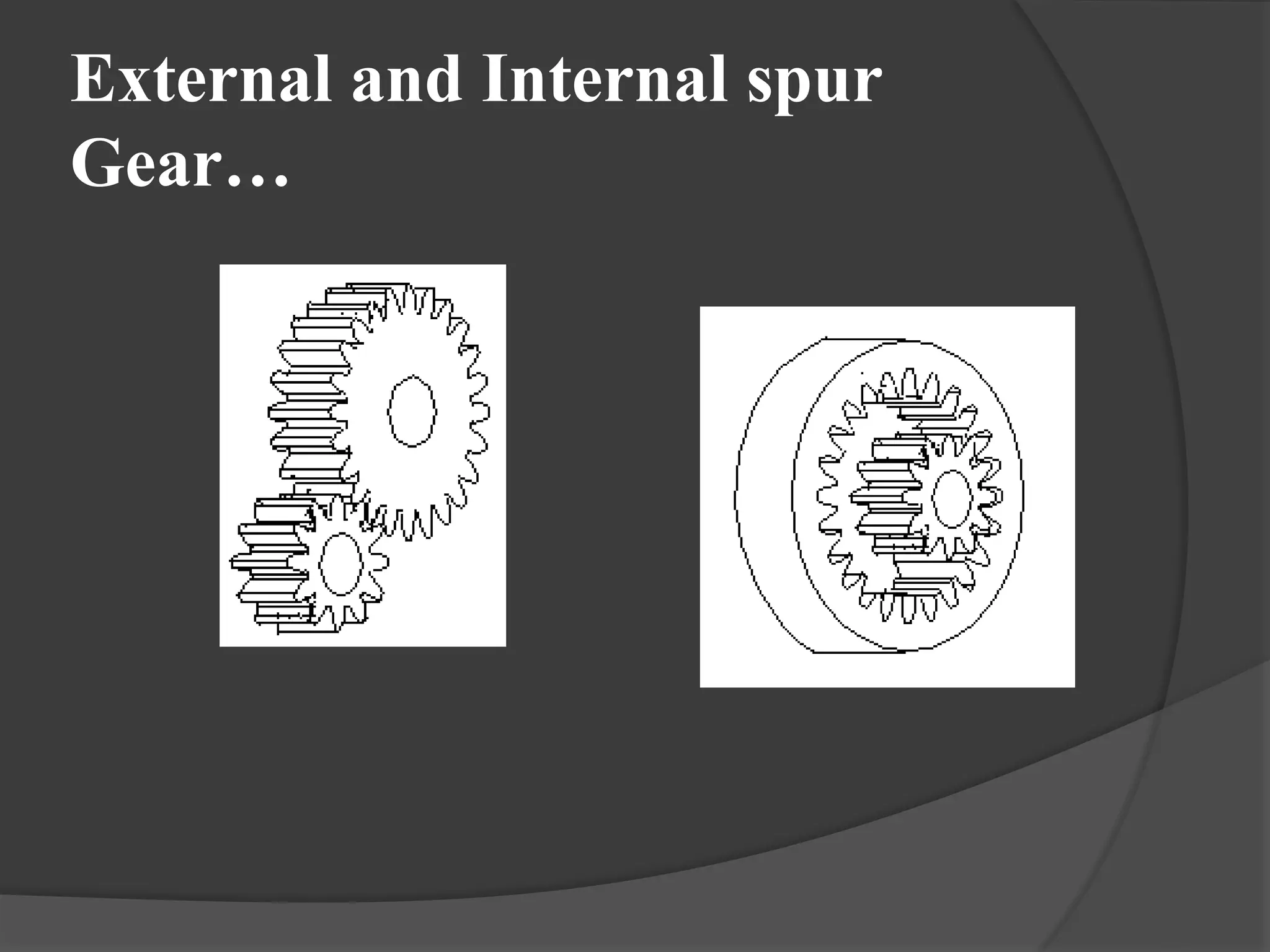

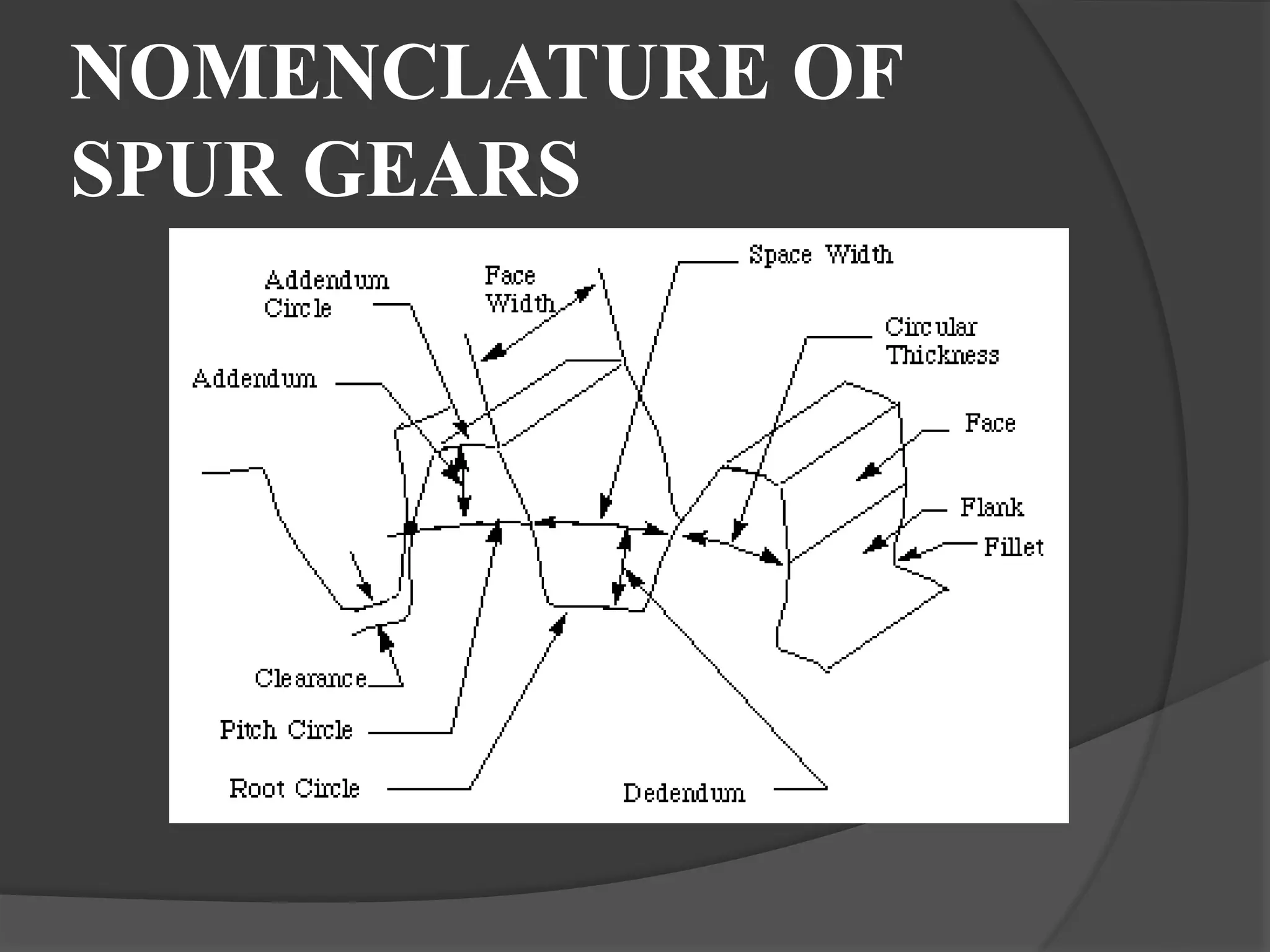

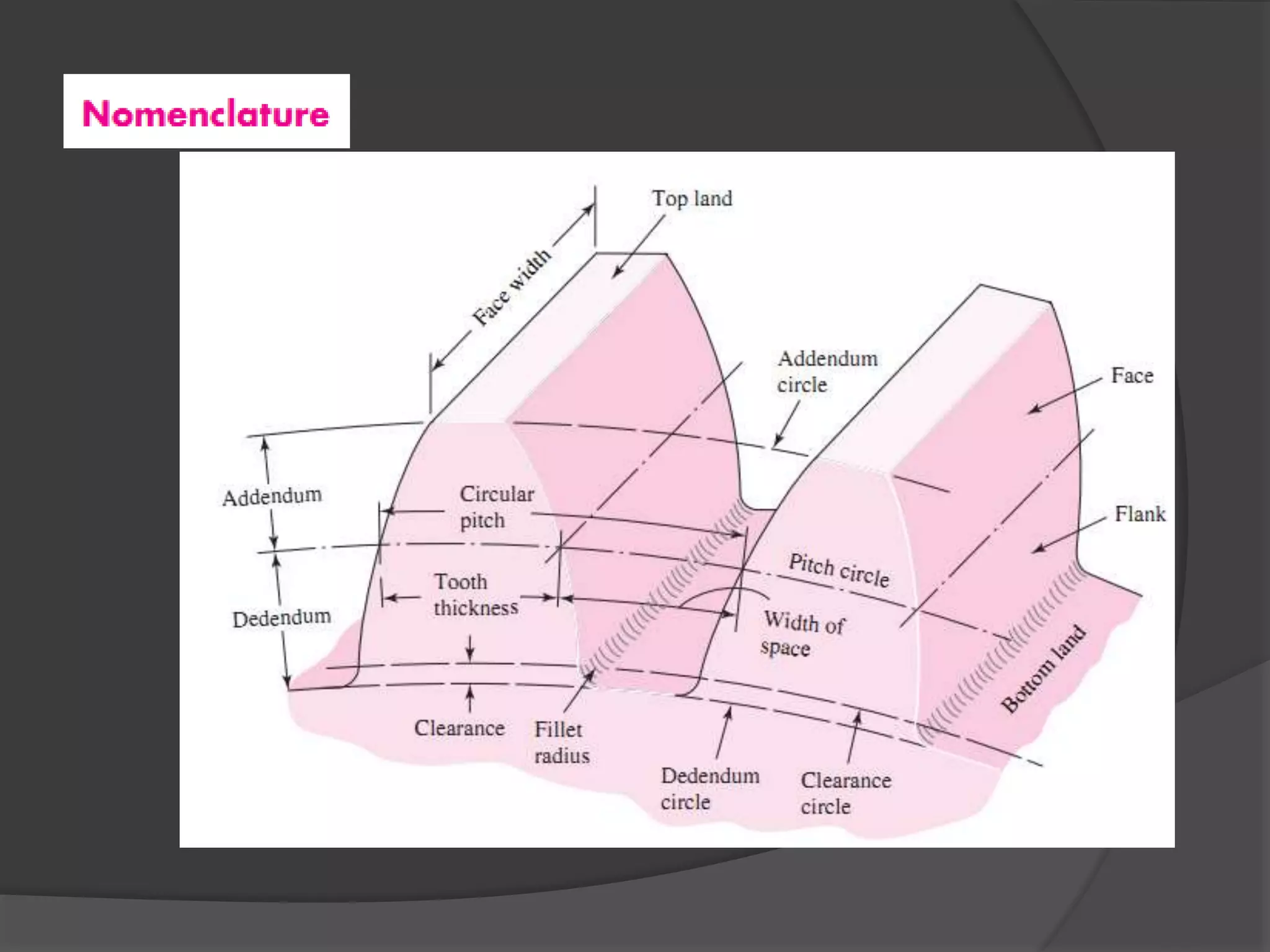

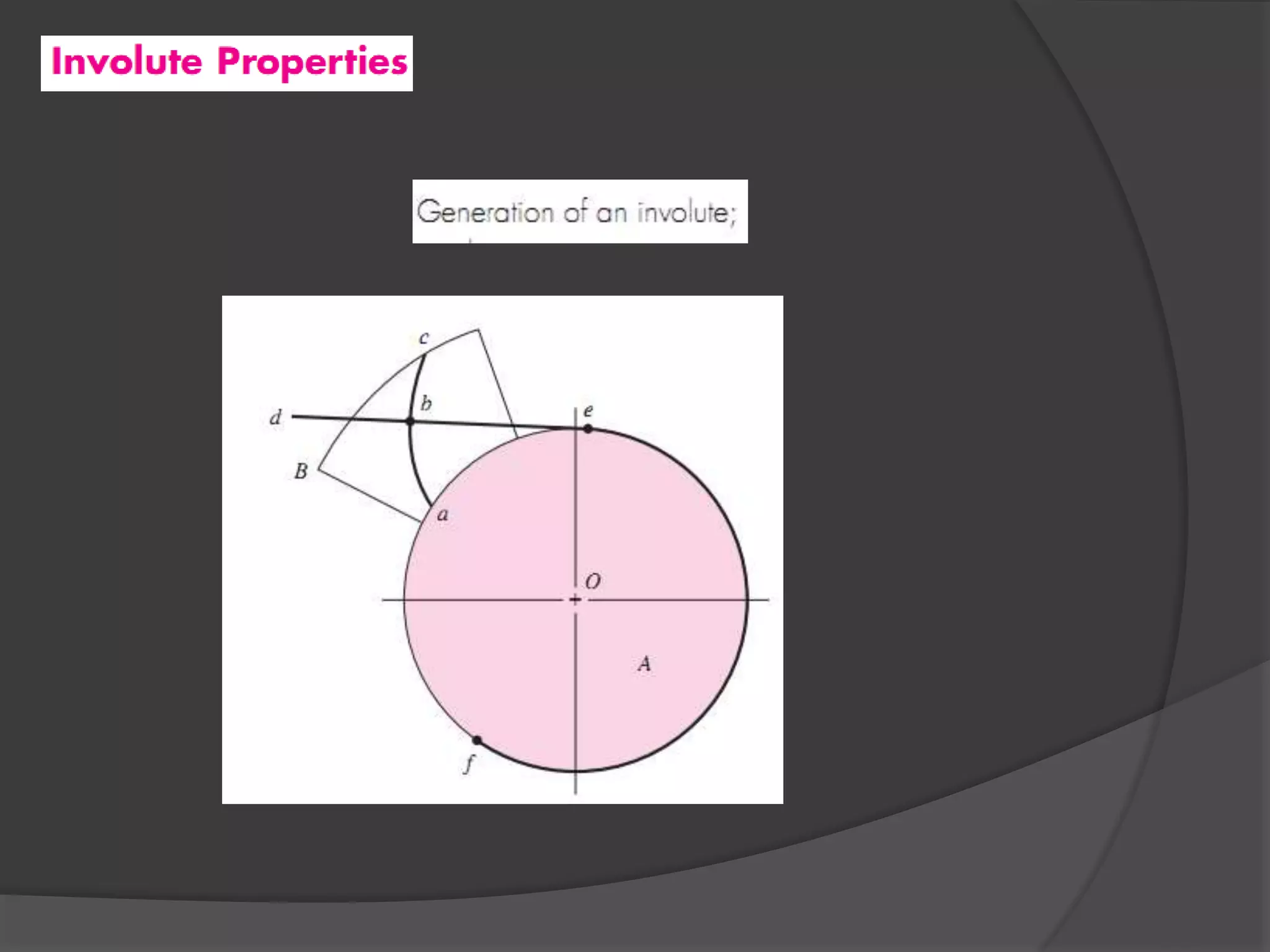

