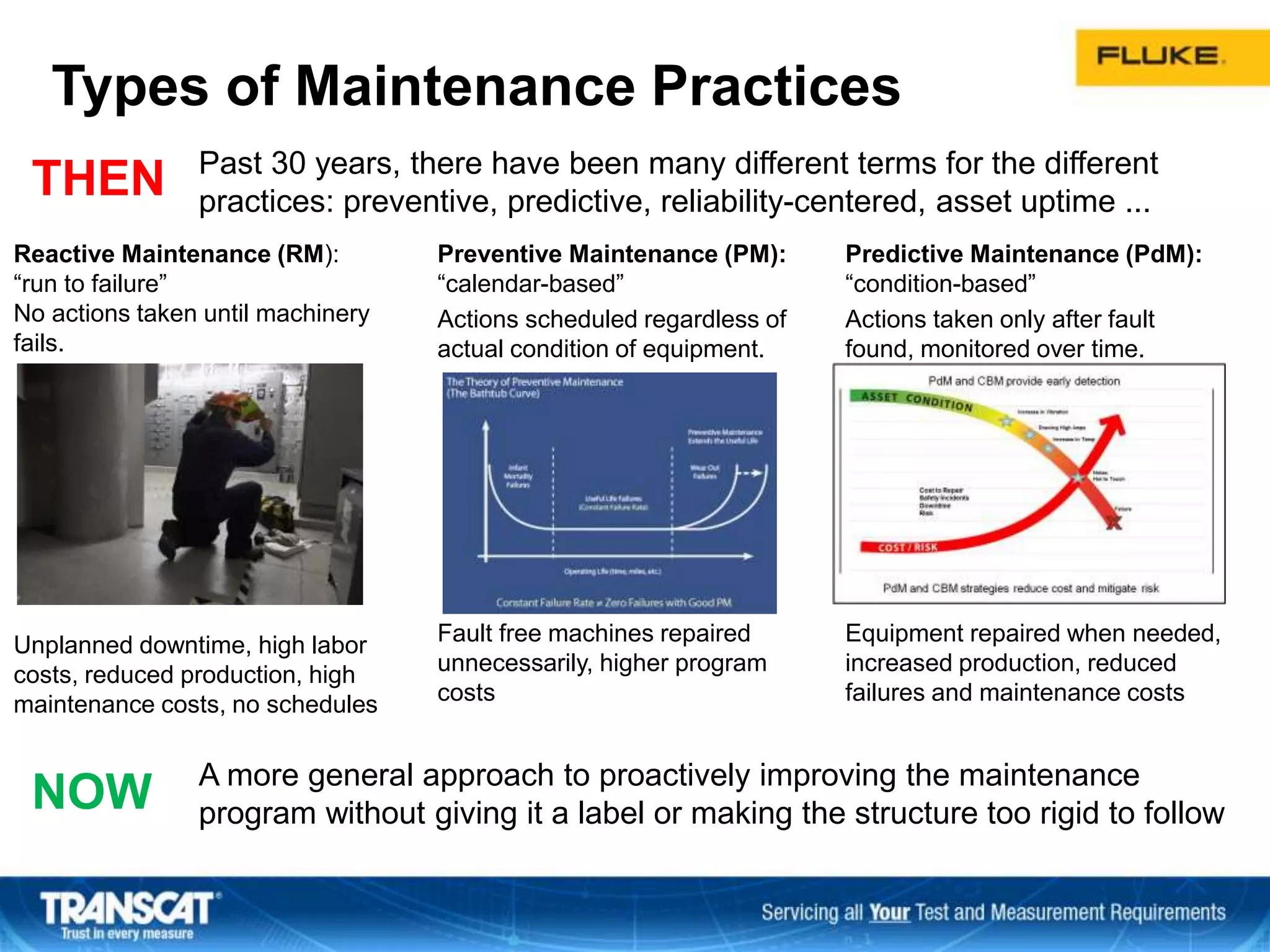

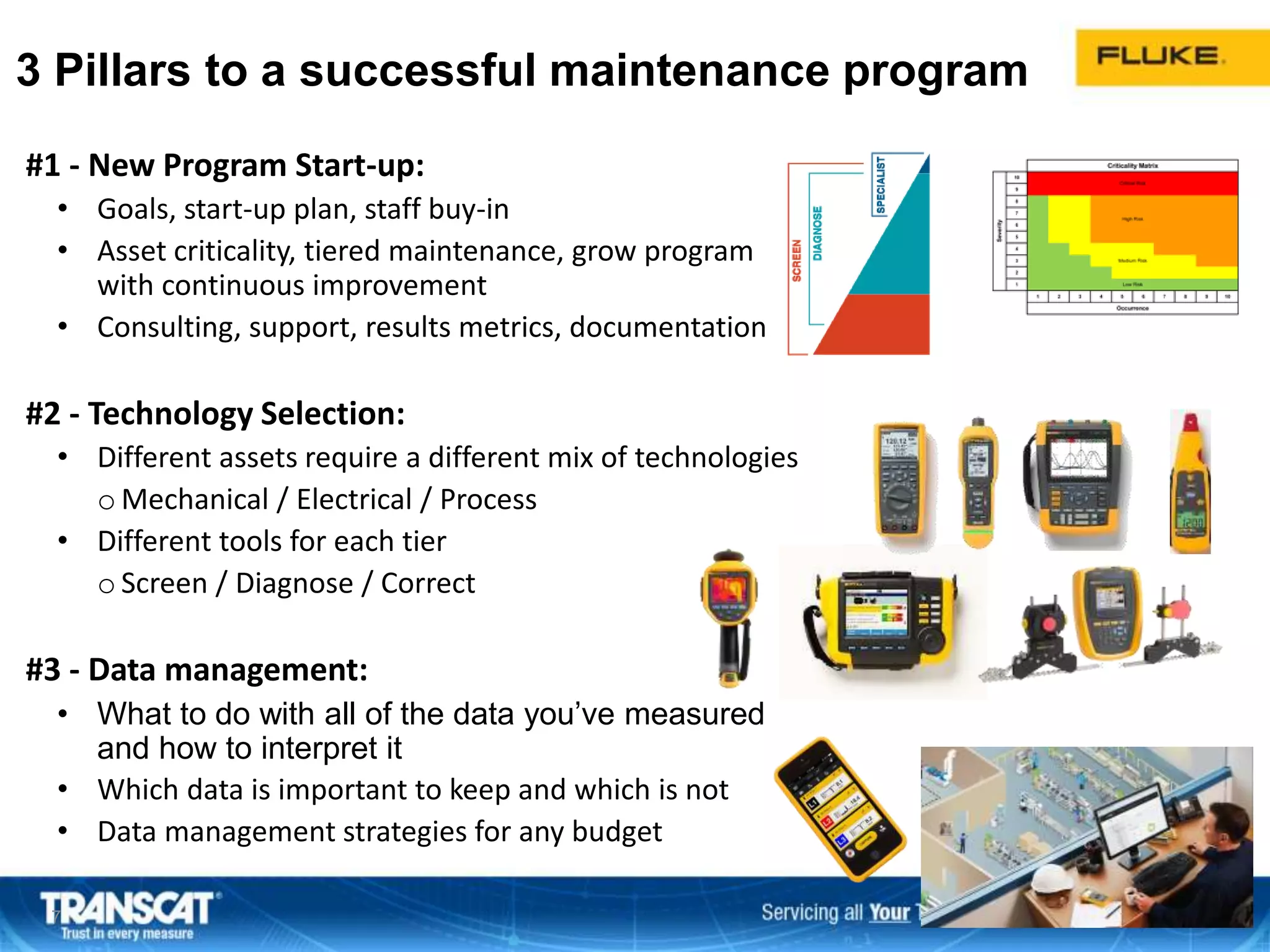

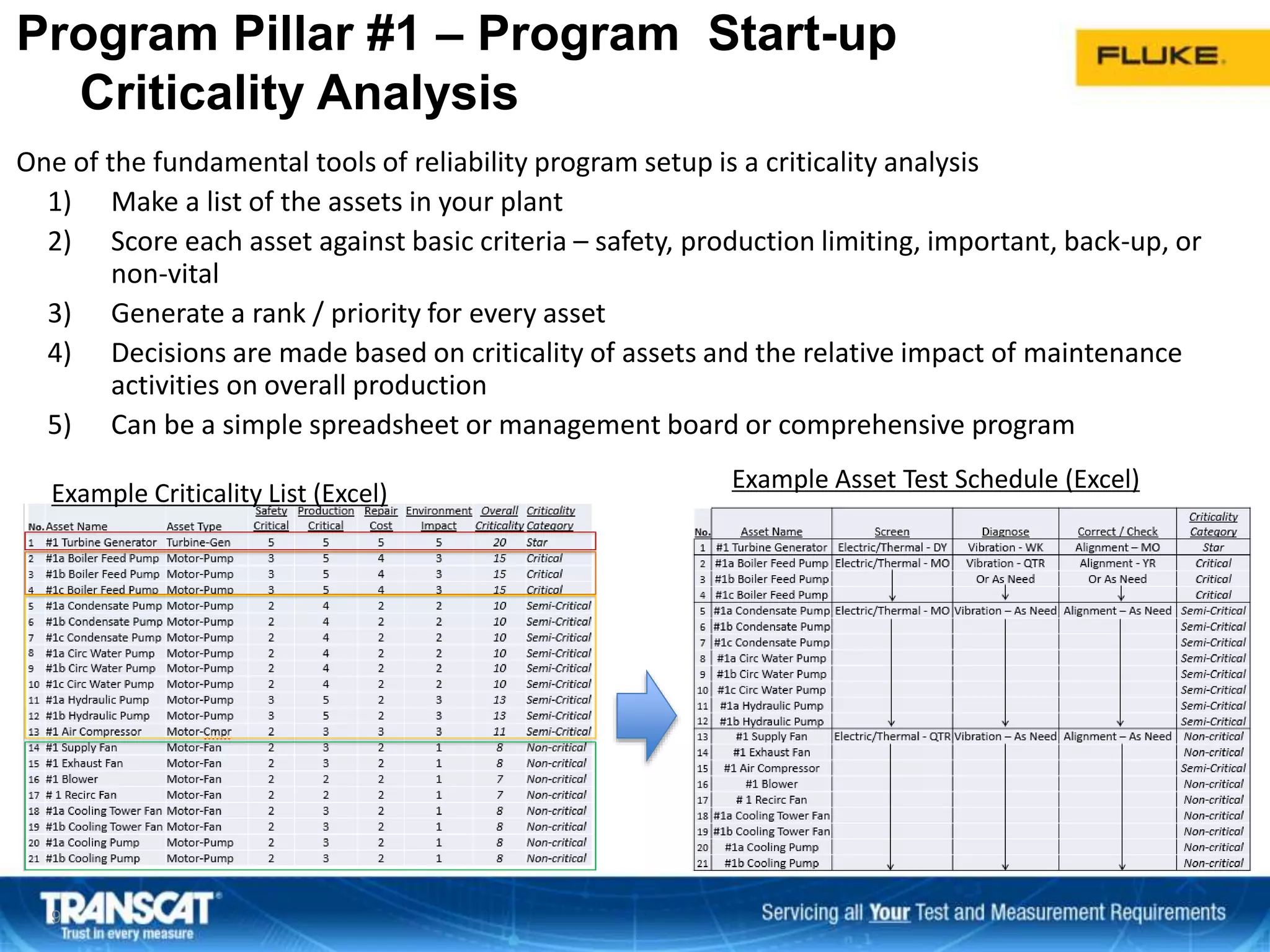

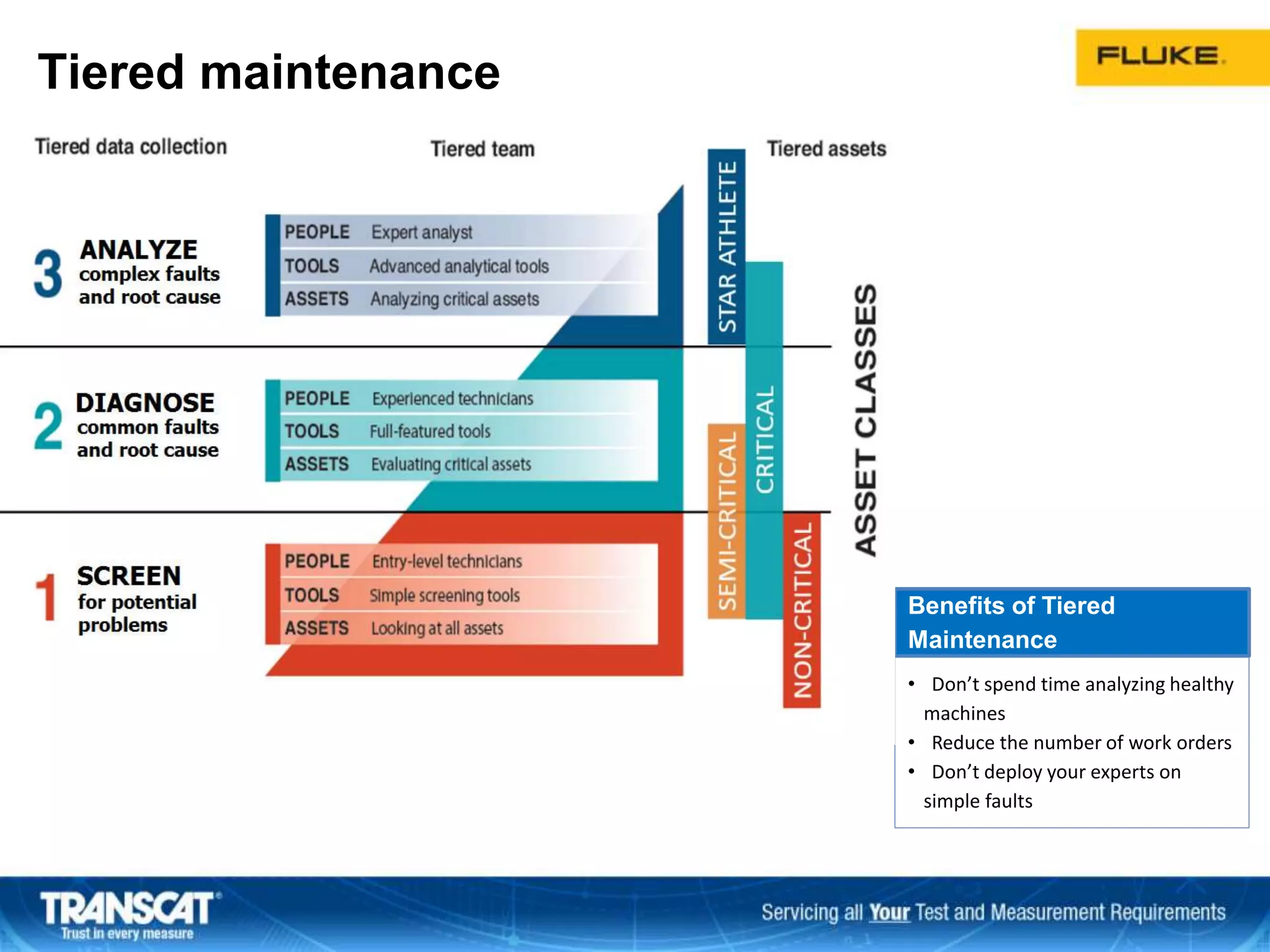

