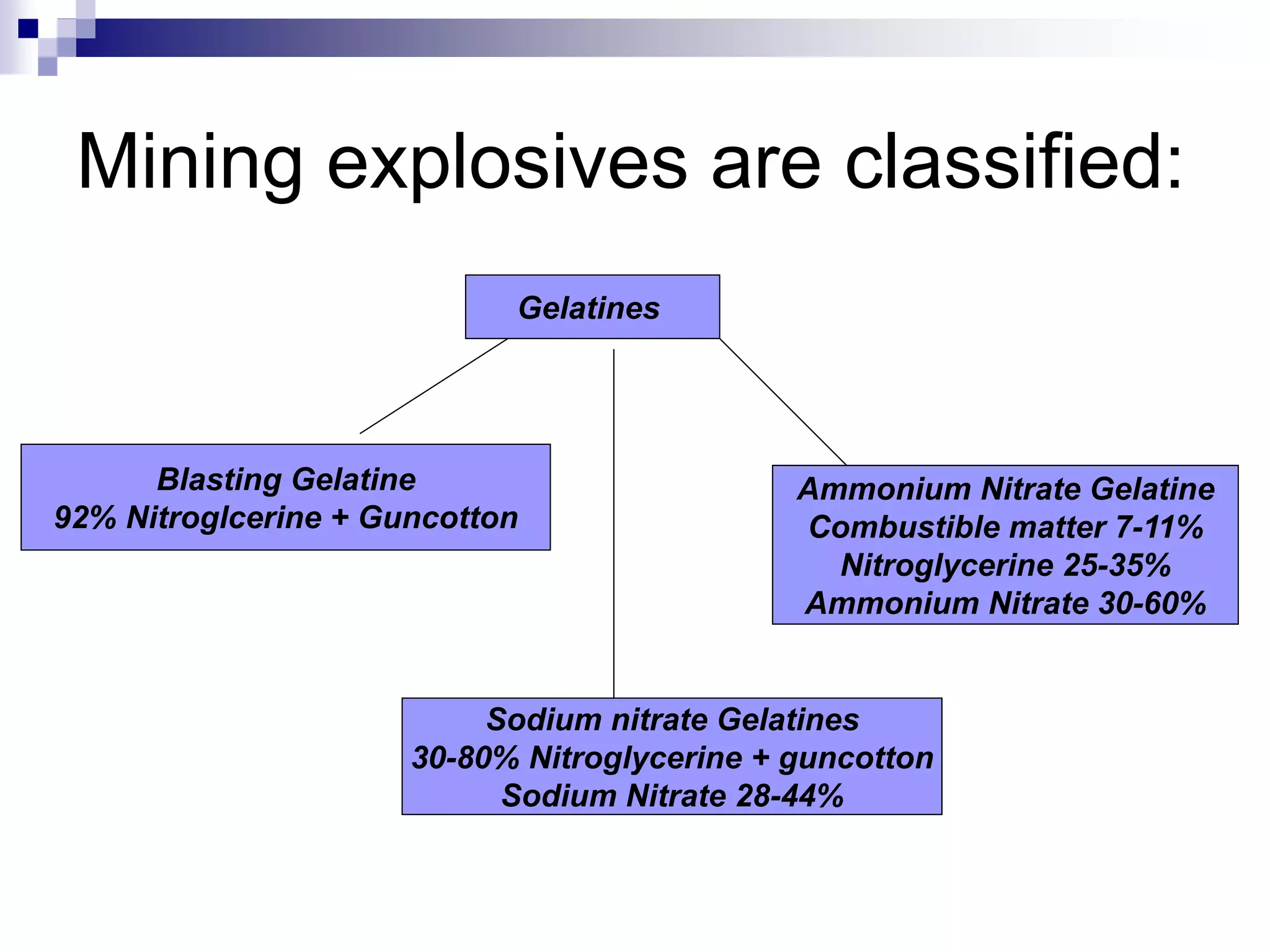

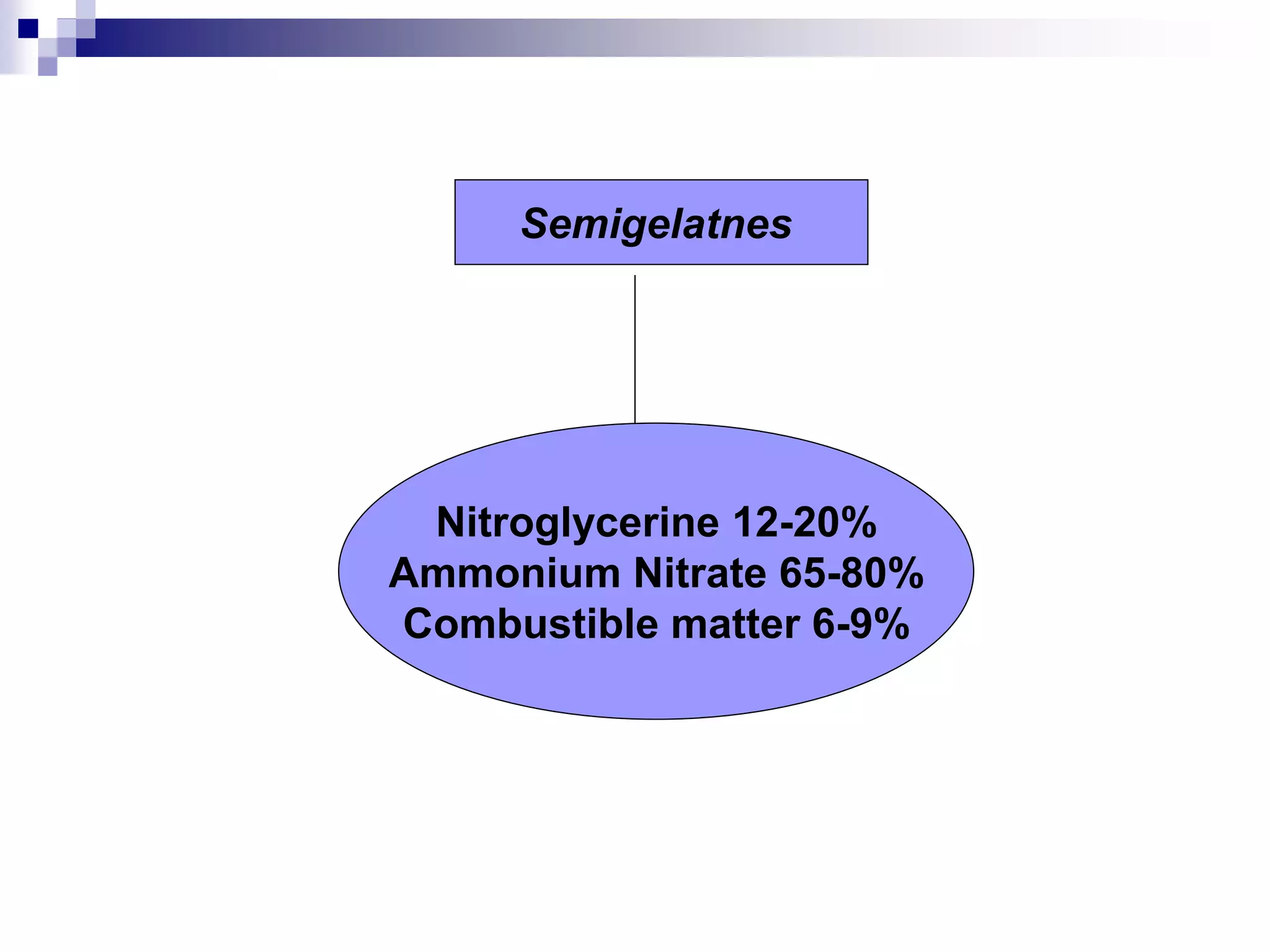

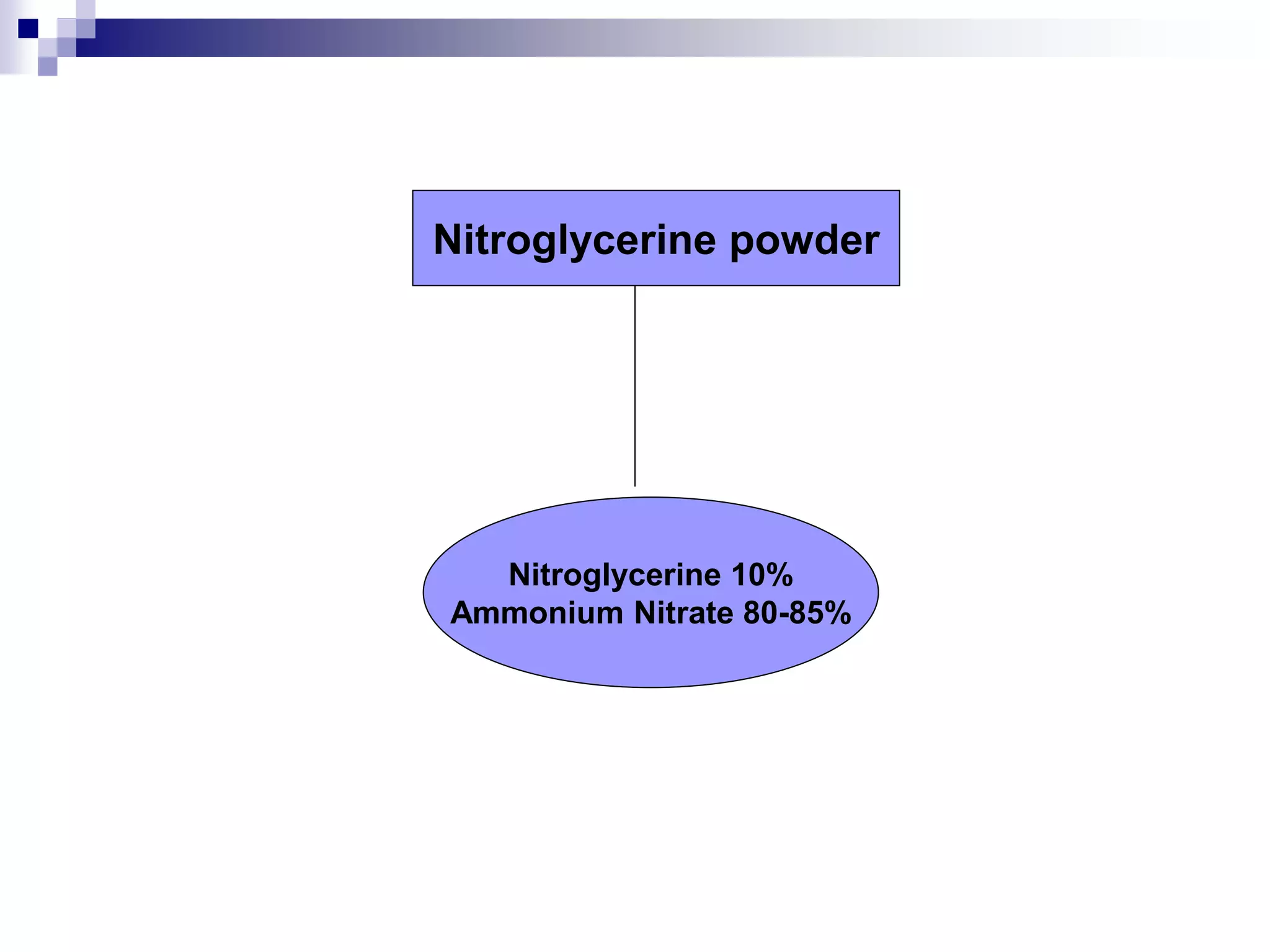