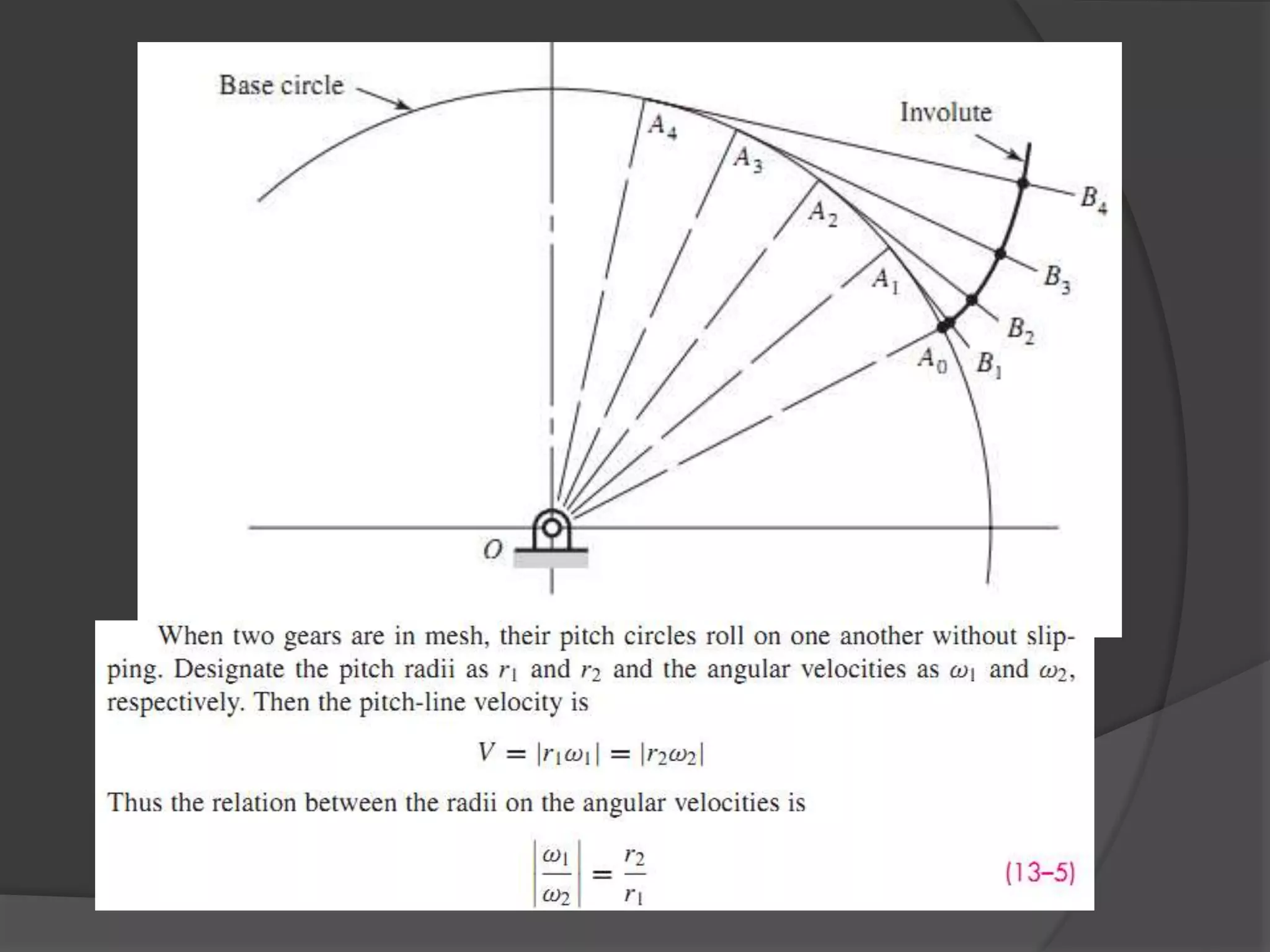

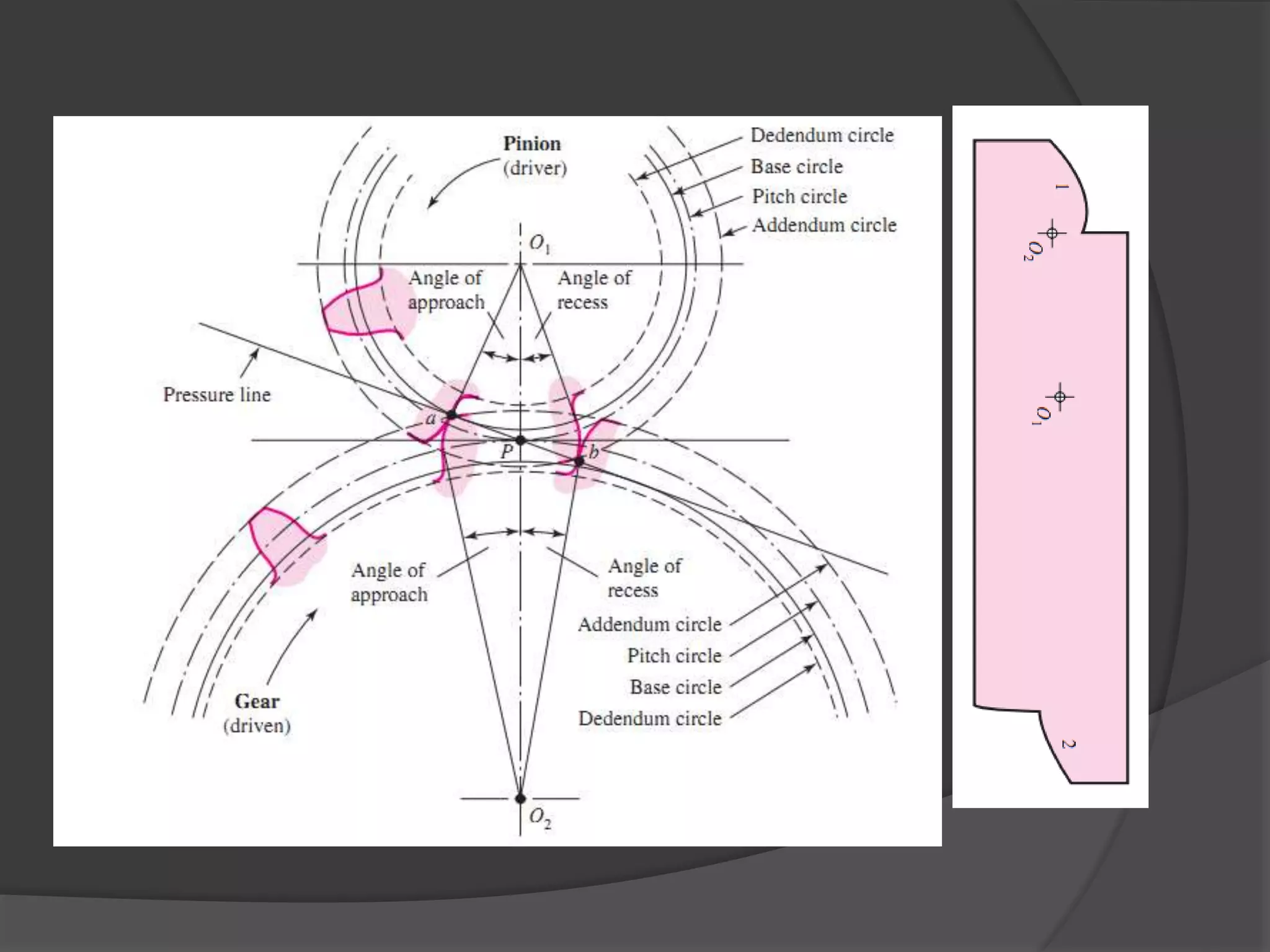

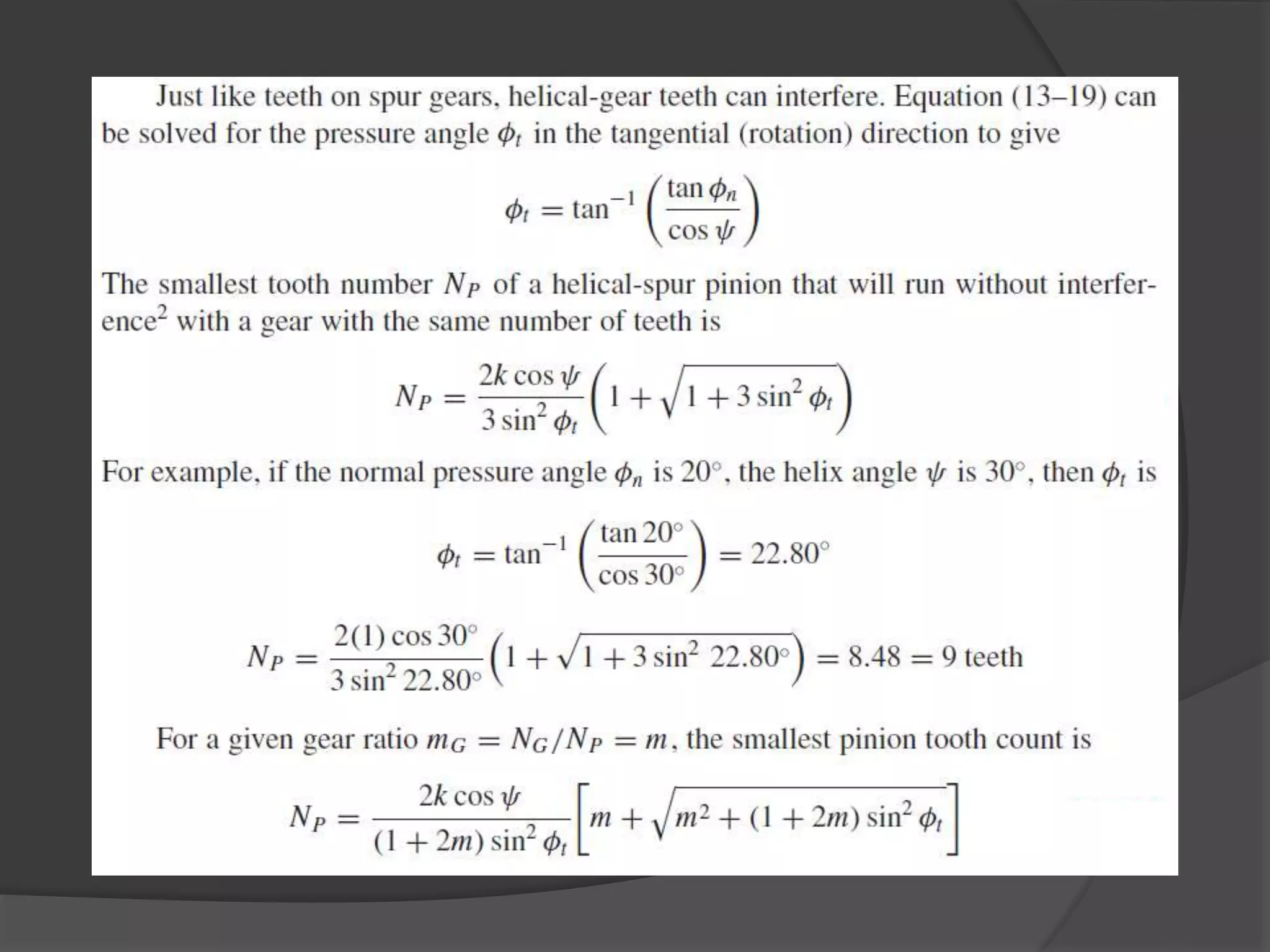

