AuxMach-1-Syllabus (1).docx

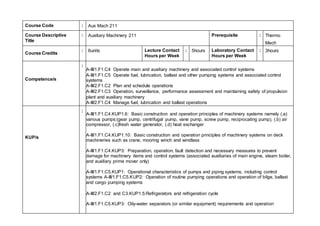

- 1. Course Code : Aux Mach 211 Course Descriptive Title : Auxiliary Machinery 211 Prerequisite : Thermo Mech Course Credits : 6units Lecture Contact Hours per Week : 5hours Laboratory Contact Hours per Week : 3hours Competence/s : A-III/1.F1.C4 Operate main and auxiliary machinery and associated control systems A-III/1.F1.C5 Operate fuel, lubrication, ballast and other pumping systems and associated control systems A-III/2.F1.C2 Plan and schedule operations A-III/2.F1.C3 Operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery A-III/2.F1.C4 Manage fuel, lubrication and ballast operations KUP/s : A-III/1.F1.C4.KUP1.6: Basic construction and operation principles of machinery systems namely (.a) various pumps:(gear pump, centrifugal pump, vane pump, screw pump, reciprocating pump), (.b) air compressor, (.c)fresh water generator, (.d) heat exchanger A-III/1.F1.C4.KUP1.10: Basic construction and operation principles of machinery systems on deck machineries such as crane, mooring winch and windlass A-III/1.F1.C4.KUP3: Preparation, operation, fault detection and necessary measures to prevent damage for machinery items and control systems (associated auxiliaries of main engine, steam boiler, and auxiliary prime mover only) A-III/1.F1.C5.KUP1: Operational characteristics of pumps and piping systems, including control systems A-III/1.F1.C5.KUP2: Operation of routine pumping operations and operation of bilge, ballast and cargo pumping systems A-III/2.F1.C2 and C3.KUP1.5:Refrigerators and refrigeration cycle A-III/1.F1.C5.KUP3: Oily-water separators (or similar equipment) requirements and operation

- 2. A-III/2.F1.C2 and C3. KUP 2.1: Start up and shut down main propulsion and auxiliary machinery, including associated system A-III/2.F1.C2 and C3. KUP 2.2: Operating limits of propulsion limits A-III/2.F1.C2 and C3. KUP 2.3: The efficient operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery. A-III/2.F1.C2 and C3.KUP2.5: Practical knowledge of the functions and mechanism of automatic control cargo-handling equipment and deck machinery A-III/2.F1.C4.KUP1: Operation and maintenance of machinery including pumps and piping systems Course Outcome/s : CO.1. Operate, maintain and troubleshoot the following auxiliary machineries in accordance with its manufacturer’s specification: 1. Various pumps (gear, centrifugal, vane, screw, reciprocating) 2. Air compressor 3. Fresh water generator 4. Heat exchanger CO2. Operate ballast and pumping system according to ship's piping system configuration CO3. Operate oily-water separator according to manufacturer's specifications CO4. Troubleshoot the faults on automatic control of cargo-handling equipment and deck machinery such as crane, mooring winch and windlass Reference/s : 1. Table A-III/1 and Table A-III/2 Function: Marine Engineering STCW’78 as amended 2. Annex A of CMO No. 67, S. 2017: Revised PSG for BSMT and BSMarE Programs

- 3. PROGRAM OUTCOMES ADDRESSED INTRODUCTION PRACTICE DEMONSTRATIVE PO1 Applyknowledge inMathematics,Science and Technologyinsolvingproblemsrelatedtothe professionandworkplace. PO2 Use appropriate techniques,skillsandmoderntoolsin the practice of the professioninordertoremain globallycompetitive. PO3 Demonstrate competencyinmaintainingsafe engineeringwatch. PO4 Applyelectrical,electronicsandcontrol engineering. PO5 Demonstrate the competencerequiredinthe maintenance andrepairof the shipboardmachinery and equipment. PO6 Demonstrate competencyincontrollingthe operation of the shipandcare for personsonboard.

