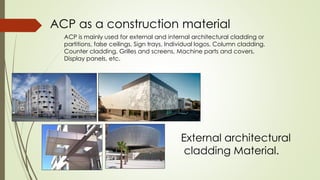

Aluminum composite panels (ACP) consist of two thin aluminum sheets bonded to a non-aluminum core. They provide excellent mechanical performance at minimal weight due to a sandwich structure with the core taking shear loads and the skins taking in-plane stresses. ACP offers properties like light weight, insulation, heat resistance, and durability. It is commonly used for architectural cladding, partitions, ceilings, and more. Examples of buildings that use ACP include Spaceship Earth and the Guggenheim Museum due to its design flexibility, rigidity, and efficiency.