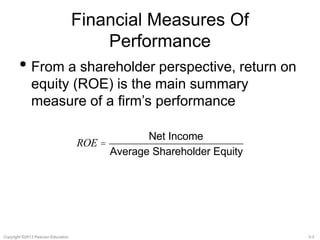

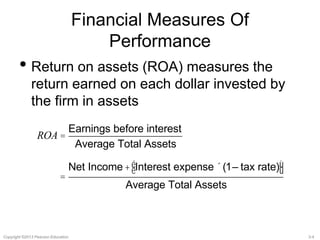

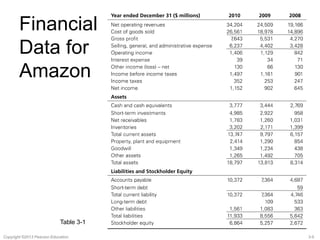

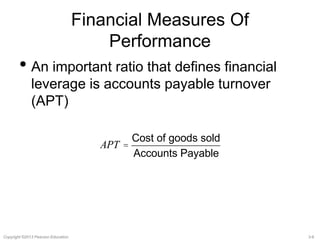

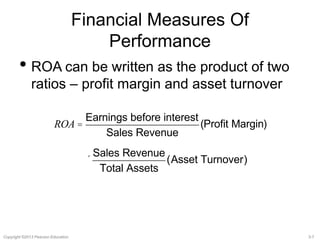

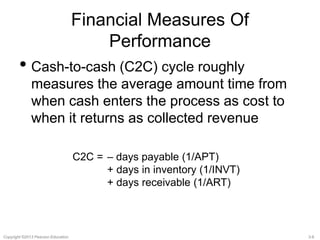

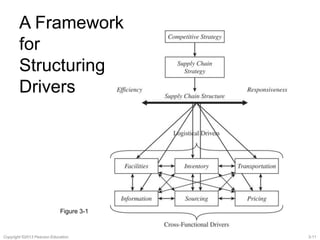

This document discusses key drivers and metrics for measuring supply chain performance. It begins by outlining learning objectives around financial measures, supply chain drivers, and relating supply chain strategy to competitive strategy. The document then defines various financial measures like return on equity, return on assets, and cash-to-cash cycle. It identifies the main drivers as facilities, inventory, transportation, information, sourcing, and pricing. For each driver, it outlines the role, components of decisions, and trade-offs between responsiveness and efficiency. Key metrics for each driver are also defined.