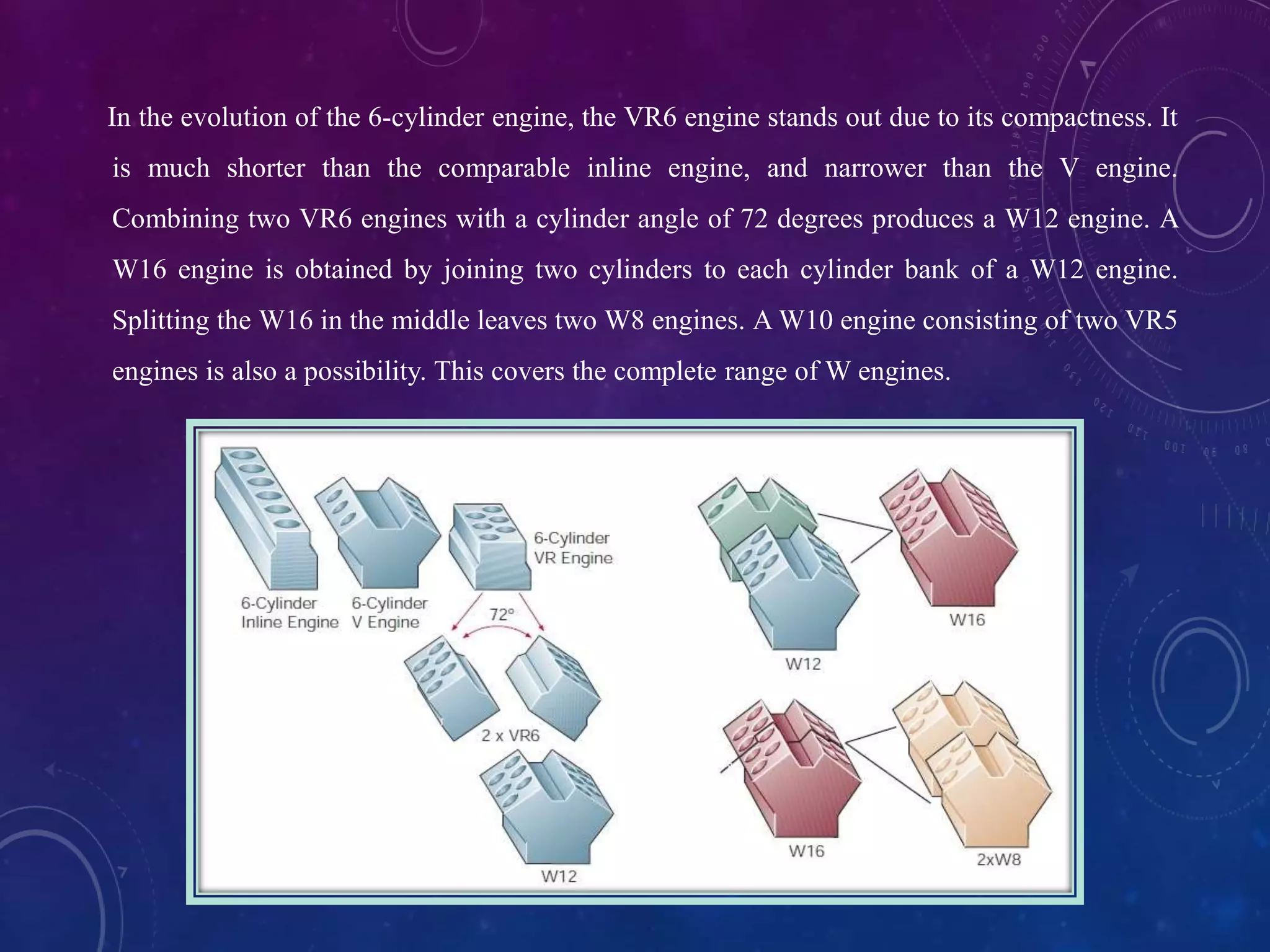

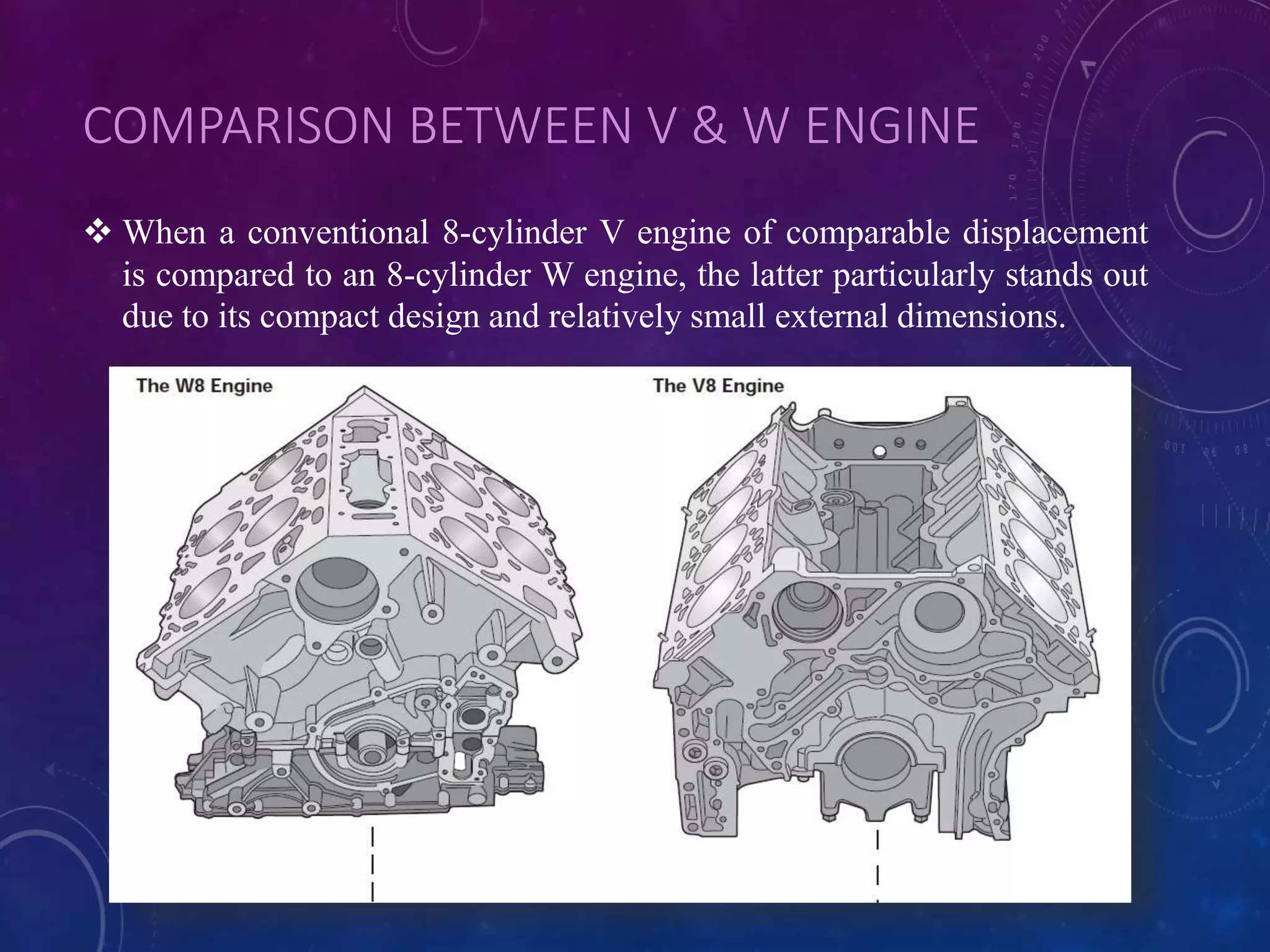

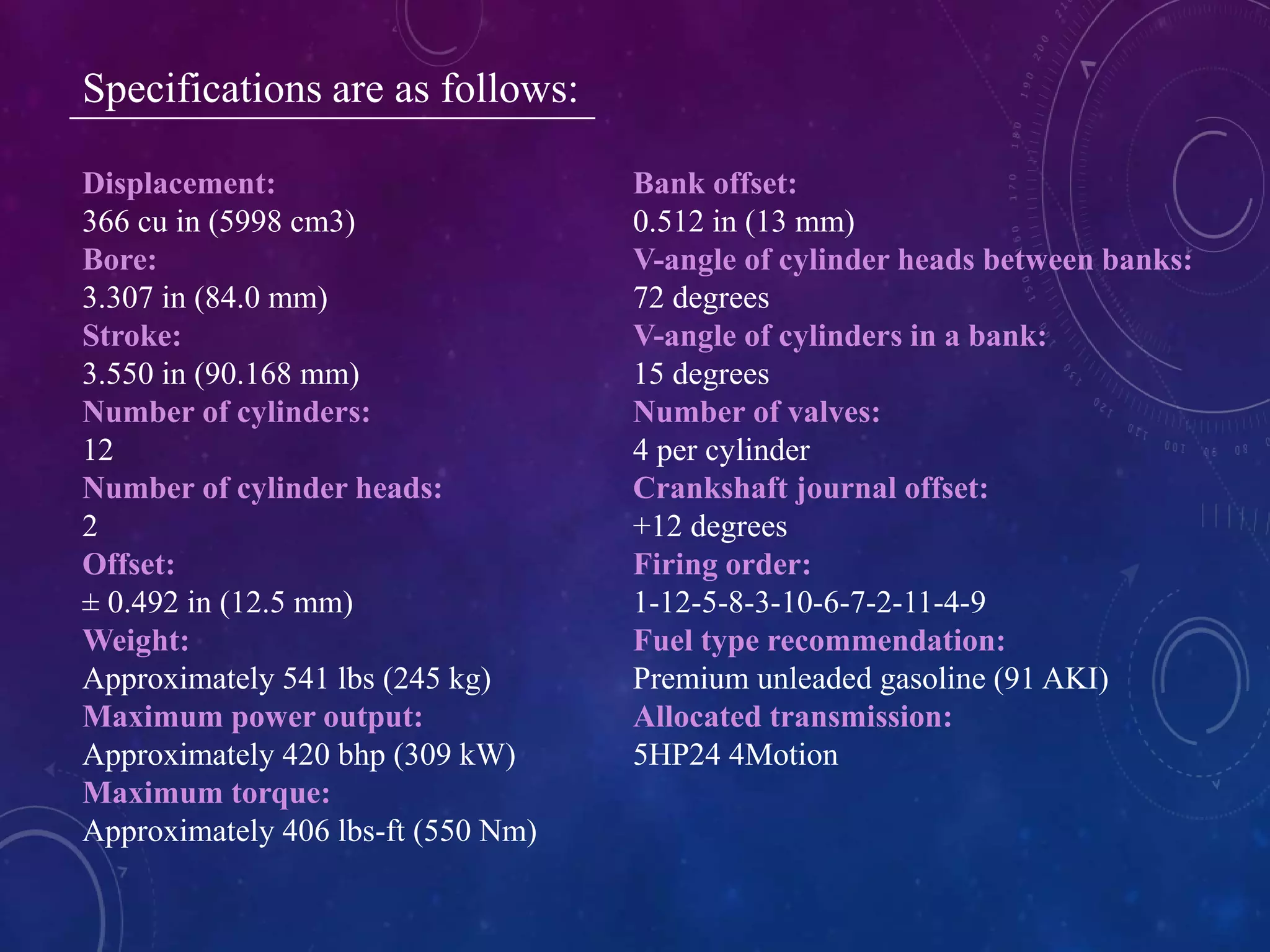

The document discusses the development and specifications of the W engine created by Volkswagen, highlighting its compact design achieved by combining features of V and VR engines. It details various configurations such as W8, W12, and W16 engines, along with comparisons to traditional V engines in terms of size and efficiency. The advantages and disadvantages of the W engine are also outlined, including its large output power and complexity in production.