List of material testings and frequency in IIT.pdf

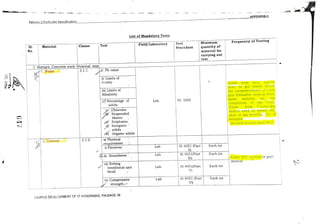

- 1. APPENDIx3 Volume-3 ParticularSpecification ListofMandatoryTests Minimum Frequency of Testing Field/Laboratory Test Clause Test quantity of material for SI. Material Procedure No. carrying out test I. Mortars,Concretework (Nominal mix)_ .Water 3.1.1 iPhvalue ii) Limits of Acidity Water írom each source shall be got tested before ii) Limits of Alkalinity the c o m m e n c e m e n t of work and thereaiter once in ever months tll IS: 3025 three tne Lab is Percentage ot solids Completion ot the work irom Water Municipal aChlorides Suspended Matter source need be tested only once in six months. No. of samples Sulphates, for each source shall be 3 Inorganic solids e) Organic solids a) Physical requirement i) Fineness 2. Cement 3.1.2 Lab IS 4031 (Part Each lot IS 4031(Part Each lot 4ii) Soundness Lab Every 200 tonnes or part thereof ii) Setting time(Initial and final) Each lobt IS 4031(Part V Lab IS4031 (Part VI) Lab Each lot iv) Compressive strength CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 38

- 2. IS 4031 (Part VI) Lab Each lot v) Consistency of standard cement paste Organic impuritiesll| Every 100Cum or part thereof or more iírequently asdecided by E-in-C Every 100 Cum or part thereof or more frequently asdecidedby E-in-C 100Cum or part thereoi 3. Sand Ficld AppendixB 100Cum 3.1.4.1 Silt content Field Appendix'D 100Cumn 3.1.4.2 Field or Lab AppendixC' 100Cum Particle size distribution a, b, C, 3.1.4.4 d &e Every i00 Cum or part thereof or more frequently 3.1.4.5 Bulking of sand Field Appendix'E' 100Cum as decided by E-in-C | 1. Concretework (NominalmiX visual IS 2386 Part One test for II One test for each source A) Percentage ofsoft General or deleterious 4.1.2.2 inspection/Laboratory Test where required by the E-in-C Field/Lab each source material Every I00 Cum or part thereoi Every 100 Cum or pat thereoI_ 10 Cumn Particle size distribution a) Estimation of organicimpurities b Surface moisture 4.1.2.3 Appendix'A' 4.1.2.5 Field Lab 10 Cumn IS 2386 Part Stone aggregate II IS 2386 10 Cum Every 100 Cum or part thereof Every 100 Cum or part thereof Every 100 Cum or part thereot_ Every 100 Cum or part thereot Every i00 Cum or part thereof Every 100 Cum or part thereof 15 Cum or part thereof_ Field/Lab c)Determination of 10% fine value ).Specific gravity Pield/Lab IS 2386 10 Cumn Field/Lab IS 2386 10 Cun e) Bulk density, Field/Lab 1S 2386 10 Cum Field/Lab ) Aggregate çrushirng strength g) Aggregate impact value Slumptest IS 23866 10 Cum Field/Lab Is 2386 10 Cum Concrete) 4.2.3 Field Appendix D 10Cumn CAMPUS DEVELOPMENT OF UT HYDERABAD, PACKAGE 38

- 3. 111.Reinforced Cementconcretework_ a Rcintorced Cementconcrete work(nominal mix)_ Appendix'D' of Chapter 4 i Every 5 Curn or part thereof 5.4.1 i) 5 cun in Case of a) slump test Ficld column 1) 20 curn for | ii) Every 20 cum or part slabs, beans thereof and connected columns iii) 20 Cum Every 20 Cum or part for other RCC thereof work for all other Small items and where RCC done in a day is less than 5 Cum test may be carried out as required by E-in-C._ i 5 cum in i Every 5 Cum or part 5.4.9 b) Cube test Field/Lab Appendix'A' case of thereoi column ii 20 cum for ii) Every 20 Cum or part slabs, beams thereof and connected columns ii) 20 cum i) Every20 Cum or part for other RCC thereof work for all other small items and where RCC done in a day is less than | 5 Cum, test| CAMPUS DEVELOPMENT OF IT HYDERABAD, PACKAGE 38

