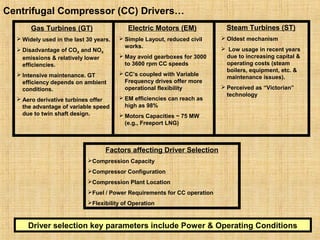

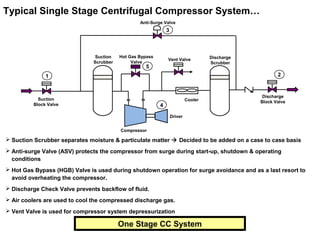

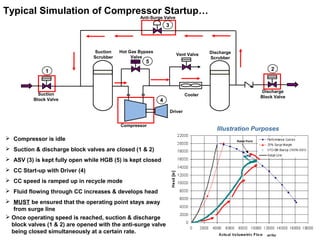

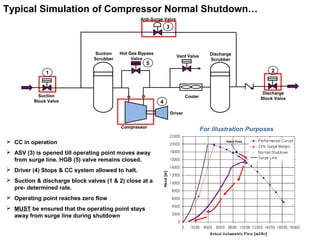

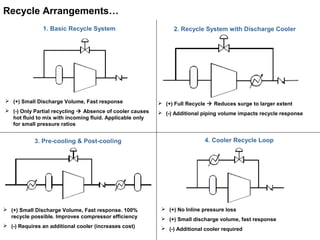

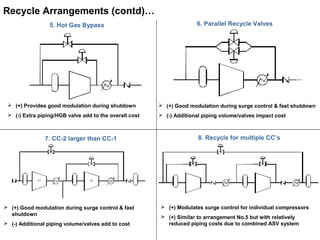

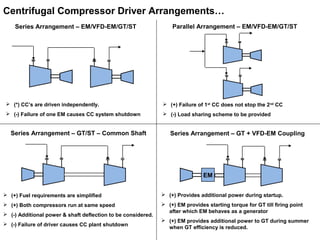

This document serves as a comprehensive beginner's guide to the design and simulation of centrifugal compressor systems, covering system characteristics, drivers, and operational scenarios including start-up and shutdown. It emphasizes the importance of maintaining operational points away from surge lines and discusses various driver options and anti-surge systems. Furthermore, it outlines factors to consider in system design, including power requirements, efficiency, and the robustness of the anti-surge mechanism.

![Centrifugal Compressor (CC) System Characteristics…

Compressor Maps dictate “behaviour” of the CC

CC Maps are a plot between Polytropic Head (or pressure ratio) vs. Volumetric Flow

Compressor to be operated always away from the surge line

Absorbed power is the least at the surge line

Range of CC operation is the enclosed region of the maps

beyond which guarantee is not provided by the manufacturer

Typically operating point is maintained within 10% to 12% of the

surge line. This can be increased on a case to case basis.

−

×

−

×

××

=

−

1

1

1

n

n

in

out

gas

inavg

p

P

P

n

n

MW

TRZ

H

ratioessure

P

P

KetemperaturInletT

onentPolytropicn

kgmolkgweightmolecularGasMW

factorilitycompressibAverageZ

KkgmolkJtConsGasR

kgFlowrateMassQ

kgkJHeadPolytropicH

in

out

in

gas

avg

in

p

Pr

,

exp

/,

/314.8,tan

sec/,

/,

=

=

=

=

=

=

=

=

inp QHPower ×=

Compressor to be operated within surge limits

Speed 4

Stone Wall

RegionSpeed 1

Speed 2

Speed 3

Actual Volumetric Flow [m3

/hr]

PolytropicHead[morkJ/kg]

Surge Line Surge Margin

Actual Volumetric Flow [m3

/hr]

Efficiency[%]

Speed 1 Speed 4

Speed 2 Speed 3](https://image.slidesharecdn.com/compressorbasics-171218195307/85/Centrifugal-Compressor-System-Design-Simulation-3-320.jpg)