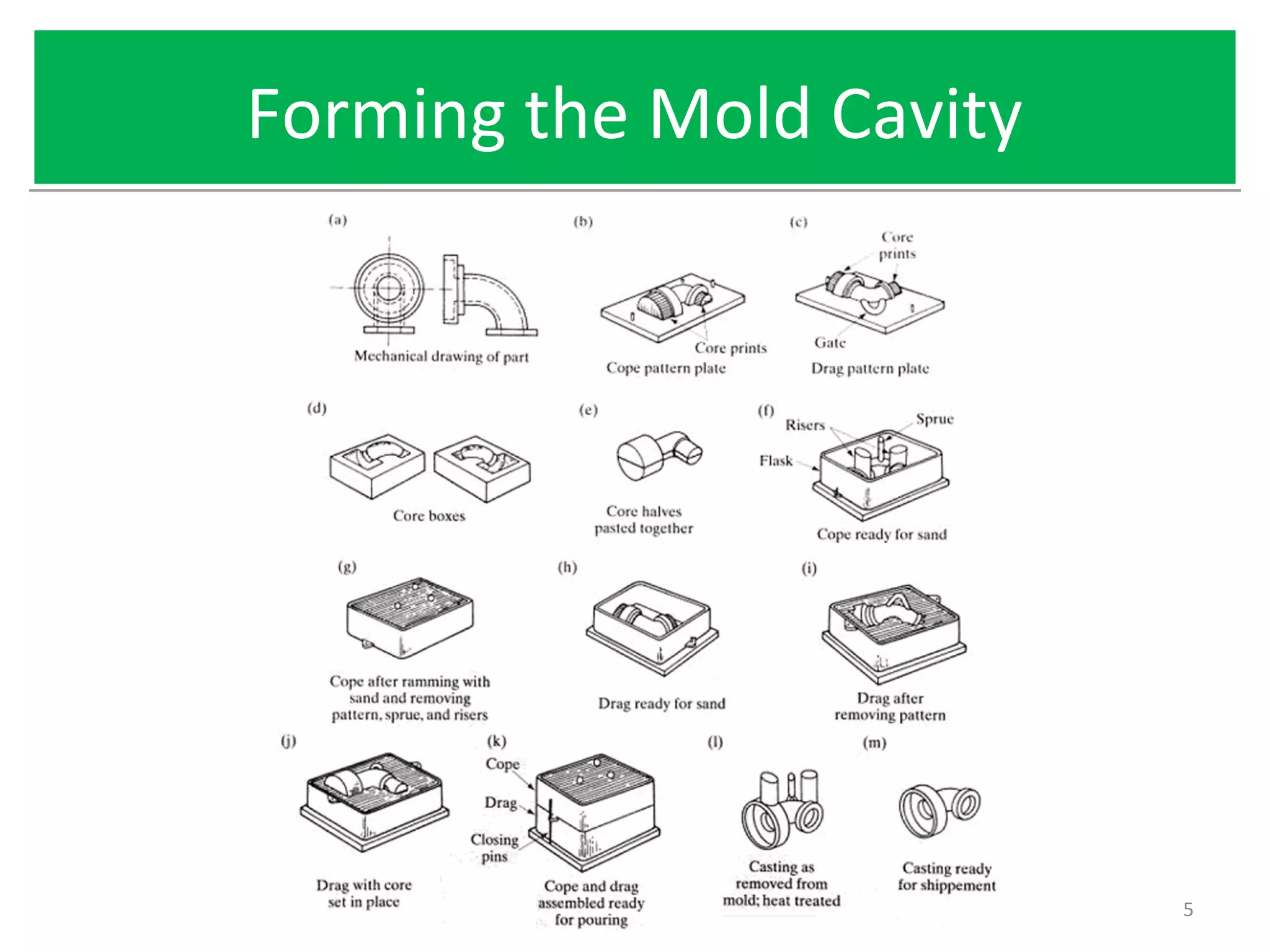

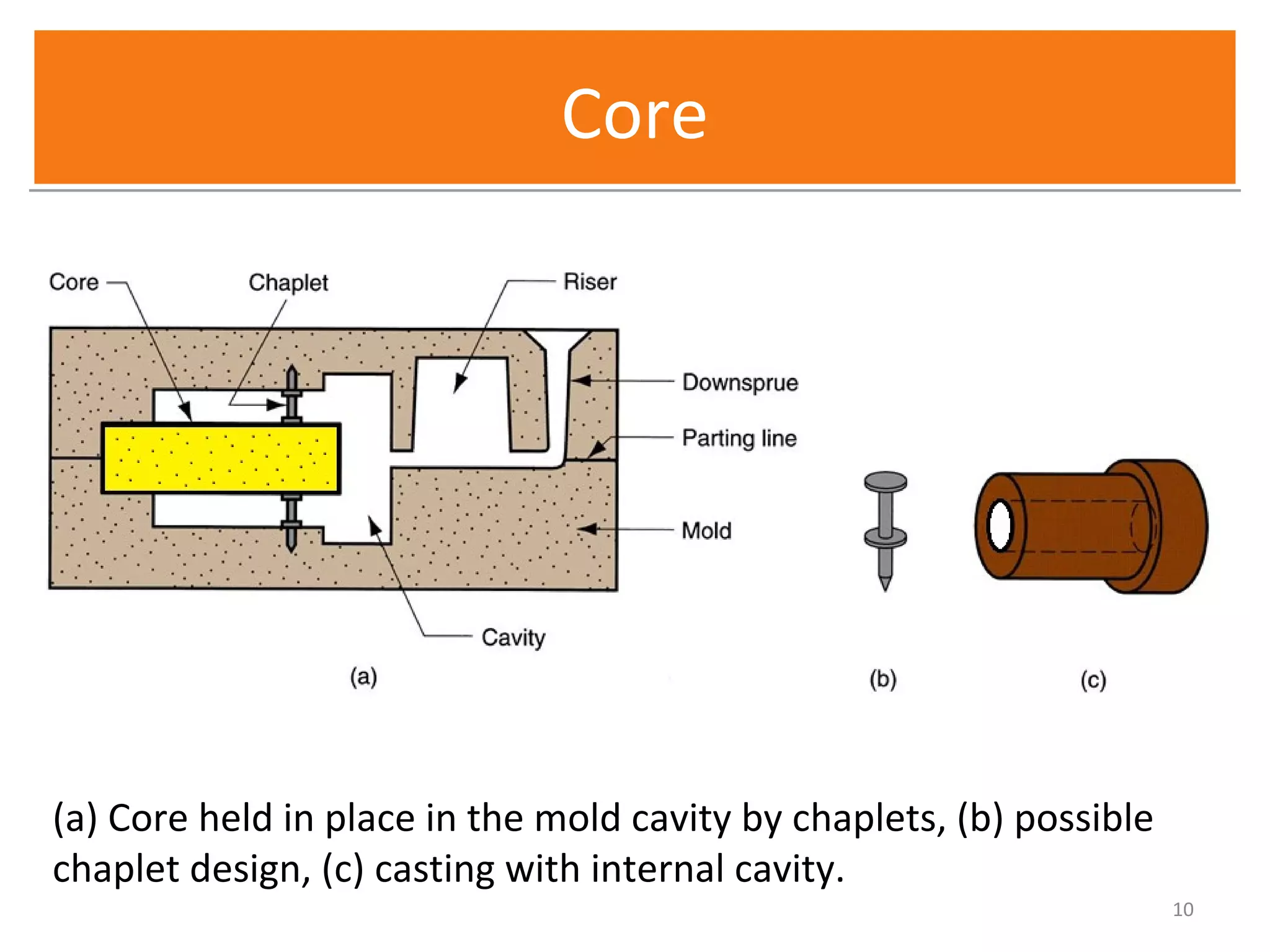

