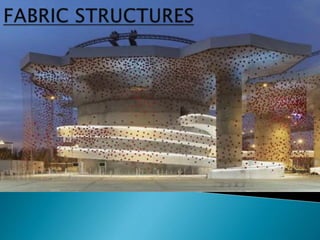

Fabric structures

- 2. FABRIC STRUCTURES ARE FORMS OF CONSTRUCTED FIBERS THAT PROVIDE END USERS A VARIETY OF AESTHETIC FREE- FORM BUILDING DESIGNS. CUSTOM-MADE FABRIC STRUCTURES ARE ENGINEERED AND FABRICATED TO MEET WORLDWIDE STRUCTURAL, FLAME RETARDANT, WEATHER-RESISTANT, AND NATURAL FORCE REQUIREMENTS. FABRIC STRUCTURES ARE CONSIDERED A SUB-CATEGORY OF TENSILE STRUCTURE. A FABRIC STRUCTURE’S MATERIAL SELECTION, PROPER DESIGN, ENGINEERING, FABRICATION AND INSTALLATION ALL WORK TOGETHER TO ENSURE A SOUND STRUCTURE. THE MATERIAL’S ROLE IN THE STRUCTURE’S PERFORMANCE MAKES THE SELECTION PROCESS ESPECIALLY IMPORTANT. THIS IS PARTICULARLY TRUE WITH TENSILE AND AIR-SUPPORTED STRUCTURES BECAUSE THEIR MEMBRANES, AS WELL AS THEIR FRAMES, CARRY THE LOADS.

- 3. Common Shapes and Forms: • Mast Supported • Point Supported • Arch Supported • Frame Supported • Simple Saddle

- 4. Mast-supported systems Tent-like structures in form One or several peaks supported by central poles and perimeter cables Typically use compression ring or “bale” ring

- 5. Point-supported Clear span avoids a center mast Often hypar shaped (two high, two low connection points) Utilizes an exterior frame or series of peripheral masts

- 6. Arch-supported Introducing a curved compression member Cross arches often used

- 7. Frame supported Space frame Fabric attached to a structural frame Structural components carry forces Fabric is purely used as a cladding

- 8. Simple Saddle/Hypar Double curvature Two (2) high points, Two (2) Low points “Saddle” shape Horizontal or Vertical Minimal surfaces

- 9. Polyesters Vinyl-coated polyester Vinyl-laminated polyesters Fiberglass PTFE-coated fiberglass Woven PTFE ETFE foil

- 10. Polyesters Polyester is the most frequently used base material because of its strength, durability, cost and stretch. Polyesters laminated or coated with PVC films generally are the least expensive for longer-term fabrications. Laminates usually consist of vinyl films over woven or knitted polyester meshes (called scrims or substrates). Coated fabrics typically use a high-count, high-tensile base fabric coated with a bondable substance for extra strength. One fabric manufacturing method places polyester fabric under tension before and during the coating processes. The result is that yarns in both directions of the weave have identical characteristics, giving the fabric increased dimensional stability. Lighter fabrics (200 to 270g/m2) commonly are used as acoustic and insulated liners suspended beneath a structure’s envelope. For long-term exterior use, heavier materials are needed: 20- to 26-oz. (680 – 880gm) fabrics with top coatings of polyvinyl fluoride (PVF, of which Tedlar is an example) or poly vinylidene fluoride (PVDF, of which Vidar, Fluorex and Kynar are examples). These top coatings provide a protective finish to withstand environmental degradation.

- 11. Vinyl-coated polyester is the most common fabric for producing flexible structures, such as custom-designed awnings, canopies, walkways, tent halls, smaller air-supported structures and light member-framed structures. Vinyl-coated polyester is composed of a polyester scrim, a bonding or adhesive agent, and exterior PVC coatings. The polyester scrim supports the coating (applied initially in liquid form) and provides the tensile strength, elongation, tear strength and dimensional stability of the finished fabric. The scrim is made of high-tenacity, continuous-filament yarns, which have high dimensional stability, and can be bent thousands of times without losing any tensile properties. The base fabric’s tensile strength is determined by the size (denier) and strength (tenacity) of the yarns and the number of yarns per linear inch or meter. The bigger the yarn and the more yarns per inch, the greater the finished product’s tensile strength. For architectural applications, base fabrics typically weigh between 2.5 and 10 oz/yd2, with a tensile strength between 300 (2.662 N/5cm) and 650 lbs/in (5.60 N/5cm), although fabrics intended only for tent use may have lower measurements. The adhesive agent provides a chemical bond between the polyester fibers and the exterior coatings and prevents wicking of moisture into the fibers. Wicking is the capillary like action of fiber to absorb water, which could result in freeze-thaw damage. The PVC coating liquid (vinyl Organisol or Plastisol) contains chemicals to achieve desired properties regarding color, water resistance, mildew resistance and flame retardancy. The fabrics also can be made with high levels of light transmission or complete opaqueness. After the coating is applied to the scrim, the fabric goes through a heating chamber to dry the liquid coating.