- 4. FUNCTION: Marine engineering at the operational level COMPETENCIES: A-III/1.F1.C4 Operate main and auxiliary machinery and associated control systems A-III/1.F1.C5 Operate fuel, lubrication, ballast and other pumping systems and associated control systems A-III/2.F1.C2 Plan and schedule operations A-III/2.F1.C3 Operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery A-III/2.F1.C4 Manage fuel, lubrication and ballast operations Knowledge, Understanding and Proficiencies: A-III/1.F1.C4.KUP1.6: Basic construction and operation principles of machinery systems namely (.a) various pumps:(gear pump, centrifugal pump, vane pump, screw pump, reciprocating pump), (.b) air compressor, (.c)fresh water generator, (.d) heat exchanger A-III/1.F1.C4.KUP1.10: Basic construction and operation principles of machinery systems on deck machineries such as crane, mooring winch and windlass A-III/1.F1.C4.KUP3: Preparation, operation, fault detection and necessary measures to prevent damage for machinery items and control systems (associated auxiliaries of main engine, steam boiler, and auxiliary prime mover only) A-III/1.F1.C5.KUP1: Operational characteristics of pumps and piping systems, including control systems A-III/1.F1.C5.KUP2: Operation of routine pumping operations and operation of bilge, ballast and cargo pumping systems A-III/2.F1.C2 and C3.KUP1.5:Refrigerators and refrigeration cycle A-III/1.F1.C5.KUP3: Oily-water separators (or similar equipment) requirements and operation A-III/2.F1.C2 and C3. KUP 2.1: Start up and shut down main propulsion and auxiliary machinery, including associated system A-III/2.F1.C2 and C3. KUP 2.2: Operating limits of propulsion limits A-III/2.F1.C2 and C3. KUP 2.3: The efficient operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery. A-III/2.F1.C2 and C3.KUP2.5: Practical knowledge of the functions and mechanism of automatic control cargo-handling equipment and deck machinery A-III/2.F1.C4.KUP1: Operation and maintenance of machinery including pumps and piping systems

- 5. COURSE OUTCOMES: Assessment Methods: CO.1. Operate, maintain and troubleshoot the following auxiliary machineries in accordance with its manufacturer’s specification: 1. Various pumps (gear, centrifugal, vane, screw, reciprocating) 2. Air compressor 3. Fresh water generator 4. Heat exchanger Performance CO2. Operate ballast and pumping system according to ship's piping system configuration Performance CO3. Operate oily-water separator according to manufacturer's specifications Performance CO4. Troubleshoot the faults on automatic control of cargo-handling equipment and deck machinery such as crane, mooring winch and windlass Performance CO.1. Operate, maintain and troubleshoot the following auxiliary machineries in accordance with its manufacturer’s specification: 1. Various pumps (gear, centrifugal, vane, screw, reciprocating) 2. Air compressor 3. Fresh water generator 4. Heat exchanger

- 6. Learning Outcomes Topic Teaching-Learning Activity (TLA) Equipment and Materials Assessment Indicative Hours At the end of the session, the students should be able to: LO1: Explain the Working Principles of the Different Auxiliary Machineries such as; a. Pumps b. Heat exchanger c. Air Compressor d. Fresh water generator 1. Working Principles of the Different Auxiliary Machineries such as; 1.1 Pumps a. Gear Pump b. Screw Pump c. Reciprocating Pump d. Centrifugal Pump 1.2 Heat Exchanger a. Shell and tube type b. Plate type 1.3 Air Compressor 1.4 Fresh Water Generator Motivation: Show videos of different Auxiliary Machineries Introduction: Questioning prompts and discussion about the pictures presented Lesson Proper: Interactive discussion of the working principles of the different auxiliary machineries such as: a. Pumps b. Heat Exchanger c. Air compressor d. Freshwater Generator Reinforcement: At the MACH Shop, familiarization on the actual equipment of: 1. Pumps 2. Heat Exchanger 3. Air compressor 4. Freshwater Generator Synthesis: Reflective writing on the different auxiliary machineries. Videos clips PPT Laptop Whiteboard Marker Pumps Heat Exchanger Air compressor Freshwater Generator Laboratory manual Assessment No. 1 Multiple choice Enumeration Essay type About the topic Working Principles of the Different Auxiliary Machineries such as; 1.1 Pumps a. Gear Pump b. Screw Pump c. Reciprocating Pump d. Centrifugal Pump 1.2 Heat Exchanger a. Shell and tube type b. Plate type 1.3 Air Compressor 1.4 Fresh Water Generator PRELIM WEEK 1 8HRS Prelim week 1

