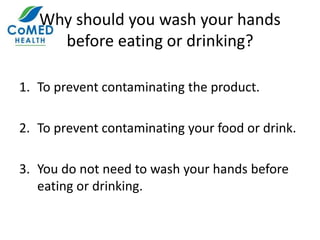

This document outlines basic principles of good manufacturing practices (GMP) for sanitation and hygiene, personal hygiene, premises cleaning, and maintenance. Some key points include: washing hands frequently and properly, not allowing illness or lesions in production areas, wearing protective clothing, prohibiting smoking/eating/drinking in production areas, conducting regular cleaning and maintenance, and completing cleaning records. Visitors, contractors and all employees must follow these hygiene procedures to prevent product contamination.