Seeking Assignments in QA/QC , Project Site , Piping Welding/Fabrication , Inspection Expediting , Project Planning Management with a high growth oriented organization

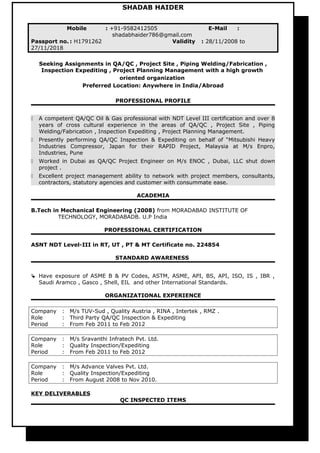

- 1. SHADAB HAIDER Mobile : +91-9582412505 E-Mail : shadabhaider786@gmail.com Passport no. : H1791262 Validity : 28/11/2008 to 27/11/2018 Seeking Assignments in QA/QC , Project Site , Piping Welding/Fabrication , Inspection Expediting , Project Planning Management with a high growth oriented organization Preferred Location: Anywhere in India/Abroad PROFESSIONAL PROFILE A competent QA/QC Oil & Gas professional with NDT Level III certification and over 8 years of cross cultural experience in the areas of QA/QC , Project Site , Piping Welding/Fabrication , Inspection Expediting , Project Planning Management. Presently performing QA/QC Inspection & Expediting on behalf of “Mitsubishi Heavy Industries Compressor, Japan for their RAPID Project, Malaysia at M/s Enpro, Industries, Pune Worked in Dubai as QA/QC Project Engineer on M/s ENOC , Dubai, LLC shut down project . Excellent project management ability to network with project members, consultants, contractors, statutory agencies and customer with consummate ease. ACADEMIA B.Tech in Mechanical Engineering (2008) from MORADABAD INSTITUTE OF TECHNOLOGY, MORADABADB. U.P India PROFESSIONAL CERTIFICATION ASNT NDT Level-III in RT, UT , PT & MT Certificate no. 224854 STANDARD AWARENESS Have exposure of ASME B & PV Codes, ASTM, ASME, API, BS, API, ISO, IS , IBR , Saudi Aramco , Gasco , Shell, EIL and other International Standards. ORGANIZATIONAL EXPERIENCE Company : M/s TUV-Sud , Quality Austria , RINA , Intertek , RMZ . Role : Third Party QA/QC Inspection & Expediting Period : From Feb 2011 to Feb 2012 Company : M/s Sravanthi Infratech Pvt. Ltd. Role : Quality Inspection/Expediting Period : From Feb 2011 to Feb 2012 Company : M/s Advance Valves Pvt. Ltd. Role : Quality Inspection/Expediting Period : From August 2008 to Nov 2010. KEY DELIVERABLES QC INSPECTED ITEMS

