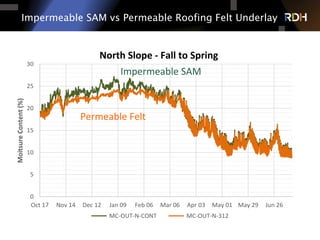

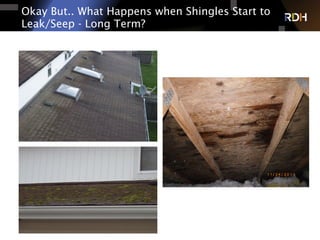

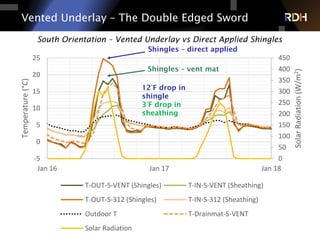

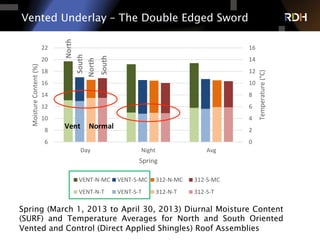

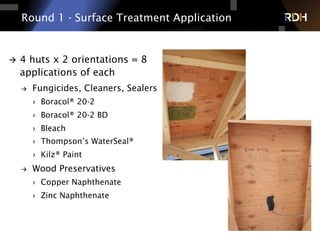

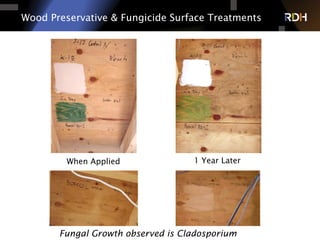

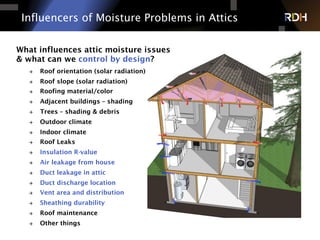

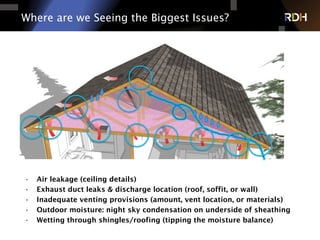

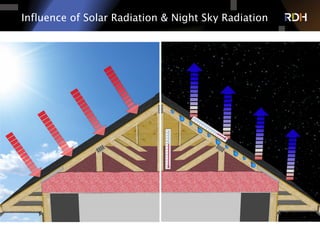

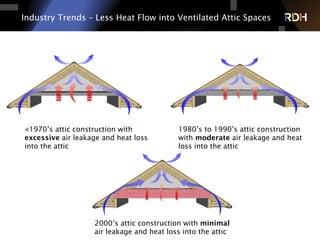

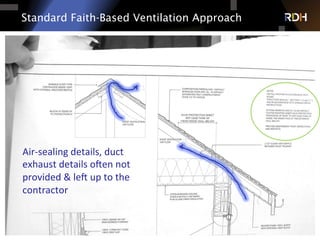

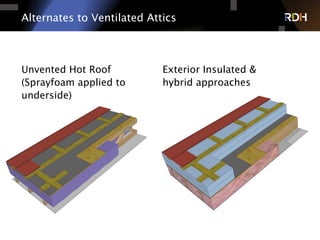

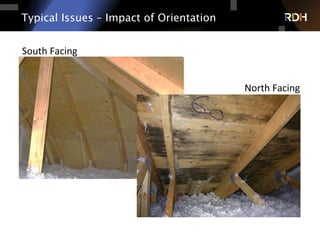

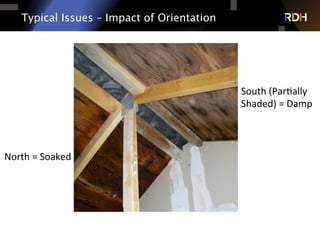

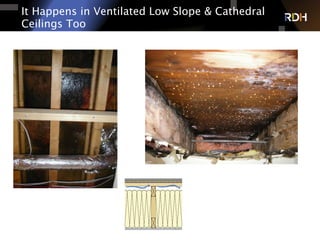

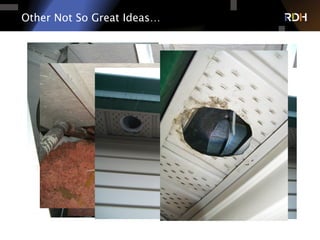

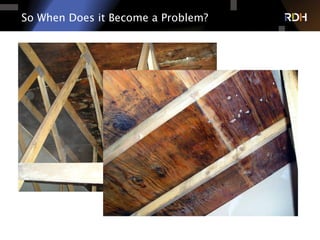

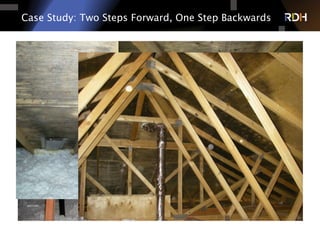

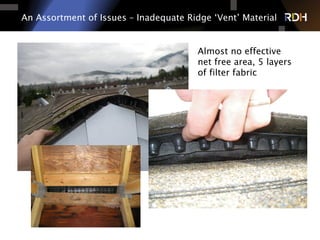

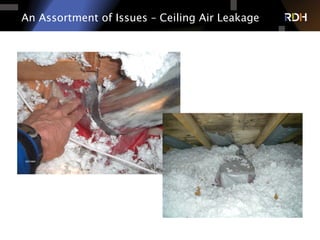

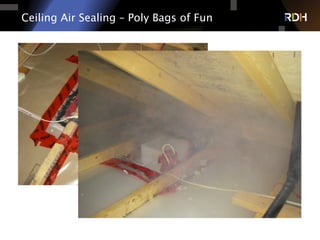

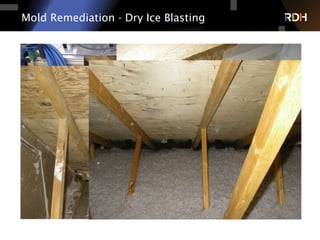

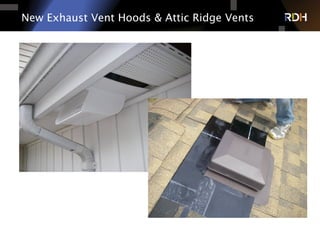