- 4. nay be carricd out as required by E-in-C. 6 Ready mix concrete a Slump test Field test Every truck Every truck load of concrete load of or part thereof concrete or part thereof b) Cube test Field Lab test As per As specified for RCC work particular specilication Once c) Chloride content of green concrete Laboratory for Once for each source of each source concrete of concrete C Steel for reinforced cement concrete | 5.1.2 A) Physical test a)For consignment a) For consignment 100 over 100 below Tons i) Under 10mm dia, one sample for each 50 Tons or part thereof Tons a Tensile strength b)Retest c Rebound test d Nominal mass Lab/Field Lab/Field ab/Field Lab/Field IS1608 IS1786 IS1786 Under 10mm dia one sample for each 80 IS 1786 tones or part thereof e) Bend Test Each lot from Lab/Field IS 1599 each source ii)10mm to i) 10mm to | for each dia 16mm dia, | 16mm sample one sample each for each 90 dia, one for 70tons or tons or part thereof. part thereof CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 3B

- 5. Over ) Vlongation T'ent R) Proot ren Lab/Piell Lnb/Vielt Over i) dia, 16mm 16mm dia, N.170 one sample one sample for each 90 for each 90 tona or part thereof tons ot part thereof One test for each source of . Chemieal analysiN of TMT reintoreement barN purchase for each diameter ofbar rick wor Bticks 63 to Dimensions As per Table 3 and 4 of Compressive strength Chapter 6 of CPWD Appendix A. B,C&D of Chapter ó As per Table Specifications 3 and 4 of LaboratorY c Water Chapter6 of CPWD absorption Enlorescenoe Specification V.Block wor a DimensionaltestLaboratory b) Compressive strength AACAACblock Laboratory Every 20,000 blocks or part thereof of same size and Laboratory c)Drying shrinkage IS 2185 same manufacturer d Moisture Laboratory Laboratory movement el1Water absorption. V7Wood work Moisture Field/ Laboratory Test i. Timber 9.1.6 AppendixC 1 Cum Every one cim or part thereof CAMFUS DEVELOPMENTOF IT HYDERABAD. PACKAGE 33

- 6. ii. Flush door T9.7.10 a) End immersion 26 shutters As per sampling and testing specified in Clause-9.7.10 of CPWD Specifications. IS:2202 test (Part-1) :1991 1S: Laboratory b) Knife test 2202 (Part 2): 1983 c) Adhesion test Appendix 'F' IS: 5523 Ifthe cost of as required by Engineer fittings ii. Aluminum door or Thickness of anodic Laboratory windows fittings coating 1969 exceed Rs.20,000/ iv. Mortice 9.21.14 Testing of Spring Laboratory IS: 2209- 50 Nos. Locks 1976 as required by Engineer Appendix'C VII. Structural Steel work Structural Steel 10.17 aTensile Strength Laboratory IS:1599- 20 Tonne Every 50 Ton or part thereof 1985 b) Bent Test VIII. Flooring Cement baseddesigner tile iii. Wear on individual specimen iv. Water absorption v. Wet transverse Strength IX. Paver block Compressive strength Laboratory Every 5000 Blocks or part thereof of same type and samemanufacturer. X.Stainlesssteel works CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 38