- 7. LO2: Identify the components, parts, and their function of the Different Auxiliary Machineries such as; a. Pumps b. Heat exchanger c. Air Compressor d. Fresh water generator 2. Components, parts and their Functions of the Different Auxiliary Machineries such as; 2.1 Pumps e. Gear Pump f. Screw Pump g. Reciprocating Pump h. Centrifugal Pump 2.2 Heat Exchanger c. Shell and tube type d. Plate type 2.3 Air Compressor 2.4 Fresh Water Generator Motivation: Show videos of different Auxiliary Machineries Introduction: Questioning prompts and discussion about the pictures presented Lesson Proper: Group activity: Class will be divided into 5 groups to identify the Components, parts and their Functions of the Different Auxiliary Machineries such as; a. Pumps b. Heat Exchanger c. Air compressor d. Freshwater Generator Reinforcement: At the MACH Shop, familiarization on the actual parts and components of: 1. Pumps 2. Heat Exchanger 3. Air compressor 4. Freshwater Generator Synthesis: Reflective writing on the different auxiliary machineries. Video clips PPT Laptop Whiteboard Marker Pumps Heat Exchanger Air compressor Freshwater Generator Laboratory manual Assessment No. 2 Multiple choice Enumeration Essay type About the topic Components, parts and their Functions of the Different Auxiliary Machineries such as; 1.1 Pumps a. Gear Pump b. Screw Pump c. Reciprocating Pump d. Centrifugal Pump 1.2 Heat Exchanger a. Shell and tube type b. Plate type 1.3 Air Compressor 1.4 Fresh Water Generator PRELIM WEEK 2 8HRS Prelim week 2

- 8. LO3: Operate the following auxiliary machineries: a. Pumps b. Heat exchanger c. Air Compressor d. Fresh water generator 3. Operation of the different Auxiliary Machineries such as; 3.1 Pumps a. Gear Pump b. Screw Pump c. Reciprocating Pump d. Centrifugal Pump 3.2 Heat Exchanger a. Shell and tube type b. Plate type 3.3 Air Compressor 3.4 Fresh Water Generator Motivation: Show video clips on a running auxiliary machinery. Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Demonstration on how to operate the different auxiliary machineries such as; a. Pumps b. Heat Exchanger c. Air compressor d. Freshwater Generator Reinforcement: On the machine shop or Engine room simulator, actual operation of the following machineries: a. Pumps b. Heat Exchanger c. Air compressor d. Freshwater Generator Synthesis: Reflective writing on the different auxiliary machineries Video clips PPT Laptop Whiteboard Marker Pumps Heat Exchanger Air compressor Freshwater Generator Engine Room Simulator Laboratory manual Video clips Assessment No. 3 Multiple choice Enumeration Essay type About the topic Operation of the different Auxiliary Machineries such as; 3.1 Pumps a. Gear Pump b. Screw Pump c. Reciprocating Pump d. Centrifugal Pump 3.2 Heat Exchanger a. Shell and tube type b. Plate type 3.3 Air Compressor 3.4 Fresh Water Generator PRELIM WEEK 3 8HRS Prelim week 3

- 9. LO4: Troubleshoot any malfunction of the following auxiliary machineries as per manufacturer’s specifications: a. Pumps b. Heat exchanger c. Air Compressor d. Fresh water generator 4.Troubleshooting Techniques of the different Auxiliary Machineries such as; 4.1Pumps a. Gear Pump b. Screw Pump c. Reciprocating Pump d. Centrifugal Pump 4.2 Heat Exchanger a. Shell and tube type b. Plate type 4.3 Air Compressor 4.4 Fresh Water Generator Motivation: Show video clips showing troubles of a running auxiliary machinery. Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the common troubleshooting techniques as per manufacturer’s specification of the different auxiliary machineries: a. Pumps b. Heat Exchanger c. Air compressor d. Freshwater Generator Reinforcement: On the machine shop or Engine room simulator, actual troubleshooting techniques of the following machineries: a. Pumps b. Heat Exchanger c. Air compressor d. Freshwater Generator Synthesis: Reflective writing on the troubleshooting techniques of the different auxiliary machineries PPT Laptop Whiteboard Marker Pumps Heat Exchanger Air compressor Freshwater Generator Engine Room Simulator Laboratory manual Prelim Major Examination Multiple choice Operate, maintain and troubleshoot the following auxiliary machineries in accordance with its manufacturer’s specification: 1.Various pumps (gear, centrifugal, vane, screw, reciprocating) 2.Air compressor 3. Fresh water generator 4.Heat exchanger PRELIM WEEK 4 8HRS Prelim week 4

