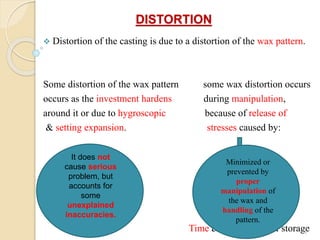

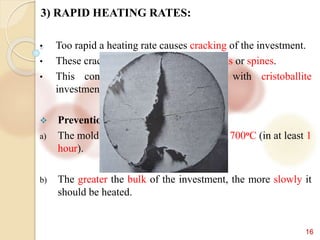

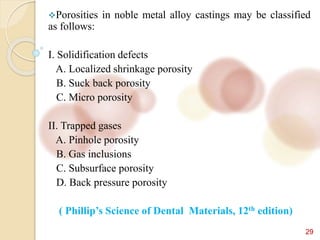

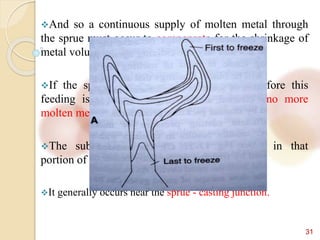

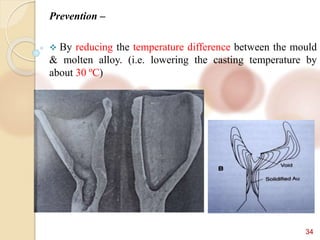

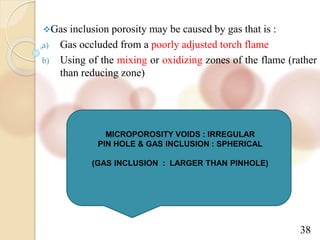

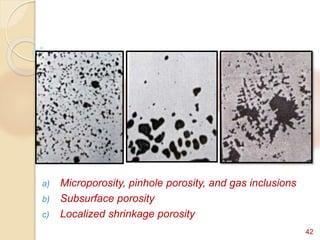

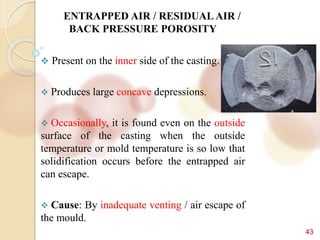

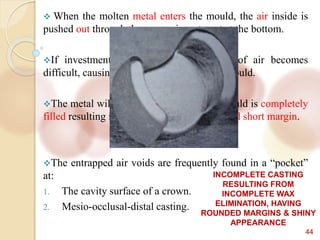

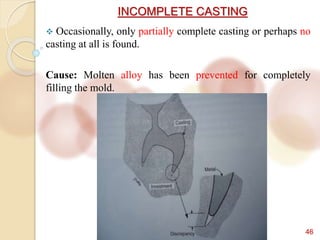

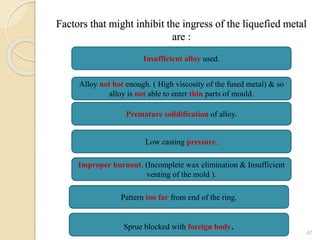

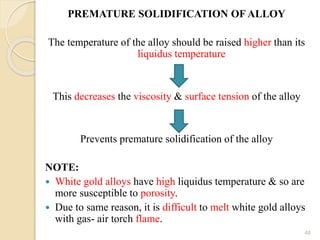

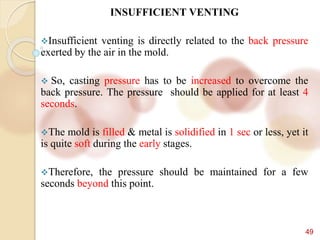

The document discusses various casting defects that can occur in dental castings including distortion, surface roughness, porosity, incomplete casting, and discoloration. It provides detailed explanations of different types of porosity defects such as localized shrinkage porosity, microporosity, pinhole porosity, gas inclusions, subsurface porosity, and back pressure porosity. Causes and methods for prevention of each type of defect are described. Surface roughness can result from factors like air bubbles in the wax pattern, water films, temperature variations during casting, foreign bodies in the mold, and composition or application of the investment material.