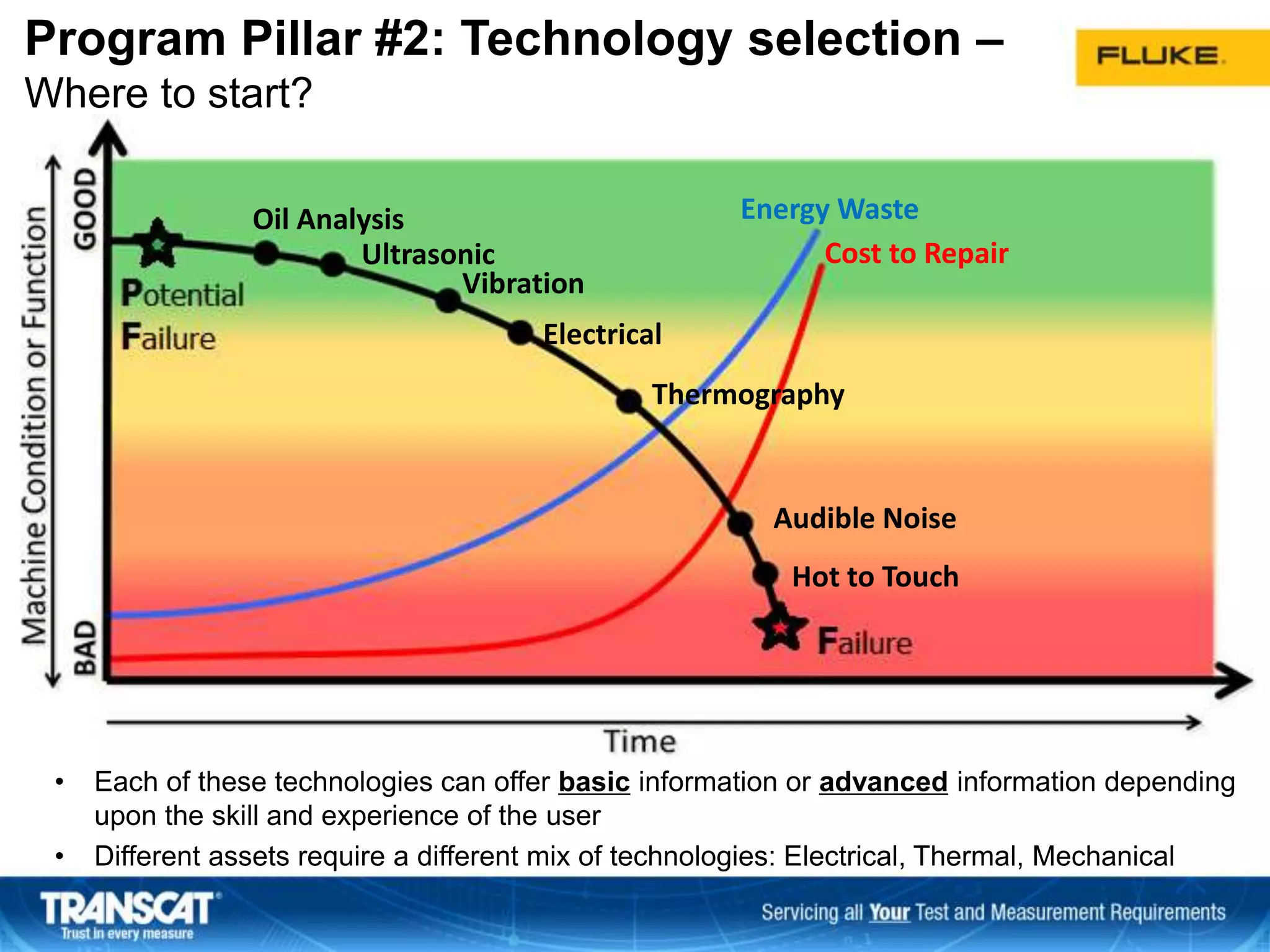

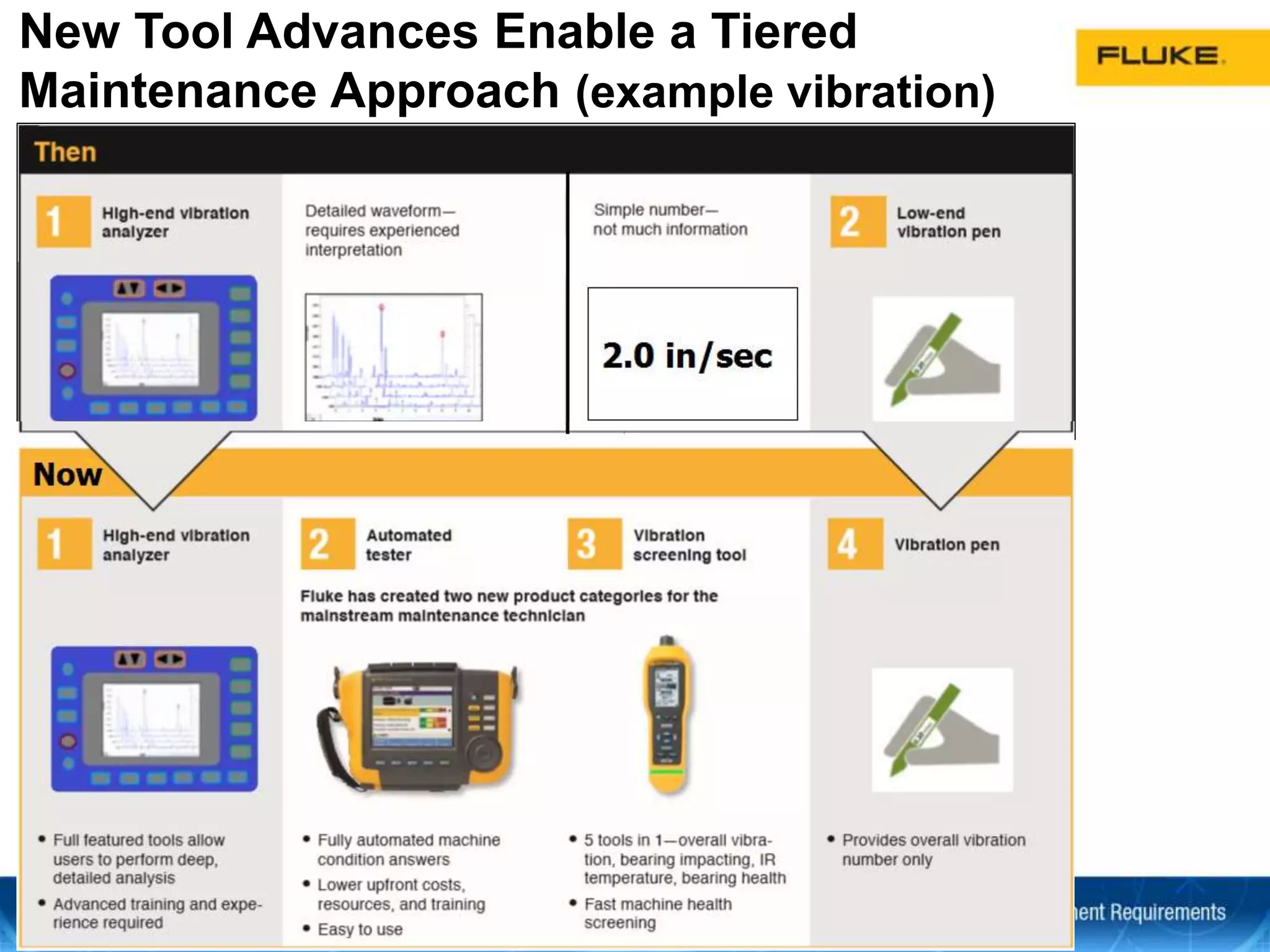

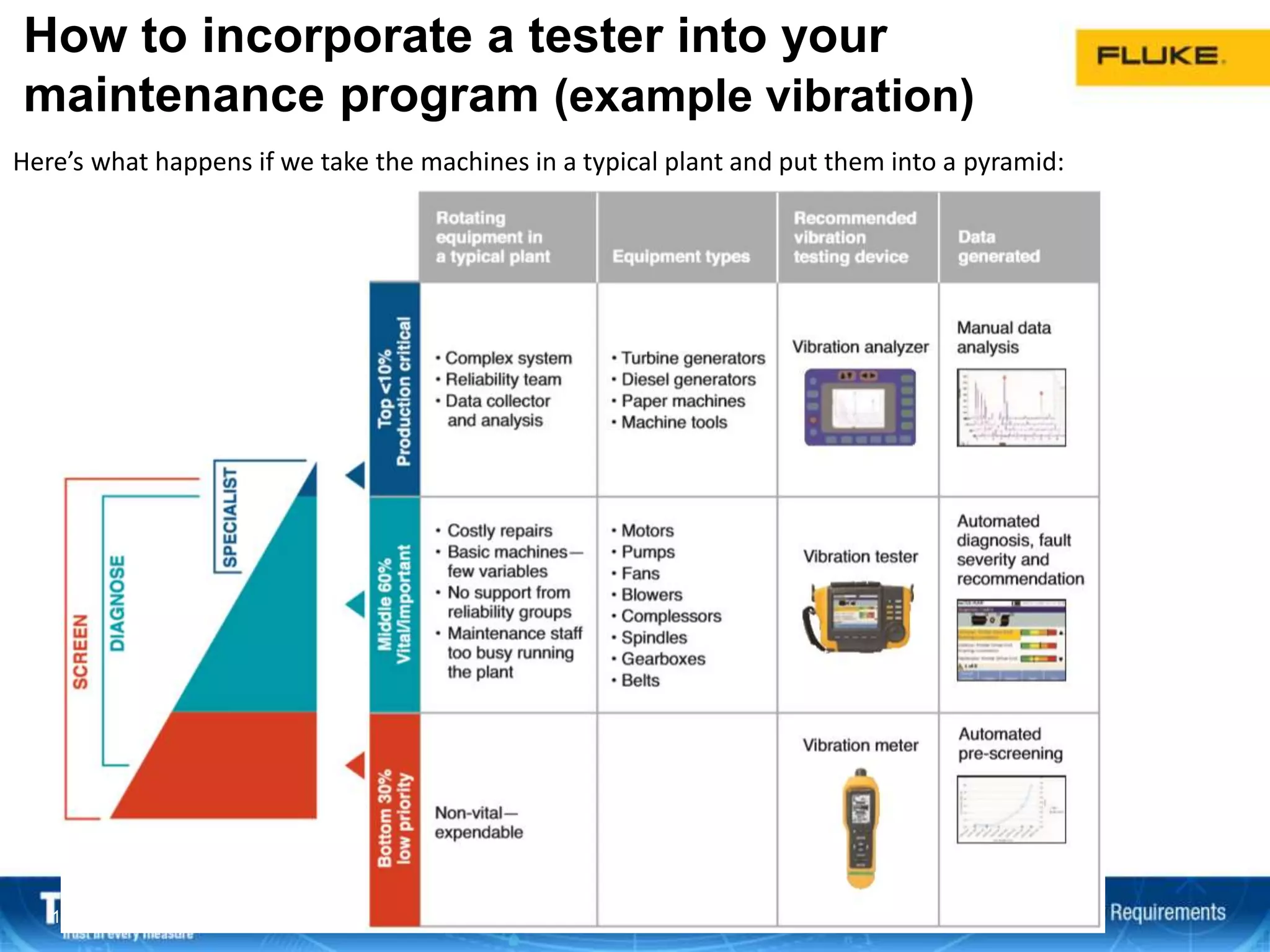

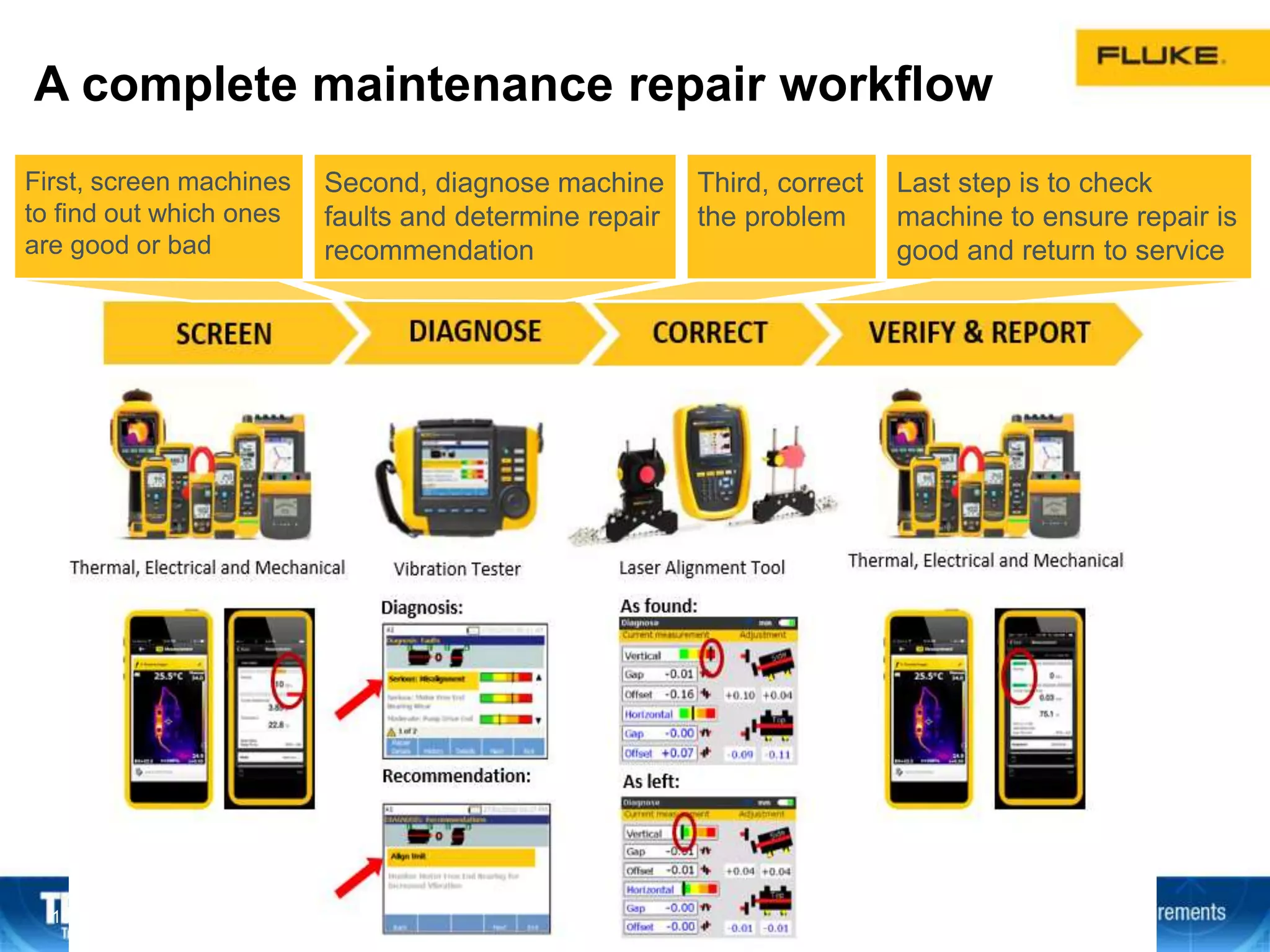

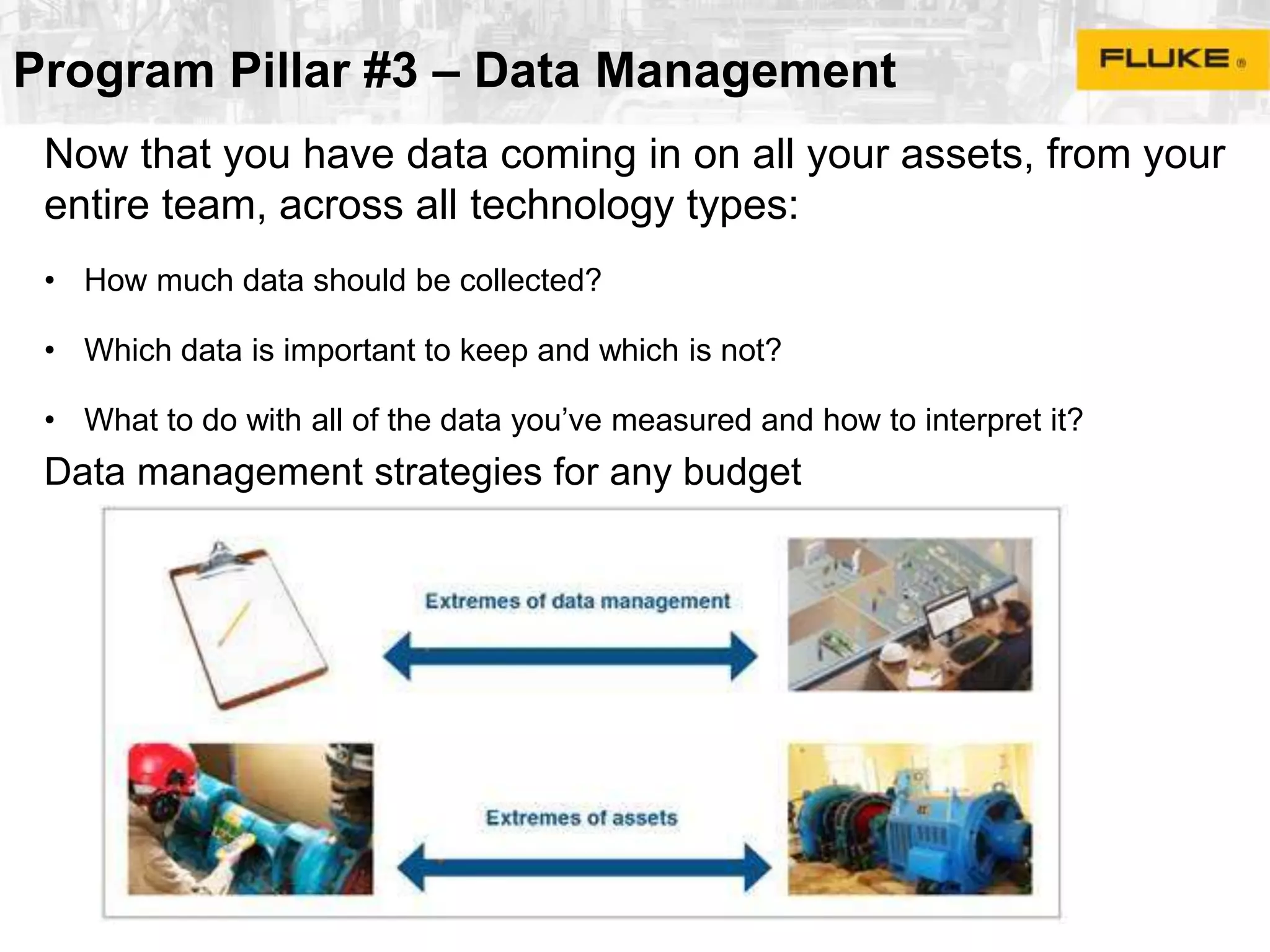

