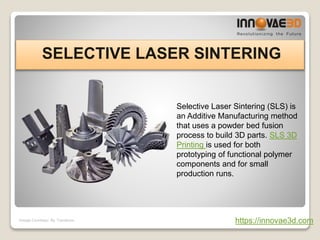

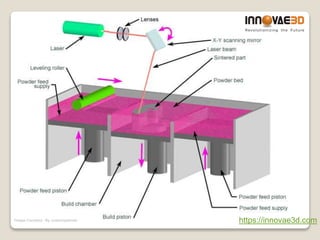

Selective Laser Sintering (SLS) is an additive manufacturing method that uses a powder bed fusion process for 3D printing parts from various materials, including plastics, ceramics, and metals. It is particularly valuable for industries needing small batch production of high-quality components, offering design freedom, fast turnaround, and strong mechanical properties. SLS is popular for customized products and reduces product development cycles while maintaining competitive costs.