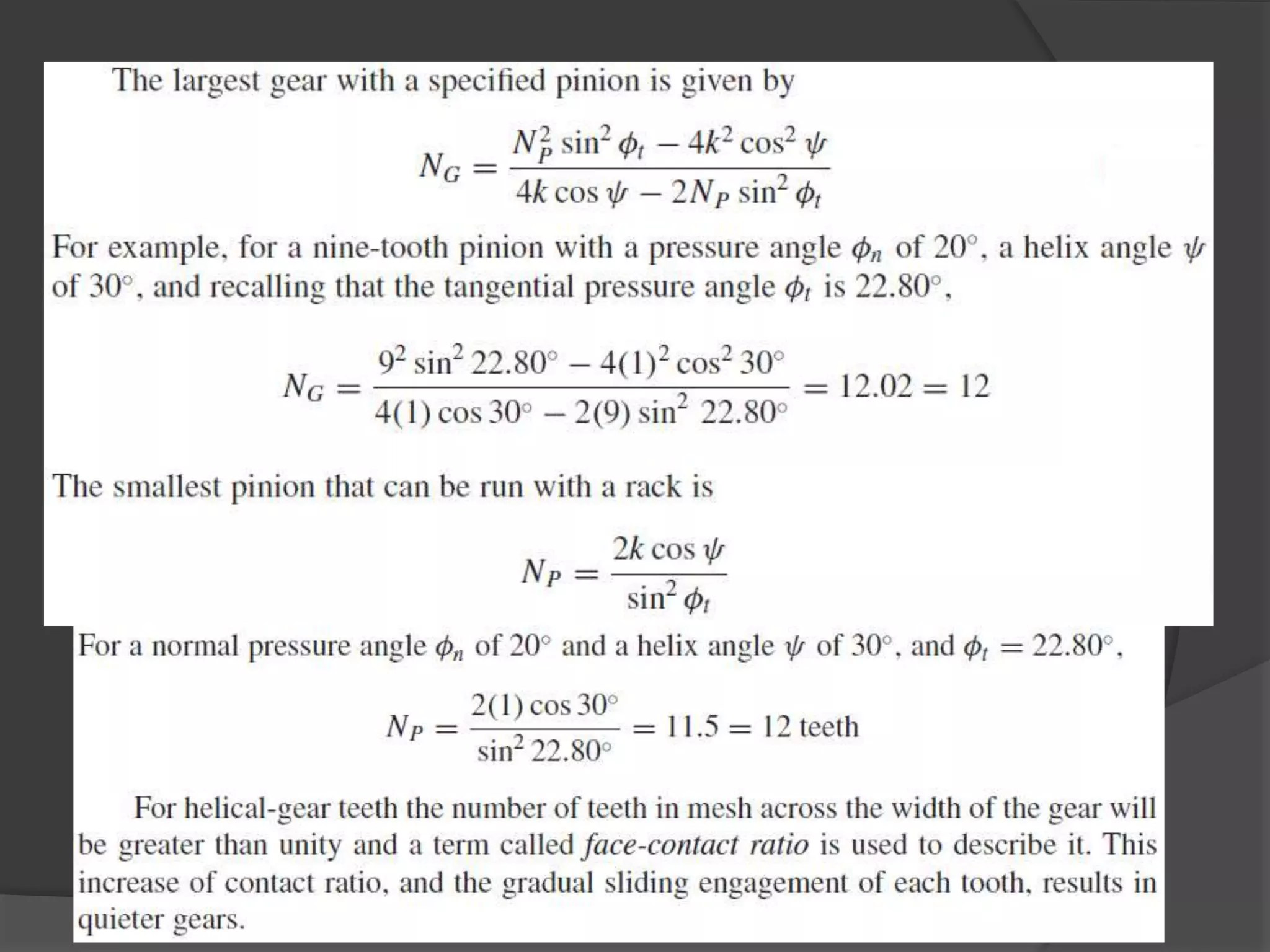

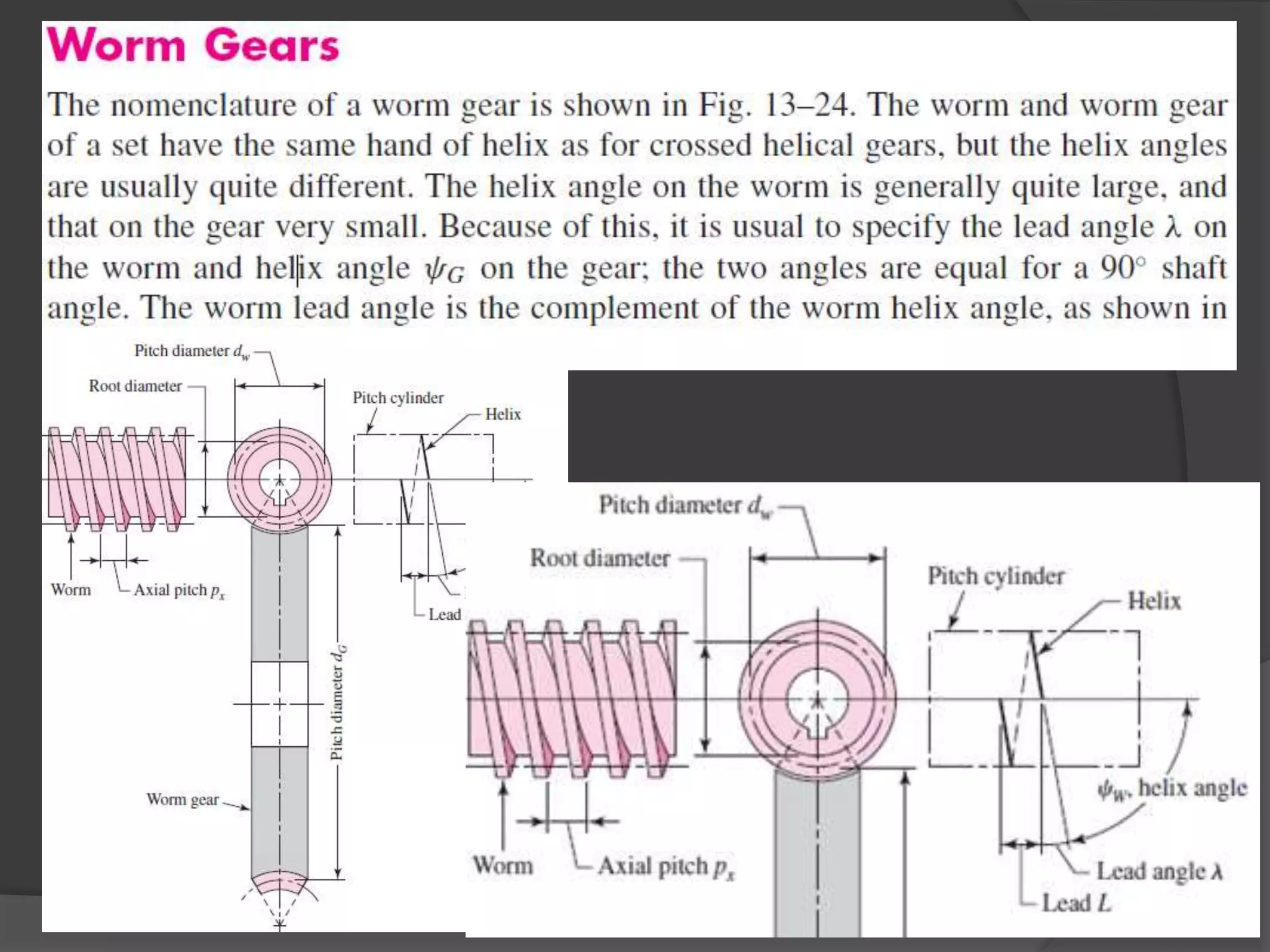

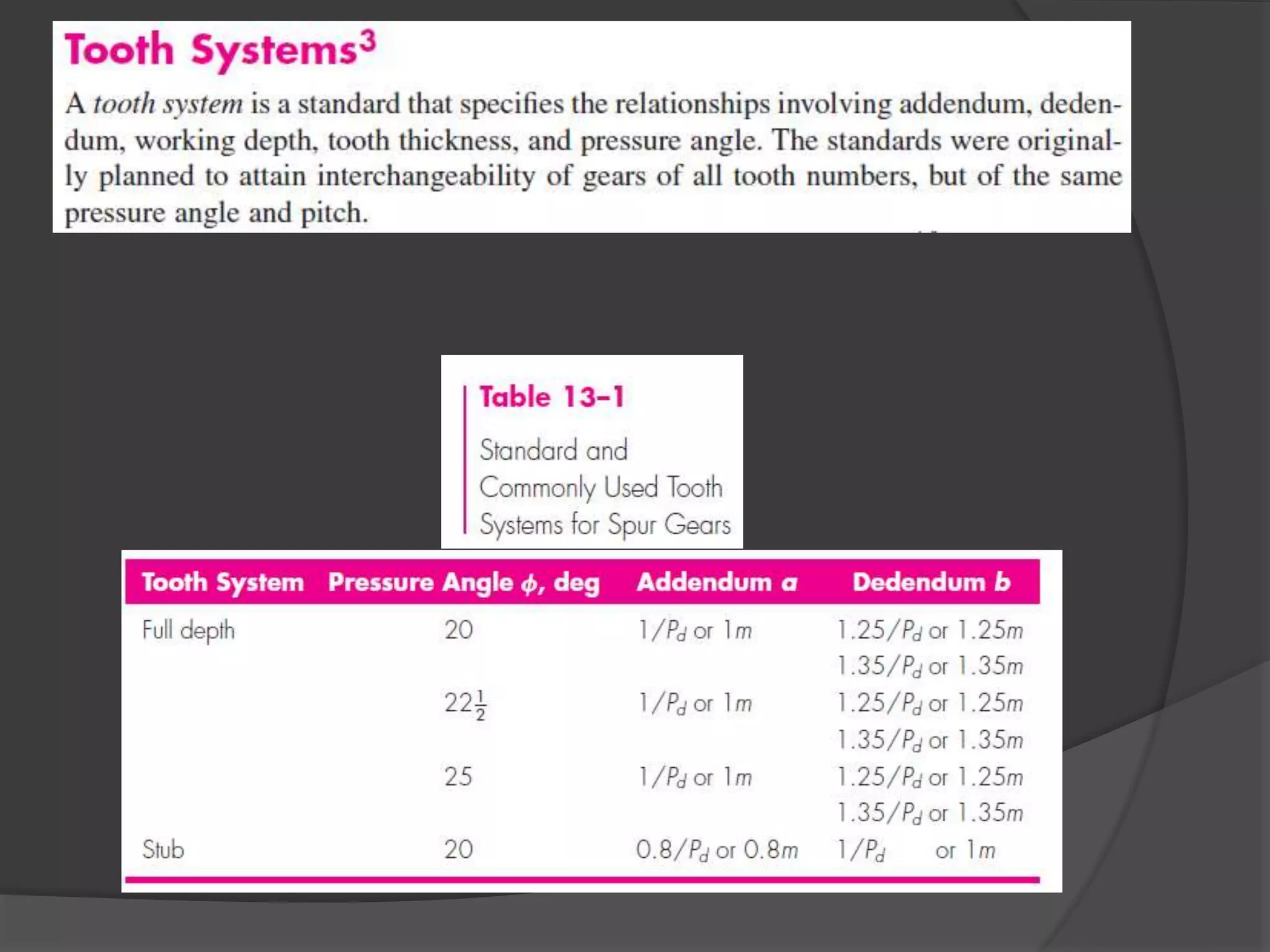

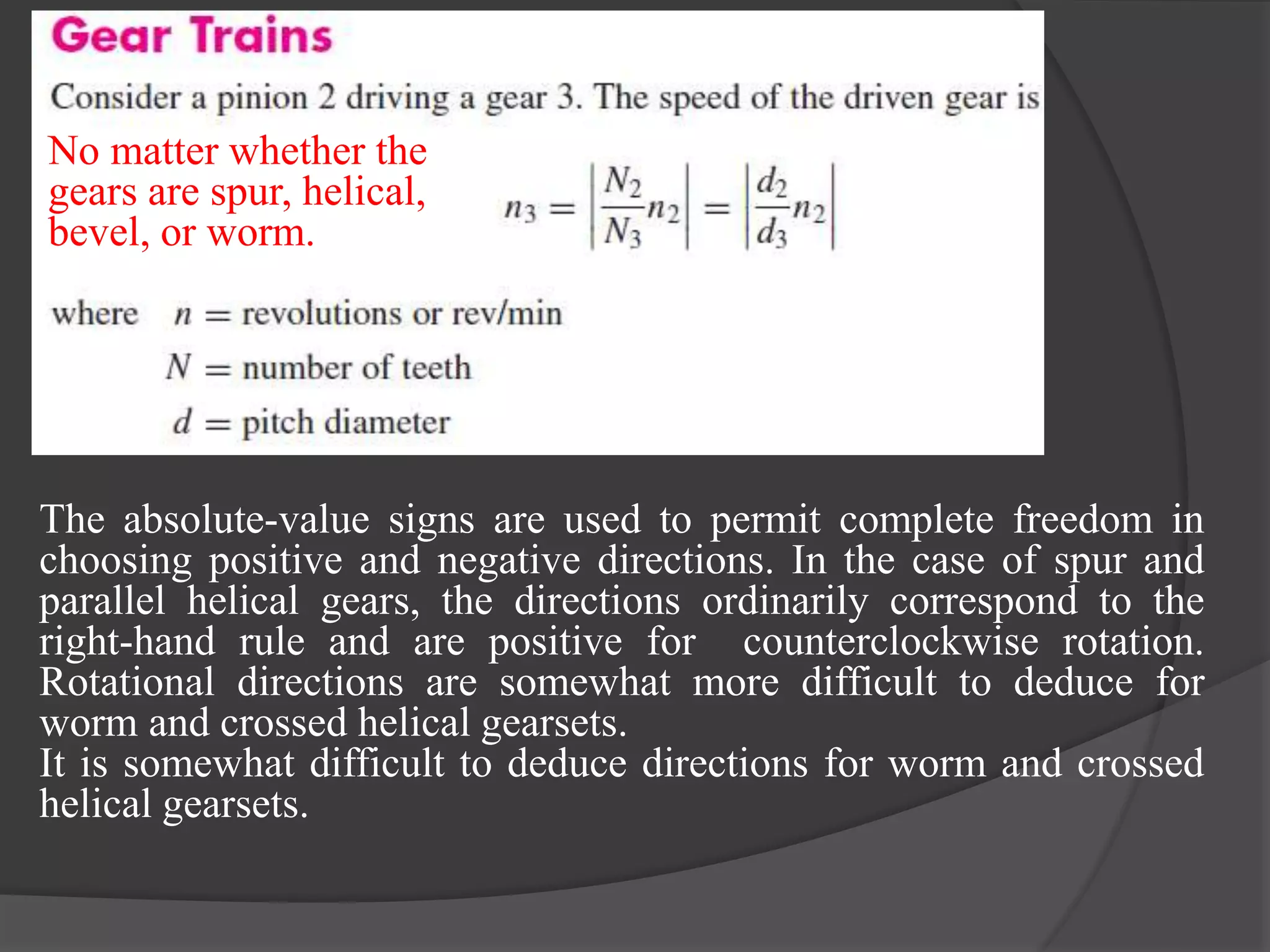