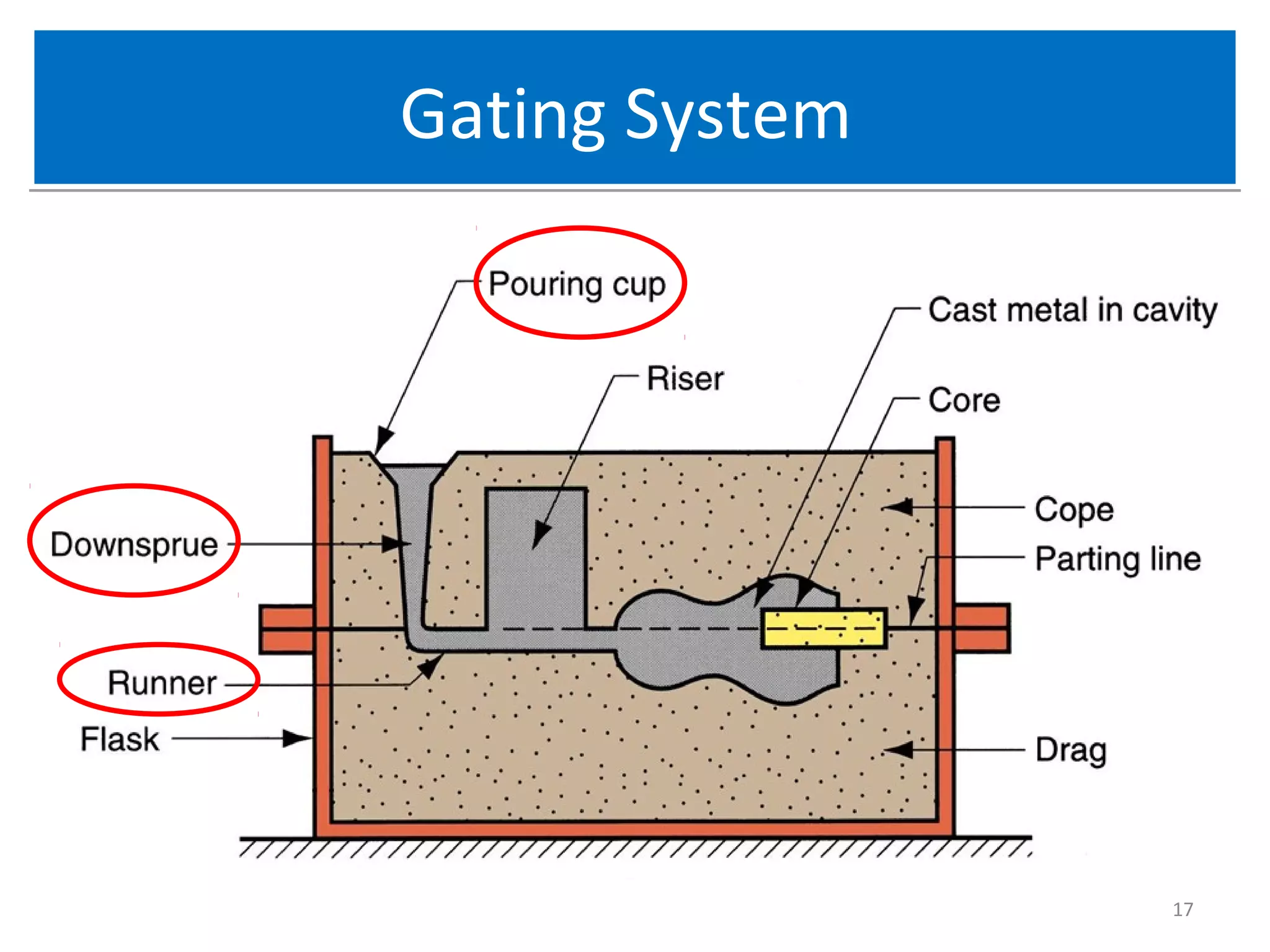

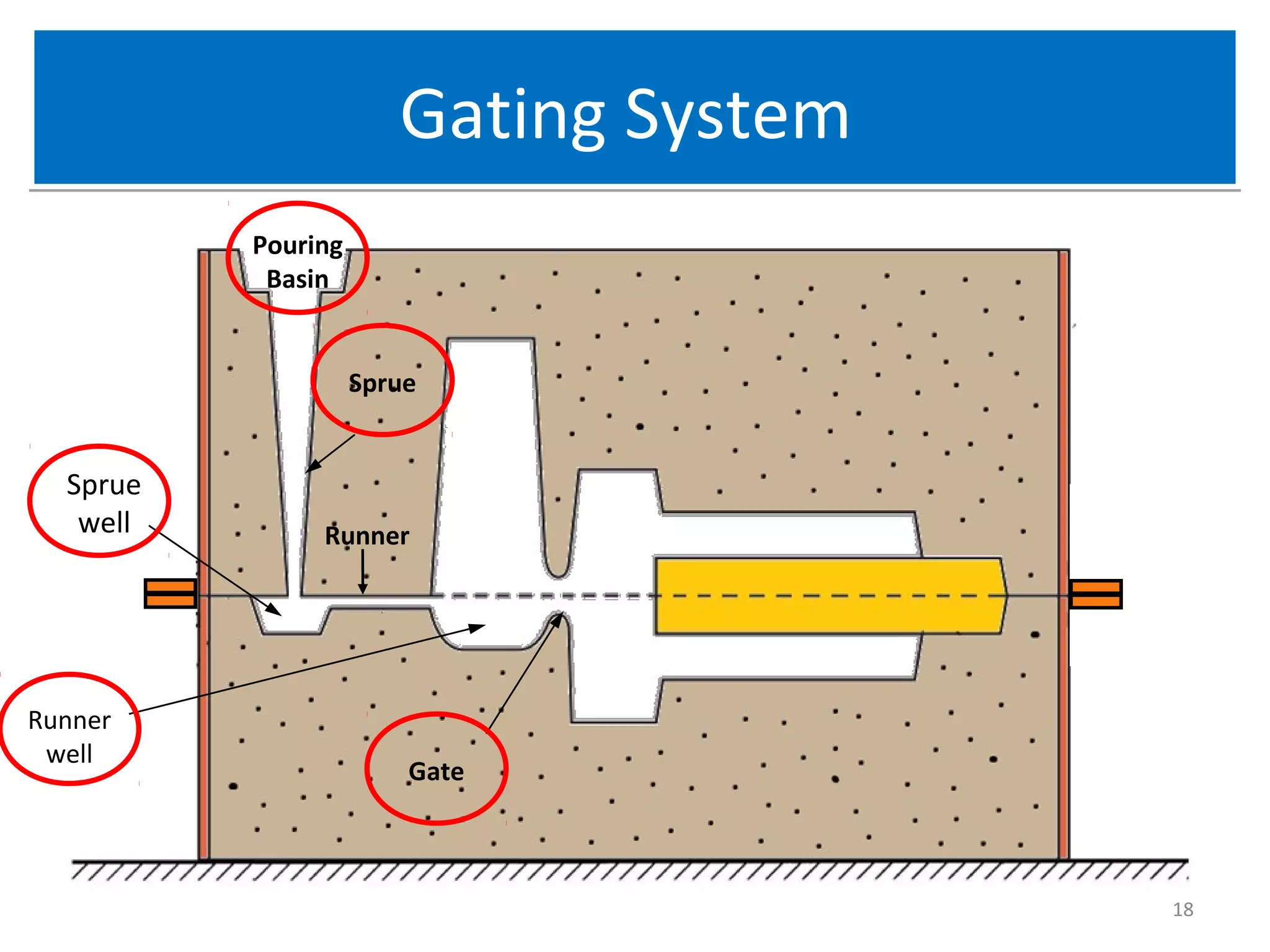

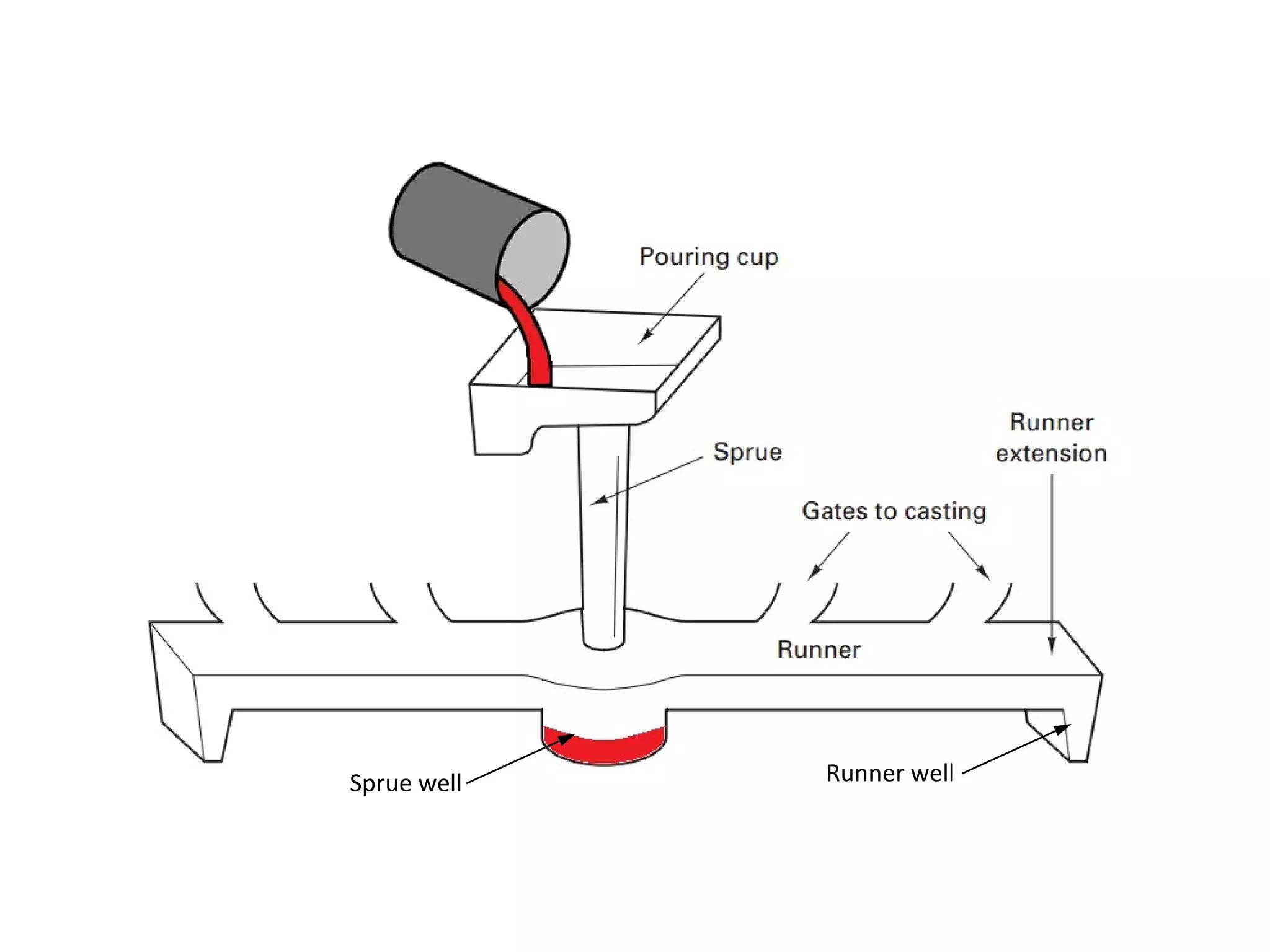

