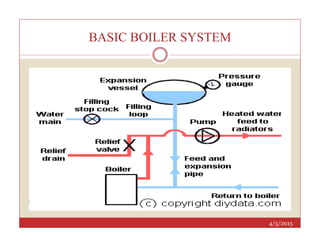

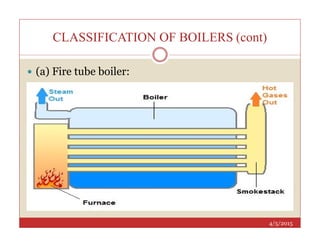

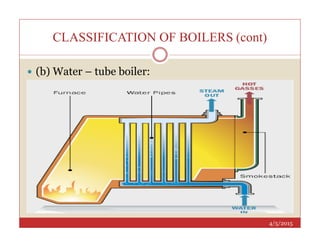

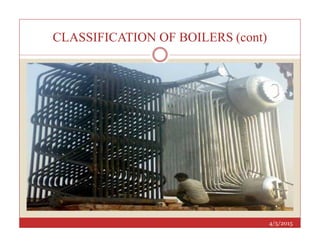

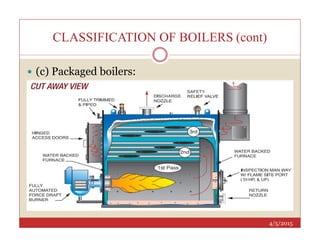

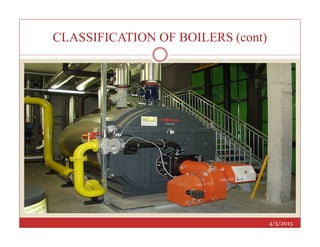

This document discusses different types of boilers. It begins with an introduction to boilers, their history, and examples of common boilers. It then covers boiler specifications and design considerations. Next, it discusses the Indian Boiler Regulation Act and its purpose. The document outlines the basic components of a boiler system and classifications of boilers including fire-tube, water-tube, and packaged boilers. It provides details on each type of boiler design. In closing, it lists references used in the document.