- 7. L One test for every 5,000 Nos or part thereof for each type and for each make. a) Chemical Laboratory AISI 304 Crampsfor STranite cladding Analysis One test for every 5,000 Kg or part thereof for each Laboratory AJSI304 a) Chemical Analysis Stainless steel hand rail source. XI. Auminium work One test for every 10,000 Kg or part thereof for each i) Extuded sections Laboratory IS 1285 a) Chemical Analysis manutacture. b Anodic coating thickness One test for every 1,000 Kg or part thereof for each manufacture Field/Lab IS 5523 X1. Water proofing compound One test for 500 litres or part thereof for manufacturer IS 2645 CICO No. 1/ STRUCO No.1 or approved equivalent Laboratory each XIII. Fire Door 2 Hour fire rated Fire rating for 2 Laboratory IS 3614 One test for each door hours manutacturer 1 Hour fire rated Fire rating for 1 Laboratory IS 3614 One test for each door hour manutacturer XTV, Façade access system 1. Eye bolt Pull out test Field Each bolt XV. External façade system 1. Extruded a Chemical analysis Lab IS 1285 One test for 10,000 Kgs or | aluminium part thereof for each section manufacturer for each CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 3B

- 8. scction. b) Anodic coating Lab/Pield One test for 5,000 Kgs or thereof IS 1868 for part manufacturer cach for cach section. 2. CGasket a) Ultimate tensilestrength Lab One test for each manufacturer b) Ultimate elongation Lab One test for each manufacturer Once for each consignment i. Thickness Lab/Ficld and for each colour 3. ACP Once for each consignment i. Aluminium foil Lab and for each colour thickness ii. Weight/Sqm Lab Once for each consignment and for each colour iv. Thermal Lab ASTM D 968 Once for each source expansion v. Tensile strength Lab ASTM DD Once for each source 638 vi. Flexural strerngth Lab ASTM D 790 Once for each source vii. Yield strength LAB ASTM D 638 Once for each source Vii. Powder coating /PVDF coating thickness As required by the Engineer CAMPUS DEVELOPMENT OF IT HYDERABAD, PACKAGE 38

- 9. Once for each consignment and for each colour Once for each consignment and for each colour a Solid colour Lab b) Metallic colour Lab Once for each colour of ACP for each source ix. Salt spray test Lab ASTM B 117 Once for each colour of ACP for each source x. Colourretention Lab ASTM D test 2244 xii. Gloss retention Lab ASTM D 523 Once for each colour ofACP test for each source Once for each colour of ACP for each source xii. Chalk Lab ASTM D resistance test 4214 Once for each colour of ACP for each source xii. Chemical Lab immersion tests Once for each colour of ACP for each source Once for each colour of ACP a) 5% HS04 Lab ASTM D 543 b) 5% NaOH Lab ASTM D 543 for each source Once for each colour of ACP for each source Every 500 Nos. of clamps c) Detergent Lab ASTM D 543 IS 277 5. Galvanized clamps Thickness Lab of galvanizing| As per relavent BoQ item specification 7. Mock up test Lab As specified in specification CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 3B

- 10. Frequency of testing Minimumn quantityofmaterial workforcarrying Field/ Test Material Clause Test Laboratory Test Procedure outthetest 500sgm.or part there-of. Laboratory IS1124 50Sq.m. () Moisture Absorption Marble 8.3 (Table8.2) -do-_ Mho'sScale IS1122 IS1124 IS1122 -do -do -do-_ )HardnessTest Ci) SpecificGravity ) Moisture LCi)SpecificGravity -d0- -d0- do Granite -do -do -do -do -do- Laboratory IS1599 20tonne Every 20 tonne or Steel if arranged by the contractor (a) Tensile strength (b) Bendtest 10.1.1 oart thereof. Every 8 tonne or part thereof Every 20 tonne or part thereof Steel tubular (a) Tensile Test Laboratory IS1608 10.13 pipes (b) Bend Test Is2329 (c) Flattening Test IS2328 Field Laboratory Test Test Procedure Min.quantity of material for Material Clause Test Frequency of testingg carrying out the test 1.Dimensions and 20,000 Nos. or part thereof Pressed IS:13630 11.4,11.5 &11.16 Laboratory 3000 Nos. ceramic tiles(for floor &wall) Vitrified tiles Surface quality |2.Physical properties 3.Chemical properties and CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 3B