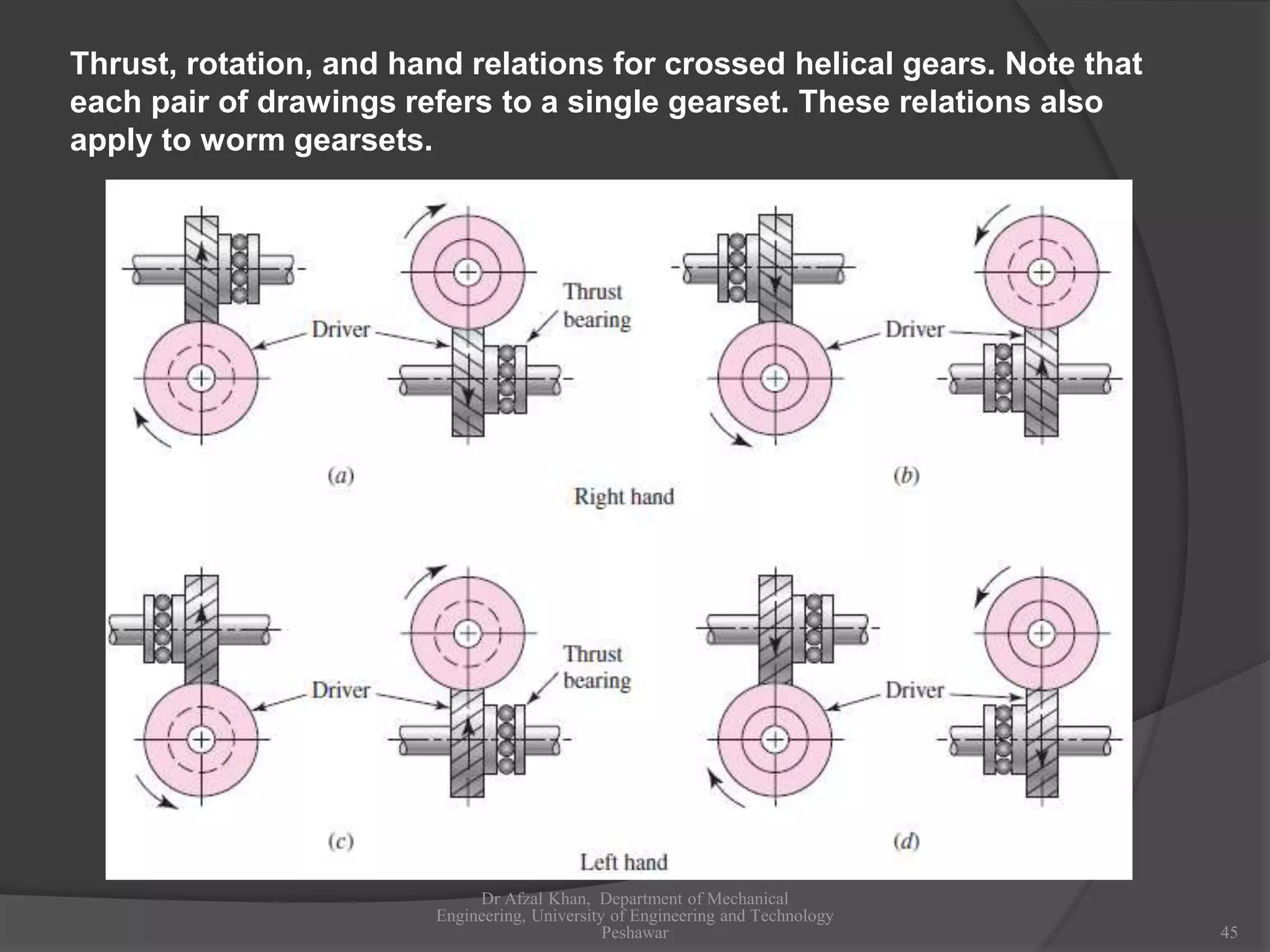

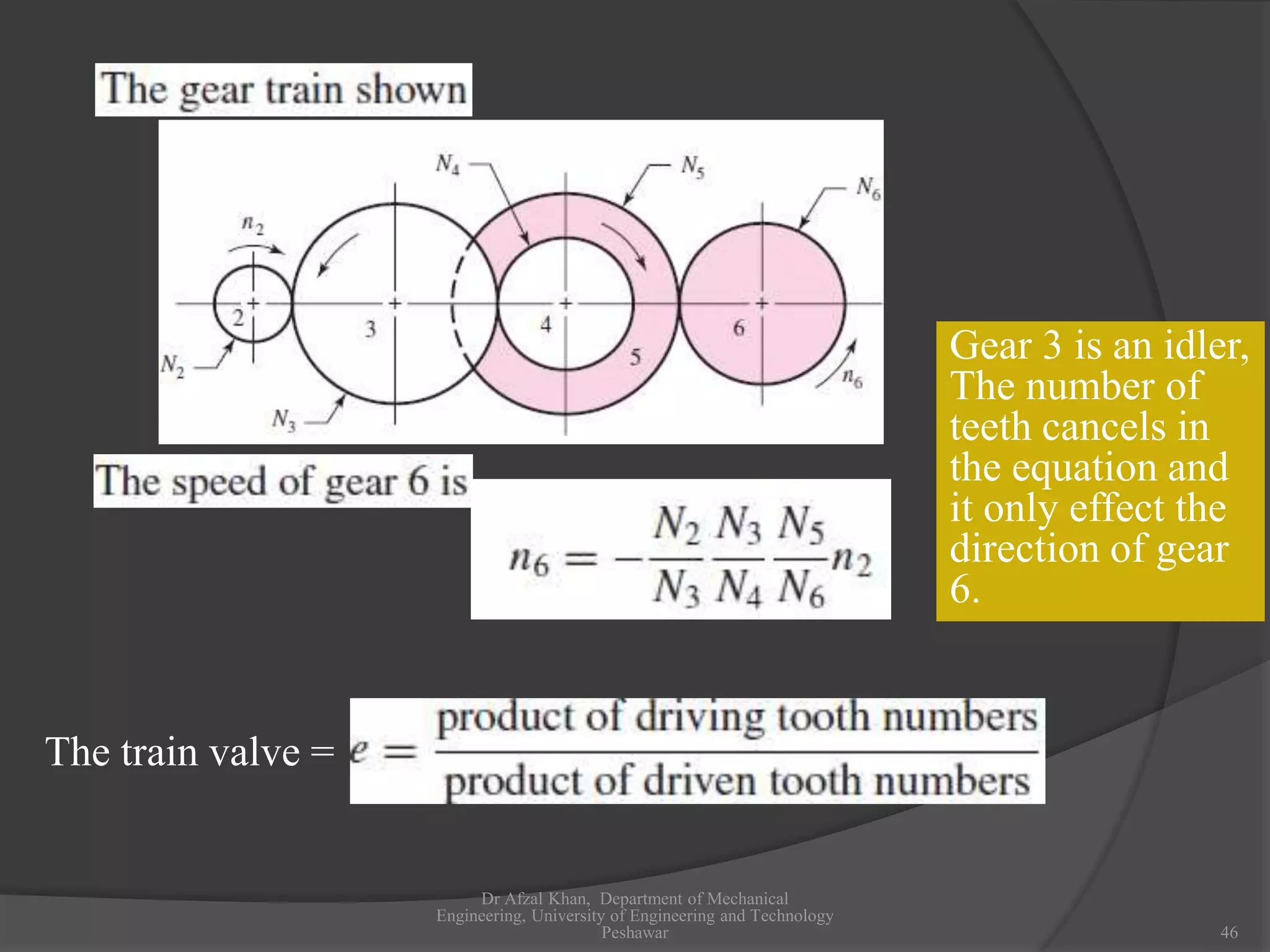

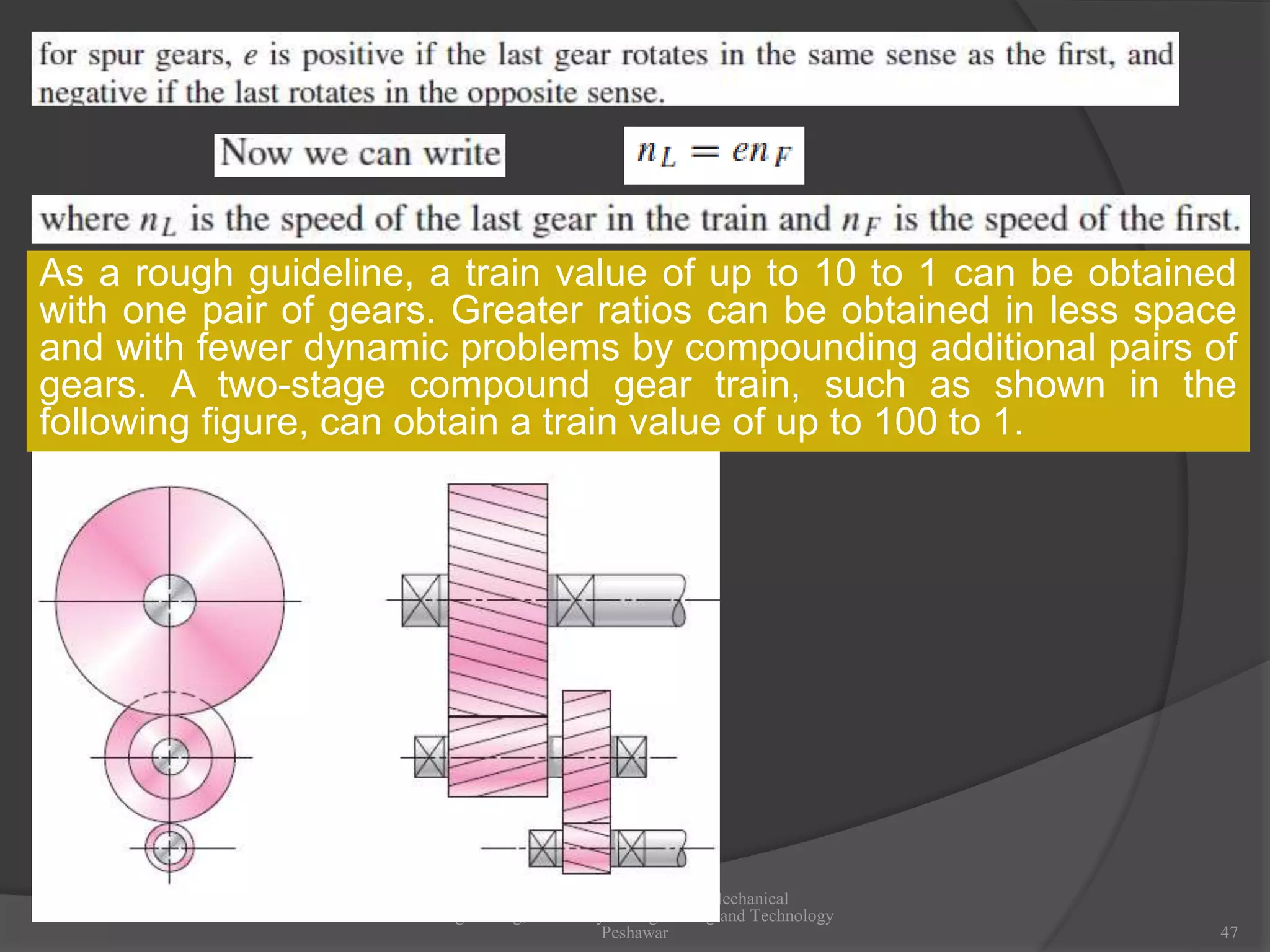

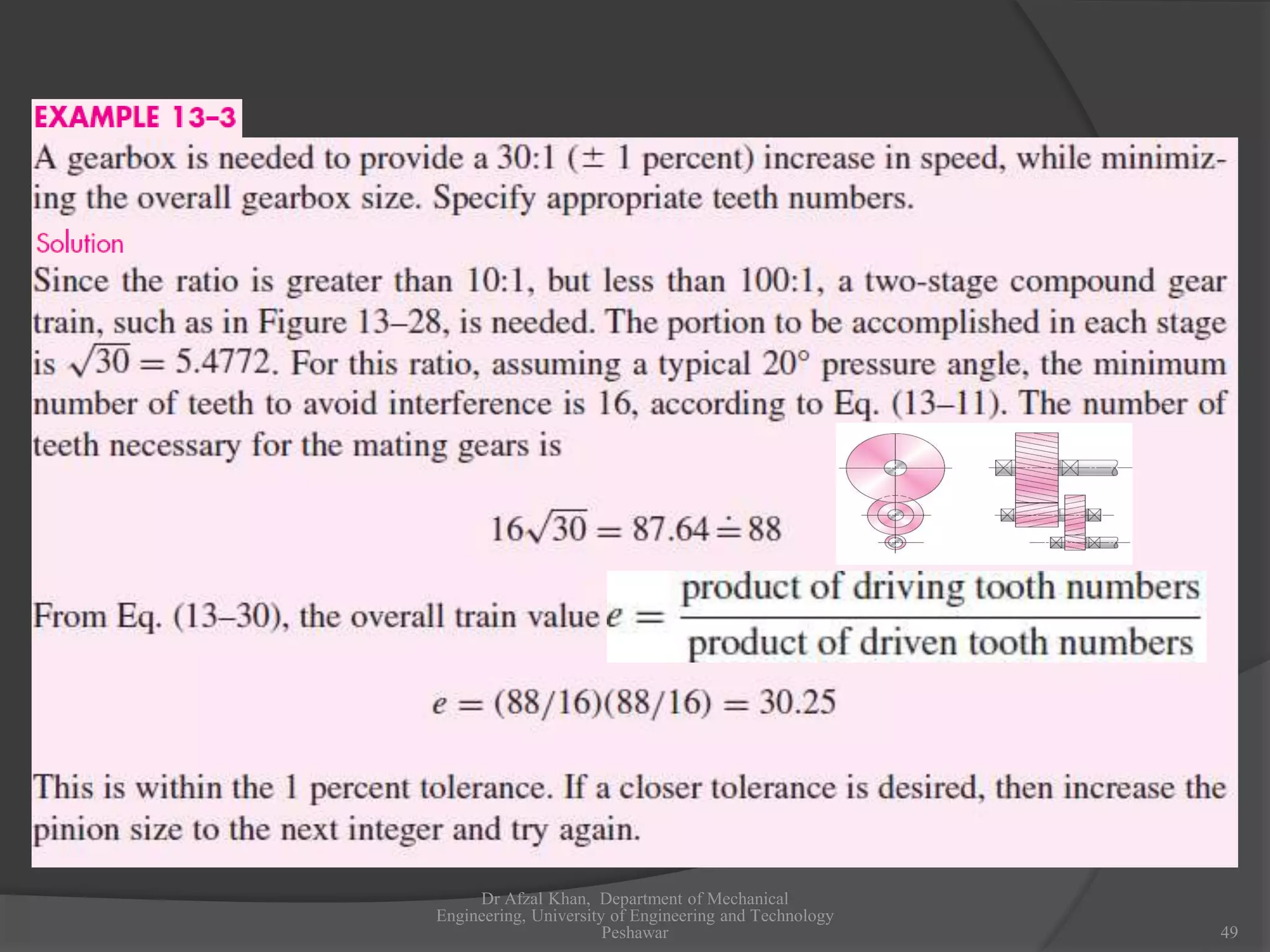

