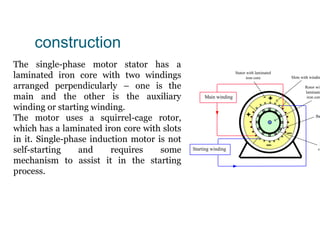

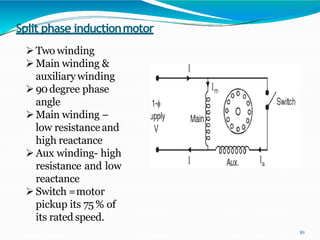

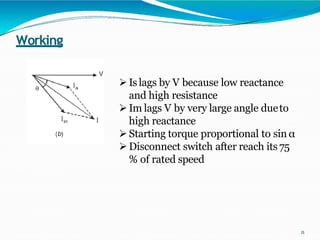

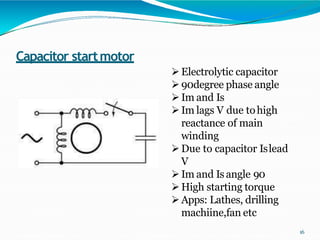

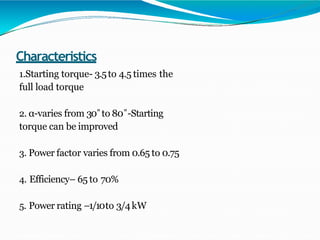

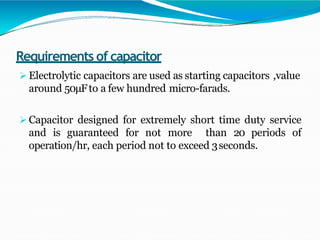

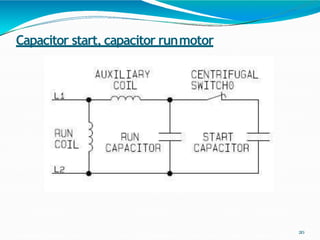

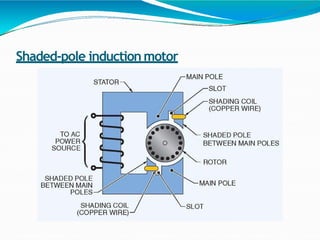

The single-phase induction motor uses two windings arranged perpendicularly on an iron core stator - a main winding and an auxiliary starting winding. It requires a mechanism to generate a rotating magnetic field to start, such as a capacitor, resistance, or secondary winding with phase shift. Common starting methods are split-phase, capacitor-start, and shaded-pole. Split-phase uses an auxiliary winding with phase shift. Capacitor-start uses a capacitor in series with the auxiliary winding. Shaded-pole uses shaded bands to generate phase shift. Applications depend on starting torque requirements.