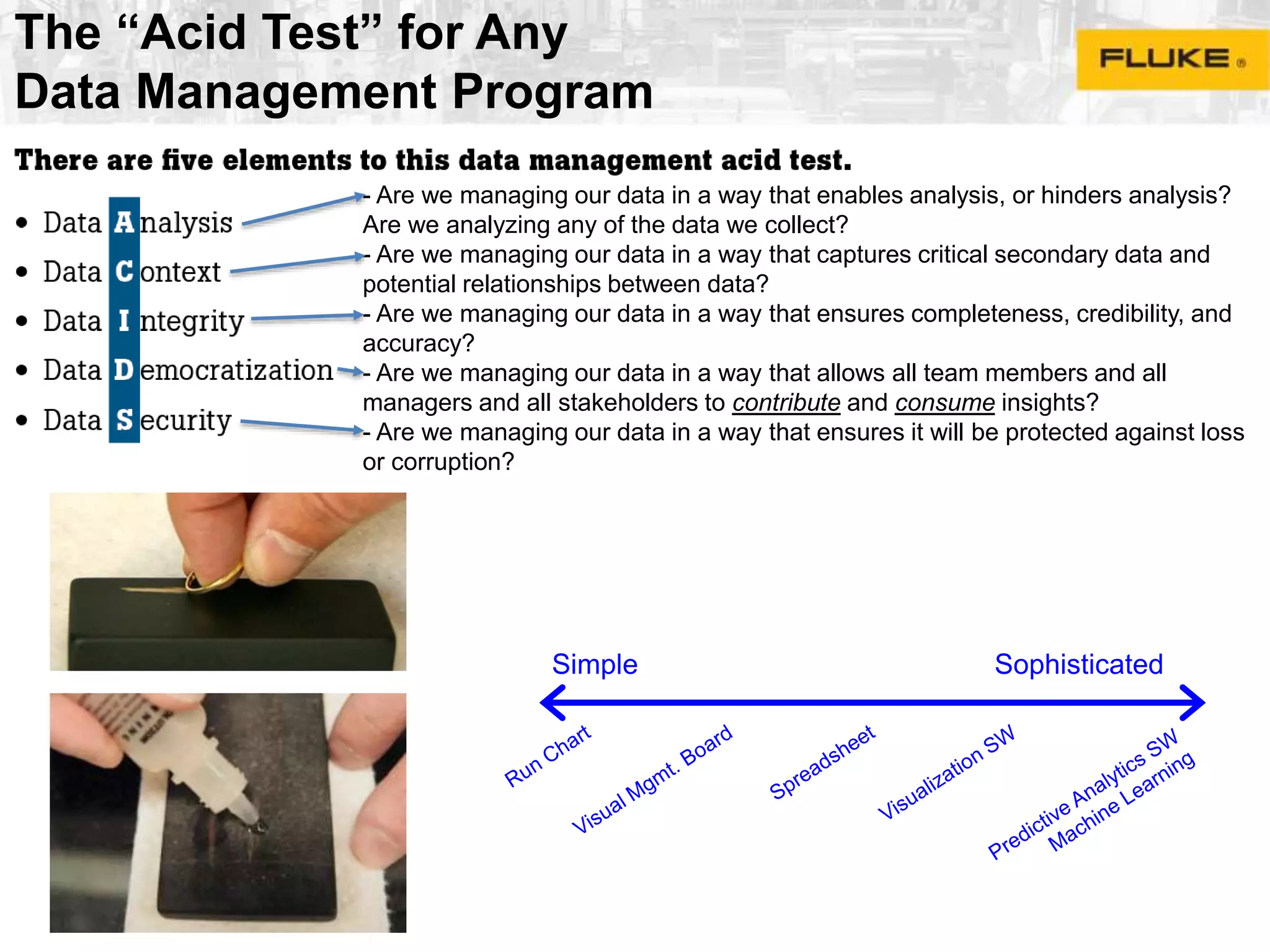

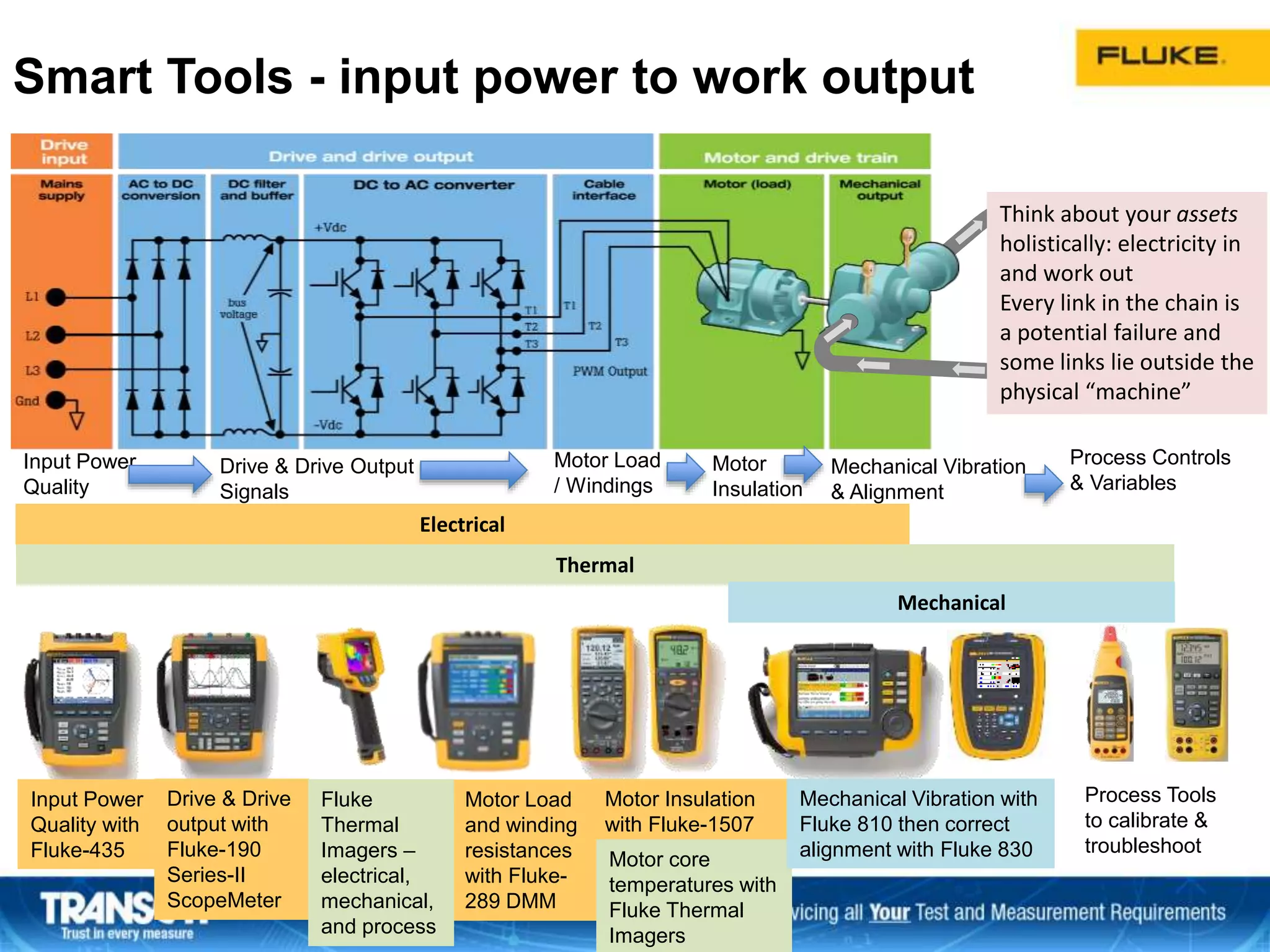

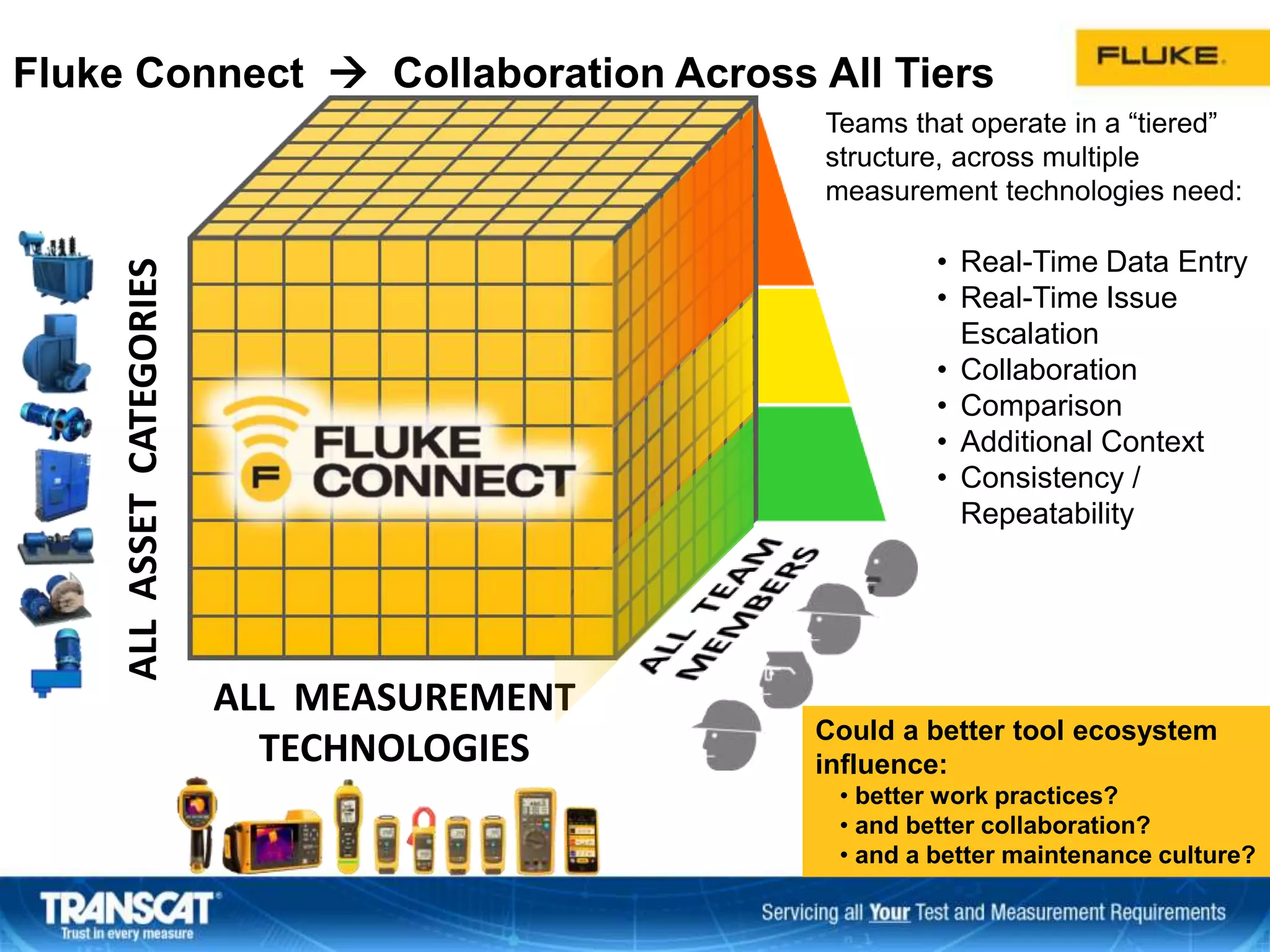

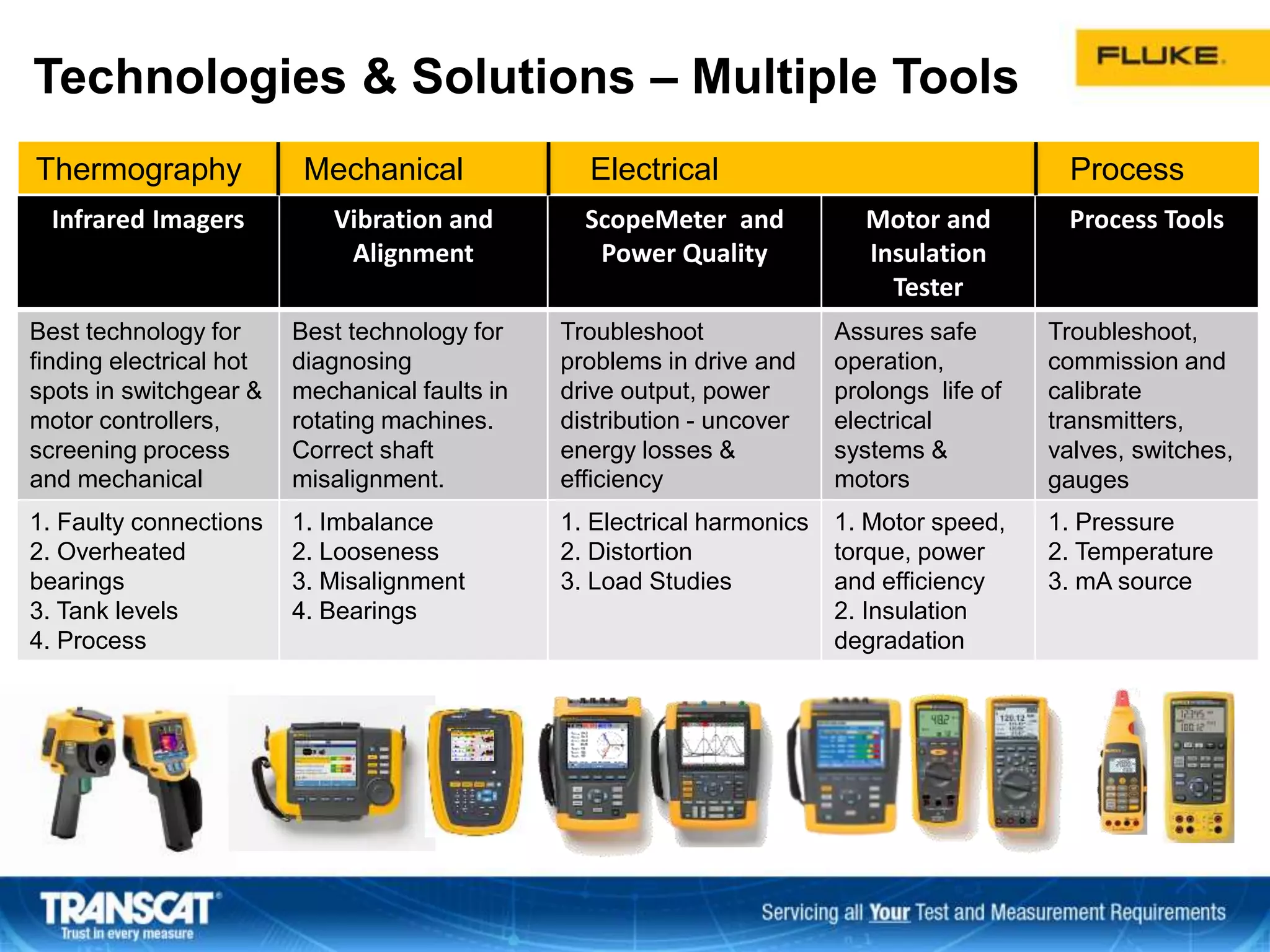