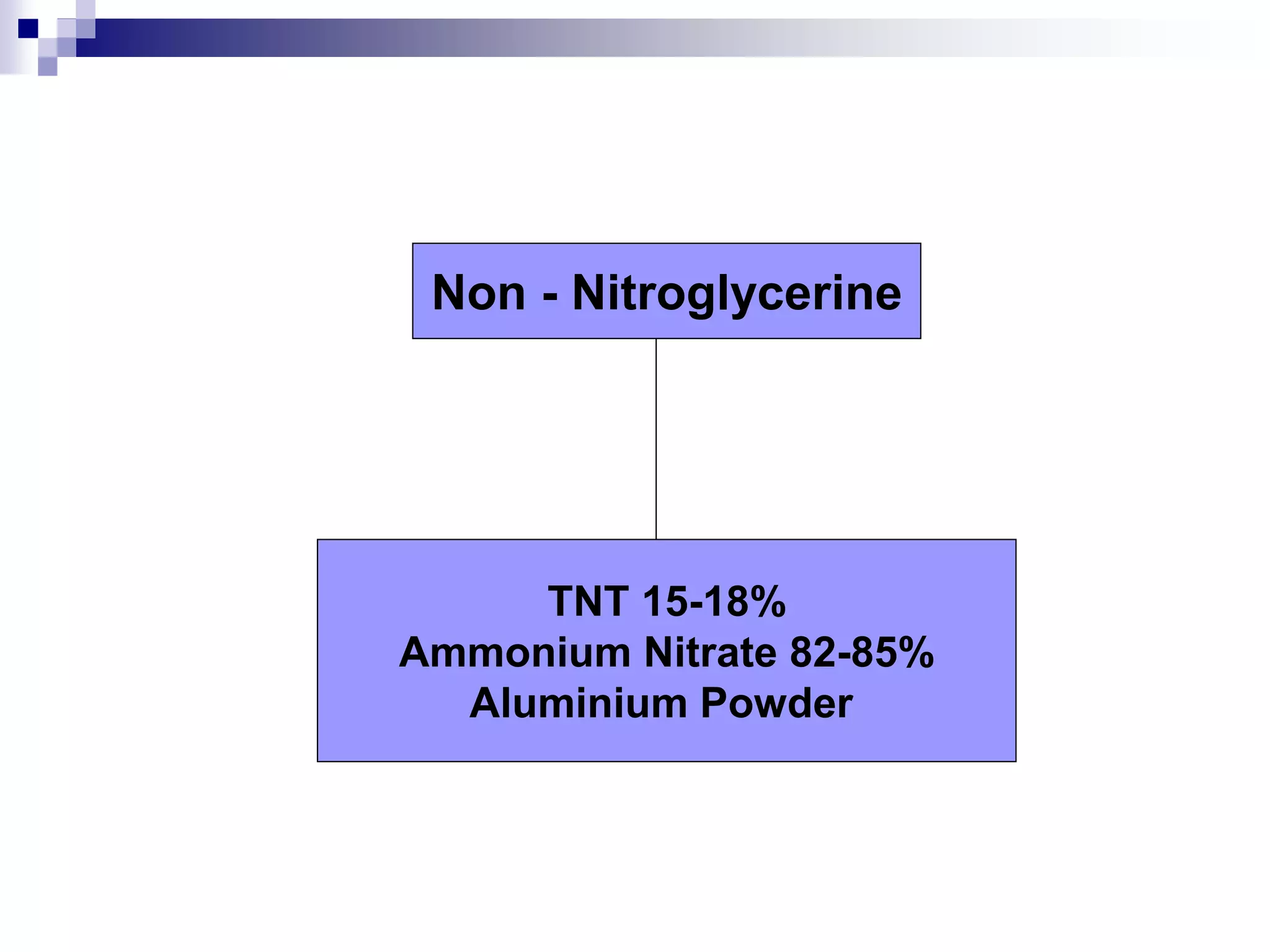

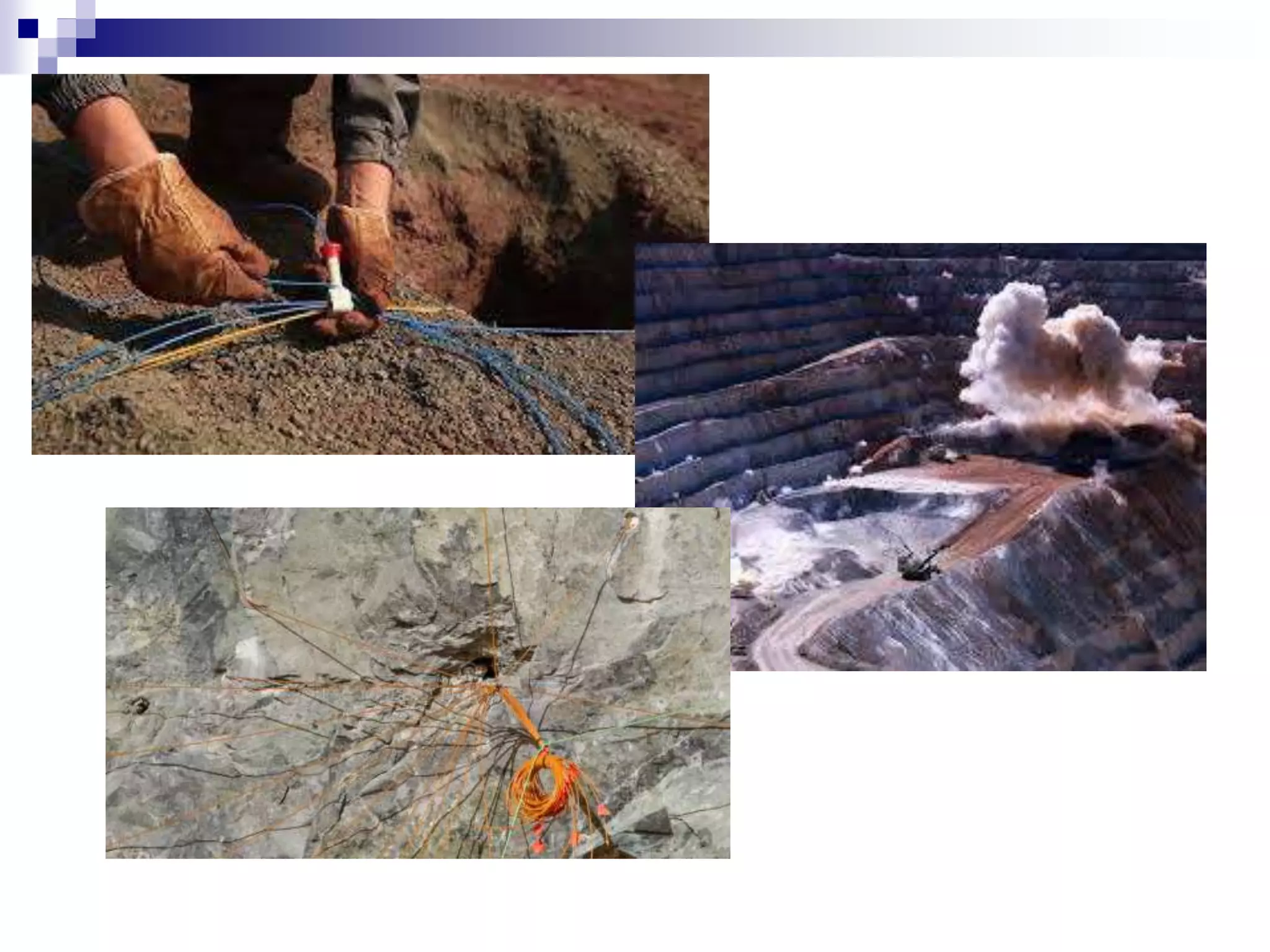

