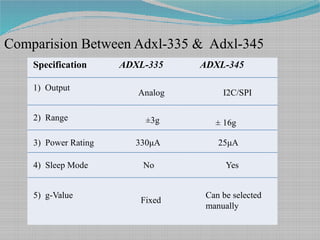

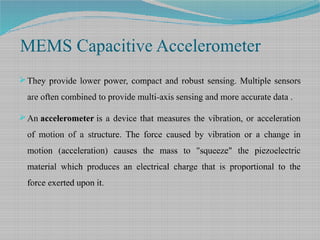

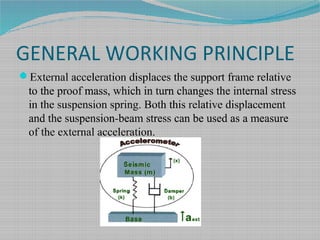

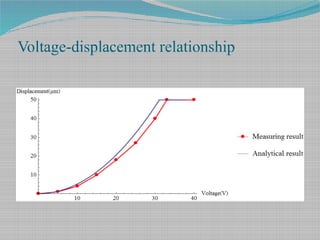

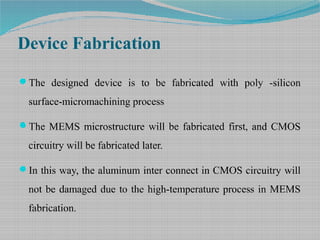

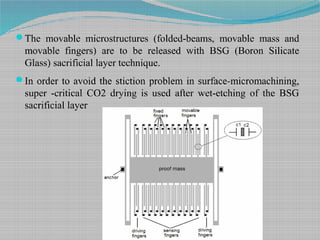

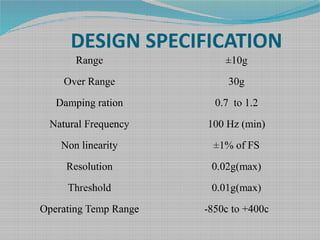

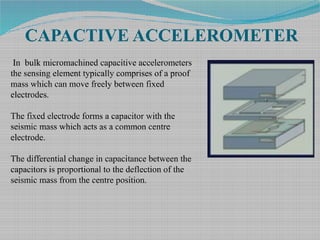

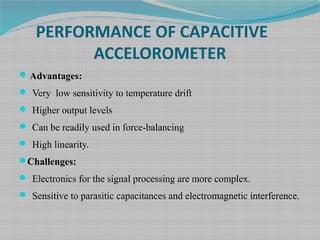

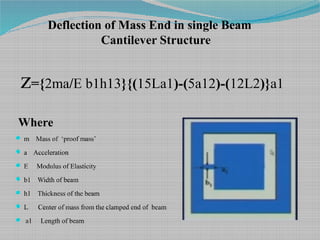

The document discusses MEMS capacitive accelerometers. It begins by introducing MEMS technology and materials used. It then explains that a MEMS capacitive accelerometer uses a movable proof mass suspended by beams between fixed electrodes, so that external acceleration causes the capacitance between electrodes to change proportionally. The document provides details on the working principles, fabrication process, design considerations like cross-axis sensitivity, and equations for capacitive variation and beam deflection under acceleration.

![Capacitive variation

C1 is the capacitance formed between the upper electrode

and the mass.C2 is the capacitance between the lower

electrode and the mass

C1=C2=C3 when the mass is at rest

With acceleration movement of the mass is like a fan and

the capacitance between the fixed electrode and movable

electrode can be found out by integration along the length

of the mass.

C1= ∫ εb2/(d0-A-B(x-a1)) dx C2=∫ εb2/(d0+A+B(x-a1)) dx

• The net change in capacitance can be found by finding C1-C2 and can be

expressed as

ΔC=C1-C2=C0(2A+(a2–a1)B)/d0[1+a2/d02]

The above equation has a linear and non linear part](https://image.slidesharecdn.com/acc-180506122818/85/MEMS-CAPACITIVE-ACCELEROMETER-41-320.jpg)

![Damping Analysis

The basic mechanism for micro mechanical

structures is squeeze film air damping.

Damping coefficient for a square mass can be

expressed in terms of the device dimensions in the

following form

Damping coefficient (c)=2[0.42µa24

/d03 ]

Natural Frequency and Damping Coefficient

d0=10

Beam

h1=90 , b1=240 , a1=600

Mass

h2=575, b2=4000, a2-a1=4000

Coventorware Analytical

Natural Frequency 842 Hz 854 Hz

Damping Coefficient 3.83 3.87](https://image.slidesharecdn.com/acc-180506122818/85/MEMS-CAPACITIVE-ACCELEROMETER-42-320.jpg)