- 10. CO2. Operate ballast and pumping system according to ship's piping system configuration LO1: Explain the working principle of ballast and pumping systems. 1. Working principle of Ballast and Pumping System Motivation: Show Video clips about a ship doing ballast and pumping system Introduction: Questioning prompts and discussion about the video presented. Lesson Proper: Interactive discussion about the working principle of ballast and pumping system Reinforcement: On the Engine Room Simulator, familiarization of the components and functions of the ballast and cargo pumping systems. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Laboratory manual Assessment No. 1 Multiple choice Enumeration Essay type About the topic Working principle of Ballast and Pumping System MIDTERM WEEK 8HRS Midterm week 5

- 11. Synthesis: Reflective writing about the components and functions of ballast and cargo pumping system. LO2: Identify the components, parts, and their function of the ballast and pumping system 2. Components, parts, and their function of the ballast and pumping system Motivation: Show Video clips about components, parts, and their function of the ballast and pumping system a ship doing ballast operation and cargo operation. Introduction: Questioning prompts and discussion about the video presented. Lesson Proper: Interactive discussion of the operation of the Ballast And Pumping System Reinforcement: On the Engine Room Simulator, operation of the ballast and pumping systems. Synthesis: Reflective writing about the operation of ballast and cargo pumping system. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Laboratory manual Assessment No. 2 Multiple choice Enumeration Essay type About the topic Components, parts, and their function of the ballast and pumping system MIDTERM WEEK 8HRS Midterm week 6

- 12. LO3: Operate ballast and pumping system. 3.Operation of Ballast and Cargo Pumping System Motivation: Show Video clips about a ship doing ballast operation and pumping operation. Introduction: Questioning prompts and discussion about the video presented. Lesson Proper: Interactive discussion of the operation of the Ballast And Pumping System Reinforcement: On the Engine Room Simulator, operation of the ballast and pumping systems. Synthesis: Reflective writing about the operation of ballast and cargo pumping system. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Laboratory manual Assessment no. 3 Multiple choice Enumeration Essay type About the topic Operation of Ballast and Cargo Pumping System MIDTERM WEEK 8HRS Midterm week 7

- 13. LO4: Troubleshoot any malfunction of the ballast, and pumping system. 4.Troubleshooting Techniques of the ballast and pumping system. Motivation: Show video clips showing troubles ballast and pumping system. Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the common troubleshooting techniques of ballast and pumping system. Reinforcement: Engine room simulator, actual troubleshooting techniques ballast and pumping system. Synthesis: Reflective writing on the troubleshooting techniques of the ballast and pumping system. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Laboratory manual Midterm Major Examination Multiple choice About the topic Operate ballast and pumping system according to ship's piping system configuration MIDTERM WEEK 8HRS Midterm week 8

- 14. CO3. Operate oily-water separator according to manufacturer's specifications LO1: Explain the working principle of an oily water separator. 1. Working principle of an oily-water separator. Motivation: Video clip on the working principle of an oily water separator. Introduction: Questioning prompts and discussion about the video presented. Lesson Proper: Interactive discussion on the working principle of an oily water separator. Reinforcement: On the machine shop or in the engine simulator, familiarization of the actual oily water separator. Synthesis: Reflective writing on the components, function and operating principle of oily water separator. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Oily Water Separator Laboratory manual Assessment no. 1 Multiple choice Enumeration Essay type About the topic Working principle of an oily-water separator. SEMIFINAL WEEK 8HRS. Semi-final week 9