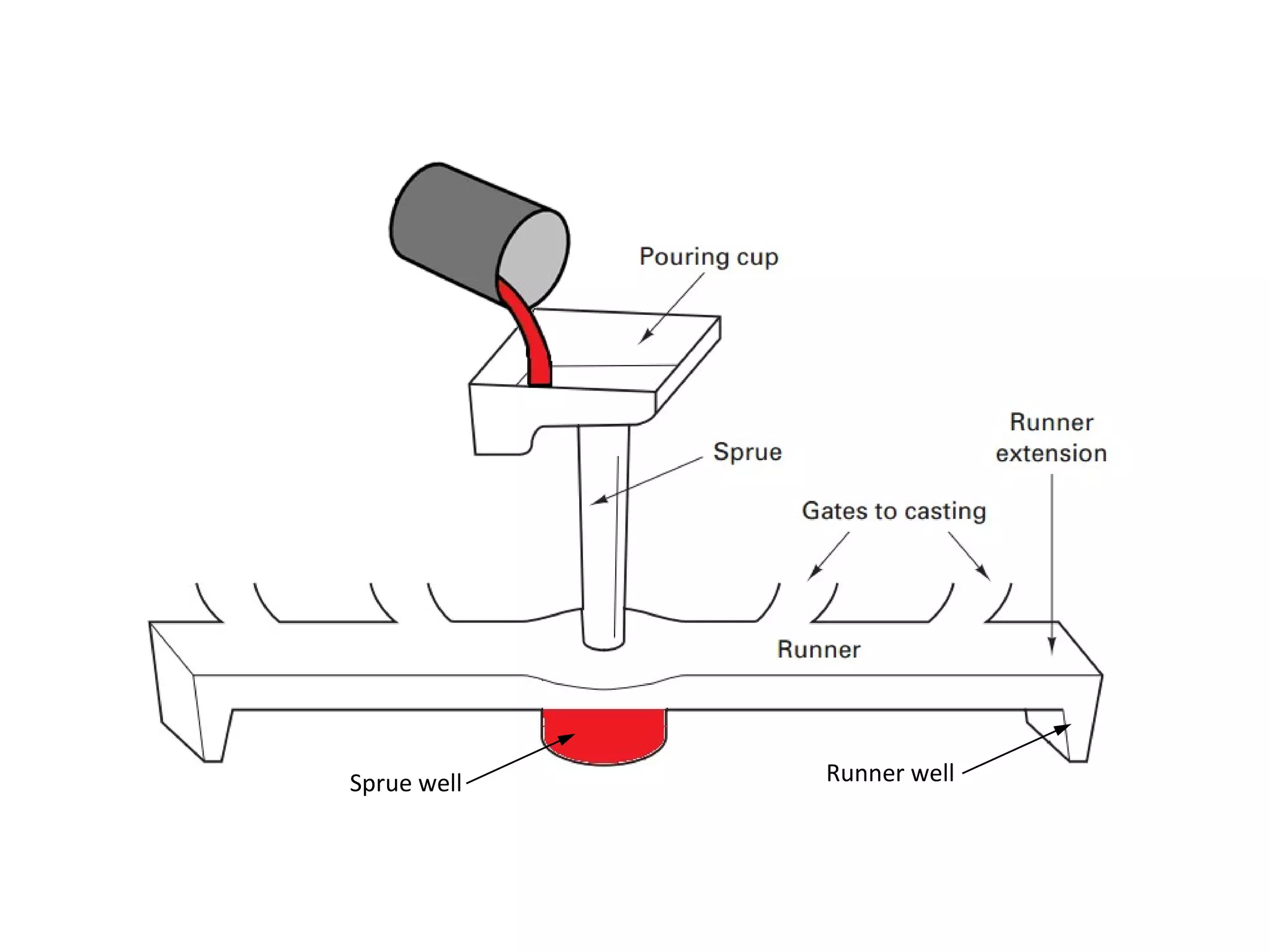

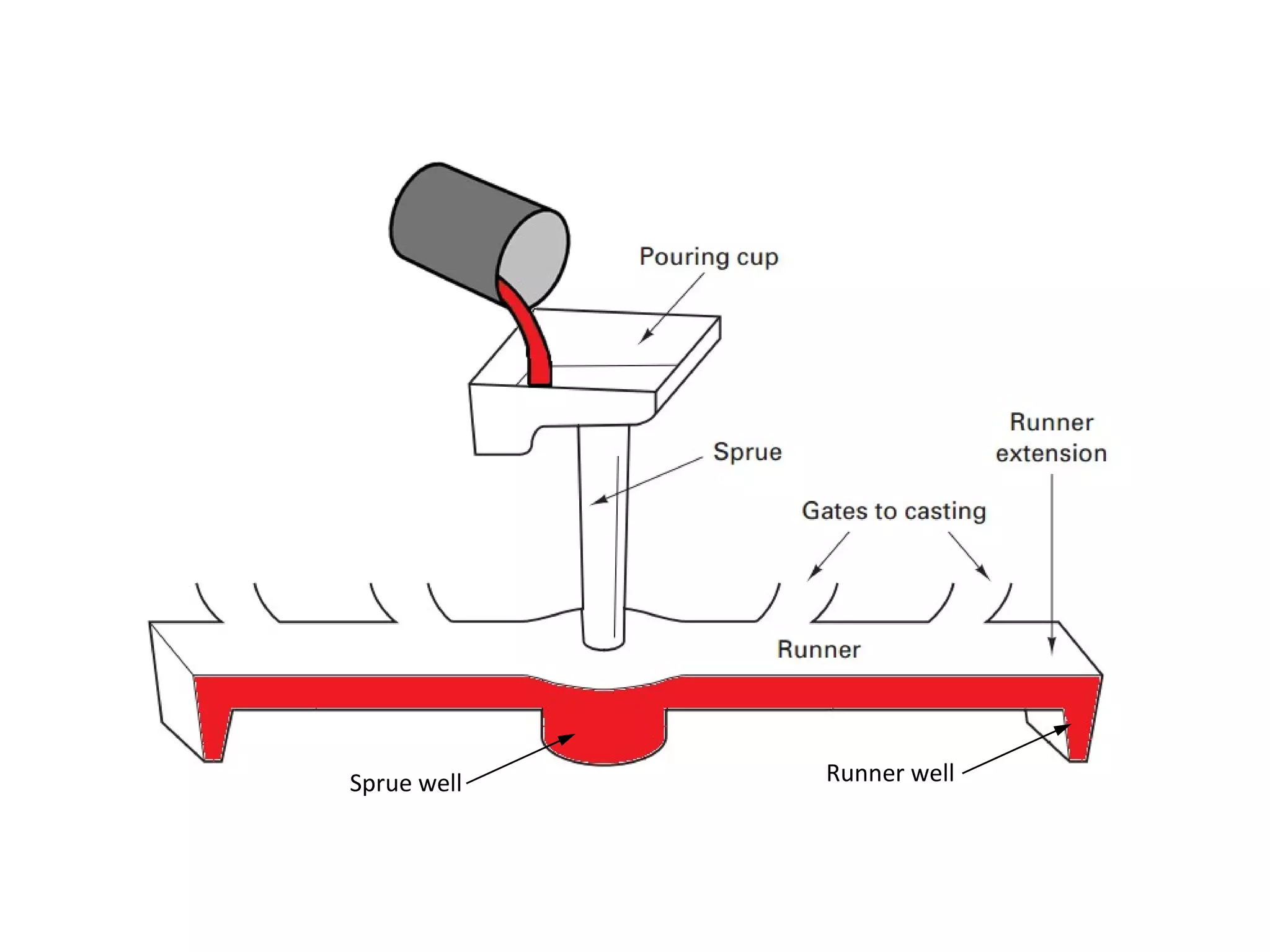