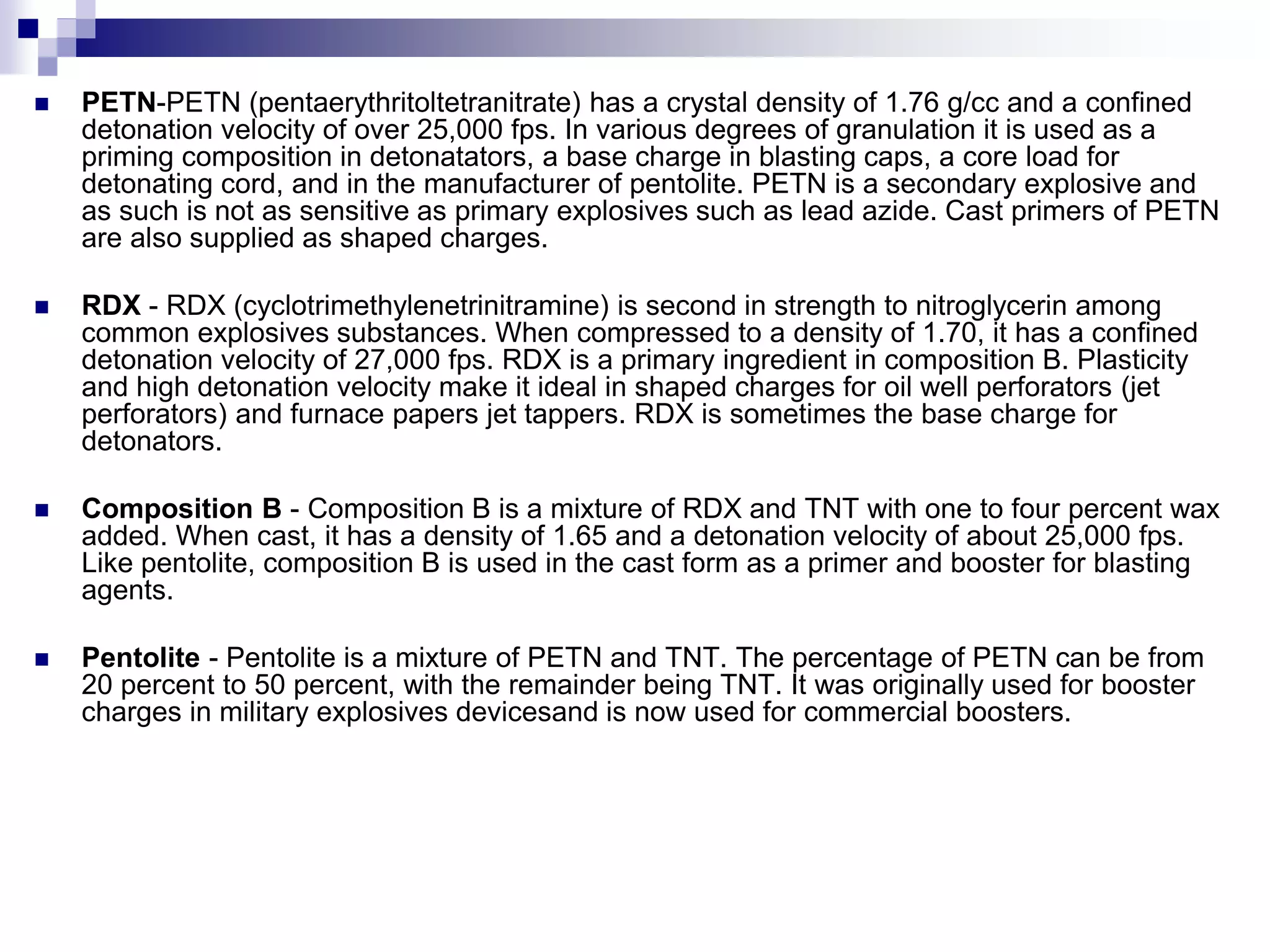

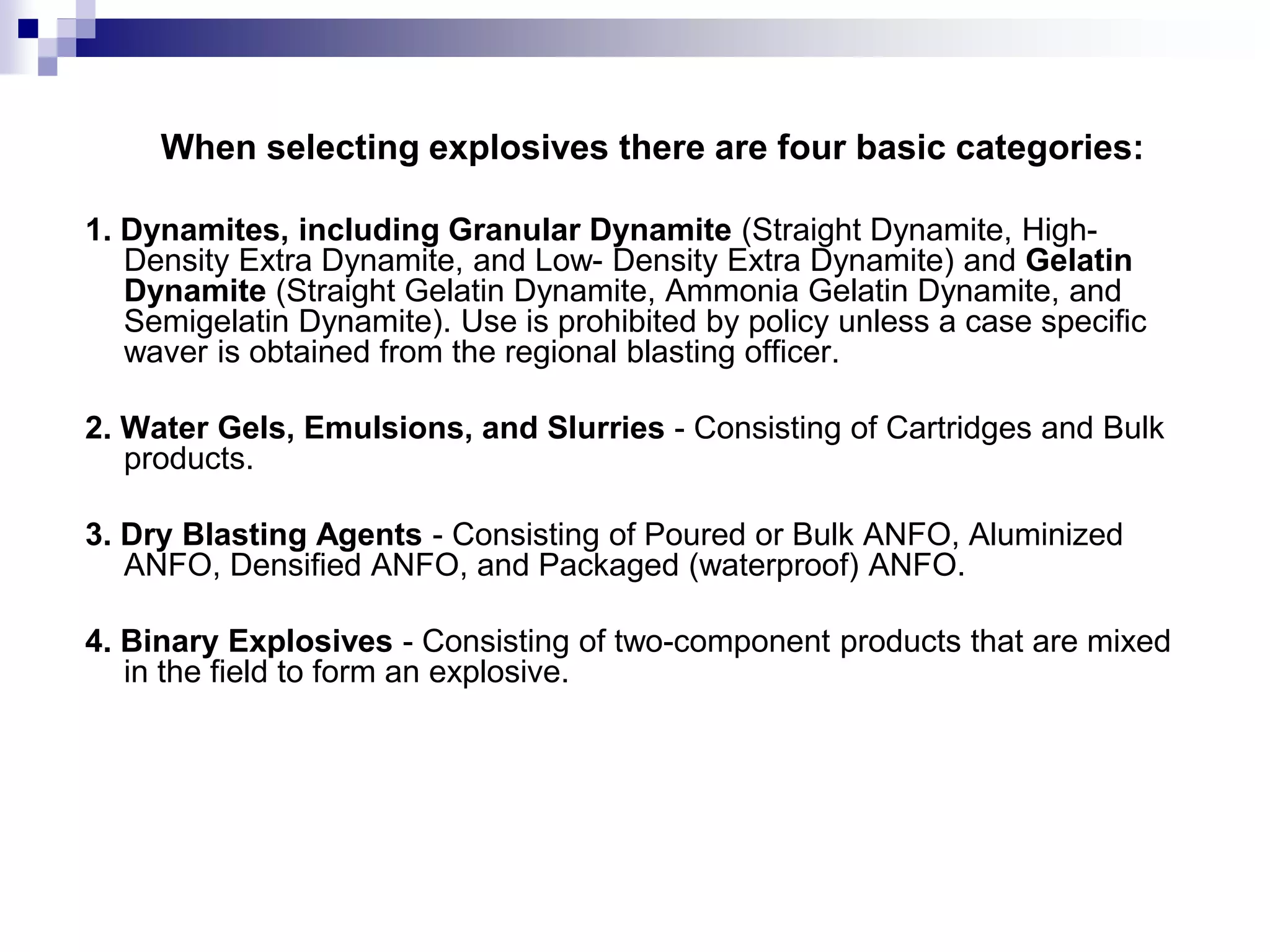

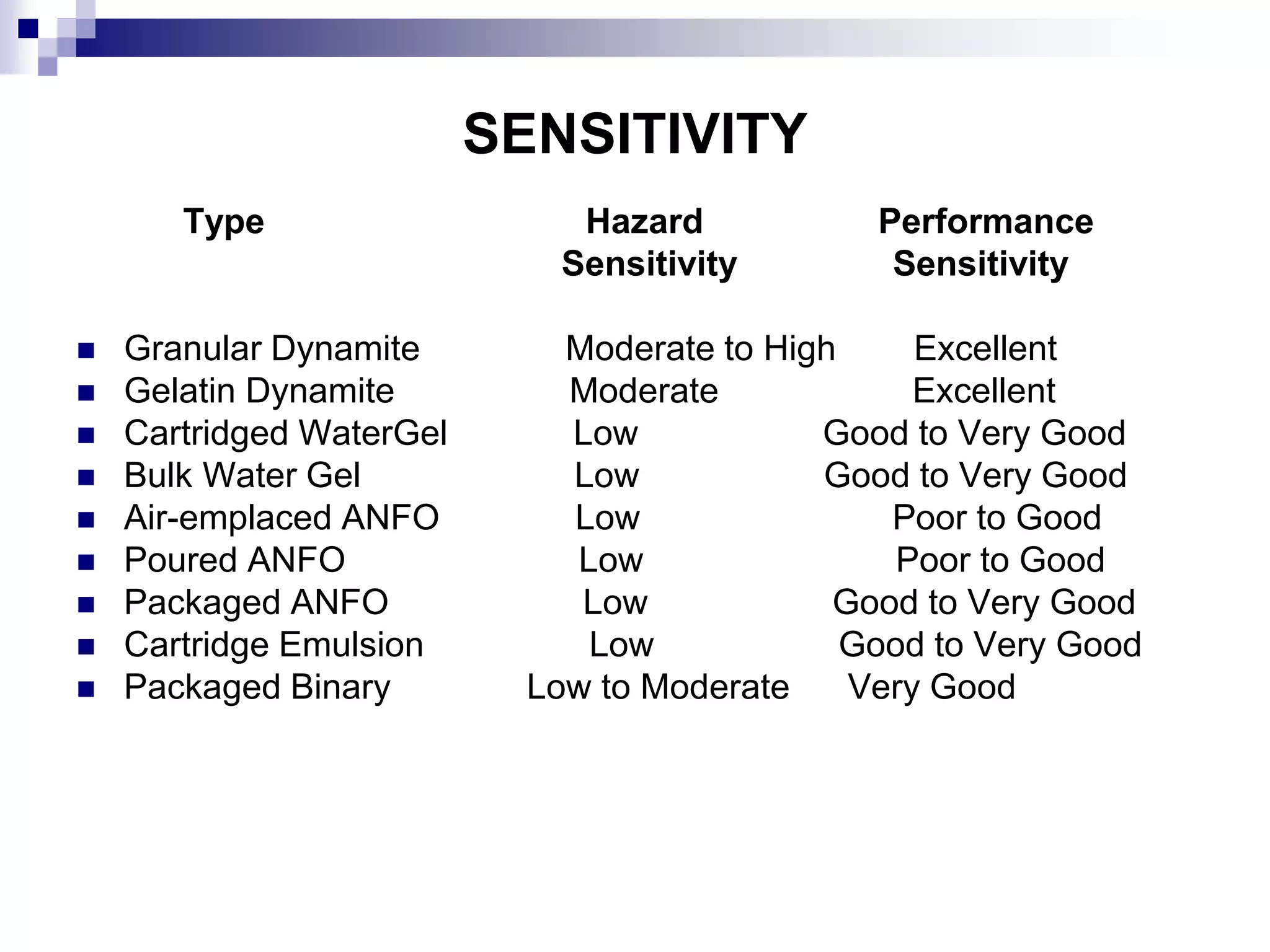