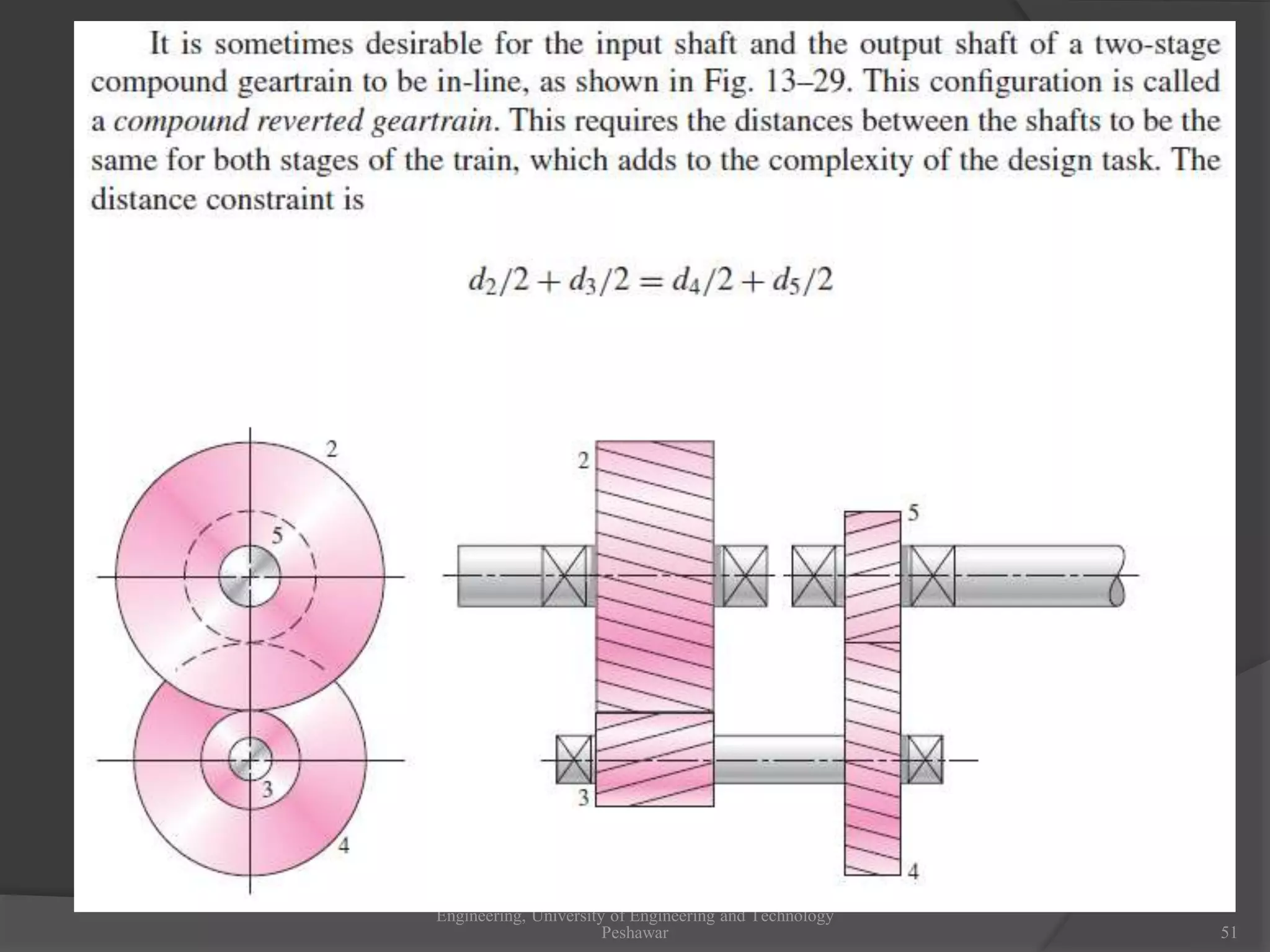

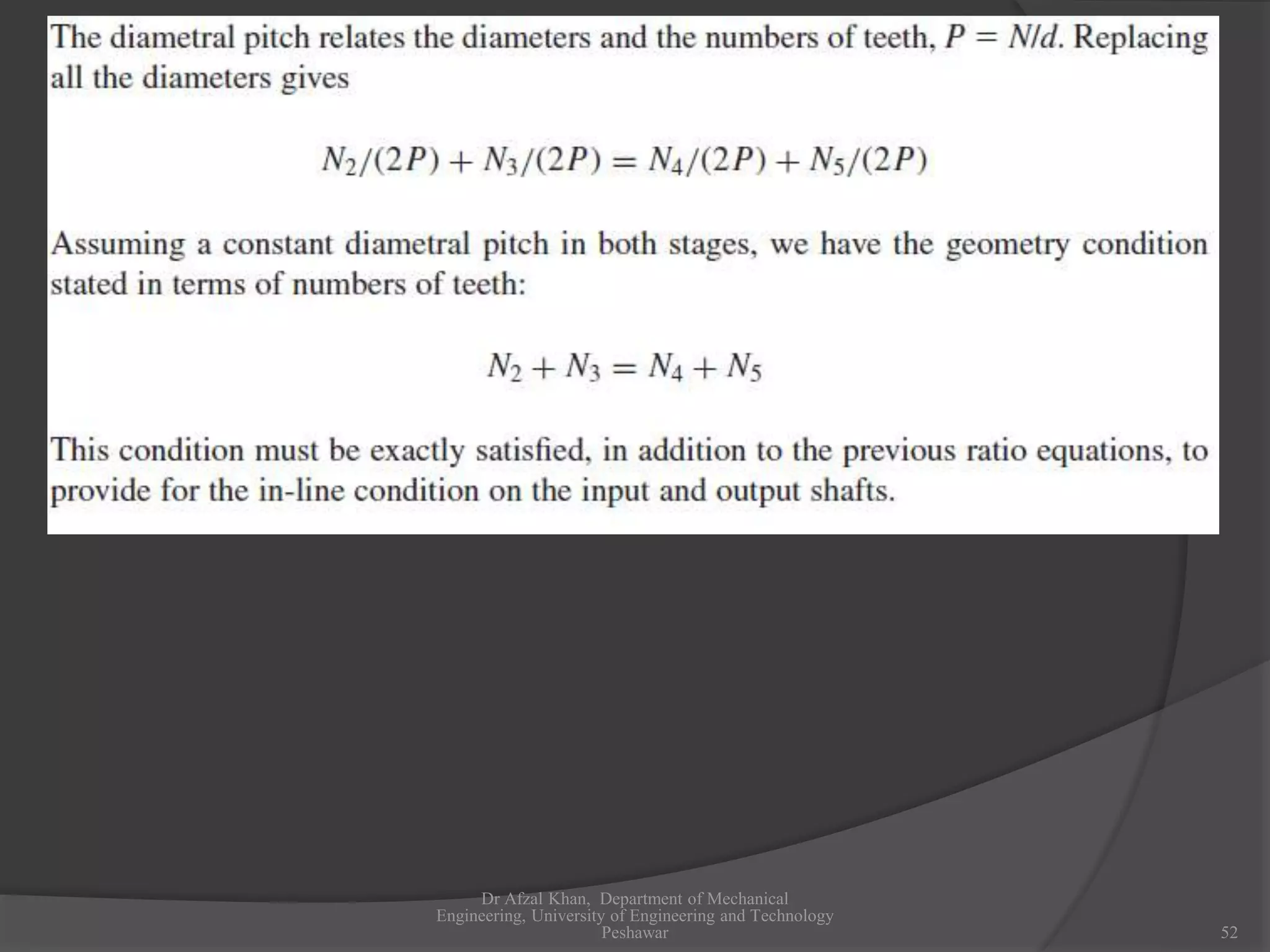

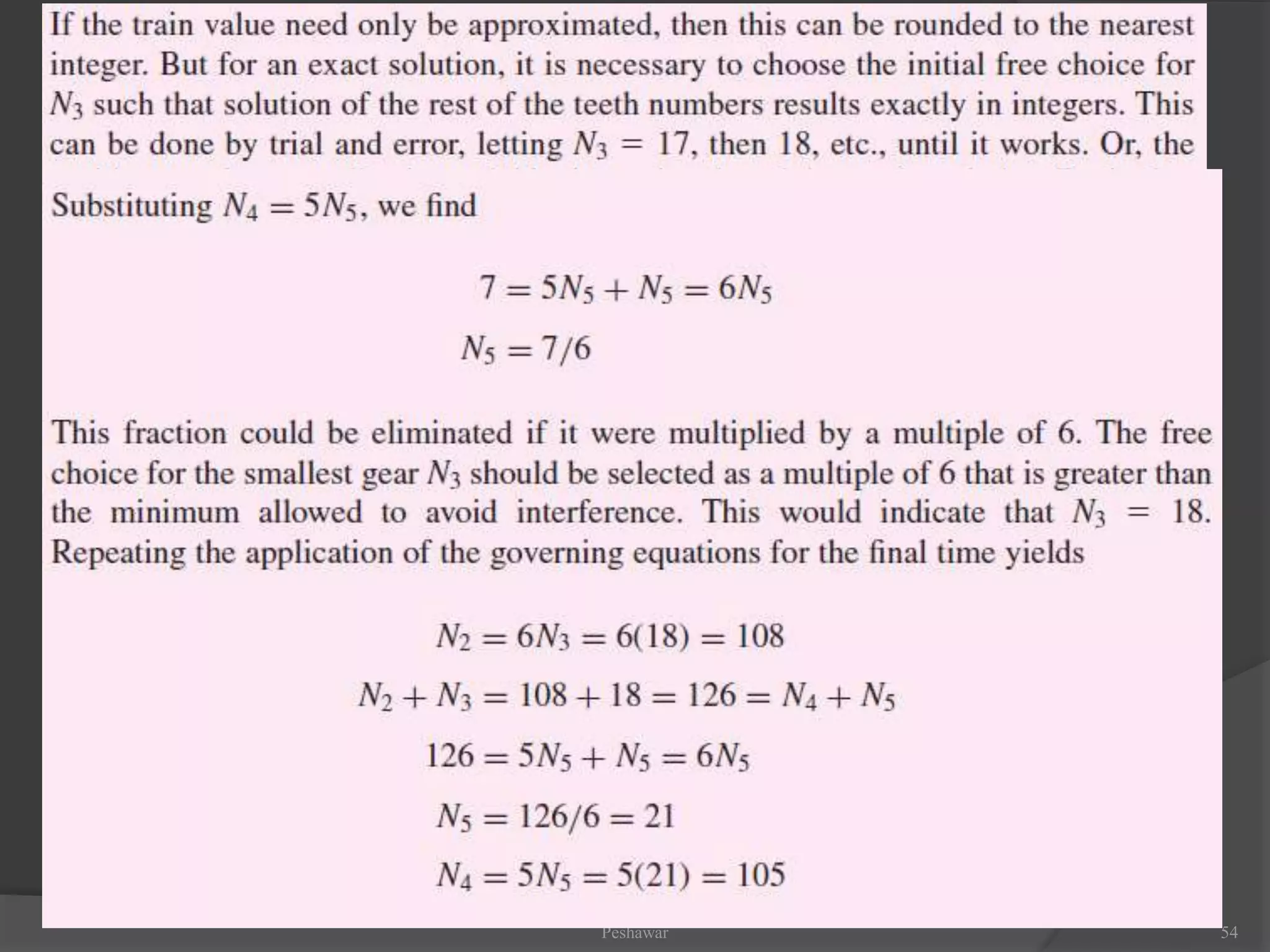

The document discusses gears and gear trains. It begins with an overview of different types of gears including spur gears, helical gears, bevel gears, and worm gears. It then provides details on gear terminology such as pitch diameter, pitch circle, addendum, and dedendum. The document also discusses how to calculate gear ratios in single and compound gear trains. Design considerations for gear trains including selecting gear tooth counts and sizes to achieve specific gear ratios are also covered.