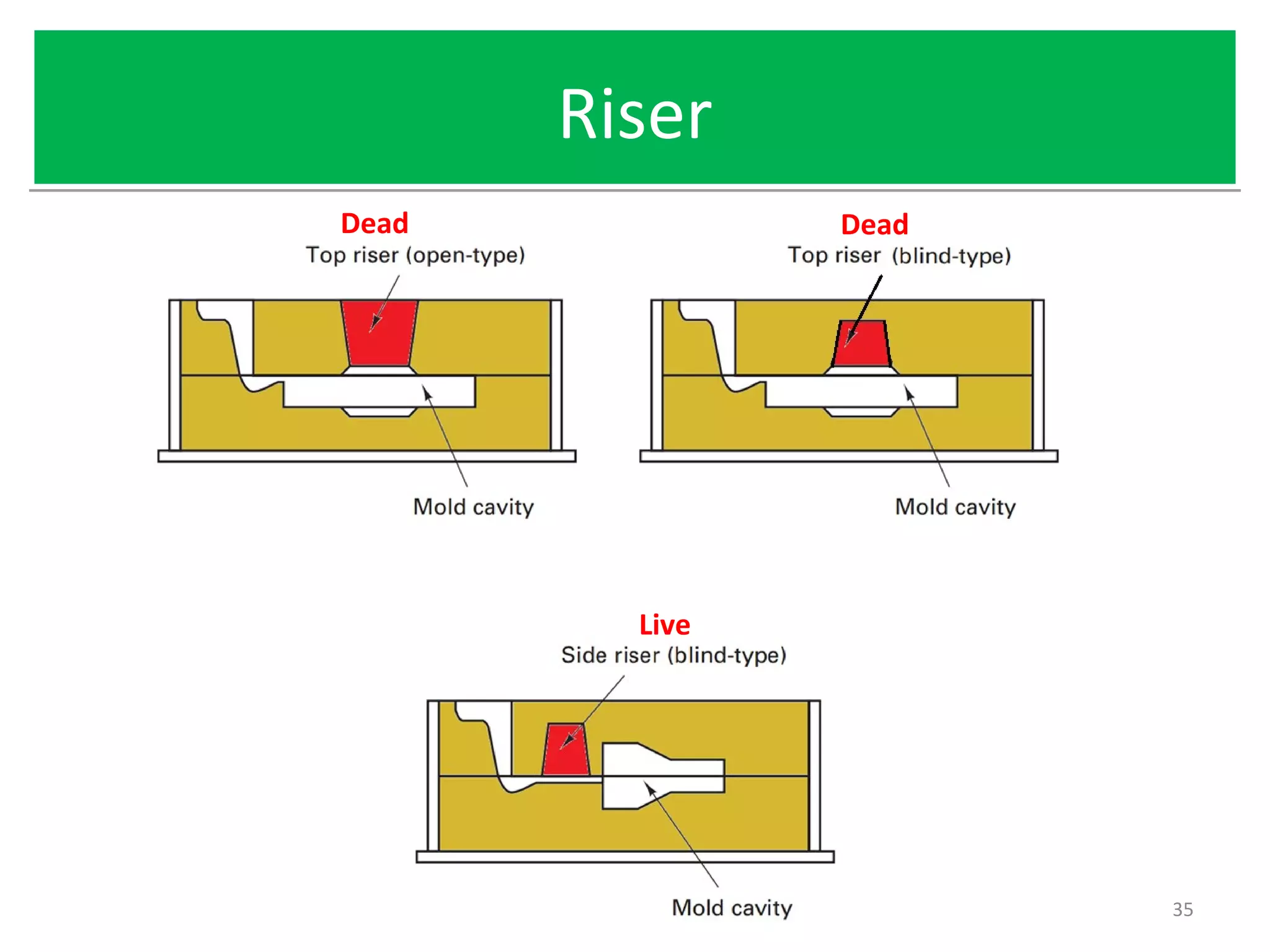

The document discusses various manufacturing processes used in casting including molds, cores, gating systems, risers, and vent holes. It describes how molds are used to form the shape of cast parts and can be open or closed. Closed molds require cores and gating systems to define internal surfaces and direct the flow of molten metal. Properly designed gating systems, risers, and vent holes are important for filling molds completely and releasing air and gases to avoid defects in castings.