- 11. Coarse Aggregate S2386 (Part Iv 16.1.1 1. Los Angles Laboratory Per200ms 2. Abrasion Value or Aggregate Impact Value IS 2386 (Partv) IS 5640 IS 2386 (Partl) 3. Flakiness Index 16.1 Table16.2Grading9 requirement IS2386 (Partl) Per100m Field Nil Fine Aggregate As required by the Engineer-in-charge 16.1.2 Deleterious materials Laboratory I$2386 (Partill) Nil As prescribed inlS73 Bitumen As required by the Engineer-in-charge 16.1.5 As prescribed in IS73 Laboratory Nil Embankment under 1. Moisture content 2. Density Laboratory Field IS2720(Partli) IS 2720 (Part AXVIII) Nil Nil 250 m 250 m° 16.3.1 (O.M C. conditions) 3. Control test on Borrow pits. 16.3.4.4 Laboratory IS2720 (PartlV) (a) Gradation Laboratory Nil One to Two tests per 8000m IS2720 (PartV) IS2720 (PartVill) (b) Plasticity Laboratory Nil -Do- (c) Proctor Test Laboratory Nil -Do (d) Deleterious content As required by the Engineer-in-charge Laboratory Nil (e) Moisture contents Laboratory IS 2720 (Partli) Nil 250m3 Bitumen Penetration Macadam 16.32 As required by the Engineer-in-charge. 1. Binder Field IS73 Nil 2. AggregateAbrasion Impact value or LOS Angles Value Per100m of Aggregate as required by the Engineer-in-chargee IS 2386 Laboratory Nil (Partiv) CAMPUS DEVELOPMENT OF IT HYDERABAD, PACKAGE 3B

- 12. 3. Flakinesslndex Laboratory IS2386 (Parll) Nil -Do- 4. StrippingValue Laboratory IS 6241 Nil -Do- 5. Gradingof Aggregate Fieldor Laboratory Is 2386 (Partl) Two tests per day per plant Situmen Mastic Wearing COurse 1. LosAnglesAbrasion| ValuelAggregatelm pact value 16.33 Laboratory S 2386 (PartiV) Nil Forevery100m 2. Flakiness Index Laboratory Is2386 (Part 1) -Do- 3. Stripping Value Laboratory IS 6241 -Do- One set of test on individual constituents and aggregate from dryer for each 100tonneS of mix subject to minimum of two sets per plant per day 4. Mix Grading Field/ Laboratory IS 2386 (Part 1) mixed

- 13. Minimum (quantity of material for carrying out test SLNo. Material Test Field/Laboratory Test Procedure Frequency of Testing FLY ASH Chemical composition Total chloride in Max 0.05% percent by mass Third party lab Loss of ignition in percent by mass test Max 5% 1. Silicon dioxide plus aluminium oxide plus iron oxide percent by mass, Min 70 2. Silicon dioxide (SiO,), percent by mass Min 35 3. Magnesium oxide(Mg0). percent by mass, Max 5 4. Total sulphar as sulphar IS: 1727 Oncepersource Third party lab Chemical composition test trioxidelSO,), percent by mass Max 5. Available alkalis as sodium oxide (Na0),percent by mass, Max 1.5 6. Loss on ignition, percent by mass, Max 5 7. Total chloride, percent by mass, Max 0.05 b Physical Fineness-specific surface in m'/kg by Blaine's permeability method. Lab test Min 320 m'/kg Evey S0 MT IS: 1727 Compressive strength at Third party lab Not less than S0 percent of the 28 days in N/mm strength of corresponding mortar Cubes test Once per source CAMPUS DEVELOPMENT OF IIT HYDERABAD, PACKAGE 38

- 14. Frequency of Minimum quantity of material for SLNo. Material|Test Field/Laboratory Test Procedure carrying outtest Testing Soundness of autoclave Max 0.8% Evey 50 MT test expansion of Lab test specimens,percent Particles retained on 45 micron IS sieve (wet sieving) Limereactivity- average compressive strength in N/mm Max 34%% Evey 50 MT Lab test Third party lab 4.5 N/mm Once per source test