- 2. SHADAB HAIDER Inspection of Equipments for Oil & Gas Onshore & Offshore installation like Tanks, pressure vessels, Heat Exchangers,Oil storage tank , Lube Oil Skids , Fuel Gas Skids , Boiler , Cross country pipelines, City Gas pipeline, line pipes, pipe fittings, Motors, Horizontal Suction and Conveying Centrifugal Pumps, compressors, plates ,fabricated Process and Power Piping, Valves, Control Valves, Pipes & Fittings, Structural Steel, Charge Heater - Convection Module, Radiant Coils, Cross over coils , Air cooled condenser , Fin Fan Cooler Lube Oil Skid inspection as per API 614 Standard Process & Power piping QA/QC inspection as per API , ASME & IBR Standards Pressure Vessels and Storage Tanks inspections as per API 510 and API 653 etc. Witnessing factory acceptance test of various equipment for assuring efficient performance. Performing various pressure tests for pressure vessels like hydro test, air test, under water air test and oil test as well as site inspection of vendors and customers. Expert on performing the Prototype and Certification Testing of equipments as per ISO, BS and API as UL Testing, Fire Testing, Cryogenic Tests, Vacuum Test etc. Hands on experience in instruments like, gauges as well as digital instruments such as vernier calliper, screw gauge, inside micro meter, digital anemometer, ferrite meter, vibration meter, sound level meter, hardness tester, ultra sound thickness gauge, go no go gauges, plug gauges, groove gauge, sprit level dial indicators, filler gauges and positive material identification (PMI) machine, MPI Machine. Sand blasting inspection using profile meter or comparator and painting inspection using digital coating meter. QC PIPING , TANKS , VALVES AND OTHER ITEMS HYDRO INSPECTION Ensure that Pressure source and test gauge are upstream side. Ensure that test blinds installed are the correct thickness. Ensure that all items such as control valves, relief valves, rupture disks, orifice plates, diaphragm instruments, expansion joints, etc., which could be damaged during pressure test have been removed or isolated, as indicated on the pressure test flow diagram. Ensure that equipment, such as filters, which have internals that may be damaged during the pressure test are either blocked from test or that internals have been removed Check all temporary supports that have been called for on the pressure test flow diagrams, piping arrangement drawings or spool drawing to ensure that they have been properly installed Ensure that equipment, such as compressors, which must not be included in the field tests have been properly blocked off with the casing drain open Check open and closed position of all valves Check for proper installation of vents and drains Verify chloride content of test water when testing stainless steels QC WELDING & NDT INSPECTION Verifying welding machine to ensure all equipment meet job requirement specifications. Elaborating and coordinating the welding specifications, and codes/standards Coordination with the field subcontractors for all welding procedure specifications and procedures qualifications reports Review course and effects of welding defects and take remedial actions Coordination with the field subcontractors and the Third Party NDT Inspection Company Review of the radiographic film and all NDT reports Auditing of the approved Third Party NDT Inspection Company Reviewing the inspection and testing methods and procedures for Radiographic, Dye Penetrant, Magnetic Particle, and Ultrasonic inspections

- 3. SHADAB HAIDER Witnessing of welder qualifications testing and procedures qualification testing Witnessing any remedial repair welding Reviewing of the welding summery reports Checking the hydrostatic test packages for NDT compliance prior to testing Advising the site subcontractors with regards to welding and testing Monitor any Post Weld Heat Treatment on site and review the completed test reporting Selection of welds for non destructive testing Recording and listing of defective welds Monitor the control and issue of welding electrodes Control the QC site welding inspectors Actively monitor site radiation safety Coordinate the issue of non-conformance reports through the site QC manager Compete site quality instructions to sub contractors when required Ensuring welding sequence as per appropriate welding procedure requirements and also maintaining welding variables. Carrying out visual inspection of welds for attaining flaw less welding operation. Handling diverse drawings for various jobs like tube bundles, structural items, setting plans, shells, storage tanks, etc. Involved in post weld heat treatment of pressure vessels (normalizing) and carrying out final inspection before dispatch. Conducting welding witness procedure qualification test; monitoring welder performance and conducting visual inspection of welds and repairs of welds in accordance with company procedure and international codes of practice QA MANGEMENT Preparation of Inspection check list in line with P.O, Data sheet , Drawings , specifications requirement for smooth operation of inspection & expediting Review of Inspection and Test Plans ( ITPs ) to verify that Contractor is performing all required inspections and witnessing all required tests . Review and approval on welding documents WPS/PQR/WPQ, Heart Treatment, NDE procedures, Hydro/Pneumatic test procedures etc. Witness of Inspection & testing activities at manufacturing units as per Inspection Test plans Preparation of Inspection Visit reports for the inspections. Review of Supplier documents/MTC’s , Hydro/Pneumatic test reports , NDT reports , Visual dimensional reports etc. and issue of IRN's Responsible for Inspection , Planning and Monitoring of all Third Party Inspectors inspection activities of all disciplines of Project . Coordination with Engineering team to sort out any Quality issues/Deviations Compiling of Manufacturers’ Data Report (Final Quality Documents) in line with project requirement & submission to Client. Preparation of Monthly Inspection progress Reports. Evaluation & Qualification Audits of new suppliers for Vendor development Coordination with Third Party Inspection agencies for arranging inspections at supplier works. Review of TPI inspection reports , IRNs and issue of MDCC based on the same Ensuring all delivery consignments are inspected prior to release for shipment. Expediting of manufacturing progress & follow up with suppliers to meet the delivery within Contractual delivery. Issuing of dispatch instructions & coordinating for dispatch of consignments with suppliers. Ensuring that the Third Party Inspections are carried out in accordance with the marked up Inspections stipulated in the Inspection and Test plans as Witness and Hold Points. Monitoring ‘RFI’ (Request For Inspection) Register, and directing TPI Inspectors for the relevant Inspection activities at site. Preparing Weekly RFI Status. The preparation of the companies QA manual control and supervision of all amendments and revisions

