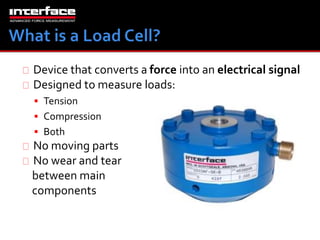

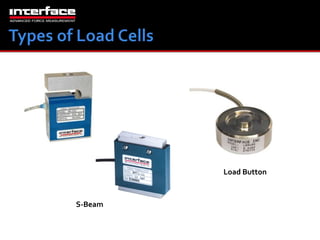

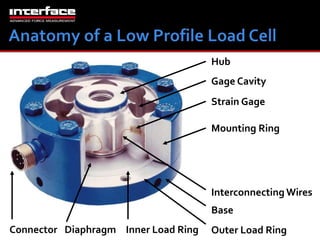

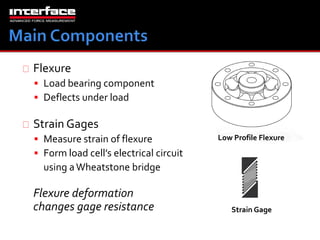

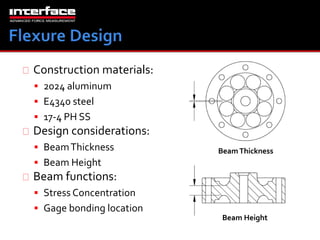

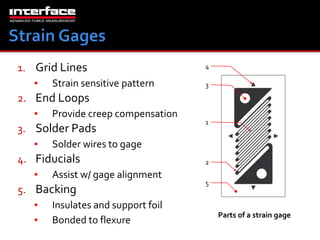

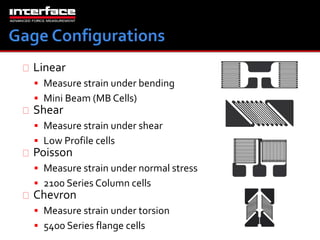

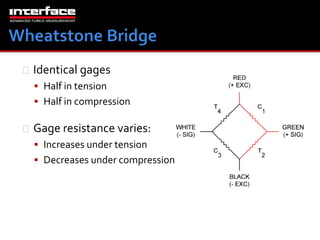

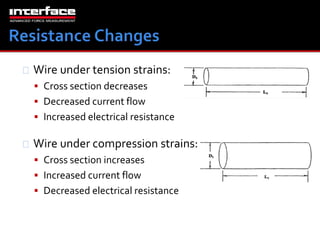

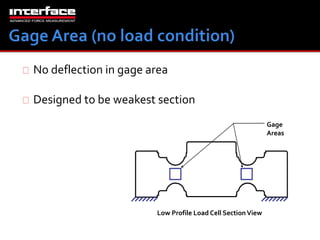

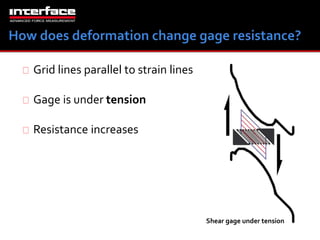

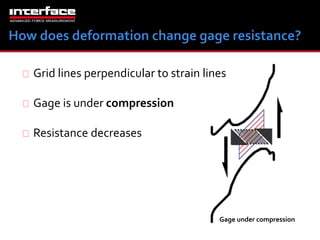

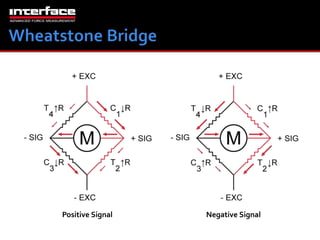

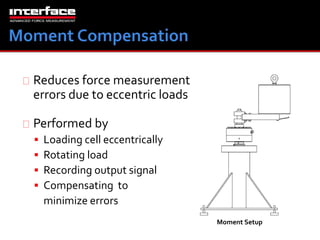

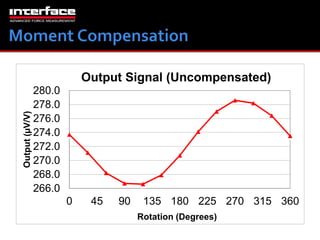

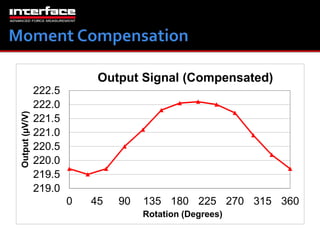

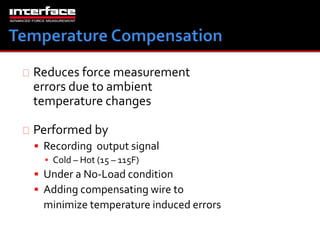

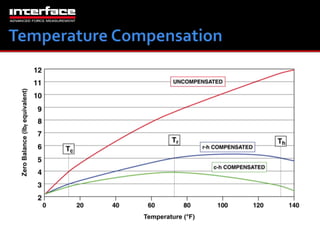

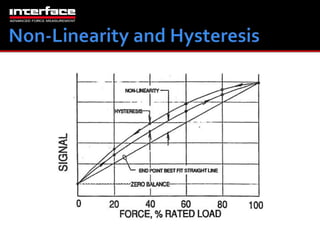

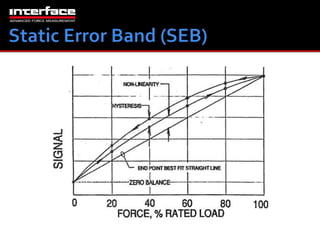

This document summarizes an upcoming webinar on load cells. The webinar will cover load cell basics, components, types, strain gage technology, moment and temperature compensation, and calibration. Key topics include how load cells convert force to electrical signals using strain gages in a Wheatstone bridge configuration, common load cell designs, and factors considered in load cell design like materials and flexure geometry. Compensation techniques are discussed to reduce errors from eccentric loads and temperature variations.