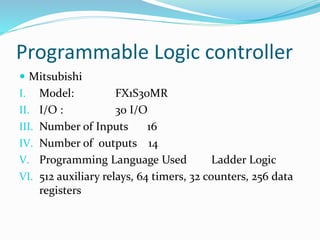

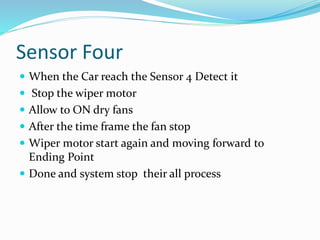

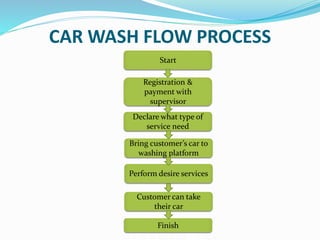

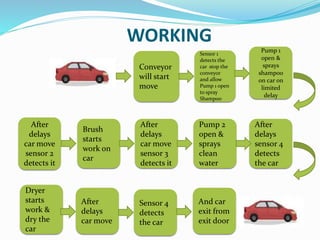

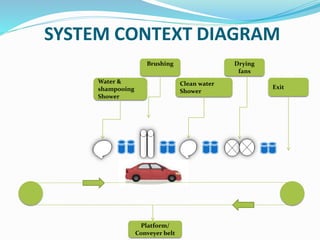

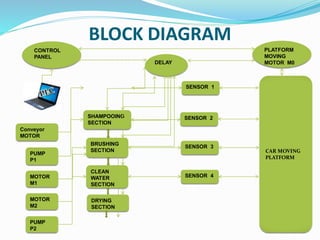

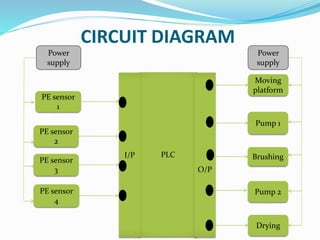

This document presents details about an automatic car wash system project created by three students at Isra University under the supervision of Mr. Asif Javed Bajwa. It describes the components, working process, and advantages of the PLC-based system. The system uses a programmable logic controller and sensors to automatically move a car through five stages - shampooing, brushing, rinsing, drying, and exit. It is intended to save time, reduce hazards, and provide an efficient service for customers.