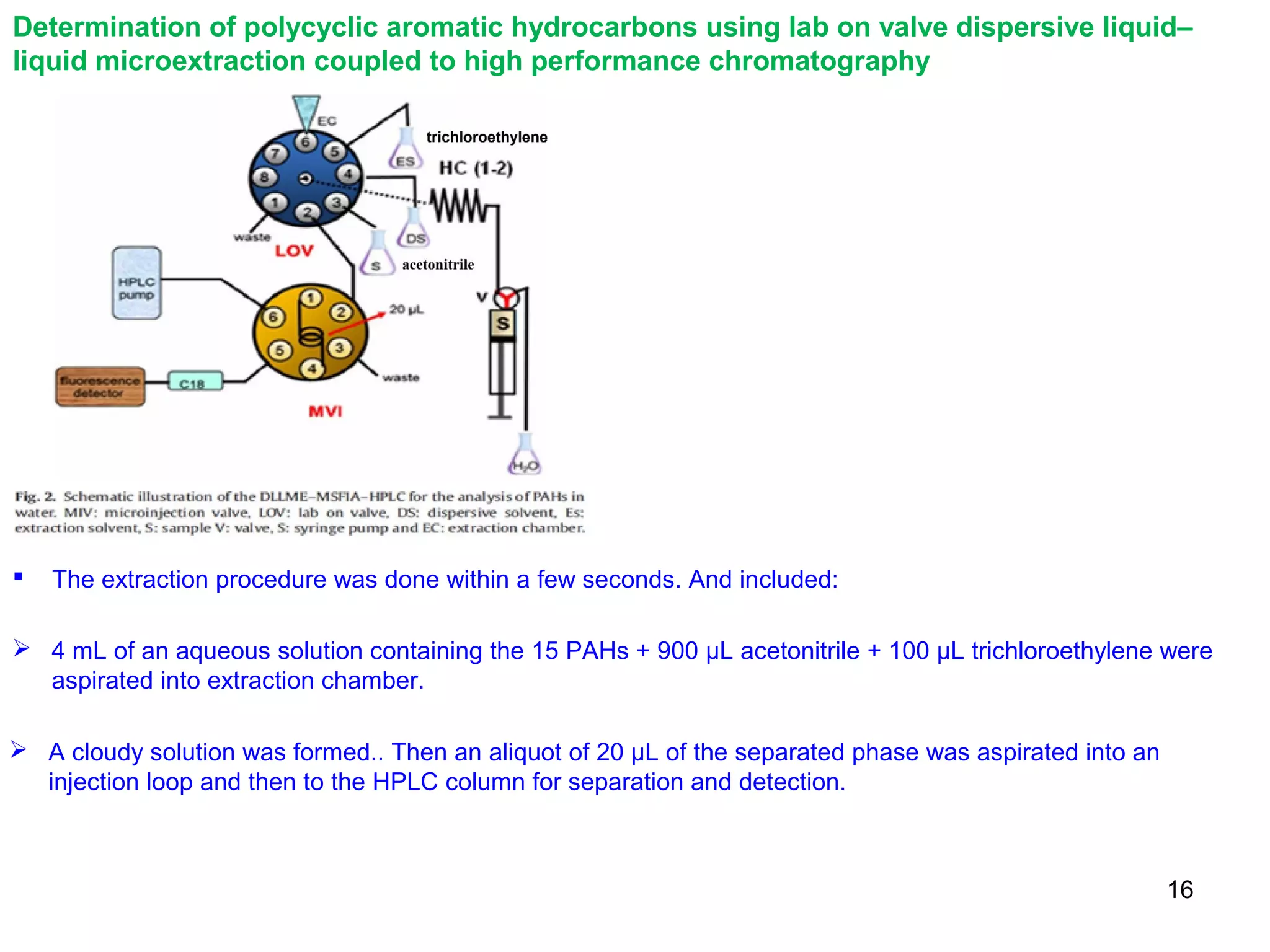

This document discusses flow injection analysis (FIA) and its applications. It begins with an introduction to FIA, describing it as a high-throughput sampling technique used in combination with other instruments. It then discusses four main categories of FIA techniques: flow injection analysis, sequential injection analysis, bead injection, and sequential injection chromatography. Several examples of applications are provided, such as using FIA to determine chloride ions or ethanol concentration. Advantages of the techniques include automation, low reagent consumption, and ability to combine with other instruments. The document concludes by emphasizing the goal of automation techniques is to provide accurate, reproducible data efficiently while simplifying protocols.

![Compound Abbreviati

on

Peak Order

Naphthalene Nap 1

Acenaphthene Acp 2

fluorene Flu 3

phenanthrene PA 4

anthracene Ant 5

fluoranthene FL 6

pyrene Pyr 7

benz[a]anthrace

ne

BaA 8

chrysene Chr 9

benzo[b]fluorant

hene

BbFl 10

benzo[a]pyrene BkFl 11

benzo[a]pyrene BaP 12

indeno[1,2,3-

cd]pyrene

IP 13

dibenzo[a,h]ant

hracene

DBA 14

benzo[g,h,i]pery

lene

BghiP 15

Table 4: The elution order and retention time of 15 PAHs

On-line DLLME–HPLC chromatograms of water spiked with 0.02

mg/L of each PAH. PAHs were preconcentrated from 4 ml of sample

17](https://image.slidesharecdn.com/c70b97eb-aed7-4b11-98cf-e1da461154bc-170105072315/75/Flow-Injection-Analysis-Dheyaa-17-2048.jpg)