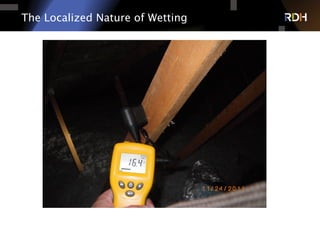

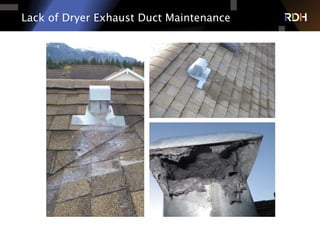

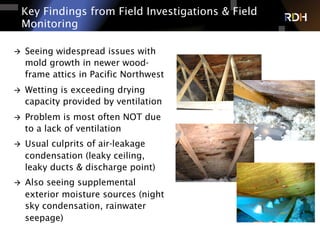

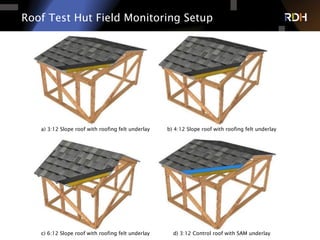

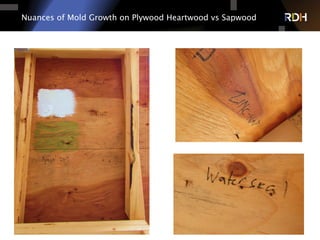

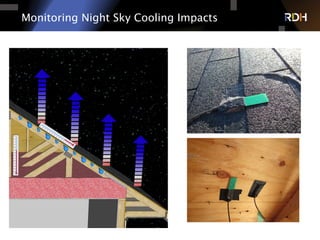

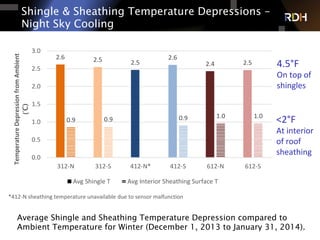

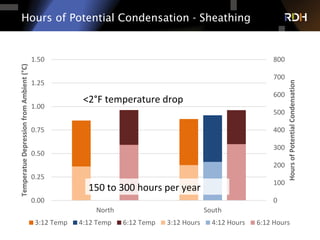

The document discusses challenges and potential solutions related to ventilated attics, focusing on moisture problems influenced by factors like air leakage and roof orientation. It presents a case study involving a townhouse complex, highlighting issues of mold growth due to inadequate ventilation and outdoor moisture sources, particularly in the Pacific Northwest. Ongoing research aims to evaluate the effectiveness of various mitigation strategies, including vented underlayment, to address these common attic moisture issues.

![0

5

10

15

20

25

30

09-‐2012

10-‐2012

11-‐2012

12-‐2012