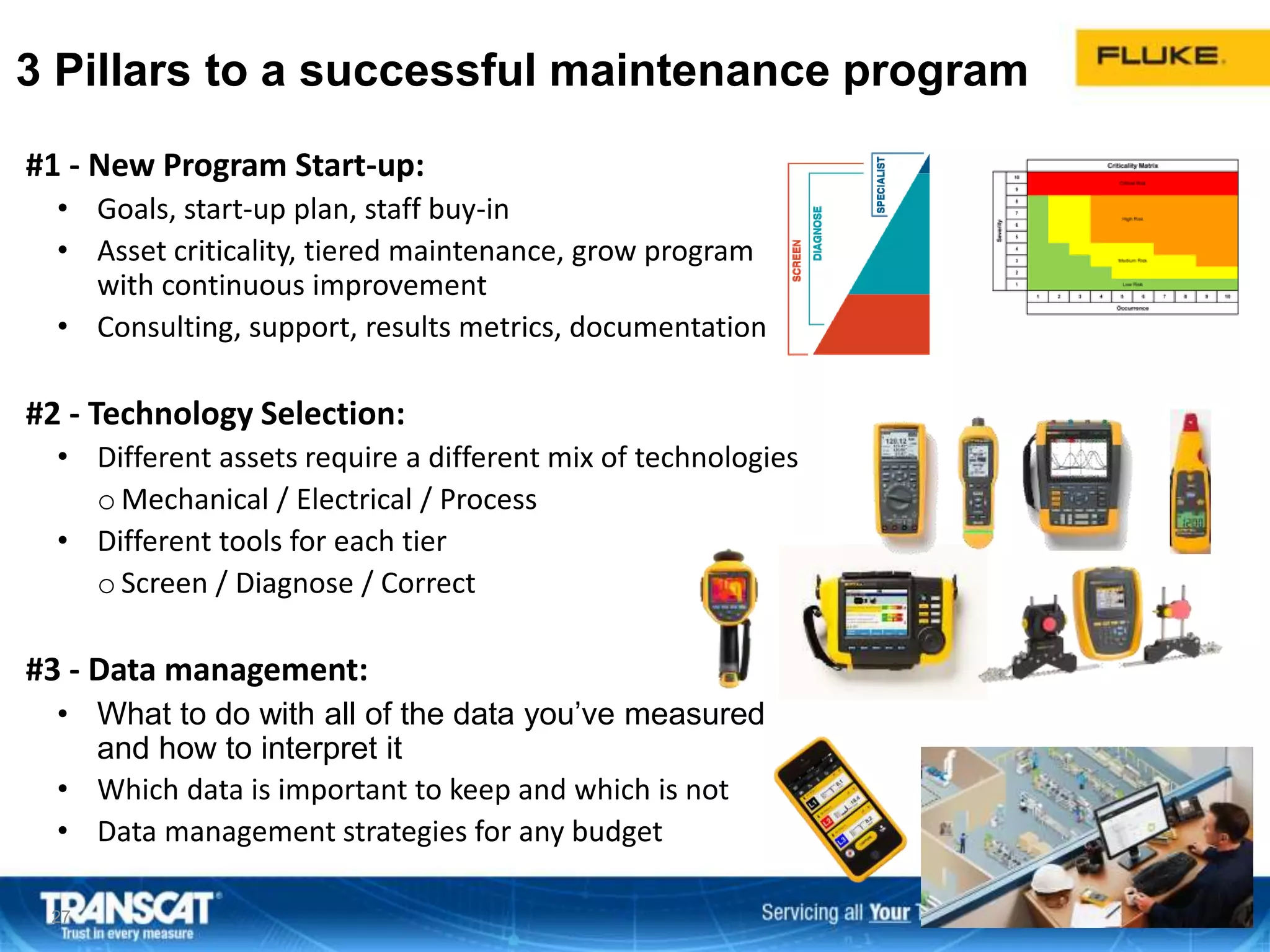

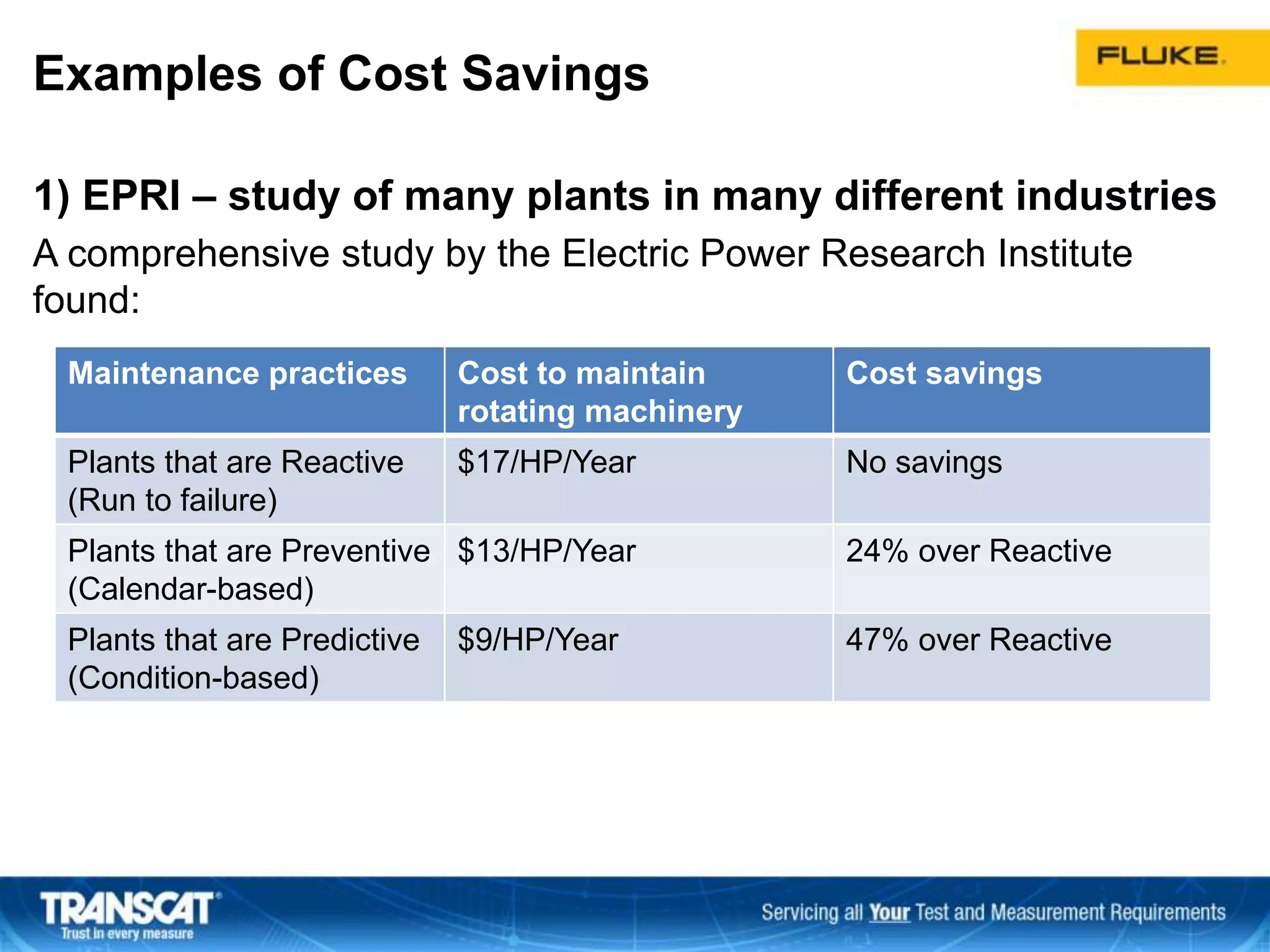

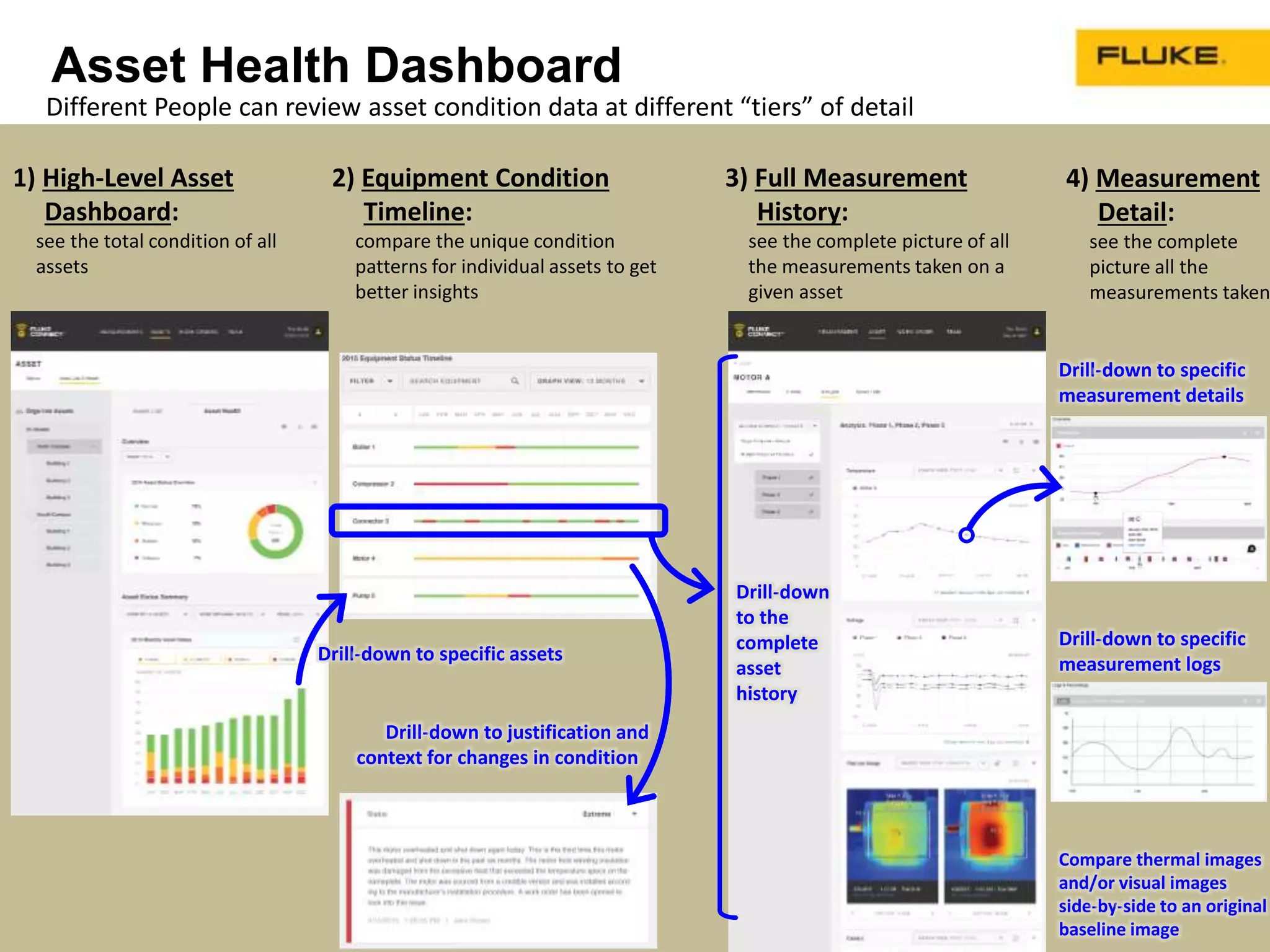

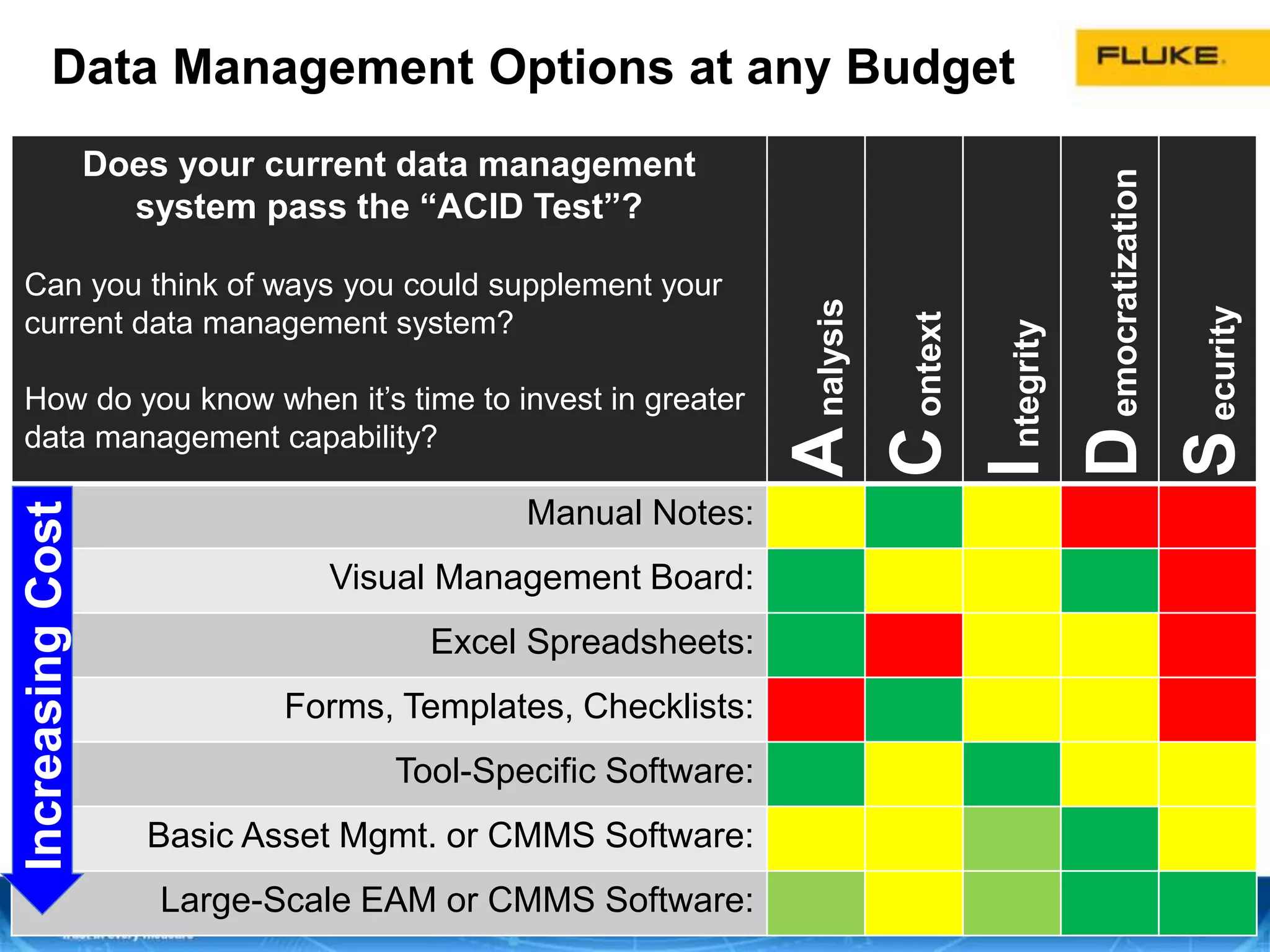

