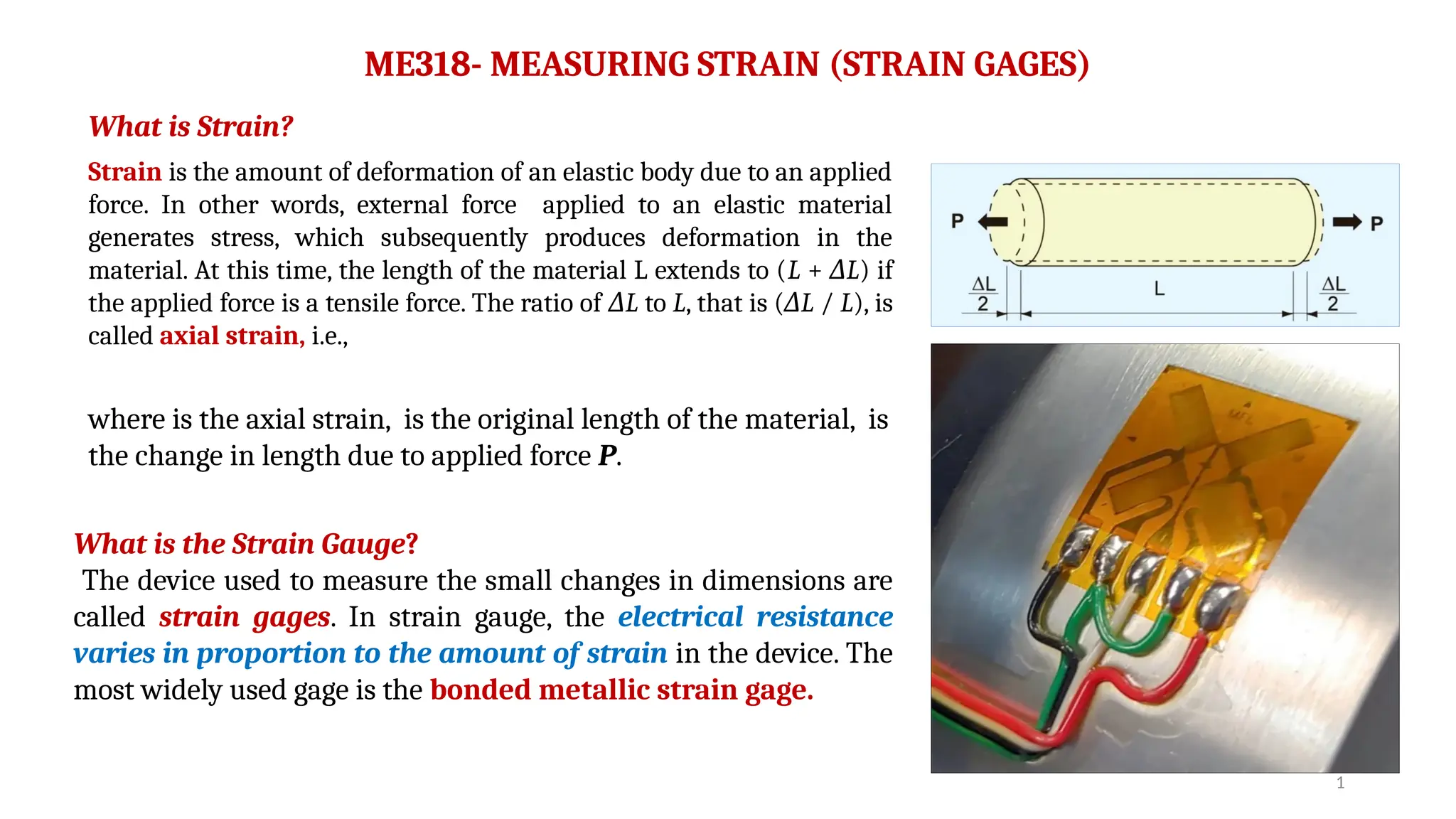

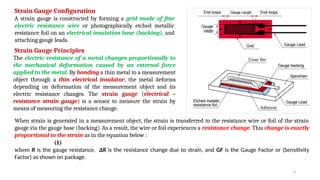

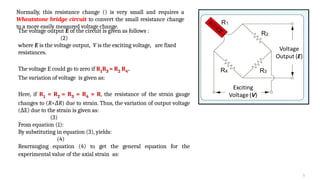

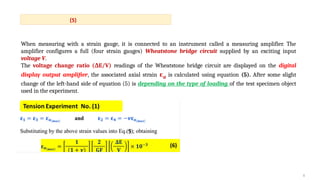

Strain gauges are devices that measure deformation in elastic materials due to applied forces, characterized by a change in electrical resistance corresponding to strain. They are compact, precise, and durable but are sensitive to temperature and require regular calibration. Common applications include measuring stresses in bridges, building components, and railroad tracks, utilizing various types such as linear and rosette gauges.