01-‐2013

02-‐2013

03-‐2013

04-‐2013

05-‐2013

06-‐2013

07-‐2013

08-‐2013

09-‐2013

10-‐2013

11-‐2013

12-‐2013

01-‐2014

02-‐2014

03-‐2014

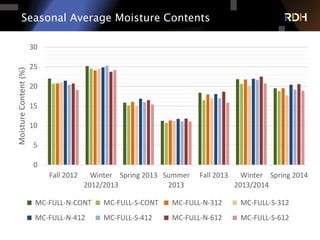

Moisture

Content

[%]

MC-‐FULL-‐S-‐CONT

MC-‐FULL-‐S-‐312

MC-‐FULL-‐S-‐412

MC-‐FULL-‐S-‐612 EMC

(1

wk)

Seasonal Roof Sheathing Moisture Contents

EMC calculated - Hailwood and Horrobin (1946)

0

5

10

15

20

25

30

09-‐2012

10-‐2012

11-‐2012

12-‐2012

01-‐2013

02-‐2013

03-‐2013

04-‐2013

05-‐2013

06-‐2013

07-‐2013

08-‐2013

09-‐2013

10-‐2013

11-‐2013

12-‐2013

01-‐2014

02-‐2014

03-‐2014

Moisture

Content

[%]

MC-‐FULL-‐N-‐CONT

MC-‐FULL-‐N-‐312

MC-‐FULL-‐N-‐412

MC-‐FULL-‐N-‐612 EMC

(1

wk)](https://image.slidesharecdn.com/theproblemswithandsolutionsforventilatedattics-150525205217-lva1-app6892/85/The-Problems-With-and-Solutions-for-Ventilated-Attics-50-320.jpg)

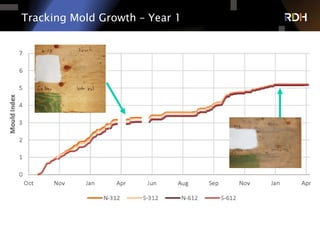

![When Does it Occur?