- 4. SHADAB HAIDER Control and the distribution of all the companies quality documentation Monitor all quality related activities on the project Perform all internal and external audits on behalf of the companies management Verify contractor quality requirements are specified to vendors and contractor documentation submittals. Attend all pre-bid meetings and coordinate all project requirements with the project bidders. Attend client quality management meetings The preparation and control of project quality system management documentation prior to project commencement. Review quality inspection personnel qualifications and training requirements Monitor the disposition of all issued nonconformance reports. Monitor the progress and effectiveness of the project quality management system. Recommend and implement improvements when required. Coordinate all QA/QC activities with the site QC manager Coordinate all QA/QC activities with the site QA/QC procurement manager Coordinate all quality related correspondence with the customers representatives. Monitor statistical method reporting. Action and close all customer complaints Control all achieve documentation upon the completion of the project. Quality Assurance and Quality Control in Mechanical Plants and on projects. Quality Management Systems based on ISO 9001:2008, My expertise had been to Develop, Update, Implement, monitor and maintain and Audit Quality Management systems based on these standards Second Party Audits: Vendor Quality and Technical assessment, Surveillance audits and Capability Surveys Environmental Controls & HSE Regulations Corrective and Preventive Actions NCR resolution and Root Cause Analysis SITE QA/QC Witnessing and sentencing of all site inspections within their disciplines Coordinate all site inspections with the site subcontractors Ensure that all inspection reports are accurate and that all attached documents are current status Ensure all work is correctly prepared prior to any inspection being undertaken Review all inspection reports for compliance Assist the site QC manager in the organisation, maintenance and control of the quality system Liase with the site construction engineers and provide assistance when requested Prepare nonconformance reports to the QA manager and assist in developing corrective actions Assist the QC manager and construction manager in resolving any discrepancies and ambiguities Coordinate with the customers QC inspectors for the resolution of site problems Coordinate with the site subcontractors to ensure that communications exist and are maintained Assist the site subcontractors in the resolution of drawing interpretation Attend the weekly QC meetings Review work procedures and method statements for compliance with good work practices and the customers contract specializations The issuance of non-conformance reports in conjunction with the site QC manager The completion of QC site instructions and coordinate their closure The review of inspection test packages during the course of construction activities Compliance with the site's health and safety regulations EXPEDITING Handled complete inspection/expediting activities of a project for Mechanical, Electrical

