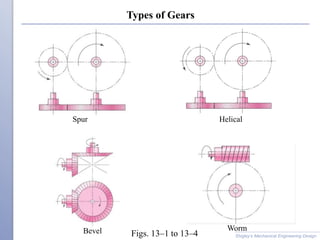

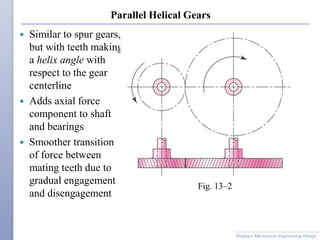

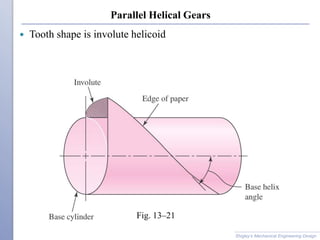

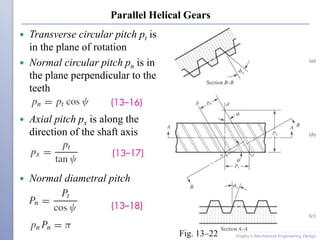

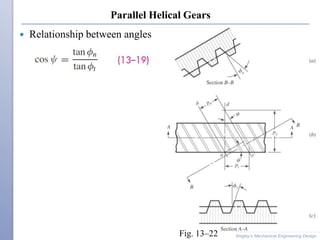

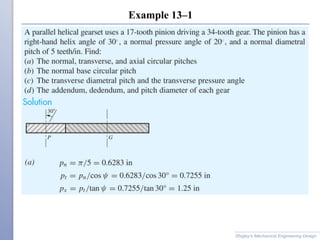

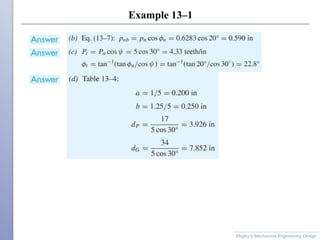

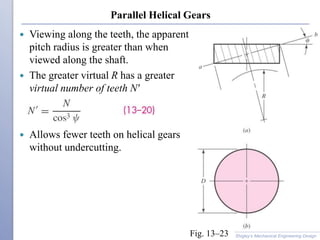

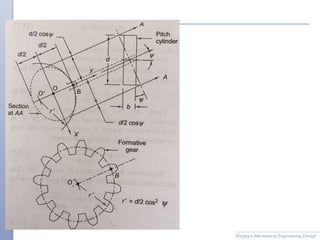

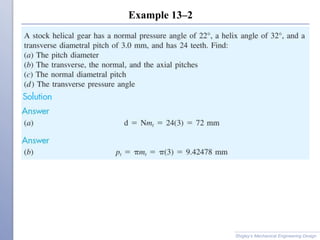

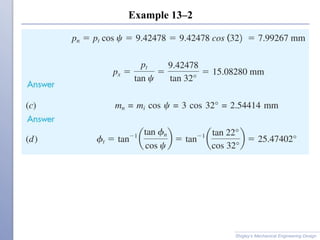

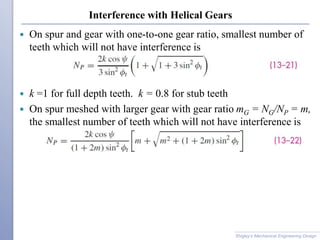

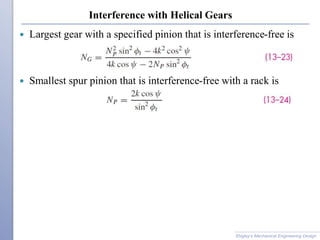

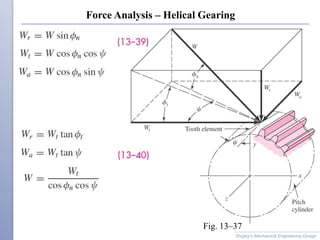

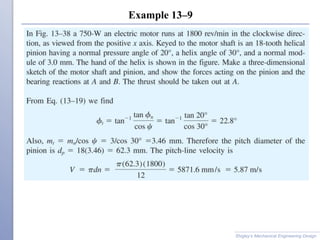

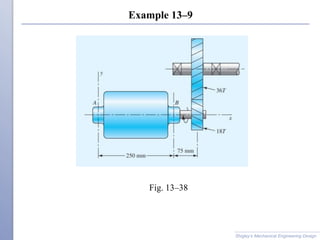

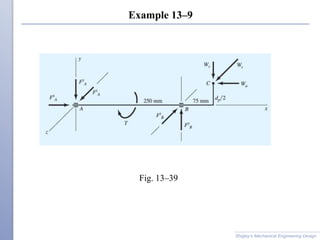

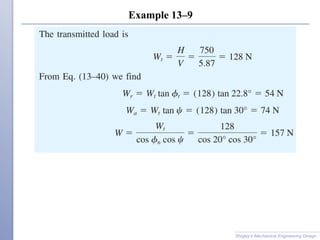

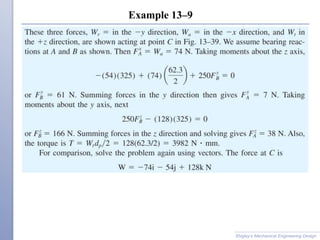

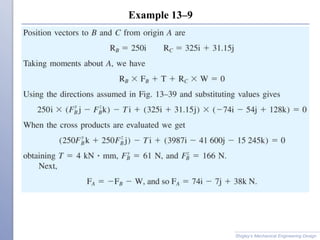

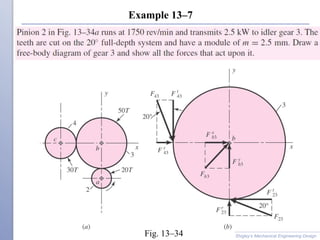

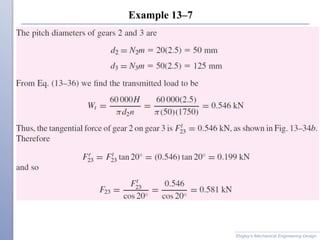

This document discusses parallel helical gears. It describes how helical gears have teeth that make a helix angle with respect to the gear centerline, adding an axial force component. This results in a smoother force transition between mating teeth during engagement and disengagement. The tooth shape for parallel helical gears is an involute helicoid. There are different pitch definitions for transverse, normal, and axial directions. Helical gears allow fewer teeth without undercutting due to an increased virtual pitch radius and number of teeth. Examples are provided to demonstrate force analyses and calculations for helical gear designs.