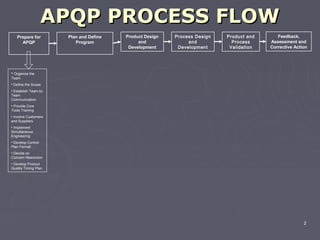

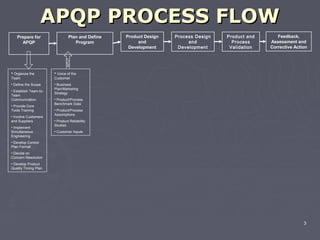

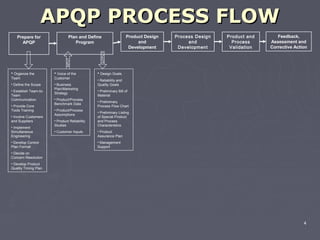

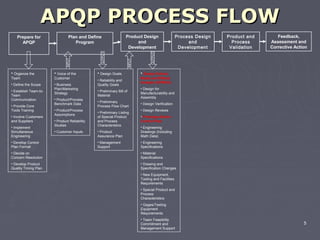

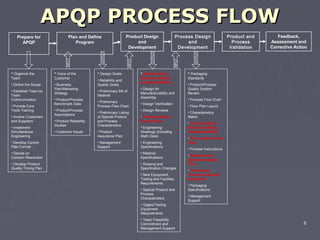

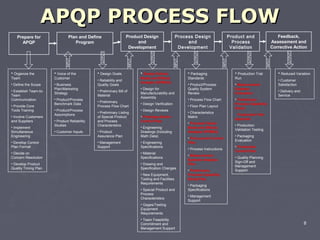

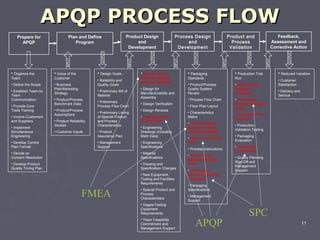

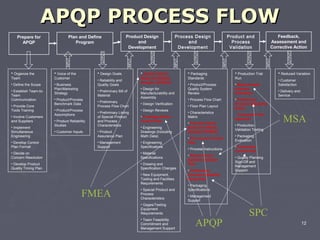

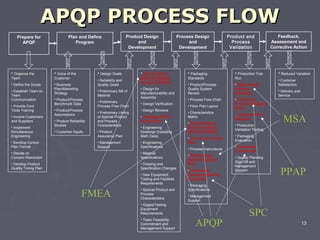

The document outlines the Advanced Product Quality Planning (APQP) process flow, which consists of 6 main steps: 1) Prepare for APQP, 2) Plan and Define Program, 3) Product Design and Development, 4) Process Design and Development, 5) Product and Process Validation, and 6) Feedback, Assessment and Corrective Action. Each step involves inputs, outputs, and activities to ensure new products and processes meet quality objectives and customer requirements. The goal of APQP is to develop and launch defect-free products and achieve reduced variation, customer satisfaction, and on-time delivery.