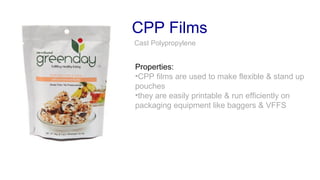

This document discusses various types of plastic food packaging films, their properties, and common uses. It describes polyethylene films like LDPE, LLDPE, and HDPE which are inexpensive, clear films used for fresh and frozen foods. PP films are soft and clear with good moisture barriers, used for plastic bags. CPP films are stiff films for baked goods. BOPP and OPP films are stretched plastic films that are stiff, clear, and resistant to heat and moisture. PET films have good oxygen barriers and are heat resistant. Nylon films allow for cooking applications. The document provides contact information for a packaging company that can help select the best food packaging films.