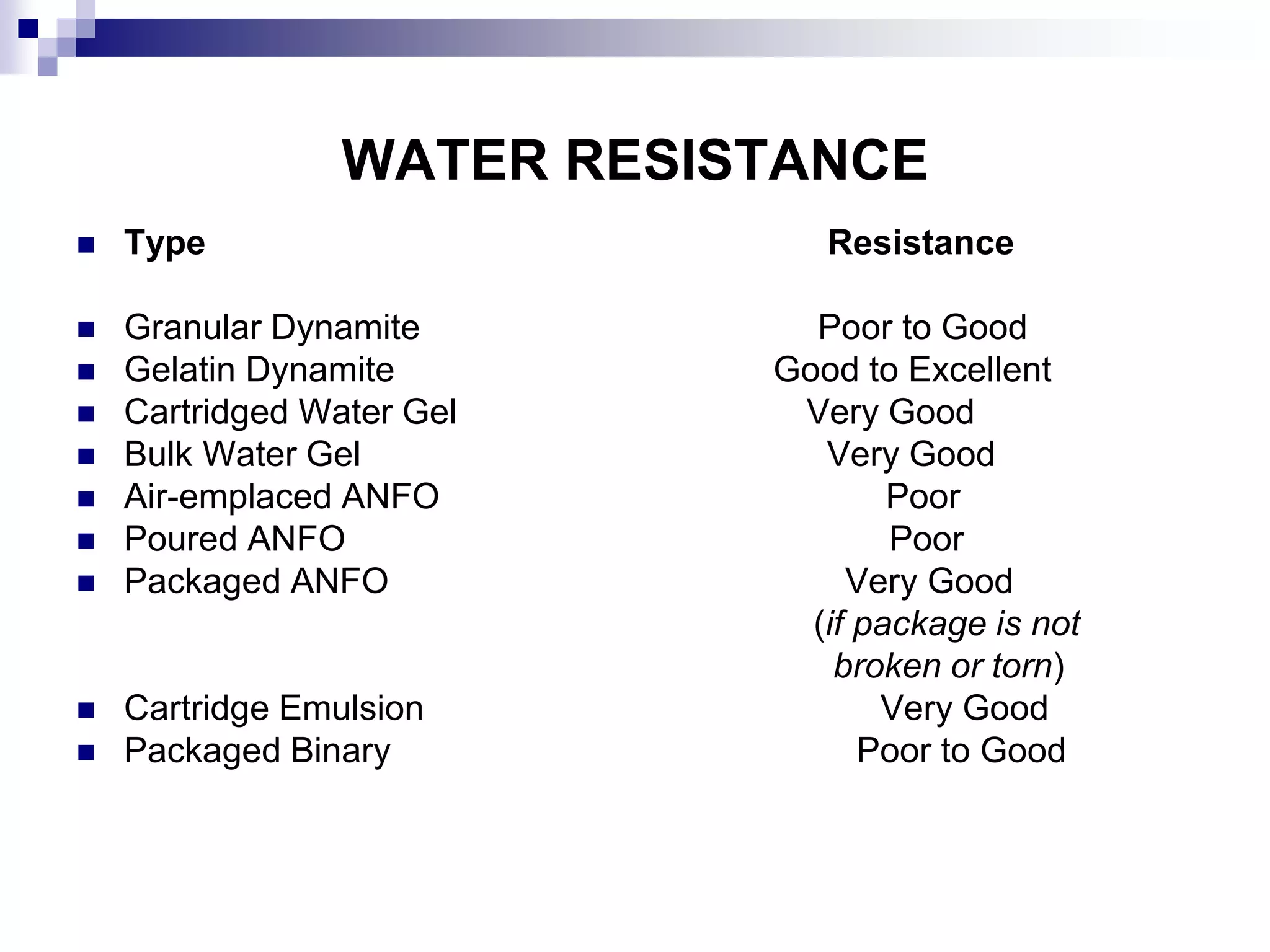

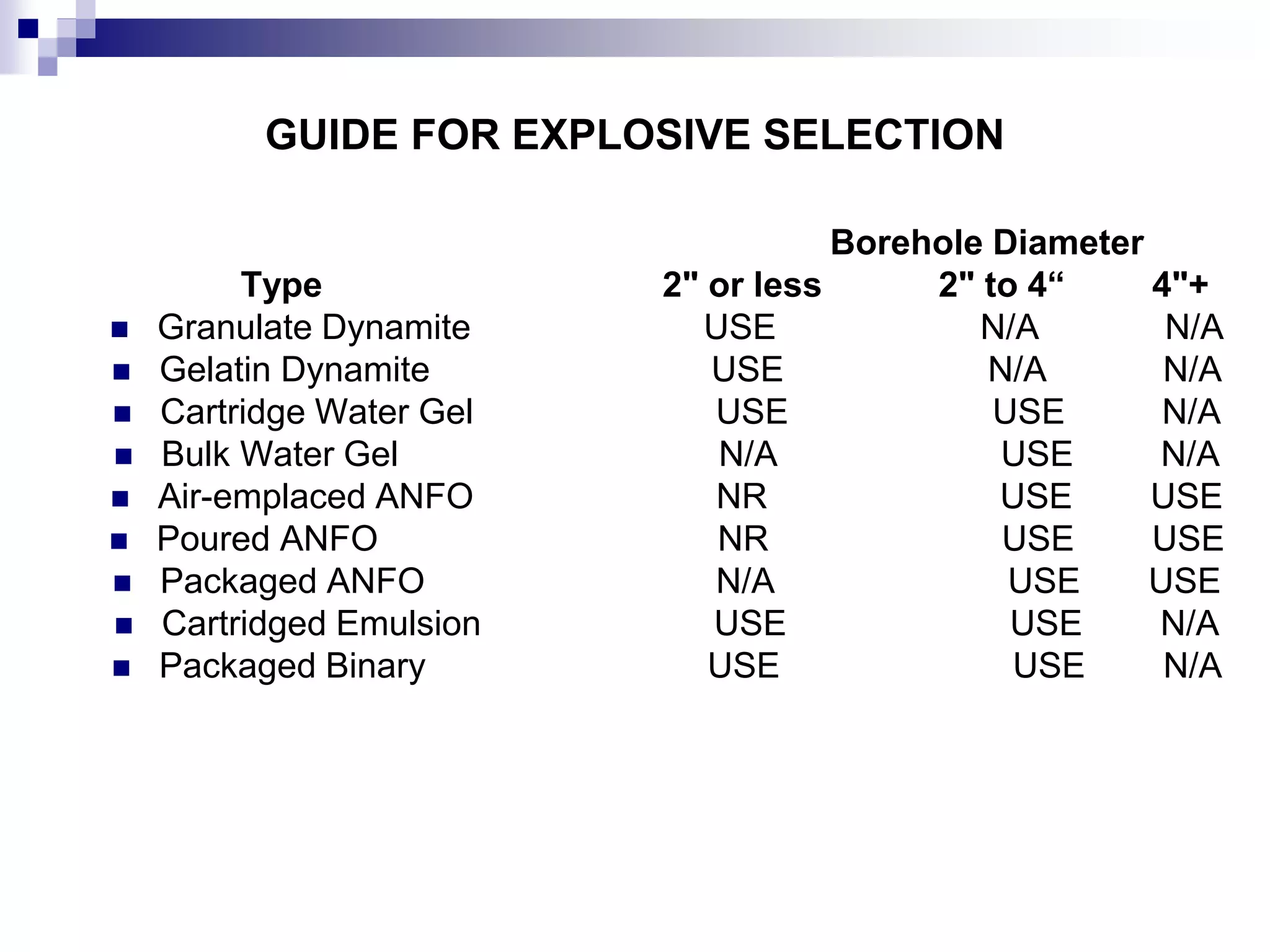

The document provides a comprehensive overview of mining explosives, defining them as substances that combust rapidly to produce gas. It categorizes explosives into low and high explosives, detailing various types such as dynamites, water gels, emulsions, and slurries, and outlines their characteristics, usages, and sensitivity levels. The document also gives guidance on selecting appropriate explosives based on borehole diameter and specific applications.