- 15. LO2: Identify the components, parts and their function of an oily-water separator. 2. Components, parts and their function of an oily- water separator. Motivation: Video clip on the Components, parts and their function of an oily-water separator. Introduction: Questioning prompts and discussion about the video presented. Lesson Proper: Interactive discussion on the Components, parts and their function of an oily-water separator. Reinforcement: On the machine shop or in the engine simulator, familiarization of the actual oily water separator. Synthesis: Reflective writing on the components, function and operating principle of oily water separator. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Oily Water Separator Laboratory manual Assessment no. 2 Multiple choice Enumeration Essay type About the topic Components, parts and their function of an oily-water separator. SEMIFINAL WEEK 8HRS Semi-final week 10

- 16. LO3: Operate of an oily water separator as per manufacturer’s specifications. 3. Operation of Oily Water Separator Motivation: Video clip on the operation of the oily water separator. Introduction: Questioning prompts and discussion about the video presented. Lesson Proper: Interactive discussion on the operation of the oily water separator. Reinforcement: On the engine simulator, operate an oily water separator. Synthesis: Reflective writing on the operation of the oily water separator. Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Oily Water Separator Laboratory manual Assessment no. 3 Multiple choice Enumeration Essay type About the topic Operation of Oily Water Separator SEMIFINAL WEEK 8HRS Semi-final week 11

- 17. LO4: Troubleshoot any malfunction of the of an oily water separator as per manufacturer’s specifications. 4. Troubleshooting Techniques of an oily water separator as per manufacturer’s specifications. Motivation: Show video clips showing troubles of an oily water separator Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the common troubleshooting techniques of an oily water separator Reinforcement: At Mach Shop using actual equipment/Engine room simulator, actual troubleshooting techniques of an oily water separator Synthesis: Reflective writing on the troubleshooting techniques of an oily water separator Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Oily Water Separator Laboratory manual Semi-final Major Examination Multiple choice About the topic Operate oily- water separator according to manufacturer's specifications SEMIFINAL WEEK 8HRS Semi-final week 12

- 18. CO4. Troubleshoot the faults on automatic control of cargo-handling equipment and deck machinery such as crane, mooring winch and windlass LO1: Explain the working principles of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass 1. Working principles of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Motivation: Show video clips showing the working of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the working principles of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Reinforcement: On the seaman’s laboratory familiarization of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Synthesis: Reflective writing on the working of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Crane Mooring winch Anchor windlass Laboratory manual Assessment No. 1 Multiple choice Enumeration Essay type About the topic Working principles of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass FINAL WEEK 8HRS Final week 13

- 19. LO2: Identify the components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass 2. Components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Motivation: Show video clips showing the Components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the Components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Reinforcement: On the seaman’s laboratory identification of the Components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Synthesis: Reflective writing on the identification of the Components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Crane Mooring winch Anchor windlass Laboratory manual Assessment No. 2 Multiple choice Enumeration Essay type About the topic Components, parts and their function of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass FINAL WEEK 8HRS Final week 14

- 20. LO3: Operate the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass 3. Operation the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Motivation: Show video clips showing the operation the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the operation of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Reinforcement: On the seaman’s laboratory operate the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Synthesis: Reflective writing on the operation of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Crane Mooring winch Anchor windlass Laboratory manual Assessment No. 3 Multiple choice Enumeration Essay type About the topic Operation the following Deck Machineries a. Crane b. Mooring Winch c. Anchor FINAL WEEK 8HRS Final week 15

- 21. LO4: Troubleshoot any malfunction of the of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass as per manufacturer’s specifications. 4.Troubleshooting Techniques of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass as per manufacturer’s specifications. Motivation: Show video clips showing troubleshooting techniques of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Introduction: Questioning prompts and discussion about the video presented Lesson Proper: Interactive discussion about the troubleshooting techniques of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Reinforcement: On the seaman’s laboratory demonstrate a troubleshooting techniques of the following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Synthesis: Reflective writing on the troubleshooting techniques of following Deck Machineries a. Crane b. Mooring Winch c. Anchor Windlass Video clips PPT Laptop Whiteboard Marker Engine Room Simulator Crane Mooring winch Anchor windlass Laboratory manual Final Major Examination Multiple choice About the topic Troubleshoot the faults on automatic control of cargo-handling equipment and deck machinery such as crane, mooring winch and windlass FINAL WEEK 8HRS Final week 16

- 22. .