- 5. SHADAB HAIDER & Instrumentation items. Coordination with Engineering, Project, Purchase , Commercial ,Finance , Logistic teams for smooth execution of Project . Attending Kick off meeting pre inspection meeting (PIM) at suppliers works prior manufacturing Preparation of Inspection check list in line with P.O , Data sheet , Drawings , specifications requirement for smooth operation of inspection & expediting . Seek Order acknowledgements and update promise dates from suppliers Regularly review pending orders with suppliers and identify critical exceptions for buyer to ensure On Time Delivery Co-ordinate with all internal customers to ensure that client requirements are met Implement checklists for suppliers to ensure that proper documentation is enclosed by suppliers to meet local regulations and company requirements Clearing Supplier invoices to ensure that queries, if any are resolved by concerned buyers Expedite In-House activities to ensure shortest turnaround time for our clients Support of data integrity in systems and documentation, including creating part numbers, BOMs, pick lists, allocation of parts, inventory transfers AUDITING Assisting the Asset Integrity Assurance Manager by acting as audit leader of assigned audits (the audit leader will preferably be assigned to audits of his own technical expertise) Managing exercises and audits to ensure the necessary strategies and controls are demonstrably in place to assure the integrity of the assets in all phases of the project lifecycle Contributing to the assurance that the facilities under development by the Company are designed and built in such a way that integrity (and hence safety and economic performance) can be maintained during all phases of the lifecycle Contributing to the preparation of look ahead plans for audits to be held Managing external resources in the execution of audits Coordinating with other auditing teams to prevent unnecessary disturbance of running projects Reviewing agendas and terms of reference to ensure clarity of purpose Preparing external parties of the auditing team for the audit Compiling and issuing report and support interpretation of its contents; follow-up and monitor closure of actions Coordinating reporting of external parties OIL & GAS ELECTRO MECHANICAL PROJECT ITEMS QC INSPECTION & EXPEDITING Item : GAS PRCS Supplier M/s Gas Flow Solution Belgium Item : Level Transmitters Supplier M/s Magnetrol Belgium Item : Valves Supplier M/s Boteli & M/s Oviko China Item : Gas detector Supplier M/s Oldham Belgium Item : ESDV Supplier M/s Ace Valves Korea Item : Level Gauges Supplier M/s Samil Korea Item : Burner Supplier M/s Reillo Italy Item : Ultrasonic Flow Mtr Supplier M/s Emerson USA Item : GC Supplier M/s Emerson USA Item : Flow Computer Supplier M/s Apex

- 6. SHADAB HAIDER Ahmedbd Item : PRCS Supplier M/s Nirmal Controls Mumbai Item : Valves Supplier M/s Sakhi Mumbai Item : DPT PT TT Supplier M/s Emerson Mumbai Item : UPS System Supplier M/s Hitachi Gndhngr Item : Burner Blower Supplier M/s Suntec Ahmedbd Item : PSVs Supplier M/s Leser & Faiger Aurngbd Item : PSVs Supplier M/s Bliss Anand Rewari Item : PSVs Supplier M/s Tyco Valves Delhi Item : MCC & PLC Panels Supplier M/s ATC Noida Item : Cables Supplier M/s KEI Bhiwadi Item : Junction Box Supplier M/s R. Stahl Chennai Item : Heater Supplier M/s Sandvik Hosur Item : Heater Panel Supplier M/s Sandvik Hosur Item : RTDs , PGs & TGs Supplier M/s Wika Pune Item : Pumps Supplier M/s KSB Nasik Item : Transformers Supplier M/s Kirloskar Mysore Item : Convection Module , Supplier M/s Technip KT India Ltd. Delhi Radiant Coils, Cross over coils Supplier M/s Technip KT India Ltd. Delhi Fuel Gas & Preparation Skid Supplier M/s Technip KT India Ltd. Delhi Item : Valves Supplier M/s Fluidline Valves Pvt Ltd. Ahmedbd Item : Valves Supplier M/s Hawa Valves Mumbai Item : Valves Supplier M/s Advance Valves Pvt Ltd. Noida Item : Pumps Supplier M/s WPIL Ghaziabd Item : Lube Oil Skid Supplier M/s Enpro Pune Item : API Tanks – API Supplier M/s Fabtec h Projects Paradeep Item : Pressure Chambers Supplier M/s Micro precision Faridabd Item : PEB Supplier M/s PEBS Pennar Hyrdbd Item : PHE , Pumps etc Supplier M/s Frick India Faridabd Item : HVAC system Supplier M/s Wolaque