- 12. Vinyl-laminated polyesters are used for awnings, tents and low-tension frame structures. Technically, a laminated fabric consists of a reinforcing polyester scrim that is calendared between two layers of unsupported PVC film. In general use, it refers to two or more layers of fabric or film joined by heat, pressure and an adhesive to form a single ply. With an open-weave or mesh polyester scrim, the exterior vinyl films bond to themselves through the openings in the fabric. Heavier base fabrics, though, are too tightly constructed to permit this lamination process, so an adhesive must bond the exterior films to the base fabric. A good chemical bond is important to prevent delamination and is critical in developing the proper seam strengths. The adhesive enables the seam, created by welding vinyl-coated fabric to another piece of the same material, to meet a structure’s shear forces and load requirements at all temperatures. By preventing wicking of moisture into the scrim’s fibers, the adhesive prevents fungal growth or freezing that can affect the exterior coating’s adhesion to the scrim. In response to EPA regulations, the adhesives are water-based. Using an open-weave scrim such as mesh might make these fabrics more economical, depending on the number and type of features required in the vinyl. What weight is necessary to withstand abrasion and wear? Is flame resistance needed? Is a particular color required? What width? Virtually any color, plus UV resistance, abrasion resistance, and colorfastness can be formulated into the vinyl, but the more of these features incorporated, the higher the cost.

- 13. ANOTHER WIDELY USED BASE MATERIAL IS WOVEN FIBERGLASS COATED WITH PTFE (ALSO KNOWN AS TEFLON) OR SILICONE. THE GLASS FIBERS ARE DRAWN INTO CONTINUOUS FILAMENTS, WHICH ARE BUNDLED INTO YARNS. THE YARNS ARE WOVEN TO FORM A SUBSTRATE. THE FIBERGLASS HAS A HIGH ULTIMATE TENSILE STRENGTH, BEHAVES ELASTICALLY AND DOES NOT UNDERGO SIGNIFICANT STRESS RELAXATION OR CREEP. THE PTFE COATING IS CHEMICALLY INERT, WITHSTANDS TEMPERATURES FROM MINUS 100F TO 450F (MINUS 73C TO 232C), IS IMMUNE TO UV RADIATION AND CAN BE CLEANED WITH WATER. PTFE-COATED FIBERGLASS IS AVAILABLE WITH AS MUCH AS 25% TRANSLUCENCY, PROVIDING DIFFUSED INTERIOR LIGHT. ITS ABILITY TO PROVIDE NATURAL DAYTIME LIGHTING AND ITS HIGHLY REFLECTIVE SURFACE FOR EFFICIENT NIGHTTIME INTERIOR LIGHTING CAN REDUCE ENERGY CONSUMPTION.

- 14. For these and other reasons, fiberglass-based fabrics have been the material of choice for stadium domes (both air- and cable-supported) and many other permanent structures, particularly in the United States. Another reason some industry experts cite for this is a perception among code officials that its high melting temperature and lack of creep, or long-term elongation, make it superior to polyester. Other industry insiders note that polyester, like fiberglass, melts rather than burns at high temperatures, and that properly constructed, polyester structures may be equally durable. Because of the differences in how polyester and fiberglass perform in fire-resistance tests, PTFE-coated fiberglass is the only membrane material that currently meets the U. S. model building codes definitions of a noncombustible material. (The three U.S. model codes are currently being reviewed and soon will be consolidated into one code.) This is a more accurate reason for the PTFE-coated fiberglass preference, but it raises questions about whether standards applied to other building materials should be applied to membranes.

