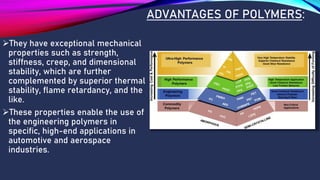

The document discusses engineering polymers, which are a group of thermoplastic materials that can be used between 100-150°C. They have good mechanical, thermal, and chemical resistance properties. Some key advantages of engineering polymers over metals include being lighter weight, more resistant to chemicals, and easier to machine without finishing. Examples of common engineering polymers discussed are polycarbonate, ABS, PMMA, PET, and PA66. Their applications include use in automotive and aerospace industries for parts that require high performance properties.