- 7. SHADAB HAIDER Delhi Item : Air Dryer, Comprssr Supplier M/s Atlas Copco Pune Item : Filter , Reciever Supplier M/s Atlas Copco Pune Item : PRS , Pumps Supplier M/s Spirax Marshall Delhi Item : Flash Vessels Supplier M/s Spirax Marshall Delhi Item : Magnetic Filters Supplier M/s Acme Ahmedbd Item : ETP STP Supplier M/s Brisanzia Delhi Item : Pumps Supplier M/s Stephenson Mumbai Item : SS Storage Tanks Supplier M/s RD Engineering Aurngbd Item : Pasteurizer Supplier M/s Axtel Vadodara Item : Dry Batch Hopper Supplier M/s Axtel Vadodara Item : Wet Mixing Tank Supplier M/s Axtel Vadodara Item : Rework Hopper Supplier M/s Axtel Vadodara Item : PSM Supplier M/s Axtel Vadodara Item : Magma Holding Tank Supplier M/s Axtel Vadodara Item : 3 Valves Supplier M/s Inoxpa Pune Item : ClP System Supplier M/s Uncorn Hyderbd Item : Pumps Supplier M/s Mather & Platt Pune Item : Pumps Supplier M/s Syntex Pumps Ghaziabd Item : EOT crane Supplier M/s Electro Mech Pune Item : DM Plant package Supplier M/s GET water solution Chennai Item : Fuel gas skid Supplier M/s Indicone Boilers Faridabd Item : Fire fitting package Supplier M/s Agnice Fire Protection Chennai Item : PRS/PRDS System Supplier M/s Circor Flow Technologies Ahmdbd PROJECTS & CLIENTS SERVED Project: NSRP Complex Project Client: Technip KT India Ltd. Project: 450 MW Combined Cycle Gas Power Plant Client: Sravathi Infratech Pvt Ltd. Project: Central UP Gas Limited (City Gas Distribution Line Project, Bareilly) Client: Avinash EM Projects Pvt. Ltd.

- 8. SHADAB HAIDER Project: Grain LNG RTLF Project Client: (CB&I) Project: XML Mariner Ethane / Propane Facility U.S.A. Client: Chicago Bridge & Iron (CB&I) Project: Jubail Export Refinery (SATORP / JERP Package – 5B) Client: Rotary Engg. Ltd. Project: Jubail Export Refinery (SATORP / JERP Package – 5B) Client: SK Engg. & Construction Project: Jubail Export Refinery (SATORP / JERP Package – 5C) Client: M. R. Al Khathalan for Contracting Project: Wasea Bulk Plant Project (BI # 10-00795) Client: Sinopac International Petroleum Service Co. Project: Mitsubishi Hitachi Power System Client: Mitsubishi Heavy Industries Corporation Project: Shell Tabangao Asset Renewal Tabangao Refinery for Euro IV Compliance [STARTREC], Philippines Client: Chiyoda Philippines Corporation / Shell Projects and Technology Project: Mitsubishi Hitachi Power System Laboratory Client: Mitsubishi Hitachi Power System Laboratory Project: City Gas Distribution Project , Bareilly Client: Central UP Gas Limited (CUGL) a JV of BPCL & GAIL India. Project: Paradeep Phosphates Limited. Client: Simon India , Delhi Project: Paradip BOOT EPC Client: IOT Infrastructure & Energy Services Ltd. Project: Lin Kou Power Plant Renewal Project Taiwan Client: Mitsubishi Hitachi Power System Project: Rabigh IWSSP Project Saudi Arabia Client: Mitsubishi Hitachi Power System Project: ESSO PNG LNG EPC4 – 594153517 Client: CB&I and Clough Joint Venture U.K. Project: Aravali Project , Cadbury Bournvita Making Plant , Dharuhera Rewari Client: A Joint Venture Between Cadbury India & Barmalt Gurgaon PERSONAL DETAILS Permanent Address : Vill- Chhajupura Sadat , Post-Amhera , District-Bijnor , U.P , India , 246726 Date of Birth : 10 Sep, 1986 Languages Known : English and Hindi

- 9. SHADAB HAIDER I hereby undertake that the above mentioned information is correct & to the best of my knowledge. Shadab Haider

- 10. SHADAB HAIDER I hereby undertake that the above mentioned information is correct & to the best of my knowledge. Shadab Haider