- 15. Woven PTFE This material is constructed of PTFE fibers woven into a fabric. As of now, only one such material is available. Woven PTFE combines the environmentally-resistant advantages of the material with its ability to withstand repeated flexing and folding, an advantage it has over coated-fiberglass fabrics. Such flexibility makes it an especially good option for convertible structures; however, it is a rather expensive material and is not as strong as either polyester or glass. ETFE foil Perhaps the newest development in the fabric structures arena is the introduction of ETFE (ethylene tetrafluoroethethylene), a transparent membrane with fabric like qualities and the advantages of PTFE, such as a self-cleaning capability. Resistant to atmospheric pollution and UV light, ETFE has a very long expected lifespan of more than 20 years. Effective thermal performance (average U value is 2.6W/m2K for a two- layer system) and high light transmission (95% visible light, 85% UV light) enable a range of applications where traditional materials, such as glass, would not be practical. It is more than 20 times lighter than glass (0.35kg/m2 for ETFE vs. 15kg/m2 for glass) and is ecologically friendly and energy efficient as its constituent materials are fluorspar, hydrogen sulphate and trichloromethane, all non petrochemical derivatives. It is 100% recyclable.

- 16. These are the least-used materials for fabric structures. Mesh is a broad term for any porous fabric with open spaces between its yarns. It can be made from almost any fiber by a variety of methods, including knitting, weaving and extrusion. In some cases it acts as a substrate to beef up other fabrics or is coated to produce specific characteristics. For architectural use, meshes typically are available as polyester weaves lightly coated with vinyl or as knitted fabrics using high-density polyethylene (HDPE), polypropylene or acrylic yarns. Polyester mesh dyes well, is strong, has a low water absorption rate and can be economical. Nylon often is used in industrial applications because of its strength and resistance to chemicals, although it does have a high water absorption rate and may cost more than polyester. Often used in agriculture, recreation and containment, polypropylene and HDPE are inert, so they can’t be stained or dyed, and are less expensive than polyester or nylon. Polypropylene, however, does have a comparatively low melting rate, a factor in some industrial applications.

- 17. Netting is considered a type of mesh, usually tight with small holes. Netting finds use in stadium interiors behind goals, golf ranges and courses, playground equipment and structures, horticulture, zoos, construction sites and other areas where protection or containment is needed. Netting consists of a nylon, polyester or polypropylene with extruded or spun yarns that is knotted or raschel knitted to form the material. Each material has its advantages and appropriate applications. Polyester holds dye better than nylon but is more expensive; nylon is easier to coat, but has a higher water absorption rate and doesn’t hold dye as well. Polypropylene floats on water, is durable and chemically resistant, but can’t be dyed. Raschel knitting is a newer, faster manufacturing method than knotting. One drawback is that the knitted material can unravel, which can be thwarted by heat-setting the netting to shrink and stabilize the fibers.

- 18. Films are transparent polymers extruded in sheet form without a supporting substrate. They are not laminated or coated. Examples include clear vinyl, polyester or polyethylene. These films are cheaper than textiles, but they are neither as strong nor as durable. Films are much weaker in tension, though more elastic, than scrim- based fabrics. Films sometimes have application in air-inflated structures. Air-inflated structures are composed of fabric tubes in which the air is pressurized, but the structure’s interior itself is not. Some air-inflated roofs or building envelopes have been made using two or three layers of films to form air pillows. The film layers are thermally welded and sealed, and the resulting pillows are inflated by small fans. The inflation increases the internal pressure to prestress the surface, creating load resistance. Such film pillows are framed by an aluminum extrusion perimeter, which must accommodate some structural movement. Films range in thickness from 30 to 200 microns and can be produced with levels of translucency varying from 25% to 95% light transmission. Films are low weight, have a life expectancy of 20 to 25 years and highly resist dirt. The inflated pillows exhibit good thermal insulation values. More research needs to be done to develop a range of standard reliable, economical details, for instance, to improve the water seals and reduce wicking.

- 19. strip tensile strength grab tensile strength trapezoidal tear strength tongue tear strength adhesion strength flame resistance finished weight base fabric weight available topcoatings resistance to cold cracking dead load structural properties life expectancy

- 20. Shading coefficients General solar, optical, thermal performance data Acoustical data Dimensional stability Colorfastness Cleanability Seam strength and stability Construction method General handling ability, including abrasion resistance, foldability, etc.