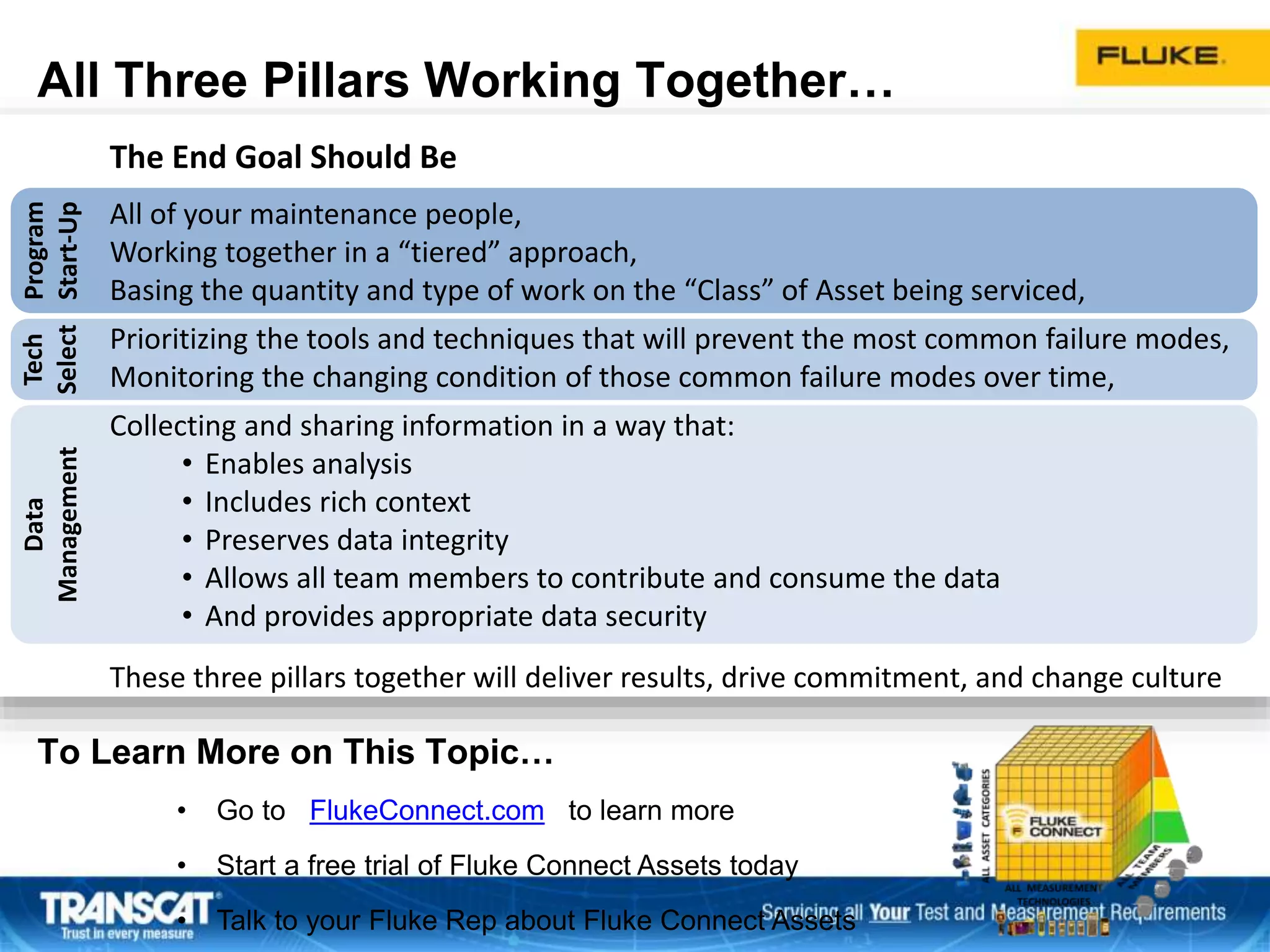

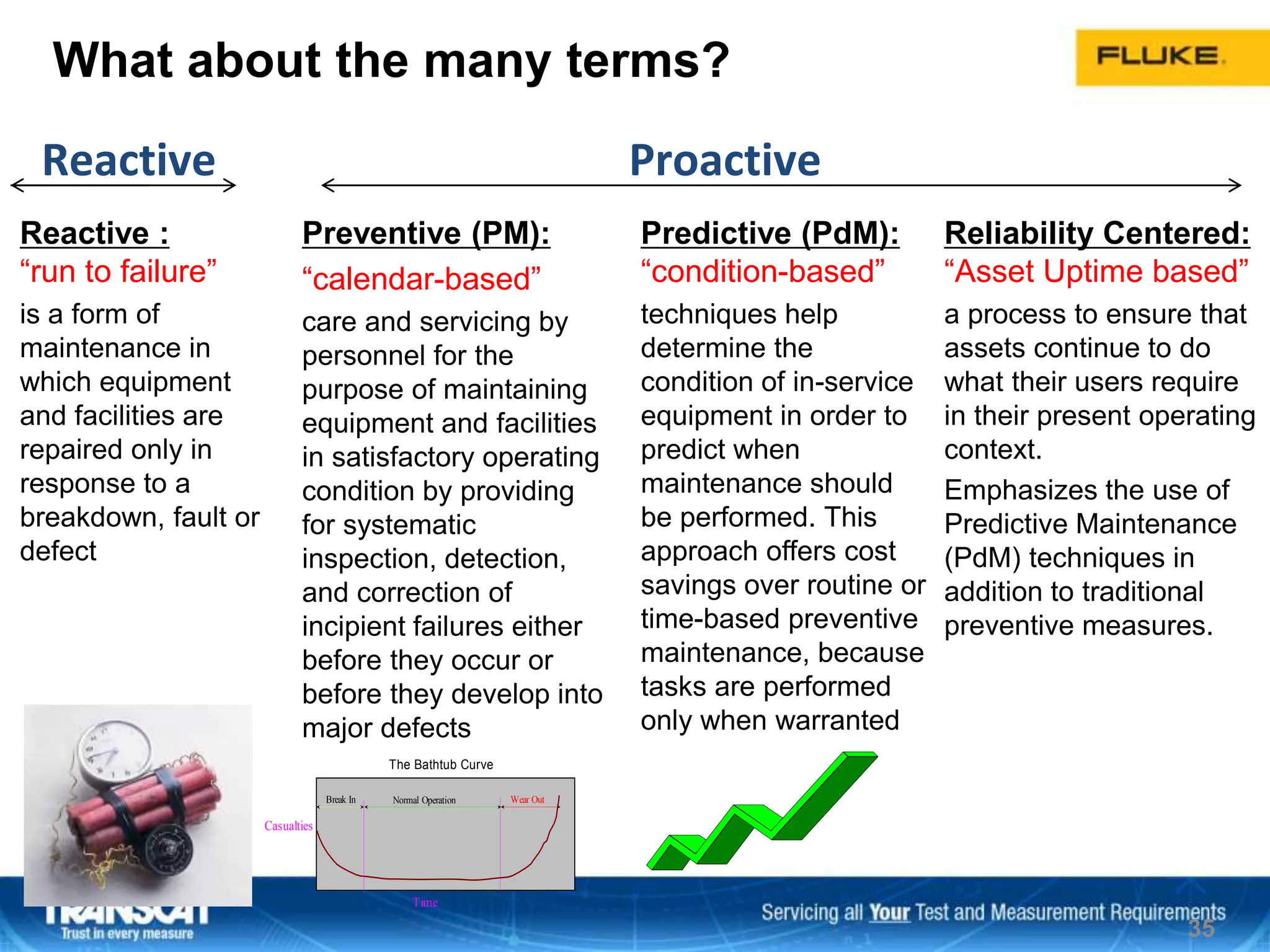

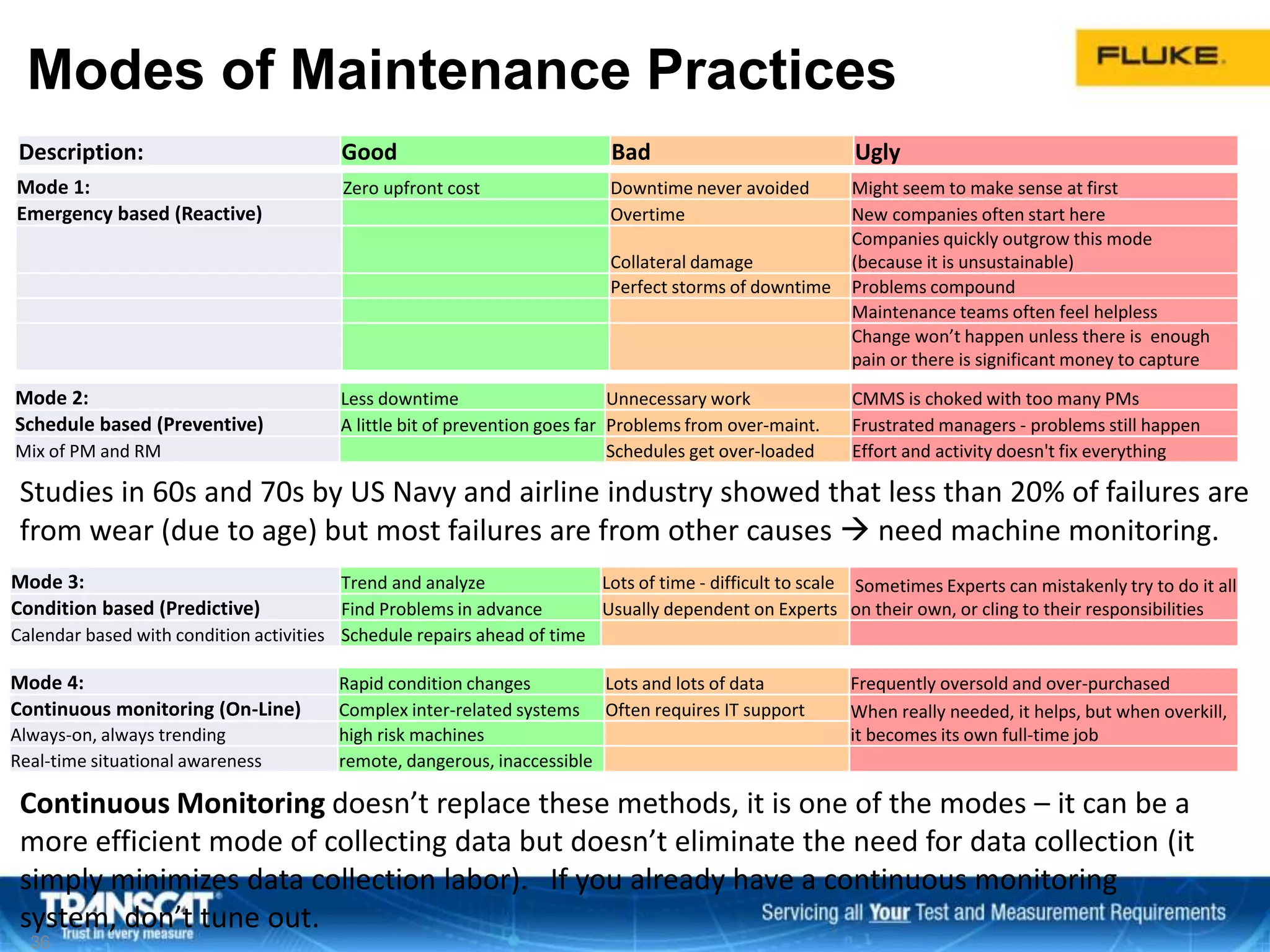

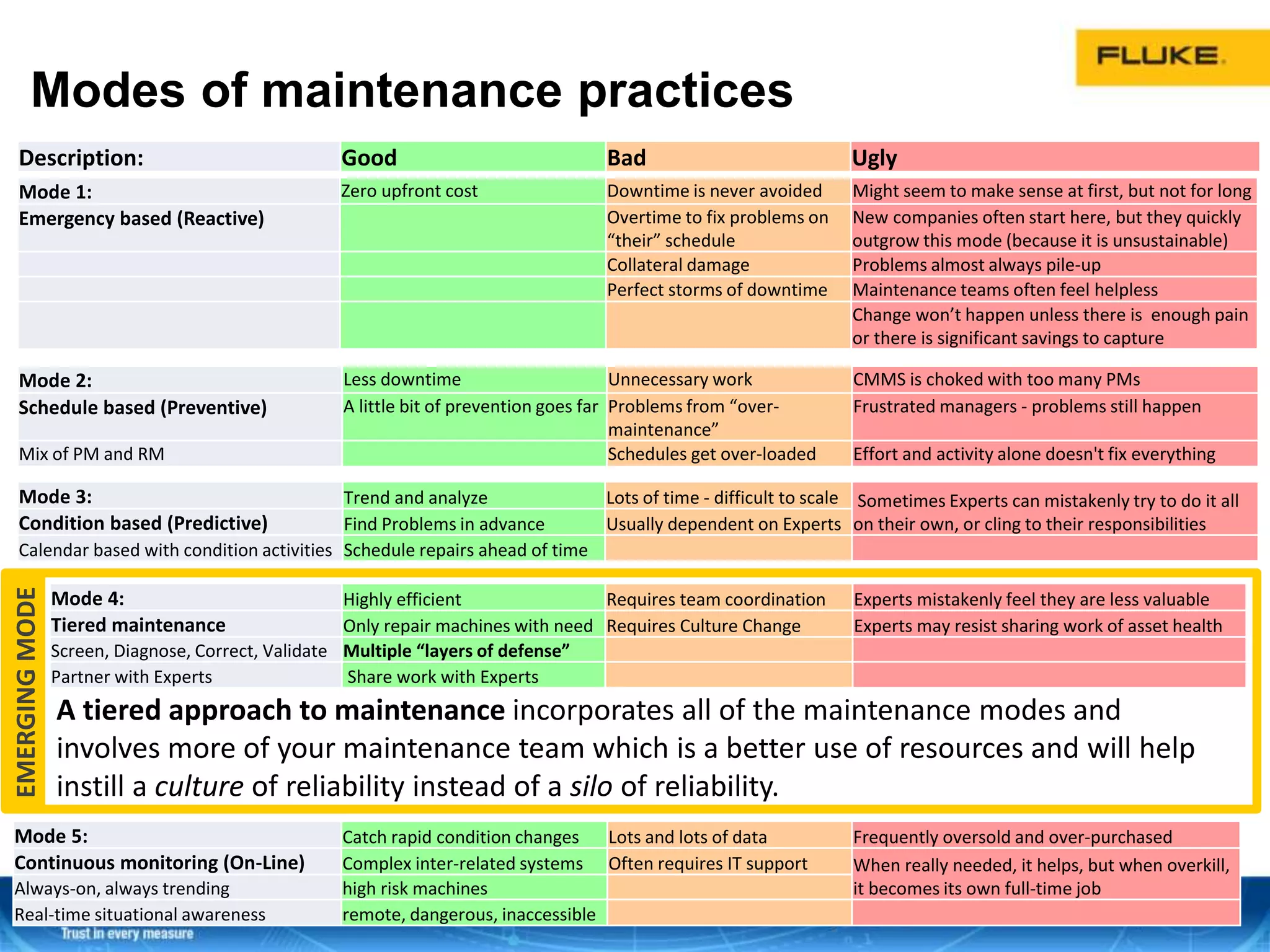

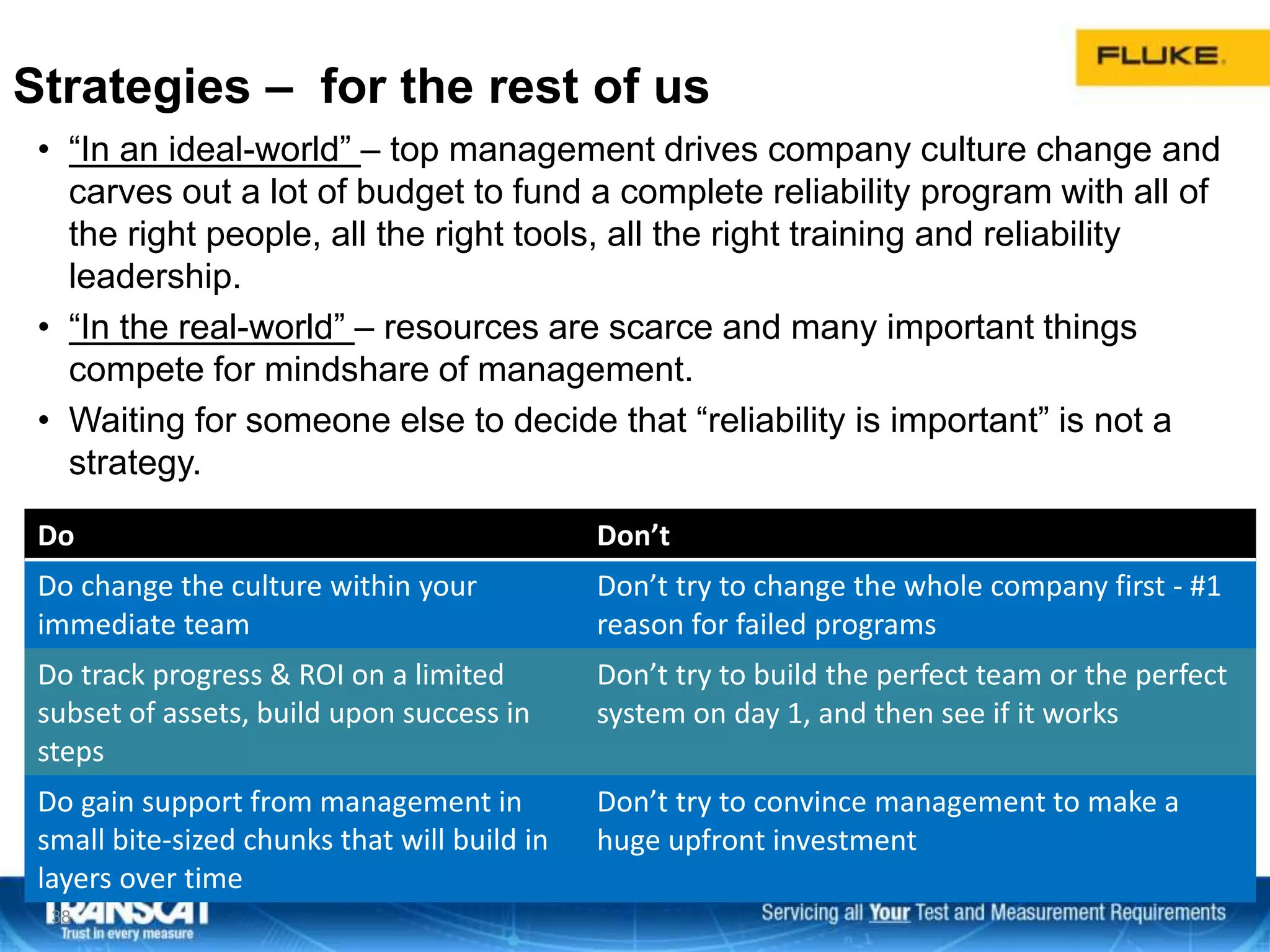

The document outlines strategies for enhancing maintenance programs through proactive methods, focusing on three pillars: program start-up, technology selection, and data management. It discusses various types of maintenance practices—reactive, preventive, and predictive—and the benefits of implementing a proactive approach, including increased safety, reliability, and revenue. Additionally, it emphasizes the need for a tiered approach to maintenance and effective data management to improve overall asset health and efficiency.