0

100

200

300

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Sol

Solar

Radiation

CONDENSE-‐Plywood-‐312

Increasin

0

5

10

15

20

25

30

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Moisture

Content

[%]

and

Temperature

[°C]

Condensation

0

5

10

15

20

25

30

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Moisture

Content

[%]

and

Temperature

[°C]

MC-‐FULL-‐N-‐312

MC-‐IN-‐SURF-‐N-‐312

T-‐IN-‐N-‐312-‐Plywood

T-‐N-‐312-‐Embedded Outdoor

-‐

Temperature Outdoor

-‐

Dewpoint

COND-‐N-‐312

Sheathing Solar

Radiation

Condensation](https://image.slidesharecdn.com/theproblemswithandsolutionsforventilatedattics-150525205217-lva1-app6892/85/The-Problems-With-and-Solutions-for-Ventilated-Attics-57-320.jpg)

![When Does it Occur on the Underside of the

Sheathing?

0

100

200

300

400

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Solar

Rad

Solar

Radiation

CONDENSE-‐Plywood-‐312

IncreasingSurf

0

5

10

15

20

25

30

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Moisture

Content

[%]

and

Temperature

[°C]

Condensation

0

100

200

300

400

500

600

700

800

900

1000

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Solar

Radiation

[W/m2]

Solar

Radiation

CONDENSE-‐Plywood-‐312

IncreasingSurfaceCondensation

25

30

perature

[°C]

0

100

200

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Solar

Radiation

CONDENSE-‐Plywood-‐312

Incre

0

5

10

15

20

25

30

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Moisture

Content

[%]

and

Temperature

[°C]

Condensation

0

5

10

15

20

25

30

Oct

02 Oct

03 Oct

04 Oct

05 Oct

06

Moisture

Content

[%]

and

Temperature

[°C]

MC-‐FULL-‐N-‐312

MC-‐IN-‐SURF-‐N-‐312

T-‐IN-‐N-‐312-‐Plywood

T-‐N-‐312-‐Embedded Outdoor

-‐

Temperature Outdoor

-‐

Dewpoint

COND-‐N-‐312

Sheathing Solar

Radiation

Condensation

Dry

Heavy

Condensa.on

Light

Condensa.on

Daily

Solar

Radia.on

Cycles](https://image.slidesharecdn.com/theproblemswithandsolutionsforventilatedattics-150525205217-lva1-app6892/85/The-Problems-With-and-Solutions-for-Ventilated-Attics-58-320.jpg)

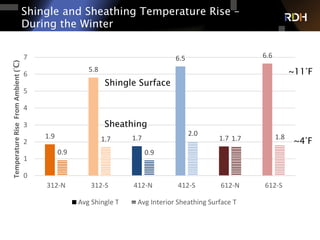

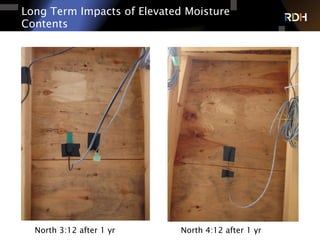

![On the Flip Side: Solar Heat Gain & Drying

Potential

0

5

10

15

20

25

30

35

40

45

50

55

60

Aug

21

00:00 Aug

21

06:00 Aug

21

12:00 Aug

21

18:00 Aug

22

00:00

Temperature

[°C]

Temperatures

-‐ 3:12

and

6:12

Slope

Roofs

-‐ Early

Spring

Conditions

T-‐OUT-‐N-‐612-‐Shingle

T-‐OUT-‐S-‐612-‐Shingle

T-‐IN-‐N-‐612-‐Plywood

T-‐IN-‐S-‐612-‐Plywood

T-‐OUT-‐N-‐312-‐Shingle

T-‐OUT-‐S-‐312-‐Shingle

T-‐IN-‐N-‐312-‐Plywood

T-‐IN-‐S-‐312-‐Plywood

Outdoor

-‐

Dewpoint

Outdoor

-‐

Temperature

South Shingles

130 -140°F

North Shingles

100-110°F

Ambient

Air up to

79°F

South Sheathing = 98°F

North Sheathing = 90°F](https://image.slidesharecdn.com/theproblemswithandsolutionsforventilatedattics-150525205217-lva1-app6892/85/The-Problems-With-and-Solutions-for-Ventilated-Attics-65-320.jpg)