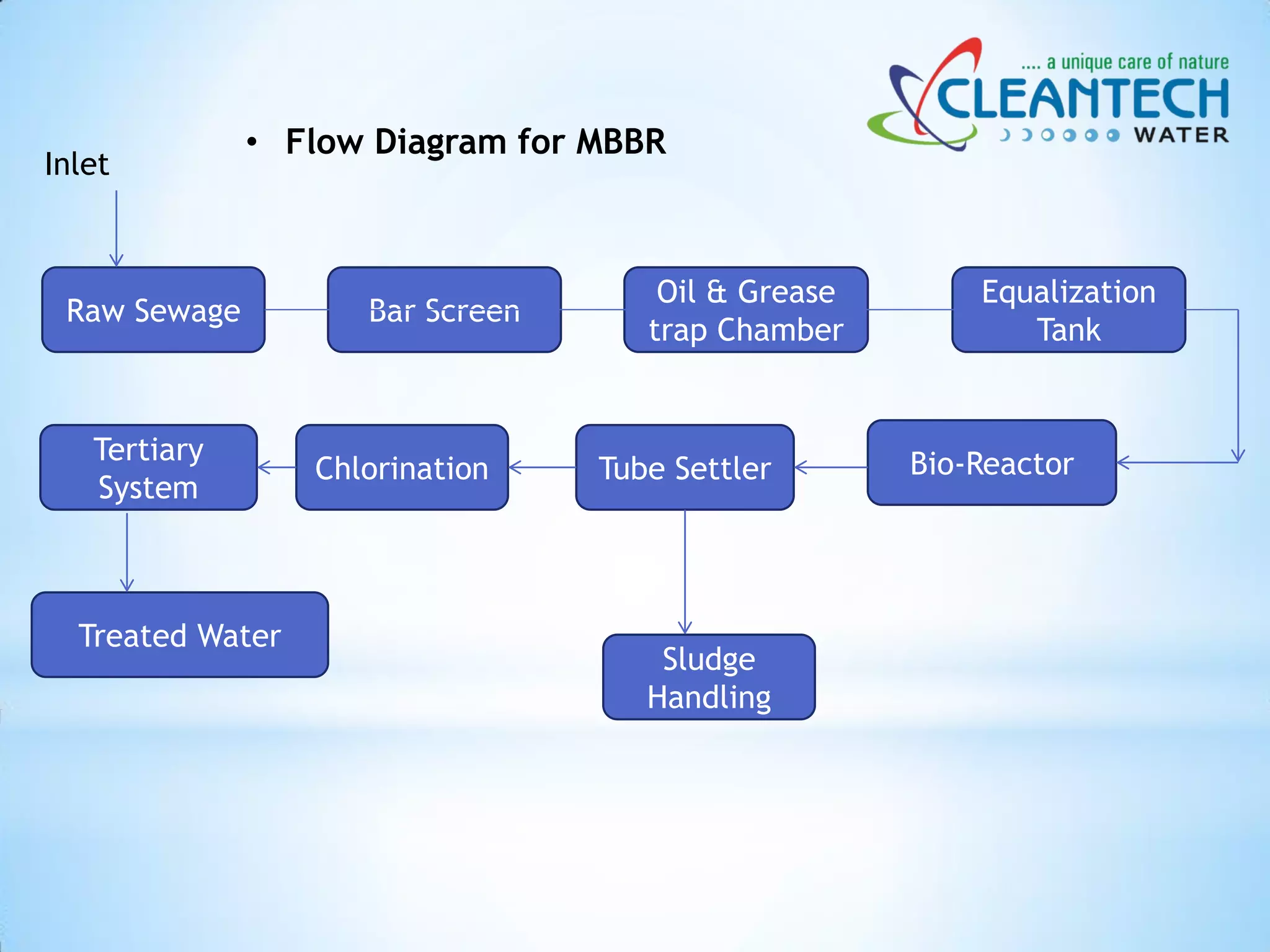

The document is a presentation on wastewater treatment by Vipul Chavda, covering various aspects such as pollutant types, treatment methods, and the importance of compliance. It discusses aerobic and anaerobic treatment processes along with different technologies like the Moving Bed Biofilm Reactor (MBBR) for efficient wastewater management. Key points include the environmental benefits, resource recovery, and the necessity for proper design and maintenance of treatment systems.